Beruflich Dokumente

Kultur Dokumente

35

Hochgeladen von

rizkisyahfinaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

35

Hochgeladen von

rizkisyahfinaCopyright:

Verfügbare Formate

2

Modif ication of Polymer Mechanical and Rheological

Properties with Functional Fillers

Marino Xanthos

2.1

Introduction

Parameters affecting the performance of polymer composites containing functional

f illers are related to:

1. The characteristics of the f iller itself, including its geometry (particle shape, particle size and size distribution, aspect ratio), its surface area and porosity, and its

physical, mechanical, chemical, thermal, optical, electrical, and other properties.

Relevant concepts introduced in Chapter 1 are further discussed in this chapter

and also in other chapters dealing with specif ic f illers and surface modif iers.

2. The type and extent of interactions at the phase boundaries, which affect adhesion

and stress transfer from the matrix to the f iller. Interfacial interactions are also

re- lated to surface characteristics of the f iller, such as surface tension and surface

re- activity. These are parameters that control its wetting and dispersion

characteris- tics. The importance of the interface is also emphasized in Chapters

4 6.

3. The method of incorporation of the f iller into the polymer melt (discussed

in Chapter

3) and

its distribution in the

f inal product

part;

processing/structure/ property relationships are brief ly discussed in this chapter

and are elaborated in other chapters covering specif ic f illers.

Given the overall importance of mechanical properties, this chapter focuses on parameters controlling such properties as related to the f iller, the f iller/polymer

inter- face, and the method of fabrication. Concepts presented below may also be

applica- ble to the modif ication of other polymer properties (e.g. permeability,

thermal ex- pansion) through the addition of functional f illers.

Functional Fillers for Plastics. Edited by M. Xanthos

Copyright 2005 WILEY-VCH Verlag GmbH & Co KGaA

ISBN 3-527-31054 -1

2.3 Modif ication of Mechanical Properties 19

2.2

The Importance of the Interface

Interactions at phase boundaries affect not only the mechanical behavior, but also the

rheology and processing characteristics, environmental resistance, sorption and diffusion, and many other properties of composites. The strength (tensile, f lexural) of a

composite and its retention at higher temperatures, after prolonged times, and under

adverse environmental conditions are particularly affected by interfacial adhesion.

The principal sources of information presented in this section are refs. [1 6].

The extent of adhesion at the polymer/f iller interface may be related to various parameters associated with adsorption and wetting. Factors related to adsorption of the

polymer onto the f iller are types of interfacial forces (primary, secondary bonds), molecular orientation/conformation at the interface, and polymer mobility. Contact angle, surface tension, and substrate critical surface tension are among factors related

to wetting.

For a drop of liquid in equilibrium on a solid surface, Youngs equation relates interfacial tensions at the solid/vapor interface, 1, liquid/vapor interface, 2, and solid/liquid interface, 12, with the contact angle, , which is a measure of the degree of

wetting taking a value of zero for ideal wetting.

1 = 12 + 2 cos

(2-1)

Critical surface tension, c, equals the surface tension of a liquid that exhibits zero

contact angle on the solid. Any liquid (melt) with a surface tension less than that of

the solids critical surface tension will wet the surface. Uncoated inorganic f illers may

have very high surface tension, > 200 mJm2, whereas polymers such as polystyrene

and polyethylene have lower surface tension, < 50 mJm2. Thus, polymer melts will

spread on the high energy surfaces of f illers, unless the c value of the f iller is

reduced by absorbed water layers ( = 21.8 mJm2), by contamination with low

surface tension impurities, or by surface irregularities. This will result in

incomplete wetting and void formation at the interface.

The need to minimize contact angle in order to maximize the work of adhesion,

Wa, is shown by the following YoungDupr equations:

Wa = 1 + 2 12

Wa = 2 (1 + cos)

(2-2)

(2-3)

The need to minimize unfavorable interfacial interactions by minimizing the interfacial tension, 12, can also be inferred from the following simplif ied GoodGirifalco equations:

12 = 1 + 2 2 (12)0.5

Wa = 2 (12)0.5

(2-4)

(2-5)

where is an interaction parameter that depends on polarity. Polarity is def ined

as the ratio of the polar component of the surface tension to the total surface tension.

2.3 Modif ication of Mechanical Properties 19

is maximal when the polarities are equal (approaching unity) and is minimal (approximately zero) when the polarities are totally mismatched. It follows that f inite 12

and low Wa are the result of disparity between polarities (as, for example, between a

non-polar polyalkene and a hydrophilic polar f iller surface). Surface modif ication of

f illers can reduce 12, modify the c of the f iller, and reduce polarity differences.

Surface modif ication of f ibrous or non-f ibrous f illers through the introduction of

new functional groups, or the modif ication of existing ones, may be accomplished by

oxidation, thermal treatment, plasma treatment, vapor deposition, ion exchange, or

through the application of additives that may react or interact with both the f iller and

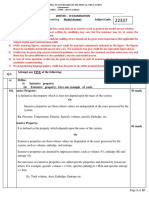

the polymer matrix. Figure 2-1 [7] shows the structure of a hypothetical mineral and

the availability of multiple sites for either direct interactions or reactions with the

polymeric matrix or through additives such as coupling agents. Surface modif ication

of the mineral for improved adhesion can, in effect, convert an ordinary f iller into a

value-added f iller with multiple functionalities. Surface modif ication is further covered in detail in Chapters 4 6 of this book.

Structure and reactivity of a hypothetical silicate mineral. 1: interlamellar

spaces; 2: exchangeable cations (acidic potential); 3: variable valence species; 4: reactive

Fig. 2-1

hydroxylic species; 5: Lewis acids; 6: anion-exchange sites; 7: bridged hydroxyl groups (reproduced from ref. [7]).

2.3

Modif ication of Mechanical Properties

2.3.1

General

Modif ication of mechanical properties and, in particular, the enhancement of

modu- lus and strength is undoubtedly one of the most compelling reasons for

incorporat- ing functional f illers into thermoplastics. Appropriate selection of a f iller

based on its

2.3 Modif ication of Mechanical Properties 21

size and shape, modulus and strength, and density is of paramount importance in order to establish its potential reinforcing capacity and to provide guidelines for its

method of incorporation into the polymer. For directional f illers with a certain

aspect ratio (e.g. short f ibers and f lakes or platelets) embedded in thermoplastic

matrices, the load is transferred from matrix to f ibers or f lakes by a shear stress

and the ends of the f ibers or f lakes do not bear a load. As a result, the properties of

the resulting composites are inferior to those of equivalent composites

containing continuous f ibers or ribbons. Although in some cases thermoplastic

composites containing con- tinuous f iber or ribbons have been produced, the

methods suitable for the produc- tion of short f iber or f lake composites are

conveniently those that are normally used for the processing of unf illed

thermoplastics (e.g., extrusion, injection molding, blow molding). Rigid f iller

particles may break during such operations with a concomitant reduction in aspect

ratio.

In Table 2-1, average values for modulus and strength of commercially available

continuous and discontinuous inorganic f ibers/ribbons/f lakes of different densities

are compared. Data have been obtained from a variety of sources [1,8 15] and often

may be subject to variation, considering measurement diff iculties, particularly for

short f illers of different origins. In particular, the strength values should be viewed

with caution since they depend on the method of testing and the effects of f laws and

edges. Data for typical polymer matrices are also included, as well as for whiskers or

single-crystal platelets, which are considered to be virtually f law-free and, therefore,

have extremely high strengths. Metallic wires have relatively large diameters and are

typically used as continuous reinforcements. The densities of particulate mineral

f illers (e.g., calcium carbonate, silica, talc, kaolin, wollastonite, aluminum

hydroxide) range from 2.4 to 2.75 g cm3. The corresponding Youngs modulus

values have been quoted as ranging from 25 to 35 GPa [14,16]. Data are often

expressed in terms of spe- cif ic properties (modulus or strength over density). It is

obvious, therefore, that for a specif ic application requiring high stiffness and

strength combined with light weight, the choice of f iller with the optimal specif ic

properties would be desirable.

In the following sections, theoretical and empirical treatments that have been used

to describe composite modulus and strength are presented for continuous f illers

(as- pect ratio approaching inf inity), discontinuous directional f illers (f inite aspect

ratio,

>1), and particulates (aspect ratio unity). An attempt is made to demonstrate the

principles governing the mechanical behavior of polymer composites through model systems rather than real molded parts having variable f iller orientation and distribution. For ease of analysis, stresses are only applied in tension, since the situation

in f lexure or compression becomes signif icantly more complicated in multiphase,

multicomponent systems. The principal sources of information presented in the following sections on modulus and strength are refs. [8,10,12,14,15,1719]. Parameters

controlling other mechanical properties are also brief ly covered.

2.3 Modif ication of Mechanical Properties 21

Comparison of commercially available high aspect ratio

f ibers, ribbons, and platelets

Tab. 2-1

Filler

Density,

Tensile Axial Modulus, GPa

Strength, g cm3

(average value)

(average value)

Inorganic Fibers

E-glass f ibers

S-glass f ibers

asbestos (chrysotile) f ibers

boron

2.54

2.49

2.5

2.57

Organic Fibers

carbon f ibers

2500 carbon nanotubes

180000 aramid f ibers

2800 polyester (terylene)

nylon f ibers

UHMWPE (Spectra 900)

1.791.86 230 340 (713)[a]

1.2

1000 1700

1.45

124 (5)[a]

1.38

1.2

1.14

2.9

0.97

117

Natural Fibers

sisal f ibers

507 (A. Sisalana)

jute f ibers

(C. capsularis)

f lax f ibers

900 (Lin usitatissimum)

cotton f ibers

wood f ibers

400

(aver. tropical hardwoods)

wood f ibers (Kraft)

Metallic Wires

steel wire

tungsten

Whiskers

silicon nitride

silicon carbide

aluminum oxide

20000

76

86

160

400

1500

1900

2000

3600

3200

600

800

2600

1.5

16.7

24.1

1.52

110

1.50

0.6

1.1

13.5

350

1.0

72

900

7.9

19.3

210

407

2390

2890

3.2

3.2

4.0

350 380

480

700 1500

5000 7000

20000

10000

5978

480

500

up to 21000[b]

10000

6000 mica

Ribbons, Flakes, Platelets

glass ribbons

2.473.84

SiC platelets

3.2

AlB2 platelets

2.7

f lakes

2.72.9

175

exfoliated silicate

2.8 3.0

1000

nanoclay platelets

exfoliated graphite platelets

2.0

polymers

0.90 1.35

(excluding elastomers)

900

3000[c]

up to

170

1000

0.23.3

[a] Anisotropic f ibers; values in parentheses

relate to the radial direction.

[b] Extrinsic property depending on manufactur-

ing process.

Tensile Axial

MPa

10000 20000

8.595

[c] Maximum value for f lakes with perfect edges;

in practice, the strength of small f lakes can be

as low as 850 MPa.

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Edexcel IGCSE Chemistry Student Book Answers PDFDokument58 SeitenEdexcel IGCSE Chemistry Student Book Answers PDFmashiad84% (51)

- Review Test VMCDokument18 SeitenReview Test VMCamogh kumarNoch keine Bewertungen

- Making SaltsDokument24 SeitenMaking SaltsFatema KhatunNoch keine Bewertungen

- Lecture Notes: Condensed Matter Theory I (TKM1) : J. SchmalianDokument70 SeitenLecture Notes: Condensed Matter Theory I (TKM1) : J. SchmalianPragyanPhukanNoch keine Bewertungen

- Water Chemistry: CHM 001 Chemistry For EngineersDokument33 SeitenWater Chemistry: CHM 001 Chemistry For EngineersEjay CabangcalaNoch keine Bewertungen

- Theory Equilibrium Distribution of Solute Between Immiscible SolventDokument3 SeitenTheory Equilibrium Distribution of Solute Between Immiscible Solventviwe100% (1)

- Aromatics Extraction System TypesDokument5 SeitenAromatics Extraction System TypesHelin HassanNoch keine Bewertungen

- Physics HL - ANSWERS - Chris Hamper - Second Edition - Pearson 2014Dokument52 SeitenPhysics HL - ANSWERS - Chris Hamper - Second Edition - Pearson 2014vasudha100% (4)

- HSAB PrincipleDokument14 SeitenHSAB Principleneha yarrapothuNoch keine Bewertungen

- PHYS 622 - Statistical Mechanics - Spring 2016: Chung-Sang - Ng@gi - Alaska.eduDokument7 SeitenPHYS 622 - Statistical Mechanics - Spring 2016: Chung-Sang - Ng@gi - Alaska.eduAmina IbrahimNoch keine Bewertungen

- Logic PuzzleufhfgDokument1 SeiteLogic Puzzleufhfgkjj77600% (2)

- Pressure Drop in Reactors Calc.Dokument22 SeitenPressure Drop in Reactors Calc.Arka Pravo BandyopadhyayNoch keine Bewertungen

- Manual For Accessory Kit To Electromagnetic Vibrator No. 2185.55Dokument2 SeitenManual For Accessory Kit To Electromagnetic Vibrator No. 2185.55Harry RamzaNoch keine Bewertungen

- Chem Cheat Sheet MasterDokument6 SeitenChem Cheat Sheet MasterTahir Hussain100% (3)

- B2 Group 1..acetone Production PDFDokument21 SeitenB2 Group 1..acetone Production PDFElif TaşdövenNoch keine Bewertungen

- Unit 1 Electromagnetic Radiation-1Dokument23 SeitenUnit 1 Electromagnetic Radiation-1Saif YounusNoch keine Bewertungen

- Production of MEKDokument91 SeitenProduction of MEKNavdeep KumarNoch keine Bewertungen

- Bull Soc Chim Belg 1992 - A Convenient Preparation of Pivalaldehyde-Some Remarks On The Bouveault SynthesisDokument3 SeitenBull Soc Chim Belg 1992 - A Convenient Preparation of Pivalaldehyde-Some Remarks On The Bouveault Synthesisjanina_nazarskaNoch keine Bewertungen

- CHEM 221/PHY 335 - Molecular Symmetry IDokument34 SeitenCHEM 221/PHY 335 - Molecular Symmetry Ipaul javed0% (1)

- EnvSci 1c03 Module NotesDokument8 SeitenEnvSci 1c03 Module NotesyadNoch keine Bewertungen

- Scanning Electron Microscope (SEM)Dokument51 SeitenScanning Electron Microscope (SEM)Maaz ZafarNoch keine Bewertungen

- Pan Pearl 2019 Test 1 - SolutionDokument14 SeitenPan Pearl 2019 Test 1 - SolutionLablab da SilvaNoch keine Bewertungen

- ACT Thrissur Plus Two Easy QuestionsDokument23 SeitenACT Thrissur Plus Two Easy QuestionsAbin PmNoch keine Bewertungen

- GEAS Exam - With AnswersDokument12 SeitenGEAS Exam - With AnswerslesterPECENoch keine Bewertungen

- Model Answer Winter 2019Dokument19 SeitenModel Answer Winter 2019Mohit D MoreNoch keine Bewertungen

- G3-14 Standard Practice For Conventions Applicable To Electrochemical Measurements in Corrosion TestingDokument9 SeitenG3-14 Standard Practice For Conventions Applicable To Electrochemical Measurements in Corrosion Testingkaren Daniela chaparro perezNoch keine Bewertungen

- SN E Flowchart PDFDokument1 SeiteSN E Flowchart PDFElaina JosephNoch keine Bewertungen

- Expansion Calculations and Loop SizingDokument2 SeitenExpansion Calculations and Loop Sizingzshehadeh0% (1)

- Comparison of Post and Pre CombustionDokument12 SeitenComparison of Post and Pre CombustionMuhammad AtifNoch keine Bewertungen

- APV DatasheetDokument2 SeitenAPV DatasheetcesarjosevenNoch keine Bewertungen