Beruflich Dokumente

Kultur Dokumente

Lalitpur Power Generation Company Limited - Welding & PWHT Requirements

Hochgeladen von

Navneet SinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lalitpur Power Generation Company Limited - Welding & PWHT Requirements

Hochgeladen von

Navneet SinghCopyright:

Verfügbare Formate

Lalitpur Power Generation Company Limited

3x 660 MW - STPP

WELDING & PWHT

REQUIREMENT OF

VARIOUS MATERIAL

USED AT SITE IN

PRESURE PARTS

1 | Page

Prepared By- Navneet Singh(FQA)

Lalitpur Power Generation Company Limited

3x 660 MW - STPP

WELDING

Welding is a materials joining process which produces coalescence of materials by heating them

to suitable temperatures with or without the application of pressure or by the application of

pressure alone, and with or without the use of filler material.

COMMANLY USED WELDING PROCESSESS AT SITE FOR WELDING PRESSURE

PARTS.

SMAW SUBMERGED METAL ARC WELDING

Shielded

metal

arc

welding (SMAW),

also

known

as manual

metal

arc

[1]

welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a

manual arc welding process that uses a consumable electrode covered with a flux to lay the

weld.

An electric current, in the form of either alternating current or direct current from a welding

power supply, is used to form an electric arc between the electrode and the metals to

be joined. The workpiece and the electrode melts forming the weld pool that cools to form a

joint. As the weld is laid, the flux coating of the electrode disintegrates, giving off vapors that

serve as a shielding gas and providing a layer of slag, both of which protect the weld area from

atmospheric contamination.

(a) SMAW - Welding Circuit

2 | Page

(b) SMAW Welding Process

Prepared By- Navneet Singh(FQA)

Lalitpur Power Generation Company Limited

3x 660 MW - STPP

GTAW GAS TUNGESTUN ARC WELDING

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc

welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area

is protected from atmospheric contamination by an inert shielding gas (argon or helium), and a filler

metal is normally used, though some welds, known as autogenous welds, do not require it.

A constant-current welding power supply produces electrical energy, which is conducted across the

arc through a column of highly ionized gas and metal vapors known as a plasma.

(a) GTAW - Welding Circuit

3 | Page

(b) GTAW Welding Process

Prepared By- Navneet Singh(FQA)

Lalitpur Power Generation Company Limited

3x 660 MW - STPP

LIST OF MATERIAL USED IN PRESSURE PARTS WITH P.NO

P.NO

P1

Group

No.

1

Common

Name

Carbon

Steel

Carbon

Steel

Tubes

Pipes

Forgings

Castings

SA 106 Gr B

P1

P4

P5A

P15E

1Cr1/2Mo

Steels

21/4

Cr1Mo

Steel

9Cr1MoV

SA 213 T12

P15E

9Cr2W

P8

18Cr-8Ni

SA 210 GR C

SA 213 T22

SA 213 T91

Fittings

SA 234

WPB

SA 106 Gr C SA 216 SA 105,

SA 670 Gr

WCB ,

SA 234

B70

SA 216 WPC

WCC

SA 335 P12 SA 182 SA 217 SA 234

F12

WC6

WP12

SA 335 P22 SA 182 SA 217 SA 234

SA 691 Gr22 F22

WC9

WP22

SA 335 P91

SA 182

F91

SA 213 T92 SA 335 P92 SA 182

F92

SA

213 SA 312 TP AISI 321

TP304H

304 H

SA

213

TP347H

SA 217 SA 234

C12A

WP 91

SA 351 SA 403

CF8

Note:- IS 1239 , IS 3589 , API 5L Gr B are considered under P.No -1 & Group No :-1

4 | Page

Prepared By- Navneet Singh(FQA)

Lalitpur Power Generation Company Limited

3x 660 MW - STPP

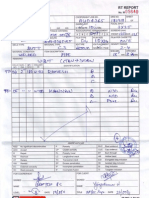

WELDING & PWHT REQUIREMENTS PRESUURE PARTS- TUBES

Welding

Material

Proces

s

Reference

GTAW

Filler

SMAW

Electrode

PWHT

Soaking

Temp(C)

Soaking

Time

(Mins)

Remark

P1 Gr 2

+

P1 Gr 2

A 210 Gr C

+

A 210 Gr C

GTAW

+

SMAW

WPS-1002/EWS

ER 80S-D2

E 7018-A1

620-650

Min 30

Mins

Eco Hanger

Tubes

P1 Gr 2

+

P1 Gr 2

P1 Gr 2

+

P4 Gr 1

P4 Gr 1

+

P4 Gr 1

A 210 Gr C

+

A 210 Gr C

A 210 Gr C

+

A 213 T 12

A 213 T 12

+

A 213 T 12

A 213 T 12

+

A 182 F 12

GTAW

+

SMAW

GTAW

+

SMAW

GTAW

+

SMAW

WPS-1002

ER 80S-D2

E 7018-1

WPS-1017

ER 80S-D2

E 7018-1

WPS-1009

ER 80S-B2

E 8018-B2

P4 Gr 1

+

P5A Gr 1

A 213 T 12

+

A 213 T 22

GTAW

+

SMAW

WPS-1011

ER 80S-B2

E 8018-B2

Eco Coils,1st

Pass Bottom

Header Joint

Hopper Panel &

Bottom Header

Tube

Water Wall

Panels

,Intermediate

Header Joints,

Back Pass

Panels,LTRH

Inlet Header

Joints , LTRH

Coils Assembly,

Roof Header &

Joints

LTRH Coil Int

Assembly

P5A Gr 1

+

P5A Gr 1

A 213 T 22

+

A 213 T 22

GTAW

+

SMAW

WPS-1014

ER 90S-B3

E 9018-B3

680-750

Min 30

Mins

P5A Gr 1

+

P5A Gr 1

A 213 T 22

+

A 213 T 22

GTAW

+

SMAW

WPS-1013

ER 90S-B3

E 9018-B3

P15E Gr 1

+

P15E Gr 1

A 213 T 91

+

A 213 T 91

GTAW

+

SMAW

WPS-1050,1036

ER 90S-B9

E 9015-B9

750-770

90 Mins

P15E Gr 1

+

P15E Gr 1

A 213 T 92

+

A 213 T 92

GTAW

+

SMAW

WPS-1058

ER

9CRWV

Thermanit

MTS-616

730-770

30 Mins

FSHIC , FSHOA

,RHOA Joints

P15E Gr 1

+

P15E Gr 1

A 213 T 91

+

A 213 T 92

GTAW

+

SMAW

WPS-1059

ER 90S-B9

E 9015-B9

730-770

30 Mins

FSHIB 98

Joints,

SHPOB -32

Joints

P8 Gr 1

+

P8 Gr 1

A 213 TP 304H

+

A 213 TP 304H

GTAW

WPS-1054

YT304H

RHOB Joints

P8 Gr 1

+

P8 Gr 1

A 213 TP 347H

+

A 213 TP 347H

GTAW

+

SMAW

WPS-1016

ER 347

E347

RHIB Joints,

FSHOB Joints,

FSHID Joints

5 | Page

Rear Arch

Panel, Rear

Hanger with

Rear Header

Joints

,LTRH Upper

Assembly,RHIA,

SHPIA,SHPIB

Joints

SHPOA ,

SHPOB,FSHIA ,

FSHIB

Prepared By- Navneet Singh(FQA)

Lalitpur Power Generation Company Limited

3x 660 MW - STPP

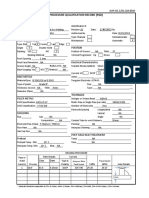

WELDING & PWHT REQUIREMENTS- PIPES

BHEL DOC-4-80-999-93172 (WPS, HT, NDT)-Pipes

6 | Page

Prepared By- Navneet Singh(FQA)

Lalitpur Power Generation Company Limited

3x 660 MW - STPP

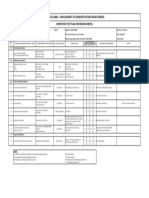

Rate of Heating & Rate of Cooling During PWHT

Thickness of Material

25 mm

> 25 50 mm

> 50 75 mm

> 75mm

Maximum Heating Rate

Above 300C

220C/hour

110C/hour

75C/hour

55C/hour

Maximum Cooling

Rate Upto 300C

220C/hour

110C/hour

75C/hour

55C/hour

Typical SR/PWHT Chart T-91 & T-92

7 | Page

Prepared By- Navneet Singh(FQA)

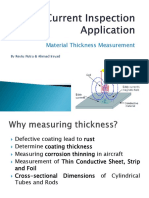

Das könnte Ihnen auch gefallen

- UT EquationsDokument2 SeitenUT EquationsNavneet Singh100% (1)

- ITP Structural SteelDokument14 SeitenITP Structural SteelNavneet SinghNoch keine Bewertungen

- TWI Welding TrainingDokument31 SeitenTWI Welding TrainingNavneet Singh67% (3)

- VIRGINIA CONCRETE CONFERENCE PRESENTATION ON CREEP & SHRINKAGEDokument38 SeitenVIRGINIA CONCRETE CONFERENCE PRESENTATION ON CREEP & SHRINKAGEsiva_civil4051100% (1)

- (RT) Iqi Penetrameter WireDokument3 Seiten(RT) Iqi Penetrameter WireNavneet Singh100% (4)

- Ultrasonic Testing FormulasDokument4 SeitenUltrasonic Testing FormulasNavneet Singh100% (1)

- Why Insulate Pipes: 3 Key Benefits of InsulationDokument13 SeitenWhy Insulate Pipes: 3 Key Benefits of InsulationnguyenNoch keine Bewertungen

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Dokument30 SeitenLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Navneet Singh100% (2)

- Inorganic BindersDokument4 SeitenInorganic Bindersadeniyi-sam100% (1)

- 13 Creep and Stress RuptureDokument25 Seiten13 Creep and Stress RuptureZdravko IvancicNoch keine Bewertungen

- Process Piping Inspection and Test PlanDokument6 SeitenProcess Piping Inspection and Test Planmanoj thakkarNoch keine Bewertungen

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDokument2 SeitenWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNoch keine Bewertungen

- FInal QAP HDPE WeldingDokument2 SeitenFInal QAP HDPE Weldingkannagi198Noch keine Bewertungen

- Pipelines - M. AmeriniDokument150 SeitenPipelines - M. Amerinihenry ardiyanto50% (2)

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDokument11 Seiten14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNoch keine Bewertungen

- Nde Manual Nov 2010Dokument186 SeitenNde Manual Nov 2010Navneet Singh100% (4)

- Welding Procecure SpecificationDokument9 SeitenWelding Procecure SpecificationNwoha PeterNoch keine Bewertungen

- ASME Code News (Questions and Answers)Dokument4 SeitenASME Code News (Questions and Answers)dj22500Noch keine Bewertungen

- Lifetime Assessment of A Steam Pipeline: 1 2 Material 15 128 (14MOV6-3)Dokument6 SeitenLifetime Assessment of A Steam Pipeline: 1 2 Material 15 128 (14MOV6-3)Costas AggelidisNoch keine Bewertungen

- Door Built Up RateDokument6 SeitenDoor Built Up RateSebb seebNoch keine Bewertungen

- Toshiba X-ray Generator ManualDokument125 SeitenToshiba X-ray Generator ManualFrancisco Diaz100% (9)

- Case Study-R12 12Dokument81 SeitenCase Study-R12 12ranjitpandeyNoch keine Bewertungen

- Walk Down Punch ListDokument7 SeitenWalk Down Punch ListGomathyselviNoch keine Bewertungen

- Sitework: 1.02 Definitions, Standard Tests 1.02 Definitions, Standard TestsDokument49 SeitenSitework: 1.02 Definitions, Standard Tests 1.02 Definitions, Standard TestsJr FranciscoNoch keine Bewertungen

- Pipe rack structure and designDokument11 SeitenPipe rack structure and designpuru55980Noch keine Bewertungen

- Adsorption by BhanuDokument20 SeitenAdsorption by BhanuHiren vaghaniNoch keine Bewertungen

- Metallographic Principles 200-860Dokument44 SeitenMetallographic Principles 200-860marian111100% (4)

- Air Reciver Vessel-1 (Compressor Unit-2)Dokument5 SeitenAir Reciver Vessel-1 (Compressor Unit-2)MD Shadikul Huq ShezanNoch keine Bewertungen

- Day 2 200 ItemsDokument25 SeitenDay 2 200 ItemsRobert DelfinNoch keine Bewertungen

- Investmech - Structural Integrity (ASME VIII - Part UG - Rules For The Design of Pressure Vessels) R0.0Dokument33 SeitenInvestmech - Structural Integrity (ASME VIII - Part UG - Rules For The Design of Pressure Vessels) R0.0CAC-39.01Noch keine Bewertungen

- API 510 Study PlanDokument7 SeitenAPI 510 Study Plankoib789100% (2)

- Boiler Design and Operation ParametersDokument88 SeitenBoiler Design and Operation ParametersNavneet SinghNoch keine Bewertungen

- Tabla de Torque para Pernos de Acero SS304Dokument1 SeiteTabla de Torque para Pernos de Acero SS304Joaquín Indacochea Beltrán88% (8)

- Wps PQRDokument7 SeitenWps PQRsobariNoch keine Bewertungen

- Tips Wps FormatDokument5 SeitenTips Wps FormatWaqas WaqasNoch keine Bewertungen

- Client: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Dokument7 SeitenClient: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Bhargav BbvsNoch keine Bewertungen

- ASME B31.3 Weldolet welding requirementsDokument10 SeitenASME B31.3 Weldolet welding requirementsAbderrahmane79Noch keine Bewertungen

- Welding CrMo Steels for Power and Petrochemical ApplicationsDokument11 SeitenWelding CrMo Steels for Power and Petrochemical Applicationsmahmoud_allam3100% (1)

- Wrapping MethodDokument5 SeitenWrapping Methodnnuek67% (3)

- Carbon Steel Pipes - Comparing AmericanDokument2 SeitenCarbon Steel Pipes - Comparing AmericanKazi Anwarul Azim SohelNoch keine Bewertungen

- WQT For CSDokument5 SeitenWQT For CSkumar08686Noch keine Bewertungen

- Handbook - Filler Metal ASTM SteelsDokument1 SeiteHandbook - Filler Metal ASTM SteelsadelNoch keine Bewertungen

- (uploadMB - Com) Basic of Piping DrawingsDokument17 Seiten(uploadMB - Com) Basic of Piping DrawingsAob AprilNoch keine Bewertungen

- PWHTDokument57 SeitenPWHTssNoch keine Bewertungen

- Api 570 Close BookDokument12 SeitenApi 570 Close BookMuNoch keine Bewertungen

- WPS PQR FormulirDokument2 SeitenWPS PQR FormulirAZaiNoch keine Bewertungen

- Potential Damage PKTDokument7 SeitenPotential Damage PKTFebri Ramdani NugrahaNoch keine Bewertungen

- Eddy Current Inspection ApplicationDokument13 SeitenEddy Current Inspection ApplicationRestu PutraNoch keine Bewertungen

- PQR Saw ProcessDokument1 SeitePQR Saw ProcessARUL ARON JOSENoch keine Bewertungen

- 10 1016@j Ijhydene 2020 02 035Dokument9 Seiten10 1016@j Ijhydene 2020 02 035TarunNoch keine Bewertungen

- Sensitization of Inconel 625Dokument9 SeitenSensitization of Inconel 625nantha kumarNoch keine Bewertungen

- ITP For Drum Screen InspectionDokument1 SeiteITP For Drum Screen InspectionkapsarcNoch keine Bewertungen

- Astm A335 p91 PipeDokument1 SeiteAstm A335 p91 PipeBhagwati SteelageNoch keine Bewertungen

- Applying Shielded Metal Arc Welding TechniquesDokument134 SeitenApplying Shielded Metal Arc Welding Techniquesgaspardo123Noch keine Bewertungen

- IPC2022-87168 - A Transparent Asme B31.8-Based Strain Assessment Method Using 3D Measurement of Dent Morphology - FinalDokument12 SeitenIPC2022-87168 - A Transparent Asme B31.8-Based Strain Assessment Method Using 3D Measurement of Dent Morphology - FinalOswaldo MontenegroNoch keine Bewertungen

- AV GasketsDokument2 SeitenAV GasketsAliNoch keine Bewertungen

- Gas Metal Arc WeldingDokument52 SeitenGas Metal Arc WeldingBalakumarNoch keine Bewertungen

- Irrigation System Materials and Installation SpecificationDokument92 SeitenIrrigation System Materials and Installation Specificationsushant_moreyNoch keine Bewertungen

- Bright Annealing Process of Stainless S Teel TubeDokument2 SeitenBright Annealing Process of Stainless S Teel TubeViraj ShiroleNoch keine Bewertungen

- GMAWDokument12 SeitenGMAWsushant47Noch keine Bewertungen

- Shielded Metal Arc WeldingDokument39 SeitenShielded Metal Arc Weldingعزت عبد المنعم100% (1)

- Remaining Life Assessment of Fiber Reinforced Plastic (FRP) Pipe in LNG Plant After 20 Years in OperationDokument13 SeitenRemaining Life Assessment of Fiber Reinforced Plastic (FRP) Pipe in LNG Plant After 20 Years in OperationLuthfi ArdiansyahNoch keine Bewertungen

- ML 1015998765Dokument42 SeitenML 1015998765ডঃ শুভম চ্যাটার্জীNoch keine Bewertungen

- Cryogenic SystemDokument1 SeiteCryogenic Systempap230% (1)

- WPSGMAW90 102011ExamplePDFDokument1 SeiteWPSGMAW90 102011ExamplePDFBhavani PrasadNoch keine Bewertungen

- FuturePipe Installation Manual 18-7-05 PDFDokument25 SeitenFuturePipe Installation Manual 18-7-05 PDFPaul WoworNoch keine Bewertungen

- Thermowell Calculation Guide V1.3Dokument19 SeitenThermowell Calculation Guide V1.3AymanelorbanyNoch keine Bewertungen

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Dokument15 SeitenFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNoch keine Bewertungen

- Tube Expander-Tools PDFDokument120 SeitenTube Expander-Tools PDFmarceilinus devaluantoNoch keine Bewertungen

- Piping Inspection 22.01.2020Dokument72 SeitenPiping Inspection 22.01.2020KarthikNoch keine Bewertungen

- WQT Form (ASME) 04-23Dokument1 SeiteWQT Form (ASME) 04-23hanz bermejoNoch keine Bewertungen

- PWHT of Dissimilar: Metal WeldsDokument48 SeitenPWHT of Dissimilar: Metal WeldswchavezbNoch keine Bewertungen

- The Heat Affected ZoneDokument24 SeitenThe Heat Affected ZoneRatan PanditNoch keine Bewertungen

- Esab, Ok 309L (29.12.16)Dokument1 SeiteEsab, Ok 309L (29.12.16)RodrigoNoch keine Bewertungen

- Corrosion Failures: Theory, Case Studies, and SolutionsVon EverandCorrosion Failures: Theory, Case Studies, and SolutionsNoch keine Bewertungen

- Bohler Bestseller Engl NTDokument28 SeitenBohler Bestseller Engl NTClaudia MmsNoch keine Bewertungen

- T-PUT Voestalpine Roll-Bonded Clad PlatesDokument8 SeitenT-PUT Voestalpine Roll-Bonded Clad PlatesVăn Trường LêNoch keine Bewertungen

- Speaking Sample Interview Hometown JobsDokument1 SeiteSpeaking Sample Interview Hometown Jobswaheed_iiuiNoch keine Bewertungen

- Is 15658 2006Dokument27 SeitenIs 15658 2006Navneet SinghNoch keine Bewertungen

- 215 UkDokument4 Seiten215 UkNavneet SinghNoch keine Bewertungen

- Sample CHPDokument1 SeiteSample CHPNavneet SinghNoch keine Bewertungen

- 2007manual Structural SteelDokument55 Seiten2007manual Structural Steelრაქსშ საჰა100% (1)

- NAB Certificate PDFDokument2 SeitenNAB Certificate PDFNavneet SinghNoch keine Bewertungen

- Washing Machine ManualDokument24 SeitenWashing Machine ManualNavneet SinghNoch keine Bewertungen

- RAL Colour - ChartDokument3 SeitenRAL Colour - ChartksyathishNoch keine Bewertungen

- Concrete Tech PresentationDokument2 SeitenConcrete Tech PresentationNavneet SinghNoch keine Bewertungen

- TG03 Pump PerformanceDokument10 SeitenTG03 Pump PerformanceKvvPrasadNoch keine Bewertungen

- NAB Certificate PDFDokument2 SeitenNAB Certificate PDFNavneet SinghNoch keine Bewertungen

- NDT AcceptanceDokument6 SeitenNDT AcceptanceNavneet SinghNoch keine Bewertungen

- Calibration BlockDokument1 SeiteCalibration BlockNavneet SinghNoch keine Bewertungen

- Training Calendar 2013 - North India - Correected Format Rev.2Dokument6 SeitenTraining Calendar 2013 - North India - Correected Format Rev.2Navneet SinghNoch keine Bewertungen

- PF (EPS) Withdrawal - Form 10CDokument6 SeitenPF (EPS) Withdrawal - Form 10Cd0101Noch keine Bewertungen

- SymphonyDokument10 SeitenSymphonyNavneet SinghNoch keine Bewertungen

- SymphonyDokument10 SeitenSymphonyNavneet SinghNoch keine Bewertungen

- Cswip Multichoice QuestionsDokument38 SeitenCswip Multichoice QuestionsNavneet Singh100% (1)

- Asme CCase N-432Dokument4 SeitenAsme CCase N-432julianmorantesNoch keine Bewertungen

- An Empirical Model To Calculate The Threads Stripping of A Bolt Installed in A Tapped PartDokument4 SeitenAn Empirical Model To Calculate The Threads Stripping of A Bolt Installed in A Tapped Partparag7676Noch keine Bewertungen

- BM2312 004Dokument30 SeitenBM2312 004julia.sacco.20Noch keine Bewertungen

- 3ap1 FG: High-Voltage Circuit-BreakerDokument2 Seiten3ap1 FG: High-Voltage Circuit-BreakerFernando VacaNoch keine Bewertungen

- Estane Skythane S185A TPU: TypeDokument1 SeiteEstane Skythane S185A TPU: Typejuliushasan2Noch keine Bewertungen

- 750-234 CB780E - 784E ManualDokument44 Seiten750-234 CB780E - 784E ManualDaɳɳy ElSamNoch keine Bewertungen

- Project TopicsDokument16 SeitenProject TopicsVasu VermaNoch keine Bewertungen

- Nupla 2007 CatalogDokument60 SeitenNupla 2007 Catalogdonnal47Noch keine Bewertungen

- 180 M3 SoftenerDokument11 Seiten180 M3 SoftenerDinesh DhakneNoch keine Bewertungen

- Reinforcing Bar Couplers: For The Construction IndustryDokument32 SeitenReinforcing Bar Couplers: For The Construction IndustryhutuguoNoch keine Bewertungen

- TC Cico SuperDokument2 SeitenTC Cico SuperHks InfrastructureNoch keine Bewertungen

- Volvo s80 Premier 2005 Wiring DiagramDokument3 SeitenVolvo s80 Premier 2005 Wiring Diagramjim100% (53)

- Global Energy Balance in The Exchanger and Losses StudyDokument4 SeitenGlobal Energy Balance in The Exchanger and Losses StudyJames Clerk MaxwellNoch keine Bewertungen

- Polyurethane Disc: Features & BenefitsDokument2 SeitenPolyurethane Disc: Features & BenefitsDiego AndradeNoch keine Bewertungen

- Authorised Examiners Lifting EquipmentDokument13 SeitenAuthorised Examiners Lifting EquipmentdunglxNoch keine Bewertungen

- Detail of Mesh-1 Reinforcement Details of Pier Cap Section D-DDokument1 SeiteDetail of Mesh-1 Reinforcement Details of Pier Cap Section D-DSaurabh PandeyNoch keine Bewertungen

- 7 9layerblownfilmlinesDokument6 Seiten7 9layerblownfilmlinesductoan32Noch keine Bewertungen

- Duct PDFDokument12 SeitenDuct PDFroshan jaiswalNoch keine Bewertungen

- TYFTY Qs BankDokument7 SeitenTYFTY Qs BankgurusamyNoch keine Bewertungen

- Romacon & Hegawa CatalogueDokument60 SeitenRomacon & Hegawa CataloguePhattapoom RoopngamNoch keine Bewertungen

- PDO SP-2217 Specification of Internal FBE and Liquid Coating Systems For Carbon Steel Piping and Line PipesDokument41 SeitenPDO SP-2217 Specification of Internal FBE and Liquid Coating Systems For Carbon Steel Piping and Line PipesMoin AltafNoch keine Bewertungen

- Functionally Graded MaterialsDokument16 SeitenFunctionally Graded MaterialsPradeepkumar Chikkamath100% (1)