Beruflich Dokumente

Kultur Dokumente

Pages From B1-20-1 - 2013 PDF

Hochgeladen von

Ahmad Jukliv Pandu YoedhawanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pages From B1-20-1 - 2013 PDF

Hochgeladen von

Ahmad Jukliv Pandu YoedhawanCopyright:

Verfügbare Formate

Pipe Threads, General Purpose (Inch)

INTRODUCTION

P

T

S

C

R

M

L

1.1 Scope

This Standard covers dimensions and gaging of pipe

threads of the following series:

NPT

NPSC

NPTR

NPSM

NPSL

p

p

p

p

p

p

p

Pipe

Taper

Straight

Coupling

Railing Fittings

Mechanical

Locknut

1.4 Sealing (NPT and NPSC Only)

1.4.1 Mating Threads. Mating threads should

always contact on the thread flanks. The design tolerances are such that mating crests and roots may clear,

contact, or interfere (see Fig. 1). This joint may not necessarily seal, unless a sealant is used.

1.2 Related Standard

Hose coupling joints are ordinarily made with straight

internal and external loose-fitting threads. There are several standards of hose threads having various diameters

and pitches, one of which is based on the American

National Standard Pipe Thread. By the use of this thread

series, NPSH, it is possible to join small hose couplings

in sizes 12 to 4, inclusive, to ends of standard pipe having

American National Standard external pipe threads,

using a gasket to seal the joint. For dimensions, tolerances, and gaging, see ASME B1.20.7.

1.4.2 Sealant. Where pressure-tight, leak-free joints

are required, it is intended that threads conforming to

this Standard be made up wrench-tight with a sealant.

To prevent galling during installation, the sealant may

have lubricating properties.

1.3 Thread Designations

1.3.1 The types of pipe threads included in this

Standard are designated by specifying in sequence the

nominal pipe size, number of threads per inch, and the

thread series symbol as follows:

1

827 NPT

1

827 NPSC

1

214 NPTR

1

827 NPSM

1

827 NPSL

Decimal equivalent notation may be substituted for

fractional pipe sizes. For example

1.4.4 Other Considerations. Out-of-roundness of

mating parts can negatively affect their ability to seal

when made up wrench tight. The products elasticity

and ductility will also affect sealing.

1.4.5 Pressure-Tight Threads Without Sealant. Pipe

threads designed for pressure-tight joints that may be

used without sealing compounds (Dryseal Threads) are

covered in ASME B1.20.3.

0.12527 NPT

For left-hand threads, add LH to the designation.

For example

1

827 NPTLH

1.5 Appendices

Useful and supplementary information that is not a

part of this Standard is presented in a nonmandatory

appendix. Specifically, the nonmandatory appendices

cover the turns of engagement method of gaging, suggested prethreading hole diameters, and an explanatory

gaging matrix.

Designations without LH will signify right-hand

threads.

1.3.2 Each of these letters in the symbols has significance as follows:

N p National (American) Standard

1

Copyright c 2013 by the American Society of Mechanical Engineers.

No reproduction may be made of this material without written consent of ASME.

This copy downloaded on 2015-05-12 15:14:59 -0500 by authorized user Fermi National Lab

1.4.3 Tightening Torque. Due to application-specific

variables such as materials, wall thickness, operating

pressures, etc., no guidance is given in this Standard

regarding joint-tightening torque. However, joints

should be tightened beyond the hand-tight engagement

position. Advancing the joint past hand-tight creates

interference between external and internal thread flanks,

produces a seal (with the use of a sealant), and helps

prevent loosening of the joint. Overtightening may be

detrimental to the sealing function of the joint.

Copyrighted material licensed to Fermi National Laboratory by Thomson Scientific, Inc. (www.techstreet.com).

ASME B1.20.1-2013

Copyrighted material licensed to Fermi National Laboratory by Thomson Scientific, Inc. (www.techstreet.com).

ASME B1.20.1-2013

Fig. 3 American National Standard Taper Pipe Thread Notation

L4

L2

L5

2P

Wrench make-up

E0

E1

E5

E2

Plane of vanish point

thread length

Plane of effective

thread length

Plane of complete

Plane of hand-tight

zero

make-up

Plane of wrench

Reference plane

K0

Copyright c 2013 by the American Society of Mechanical Engineers.

No reproduction may be made of this material without written consent of ASME.

This copy downloaded on 2015-05-12 15:14:59 -0500 by authorized user Fermi National Lab

E3

engagement

L1

L3

Table 2 Basic Dimensions of American National Standard Taper Pipe Thread, NPT (Contd)

O.D.

of

Pipe,

D

Threads/

Inch, n

Pitch

of

Thread,

P

in.

Hand-tight

Engagement

Effective Thread,

External

Threads

Pitch

Diameter,2

E1

in.

Length,1

L1

Length, L1

Plane to L2

Plane,

External

Thread,

L2 L1

Wrench Make-Up Length,

Internal Thread

Threads

Pitch

Diameter,

E3

in.

Threads

in.

Threads

Pitch

Diameter, E3

10

11

12

13

14

15

16

Length,3

L2

Length,

L3

Basic

Change Minor6

in

Diameter

Nominal Complete

Diameter

at

External Threads5

Overall

per

Small

Vanish

Length,

Pitch

Height

Turn

End

Thread,

Length,

External

Diamof

of

of

V

L5

Thread,4

eter,

Thread, Thread,

Pipe,

in.

Threads

L4

in.

E5

h

0.0625/n

Ko

17

18

19

0.26424

0.35656

0.46697

0.60160

0.74504

0.1285

0.1285

0.1928

0.1928

0.2479

3.47

3.47

3.47

3.47

3.47

0.3896

0.3924

0.5946

0.6006

0.7815

0.1870

0.1898

0.2907

0.2967

0.3909

0.28287

0.37537

0.49556

0.63056

0.78286

0.02963

0.02963

0.04444

0.04444

0.05714

0.00231

0.00231

0.00347

0.00347

0.00446

0.2415

0.3338

0.4329

0.5675

0.7014

3

3

3

3

3

0.95429

1.19733

1.54083

1.77978

2.25272

0.2479

0.3017

0.3017

0.3017

0.3017

3.47

3.47

3.47

3.47

3.47

0.7935

0.9845

1.0085

1.0252

1.0582

0.4029

0.5089

0.5329

0.5496

0.5826

0.99286

1.24544

1.59044

1.83044

2.30543

0.05714

0.06957

0.06957

0.06957

0.06957

0.00446

0.00543

0.00543

0.00543

0.00543

0.9106

1.1441

1.4876

1.7266

2.1995

0.2500

0.2500

0.2500

0.2500

0.2500

2

2

2

2

2

2.70391

3.32500

3.82188

4.31875

5.37511

0.4338

0.4338

0.4338

0.4338

0.4338

3.47

3.47

3.47

3.47

3.47

1.5712

1.6337

1.6837

1.7337

1.8400

0.8875

0.9500

1.0000

1.0500

1.1563

2.77500

3.40000

3.90000

4.40000

5.46300

0.10000

0.10000

0.10000

0.10000

0.10000

0.00781

0.00781

0.00781

0.00781

0.00781

2.6195

3.2406

3.7374

4.2343

5.2907

4.44

5.20

5.72

6.12

5.50

0.2500

0.2500

0.2500

0.2500

0.2500

2

2

2

2

2

6.43047

8.41797

10.52969

12.51719

13.75938

0.4338

0.4338

0.4338

0.4338

0.4338

3.47

3.47

3.47

3.47

3.47

1.9462

2.1462

2.3587

2.5587

2.6837

1.2625

1.4625

1.6750

1.8750

2.0000

6.52500

8.52500

10.6500

12.6500

13.9000

0.10000

0.10000

0.10000

0.10000

0.10000

0.00781

0.00781

0.00781

0.00781

0.00781

6.3460

8.3335

10.4453

12.4328

13.6749

5.10

5.20

5.80

7.00

0.2500

0.2500

0.2500

0.2500

2

2

2

2

15.74688

17.73438

19.72188

23.69688

0.4338

0.4338

0.4338

0.4338

3.47

3.47

3.47

3.47

2.8837

3.0837

3.2837

3.6837

2.2000

2.4000

2.6000

3.0000

15.9000

17.9000

19.9000

23.9000

0.10000

0.10000

0.10000

0.10000

0.00781

0.00781

0.00781

0.00781

15.6624

17.6499

19.6374

23.6124

16

1

8

1

4

3

8

1

2

0.3125

0.4050

0.5400

0.6750

0.8400

27

27

18

18

14

0.03703704

0.03703704

0.05555556

0.05555556

0.07142857

0.27118

0.36351

0.47739

0.61201

0.75843

0.1600

0.1615

0.2278

0.2400

0.3200

4.32

4.36

4.10

4.32

4.48

0.28118

0.37360

0.49163

0.62701

0.77843

0.2611

0.2639

0.4018

0.4078

0.5337

7.05

7.13

7.23

7.34

7.47

0.28750

0.38000

0.50250

0.63750

0.79178

0.1011

0.1024

0.1740

0.1678

0.2137

2.73

2.76

3.13

3.02

2.99

0.1111

0.1111

0.1667

0.1667

0.2143

3

3

3

3

3

4

1

1

1 4

112

2

1.0500

1.3150

1.6600

1.9000

2.3750

14

11.5

11.5

11.5

11.5

0.07142857

0.08695652

0.08695652

0.08695652

0.08695652

0.96768

1.21363

1.55713

1.79609

2.26902

0.3390

0.4000

0.4200

0.4200

0.4360

4.75

4.60

4.83

4.83

5.01

0.98887

1.23863

1.58338

1.82234

2.29627

0.5457

0.6828

0.7068

0.7235

0.7565

7.64

7.85

8.13

8.32

8.70

1.00178

1.25631

1.60131

1.84131

2.31630

0.2067

0.2828

0.2868

0.3035

0.3205

2.89

3.25

3.30

3.49

3.69

0.2143

0.2609

0.2609

0.2609

0.2609

212

3

312

4

5

2.8750

3.5000

4.0000

4.5000

5.5630

8

8

8

8

8

0.12500000

0.12500000

0.12500000

0.12500000

0.12500000

2.71953

3.34063

3.83750

4.33438

5.39073

0.6820

0.7660

0.8210

0.8440

0.9370

5.46

6.13

6.57

6.75

7.50

2.76216

3.38850

3.88881

4.38713

5.44929

1.1375

1.2000

1.2500

1.3000

1.4063

9.10

9.60

10.00

10.40

11.25

2.79063

3.41563

3.91563

4.41563

5.47863

0.4555

0.4340

0.4290

0.4560

0.4693

3.64

3.47

3.43

3.65

3.75

6

8

10

12

14

6.6250

8.6250

10.7500

12.7500

14.0000

8

8

8

8

8

0.12500000

0.12500000

0.12500000

0.12500000

0.12500000

6.44609

8.43359

10.54531

12.53281

13.77500

0.9580

1.0630

1.2100

1.3600

1.5620

7.66

8.50

9.68

10.88

12.50

6.50597

8.50003

10.62094

12.61781

13.87263

1.5125

1.7125

1.9250

2.1250

2.2500

12.10

13.70

15.40

17.00

18.00

6.54063

8.54063

10.66563

12.66563

13.91563

0.5545

0.6495

0.7150

0.7650

0.6880

16

18

20

24

16.0000

18.0000

20.0000

24.0000

8

8

8

8

0.12500000

0.12500000

0.12500000

0.12500000

15.76250

17.75000

19.73750

23.71250

1.8120

2.0000

2.1250

2.3750

14.50

16.00

17.00

19.00

15.87575

17.87500

19.87031

23.86094

2.4500

2.6500

2.8500

3.2500

19.60

21.20

22.80

26.00

15.91563

17.91563

19.91563

23.91563

0.6380

0.6500

0.7250

0.8750

20

21

22

23

24

ASME B1.20.1-2013

Copyright c 2013 by the American Society of Mechanical Engineers.

No reproduction may be made of this material without written consent of ASME.

Nominal

Pipe

Size

Pitch

Diameter

at

Beginning

of

External

Thread,

E0

GENERAL NOTE: The basic dimensions of the American National Standard Taper Pipe Thread are given in inches to four or five decimal places. While this implies a greater degree of

precision than is ordinarily attained, these dimensions are the basis of gage dimensions and are so expressed for the purpose of eliminating errors in computations.

NOTES:

(1) Also length of L1 ring gage and length from gaging notch to small end of L1 plug gage.

(2) Also pitch diameter at gaging notch of L1 plug gage (hand-tight plane).

(3) Also threaded length of L1 plug gage.

(4) Reference dimension.

(5) The length L5 from the end of the pipe determines the plane beyond which the thread form is incomplete at the crest. The next two threads are complete at the root. At this plane,

the cone formed by the crests of the thread intersects the cylinder forming the external surface of the pipe (L5 p L2 2P).

(6) Given as information for use in selecting tap drills (see Nonmandatory Appendix B).

Copyrighted material licensed to Fermi National Laboratory by Thomson Scientific, Inc. (www.techstreet.com).

This copy downloaded on 2015-05-12 15:14:59 -0500 by authorized user Fermi National La

Das könnte Ihnen auch gefallen

- ASME B1.20.1-2013 Absrates PDFDokument3 SeitenASME B1.20.1-2013 Absrates PDFEddyNoch keine Bewertungen

- Page No 1867-1871Dokument5 SeitenPage No 1867-1871prasad_shukla13089Noch keine Bewertungen

- BSP NPT Thread Sizes From Connexion Developments LTDDokument7 SeitenBSP NPT Thread Sizes From Connexion Developments LTDIvo Herid LesmanaNoch keine Bewertungen

- Ansi Asme B1.20.1-1983Dokument5 SeitenAnsi Asme B1.20.1-1983lorenzinho290Noch keine Bewertungen

- Astm F1498Dokument13 SeitenAstm F1498Hernando Andrés Ramírez GilNoch keine Bewertungen

- Engineering Data Catalog Pitch Diameter LimitsDokument35 SeitenEngineering Data Catalog Pitch Diameter LimitssalamrefighNoch keine Bewertungen

- Thread TypeDokument4 SeitenThread Typevikram_007Noch keine Bewertungen

- Unraveling the mysteries of pipe thread sizesDokument1 SeiteUnraveling the mysteries of pipe thread sizesJeffrey WalkerNoch keine Bewertungen

- Pipe Fitting and AdaptersDokument47 SeitenPipe Fitting and AdaptersYhia EbrahimNoch keine Bewertungen

- NPT (Asme B1.20.1)Dokument5 SeitenNPT (Asme B1.20.1)Afronie Cepoz D'nextNoch keine Bewertungen

- Threads - NPTF Taper Thread GagingDokument5 SeitenThreads - NPTF Taper Thread GagingTrushantNoch keine Bewertungen

- NPTDokument2 SeitenNPTaaaNoch keine Bewertungen

- ASME B16.9 2007 (Metric Dimensions)Dokument16 SeitenASME B16.9 2007 (Metric Dimensions)Joseph CruzNoch keine Bewertungen

- NaptDokument2 SeitenNaptaaaNoch keine Bewertungen

- American Standard Pipe Dimensions - Technical NotesDokument3 SeitenAmerican Standard Pipe Dimensions - Technical NotesGMHHENoch keine Bewertungen

- Understanding Nominal Pipe Sizes (NPS) and Pipe DimensionsDokument39 SeitenUnderstanding Nominal Pipe Sizes (NPS) and Pipe DimensionsprathikNoch keine Bewertungen

- FLUID LEAKAGE-What To Do?: John C. Cox, Business Development Manager Swagelok Company, Solon, OhioDokument6 SeitenFLUID LEAKAGE-What To Do?: John C. Cox, Business Development Manager Swagelok Company, Solon, OhiotakemetovikasNoch keine Bewertungen

- Math Tools - Pipe Diameters, Threads and Sizes A3Dokument3 SeitenMath Tools - Pipe Diameters, Threads and Sizes A3Ram CaceresNoch keine Bewertungen

- National Pipe ThreadDokument10 SeitenNational Pipe ThreadLodyNoch keine Bewertungen

- 169 PD0192ThreadsStandardReferenceGuiderev4Dokument21 Seiten169 PD0192ThreadsStandardReferenceGuiderev4Coman ovidiuNoch keine Bewertungen

- Mjitfjjl: Pipe Supports and Hangers Part 3: Middle Connection Attachment and Building Structure AttachmentsDokument37 SeitenMjitfjjl: Pipe Supports and Hangers Part 3: Middle Connection Attachment and Building Structure AttachmentsIRELECNoch keine Bewertungen

- BP Piping Joints Handbook PDFDokument57 SeitenBP Piping Joints Handbook PDFHazem KamalNoch keine Bewertungen

- PIPE Material specDokument12 SeitenPIPE Material specRana PrathapNoch keine Bewertungen

- AN vs JIC Fittings: Key Differences for Aircraft and Industrial ApplicationsDokument5 SeitenAN vs JIC Fittings: Key Differences for Aircraft and Industrial ApplicationsjteamNoch keine Bewertungen

- Mall Pipe ThreadsDokument14 SeitenMall Pipe Threadsanac_mathNoch keine Bewertungen

- Aramco Interview QuestionsDokument38 SeitenAramco Interview QuestionsMd Sharique83% (6)

- Ladc/Spe 35037: Premium Connector ConfigurationsDokument10 SeitenLadc/Spe 35037: Premium Connector Configurationssigit praNoch keine Bewertungen

- Fastener Handouts (Screw)Dokument34 SeitenFastener Handouts (Screw)cluchavezNoch keine Bewertungen

- Connection TypeDokument9 SeitenConnection Typesmelihates100% (1)

- Identifying Threads Identifying Threads: How To Use The CaliperDokument6 SeitenIdentifying Threads Identifying Threads: How To Use The CaliperkyletgerberNoch keine Bewertungen

- PIPE THREAD DimensionDokument2 SeitenPIPE THREAD DimensionAriel AnascoNoch keine Bewertungen

- The Piping Guide by David Sherwood - 1991Dokument267 SeitenThe Piping Guide by David Sherwood - 1991bavarian_sheep100% (1)

- Pipe Thread DiameterDokument3 SeitenPipe Thread DiameterNabil RamehNoch keine Bewertungen

- Chapter - 3 L-1 Bolt DesignDokument34 SeitenChapter - 3 L-1 Bolt DesignBerihunNoch keine Bewertungen

- NPT Vs NPTF 01Dokument2 SeitenNPT Vs NPTF 01Rajendra SharmaNoch keine Bewertungen

- Saudi Aramco Piping QC Inspector Sample Interview QuestionsDokument6 SeitenSaudi Aramco Piping QC Inspector Sample Interview QuestionsRichard Periyanayagam100% (3)

- Piping & Piping ComponentsDokument37 SeitenPiping & Piping ComponentsRavindra S. JivaniNoch keine Bewertungen

- Threaded Fittings General - Definition and Details - ASME B16.11 and ASME B1.20Dokument3 SeitenThreaded Fittings General - Definition and Details - ASME B16.11 and ASME B1.20abhay_patil_22Noch keine Bewertungen

- Threads Standard Reference Guide Rev4 PDFDokument21 SeitenThreads Standard Reference Guide Rev4 PDFPham CongNoch keine Bewertungen

- Flanges General For DummiesDokument68 SeitenFlanges General For DummiesditoNoch keine Bewertungen

- ANスレッドサイズ表Dokument1 SeiteANスレッドサイズ表busuyomeNoch keine Bewertungen

- Pipe Thread Standards and TypesDokument2 SeitenPipe Thread Standards and Typessushant shirsatNoch keine Bewertungen

- Taper Thread TorqueDokument1 SeiteTaper Thread TorqueRichardNoch keine Bewertungen

- BS 2779-1986 Ó ÖÆ ÇÃÜ Â ÜÂÝÎÆ (BSP)Dokument20 SeitenBS 2779-1986 Ó ÖÆ ÇÃÜ Â ÜÂÝÎÆ (BSP)Vaibhav ShuklaNoch keine Bewertungen

- Piping Olets: Branching Fittings GuideDokument3 SeitenPiping Olets: Branching Fittings Guiderenger20150303100% (1)

- Mechanical ComponentsDokument14 SeitenMechanical ComponentspushkarajNoch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Which Process?: A Guide to the Selection of Welding and Related ProcessesVon EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesNoch keine Bewertungen

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Reflow Soldering: Apparatus and Heat Transfer ProcessesVon EverandReflow Soldering: Apparatus and Heat Transfer ProcessesNoch keine Bewertungen

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionVon EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNoch keine Bewertungen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Daftar Pustaka FIXDokument2 SeitenDaftar Pustaka FIXAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- 680815Dokument223 Seiten680815Ahmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Yahya Sukma Nugraha - CV - Tanpa FotoDokument2 SeitenYahya Sukma Nugraha - CV - Tanpa FotoAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Iso 6892 PDFDokument4 SeitenIso 6892 PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Licensing Information Form For API Spec 5BDokument1 SeiteLicensing Information Form For API Spec 5BAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Program Fact Sheet Radiography PDFDokument2 SeitenProgram Fact Sheet Radiography PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- 4534-2006 Pre PDFDokument6 Seiten4534-2006 Pre PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Yahya Sukma Nugraha - CVDokument2 SeitenYahya Sukma Nugraha - CVAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Hot Rolled 300S0 Product Data Sheet PDFDokument2 SeitenHot Rolled 300S0 Product Data Sheet PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- M Ce 345 PDFDokument17 SeitenM Ce 345 PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- LME High Grade Zinc PDFDokument1 SeiteLME High Grade Zinc PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Ethanol Fuels: Energy Balance, Economics, and Environmental Impacts Are NegativeDokument8 SeitenEthanol Fuels: Energy Balance, Economics, and Environmental Impacts Are Negativesridhar.ashwathNoch keine Bewertungen

- 4799 PDFDokument4 Seiten4799 PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Program Fact Sheet Magnetic Particle Inspection PDFDokument2 SeitenProgram Fact Sheet Magnetic Particle Inspection PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- 4534-2006 Pre PDFDokument6 Seiten4534-2006 Pre PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- 32 Oct-Dec52 PDFDokument56 Seiten32 Oct-Dec52 PDFAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- American National Standard For Electrical Rigid Steel Conduit (ERSC)Dokument9 SeitenAmerican National Standard For Electrical Rigid Steel Conduit (ERSC)Ramesh V-sNoch keine Bewertungen

- Interfacing The Standard Parallel PortDokument17 SeitenInterfacing The Standard Parallel Portshawnleegabriel100% (4)

- Ethanol Fuels: Energy Balance, Economics, and Environmental Impacts Are NegativeDokument8 SeitenEthanol Fuels: Energy Balance, Economics, and Environmental Impacts Are Negativesridhar.ashwathNoch keine Bewertungen

- KalenderDokument2 SeitenKalenderAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Syllabus of Tribology Unit IDokument1 SeiteSyllabus of Tribology Unit IAhmad Jukliv Pandu YoedhawanNoch keine Bewertungen

- Smithy: Applications of ForgingDokument8 SeitenSmithy: Applications of Forginghuman kindNoch keine Bewertungen

- BS Flange Tables EDokument3 SeitenBS Flange Tables ERashedul HasanNoch keine Bewertungen

- HomgeDokument80 SeitenHomgeRobert HarveyNoch keine Bewertungen

- Of Kent USA Not ReproduceDokument53 SeitenOf Kent USA Not Reproducetapas ranjan jenaNoch keine Bewertungen

- List of Manufacturing Processes - Wikipedia, The Free EncyclopediaDokument9 SeitenList of Manufacturing Processes - Wikipedia, The Free EncyclopediaKhalid SheikhNoch keine Bewertungen

- Gating System: The Passage That Leads The Molten Metal Into The Mould CavityDokument15 SeitenGating System: The Passage That Leads The Molten Metal Into The Mould CavityjohnrabikNoch keine Bewertungen

- Vise 1 Goog2 PDFDokument5 SeitenVise 1 Goog2 PDFKristine KellerNoch keine Bewertungen

- Module 1 - EIM Prepare Electrical Power and HydraulicDokument58 SeitenModule 1 - EIM Prepare Electrical Power and HydraulicNoel Bua-ay100% (1)

- Apm Et13e Chapter 11 Fire ProtectionDokument65 SeitenApm Et13e Chapter 11 Fire ProtectiontuNoch keine Bewertungen

- P.E.S College of Engineering, Mandya: Report On Recent Technologies in Workholding Device"Dokument17 SeitenP.E.S College of Engineering, Mandya: Report On Recent Technologies in Workholding Device"kiran kumarNoch keine Bewertungen

- RollingDokument9 SeitenRollingFiq IskandarNoch keine Bewertungen

- ShopNotes No. 136 FullDokument52 SeitenShopNotes No. 136 FullKen Lock100% (3)

- Standard Weld JointDokument3 SeitenStandard Weld Jointtalparadipak100% (1)

- Cutting Tool MaterialsDokument44 SeitenCutting Tool MaterialsGokul AnugrahNoch keine Bewertungen

- MANUFACTURING TECHNOLOGY ASSIGNMENT (Bahirdar University)Dokument18 SeitenMANUFACTURING TECHNOLOGY ASSIGNMENT (Bahirdar University)TsihatesfaNoch keine Bewertungen

- (Corus) SHS Jointing - Flowdrill and Hollo-BoltDokument13 Seiten(Corus) SHS Jointing - Flowdrill and Hollo-Bolt_at_to_Noch keine Bewertungen

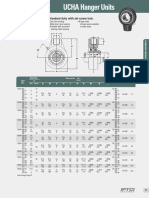

- UCHA Hanger Units: Standard Duty With Set Screw LockDokument1 SeiteUCHA Hanger Units: Standard Duty With Set Screw LockRicardo KharisNoch keine Bewertungen

- Length Calibration For Pin Gauge and Feeler Gauge. - SarmientoDokument38 SeitenLength Calibration For Pin Gauge and Feeler Gauge. - SarmientoEricson Ramos100% (1)

- Alloy Steel (8740) NAS Shear Type Lockbolts - ArconicDokument3 SeitenAlloy Steel (8740) NAS Shear Type Lockbolts - ArconicAnonymous mq0U43UsPNoch keine Bewertungen

- EDM (Electric Discharge Machine)Dokument29 SeitenEDM (Electric Discharge Machine)Tanvi KhuranaNoch keine Bewertungen

- MP 2nd Mid-Sem Question PaperDokument1 SeiteMP 2nd Mid-Sem Question PaperAnshul KhandelwalNoch keine Bewertungen

- Master Grinding WheelsDokument82 SeitenMaster Grinding WheelsHouariKouadriNoch keine Bewertungen

- METALWORKING PROCESSES GUIDEDokument15 SeitenMETALWORKING PROCESSES GUIDERonie DagaleaNoch keine Bewertungen

- Presentation 1Dokument28 SeitenPresentation 1ikamelyaastutiNoch keine Bewertungen

- f1554 Grade 55 Anchor BoltsDokument4 Seitenf1554 Grade 55 Anchor BoltsRico PadillaNoch keine Bewertungen

- Lista de AccesoriosDokument8 SeitenLista de AccesoriosRONALDNoch keine Bewertungen

- TTS-100 Tormek JIGSDokument4 SeitenTTS-100 Tormek JIGSRAFIDYNoch keine Bewertungen

- Asme Ix Changes 2017Dokument4 SeitenAsme Ix Changes 2017END - PTSC S.A.S.Noch keine Bewertungen

- 2tda180503 SH01 CDokument1 Seite2tda180503 SH01 CnightmanmxNoch keine Bewertungen

- Sheet Metal Gauge Size Chart-Stainless SteelDokument2 SeitenSheet Metal Gauge Size Chart-Stainless Steellorenzinho290Noch keine Bewertungen