Beruflich Dokumente

Kultur Dokumente

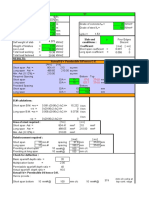

Beam - Cantilever - CB

Hochgeladen von

FrederickV.VelascoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Beam - Cantilever - CB

Hochgeladen von

FrederickV.VelascoCopyright:

Verfügbare Formate

Job Information

Engineer

Checked

Approved

Included in this printout are data for:

Design Group

Design Brief

Design Code

Members

Design Group Summary - G11

Member

Design

Span

Type

Shear

Span

Summary: the group is safe

Beam Spans

Member

Span

Length

Top

Btm

Side

(m)

(cm)

(cm)

(cm)

Type

Link Size

Beam Supports

Member

Length

Support

Col. Width

(m)

Type

(cm)

Node

Member 11 - Shear Results Summary

Distance

Vu

Vc

Av Required

(kN)

(kN)

(mm2)

Span

(m)

Summary: the member is safe

Span / Depth

Length

Member

Span

(m)

Summary: the group is safe

Member M11 Span 1

Basic

Modified

Span

Limit

Limit

Depth

Type

Detailed ACI Design Requirements

Section Property: 250 x 400

Span Length

Width

Covers:

= 1.650

= 250 mmDepth

Rectangular section

= 400 mm

Top = 40 mm Bottom = 40 mm Side = 40 mm

Member M11 Span 1

Detailed ACI Main Reinforcement

Hogging: at 0.200 m from the start of the member

Moment applied to section

= 131.42 kNm

Effective depth of tension reinforcement

= 316 mm

Depth to compression reinforcement

d'

= 59 mm

Limit for compression steel

Rn

= (Mu/bd2)

Rnt

= 4.78

= 5.86

Rn > Rnthence compression steel required.

As'

= (M'n/fy (d - d'))

Tension Bars provided

= 379.2 mm2

= 3#22 3#22

Actual area of tension reinforcement

= 2322 mm2

Minimum area of tension reinforcement

= 0.51 % 10.5

Actual % of tension reinforcement

= 2.94 %

Compression Bars provided

= 2#19

= 568 mm2

Actual area of compression reinforcement

Actual % of compression reinforcement

= 0.72 %

Minimum horizontal distance between top bars

= 33 mm 3.3.2(c)&7.6.1

Smallest actual horizontal space between top bars

= 42 mm

Minimum horizontal distance between bottom bars

= 33 mm 3.3.2(c)&7.6.1

Smallest actual horizontal space between bottom bars

= 113 mm

Maximum spacing of tension bars, s

= 380 (280/fs) - 2.5cc 300(280/fs)

= 458.18 mm

Largest actual space between tension bars

= 64 mm

Actual neutral axis depth in section

= 127.16 mm

Moment capacity of section

= 149.73 kNm

OK

Sagging: at 1.650 m from the start of the member

Moment applied to section

= 2.04 kNm

Effective depth of tension reinforcement

= 338 mm

Depth to compression reinforcement

d'

= 62 mm

Limit for compression steel

Rnt

= 4.78

Rn

= (Mu/bd2)

= 0.08

As

= (M/fy z)

= 24.5 mm2

Tension Bars provided

= 2#19

Actual area of tension reinforcement

= 0 mm2

Minimum area of tension reinforcement

= 0.51 % 10.5

Actual % of tension reinforcement

= 0.00 %

Actual neutral axis depth in section

= 0.00 mm

Moment capacity of section

= 0.00 kNm

NOT OK

Member M11 Span 1

Detailed ACI Span / Depth Check

10.6.4

Basic span / depth ratio

Strength modification factor

= 8.00

= 0.4 + fy / 700

Hence, modified span / depth ratio

Actual span / depth ratio

9.5.2.1

= 0.79

= 6.34

= 4.13

OK

Member M11 Span 1

Detailed ACI Shear Reinforcement

High shear zone: 0.200 m to 1.649 m

Actual spacing of ties, s

= 150 mm

Design axial force, Nu

= -2.80 kNm

Shear force, Vu

= 103.93 kN

Vc = 0.17 [1 + (0.29 Nu/Ag)] fc' bw d

= 61.01 kN

required (Av/s)

R11.5.7

= (Vu - Vc/fytd)

= (103932.02 - 0.85 61005.59/0.85 275 315.8)

Av, min

= 0.062 fc'(bws/fyt) = 38.7 mm2

(11-13)

(0.35 bws) / fyt

11.5.6.3

area of links provided (2#10), Av

Maximum spacing of ties

= 47.7 mm2

= 142.0 mm2

= 158 mm11.5.5.1&11.5.5.3

OK

11.2&11.3

= 705.5 mm2/m

Das könnte Ihnen auch gefallen

- Astm e 797 - 2015Dokument7 SeitenAstm e 797 - 2015Gerardo Mediavilla100% (3)

- (Bungee Jumper) : Activity No. 7Dokument3 Seiten(Bungee Jumper) : Activity No. 7Princess Lheakyrie CasilaoNoch keine Bewertungen

- Beam - Main Beam - GM7Dokument87 SeitenBeam - Main Beam - GM7FrederickV.VelascoNoch keine Bewertungen

- Branch Reinforcement Pad Requirement CalculationDokument1 SeiteBranch Reinforcement Pad Requirement Calculations.mladinNoch keine Bewertungen

- Design of Slabs: Total LoadDokument8 SeitenDesign of Slabs: Total LoadGurucharan PrajapatiNoch keine Bewertungen

- BEAM Idp ProjectDokument14 SeitenBEAM Idp ProjectSiti Nurulsyazni RusliNoch keine Bewertungen

- RCC One Way SlabDokument2 SeitenRCC One Way SlabAniket GunjalNoch keine Bewertungen

- Design of Singly Reinforced Beam SectionDokument6 SeitenDesign of Singly Reinforced Beam SectionREVATHY GOPALNoch keine Bewertungen

- Branch RF CalcDokument6 SeitenBranch RF CalcHarish Harish0% (1)

- Larsen & Toubro Limited: 1. Sectional PropertiesDokument8 SeitenLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNoch keine Bewertungen

- Short Span Coefficient: (Alpha - X: Depth Ok Move OnDokument4 SeitenShort Span Coefficient: (Alpha - X: Depth Ok Move OnAmok BajracharyaNoch keine Bewertungen

- Crack Width Check For Water Tank BaseDokument4 SeitenCrack Width Check For Water Tank BaseShamim Ahsan ZuberyNoch keine Bewertungen

- Beam, Slab, Column, Footing Steel CriteriaDokument19 SeitenBeam, Slab, Column, Footing Steel CriteriaNikhilNoch keine Bewertungen

- Larsen & Toubro Limited: 1. Sectional PropertiesDokument8 SeitenLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNoch keine Bewertungen

- Design of Two Way SlabDokument4 SeitenDesign of Two Way Slabpepe wosNoch keine Bewertungen

- All Slab - LSDokument15 SeitenAll Slab - LSTechnical OriliteNoch keine Bewertungen

- Singly Reinforced BeamDokument6 SeitenSingly Reinforced BeamRamyNoch keine Bewertungen

- Beam Design Detail Report: Material and Design DataDokument13 SeitenBeam Design Detail Report: Material and Design DataazwanNoch keine Bewertungen

- RC Beam Design ManualDokument4 SeitenRC Beam Design ManualYugatheeran Thavaratnasingam100% (1)

- Slab DesignDokument12 SeitenSlab Designkunjita dashoreNoch keine Bewertungen

- Continuous Beam Staad ReportDokument14 SeitenContinuous Beam Staad ReportMuhammad Shukri Bin SaharinNoch keine Bewertungen

- SFB 2Dokument1 SeiteSFB 2Gelbert SilotNoch keine Bewertungen

- F-Table Slab and Staircase (ALWAYS)Dokument15 SeitenF-Table Slab and Staircase (ALWAYS)Santosh BasnetNoch keine Bewertungen

- F3 (Fact.) F3 (Unfact.) Joint Label Unique Name Load Case/ComboDokument29 SeitenF3 (Fact.) F3 (Unfact.) Joint Label Unique Name Load Case/ComboKhim KhadkaNoch keine Bewertungen

- FFB4Dokument8 SeitenFFB4prajjwal patidarNoch keine Bewertungen

- Beam Design Detail Report: Material and Design DataDokument10 SeitenBeam Design Detail Report: Material and Design DataazwanNoch keine Bewertungen

- EA - Design of Simply Supported Composite I-Beam Sections AISC 360-05 (LRFD) v1.0Dokument2 SeitenEA - Design of Simply Supported Composite I-Beam Sections AISC 360-05 (LRFD) v1.0santhoshNoch keine Bewertungen

- Beam - Roof Beam - GM1Dokument20 SeitenBeam - Roof Beam - GM1FrederickV.VelascoNoch keine Bewertungen

- Larsen & Toubro Limited: 1. Sectional PropertiesDokument8 SeitenLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNoch keine Bewertungen

- Slab DesignDokument6 SeitenSlab DesignmadhuNoch keine Bewertungen

- FFB6Dokument8 SeitenFFB6prajjwal patidarNoch keine Bewertungen

- BM 06 Detail DesignDokument27 SeitenBM 06 Detail Designisaacjoe77Noch keine Bewertungen

- Larsen & Toubro Limited: 1. Sectional PropertiesDokument8 SeitenLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNoch keine Bewertungen

- Design of Two Way SlabDokument8 SeitenDesign of Two Way SlabdhanarajNoch keine Bewertungen

- Design of SlabDokument26 SeitenDesign of SlabMukesh Jangid100% (2)

- Design of Underground TankDokument20 SeitenDesign of Underground TankhiteshNoch keine Bewertungen

- Foundation DesignDokument88 SeitenFoundation DesignvipinNoch keine Bewertungen

- Design of Tension MembersDokument16 SeitenDesign of Tension MembersElisha ShindeNoch keine Bewertungen

- Design of Sign Board Gantry 20.2 M SpanDokument10 SeitenDesign of Sign Board Gantry 20.2 M SpanVrusha BendarNoch keine Bewertungen

- FFB1Dokument8 SeitenFFB1prajjwal patidarNoch keine Bewertungen

- BS8110 RC Beam DesignDokument2 SeitenBS8110 RC Beam DesignDicky DjayadiNoch keine Bewertungen

- Beam Design Including Torsion: SectionDokument19 SeitenBeam Design Including Torsion: SectionARSENoch keine Bewertungen

- Vertical Bracing With End Plate ConnectionDokument85 SeitenVertical Bracing With End Plate ConnectionFajar Alam HudiNoch keine Bewertungen

- HBDokument81 SeitenHBFajar Alam HudiNoch keine Bewertungen

- End Panel S3 Development of Maa Samleswari at Sambalpur: One-WayDokument1 SeiteEnd Panel S3 Development of Maa Samleswari at Sambalpur: One-Wayselvakumar sNoch keine Bewertungen

- BS EN 1993-1-1: 2005 - MMK 1/23/2020 Beam Connection DR MayDokument105 SeitenBS EN 1993-1-1: 2005 - MMK 1/23/2020 Beam Connection DR MayMohMohkNoch keine Bewertungen

- Beam & Column Design For ShearDokument7 SeitenBeam & Column Design For ShearEngineeri TadiyosNoch keine Bewertungen

- FFB3Dokument8 SeitenFFB3prajjwal patidarNoch keine Bewertungen

- Beam Design Detail Report: Material and Design DataDokument10 SeitenBeam Design Detail Report: Material and Design DataazwanNoch keine Bewertungen

- Castilated Beam DesignDokument10 SeitenCastilated Beam DesignAlphyl BalasabasNoch keine Bewertungen

- CK Tourqe CalculationDokument7 SeitenCK Tourqe Calculationamit amity100% (1)

- Reinf - conc.Beams-Design Torsional&Axially LoadedDokument1 SeiteReinf - conc.Beams-Design Torsional&Axially LoadedHermogenesGerardoIII OcanaNoch keine Bewertungen

- 171CE113-bolted ConnectionDokument9 Seiten171CE113-bolted ConnectionARJUN RNoch keine Bewertungen

- Design of Staircase: 3179 MM 3179 MM 10370 MM 3800 MM 150 MM 280 MM 500 Mpa 20 Mpa 1.5 KN/M 3.0 KN/M 0 MM 1100 MMDokument7 SeitenDesign of Staircase: 3179 MM 3179 MM 10370 MM 3800 MM 150 MM 280 MM 500 Mpa 20 Mpa 1.5 KN/M 3.0 KN/M 0 MM 1100 MMSudip ShresthaNoch keine Bewertungen

- Slab Full Report (Span) - GBDokument182 SeitenSlab Full Report (Span) - GBbce20090001Noch keine Bewertungen

- RCC11 Element DesignDokument6 SeitenRCC11 Element Designali billNoch keine Bewertungen

- RCC11 Element DesignDokument6 SeitenRCC11 Element DesignDhansiha VijiNoch keine Bewertungen

- Beam DesignDokument27 SeitenBeam Design蓉蓉Noch keine Bewertungen

- FFB5Dokument8 SeitenFFB5prajjwal patidarNoch keine Bewertungen

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- BEE Lecture1Dokument59 SeitenBEE Lecture1Jeff HardyNoch keine Bewertungen

- Assignment 6Dokument2 SeitenAssignment 6Abhilash TilakNoch keine Bewertungen

- Topic-1-Bending, Shearing and DeflectionDokument17 SeitenTopic-1-Bending, Shearing and DeflectionAngelo VilleroNoch keine Bewertungen

- Dr. Evert Hoek: Developments in Rock Engineering From 1958 To 2020Dokument4 SeitenDr. Evert Hoek: Developments in Rock Engineering From 1958 To 2020Hamzah Al-HashemiNoch keine Bewertungen

- Electronics Quarter 1 Module 6Dokument5 SeitenElectronics Quarter 1 Module 6malicdemrayzanicoleNoch keine Bewertungen

- 02 - The Influence of Multiple Fillers On Friction and Wear Behavior of Epoxy Composite CoatingDokument7 Seiten02 - The Influence of Multiple Fillers On Friction and Wear Behavior of Epoxy Composite CoatingSURESHNoch keine Bewertungen

- Lipson CrystalsX Rays TextDokument110 SeitenLipson CrystalsX Rays TextCarolina AlpucheNoch keine Bewertungen

- ELLIPSEDokument29 SeitenELLIPSEgachaacc335Noch keine Bewertungen

- Mixed Methods and Processes in Applied Linguistics ResearchDokument343 SeitenMixed Methods and Processes in Applied Linguistics ResearchSCARLET PAULETTE ABARCA GARZONNoch keine Bewertungen

- Simple Harmonic MotionDokument7 SeitenSimple Harmonic MotionRaju SinghNoch keine Bewertungen

- DoDokument8 SeitenDoJaderson RobertoNoch keine Bewertungen

- Math Motivational Quotes For YouDokument1 SeiteMath Motivational Quotes For YouMauro UbungenNoch keine Bewertungen

- QuestionsDokument6 SeitenQuestionsjethro ganeloNoch keine Bewertungen

- Individual Geogrid Junction Strength: Standard Test Method ForDokument8 SeitenIndividual Geogrid Junction Strength: Standard Test Method Forivan_cm17Noch keine Bewertungen

- Force and FrictionDokument11 SeitenForce and FrictionMeena Amina ReyhoundNoch keine Bewertungen

- Apr May 2021 Final IalDokument18 SeitenApr May 2021 Final Ialnew yearNoch keine Bewertungen

- Biaxial Interference Figures F12Dokument20 SeitenBiaxial Interference Figures F12dcegarciamapuaNoch keine Bewertungen

- 2021 Maths Form 4 Mid Term Exams Question PaperDokument15 Seiten2021 Maths Form 4 Mid Term Exams Question PaperKishan KumarNoch keine Bewertungen

- Development of Small Injection Moulding Machine For Forming Small Plastic Articles For Small-Scale IndustriesDokument14 SeitenDevelopment of Small Injection Moulding Machine For Forming Small Plastic Articles For Small-Scale IndustriesHenry PutraNoch keine Bewertungen

- Pte Apeuni 20230109 Weekly Kdij42 enDokument250 SeitenPte Apeuni 20230109 Weekly Kdij42 enAarogyam AyurvedNoch keine Bewertungen

- Chapter - 3 3. Superconductors: 3.1. Basic Theory of SuperconductivityDokument8 SeitenChapter - 3 3. Superconductors: 3.1. Basic Theory of SuperconductivitymigadNoch keine Bewertungen

- 5 Forces Model of Ipad - Infomanagement - LagdaDokument2 Seiten5 Forces Model of Ipad - Infomanagement - LagdaEfjay LagdaNoch keine Bewertungen

- Samle Log Sheet (98f0001)Dokument6 SeitenSamle Log Sheet (98f0001)Ajin SNoch keine Bewertungen

- Lateral Earth - Rankine Active and Passive Rev 1Dokument22 SeitenLateral Earth - Rankine Active and Passive Rev 1mnmusor100% (1)

- The First Law of Thermodynamics - 040170170000Dokument50 SeitenThe First Law of Thermodynamics - 040170170000xixoNoch keine Bewertungen

- Electric Charge and Static ElectricityDokument23 SeitenElectric Charge and Static ElectricityJoseph Ken AlcalaNoch keine Bewertungen

- Circle Geometry PDFDokument0 SeitenCircle Geometry PDFUpasna KhastgirNoch keine Bewertungen

- CE322 Assignment 3Dokument5 SeitenCE322 Assignment 3PARAN, DIOSCURANoch keine Bewertungen