Beruflich Dokumente

Kultur Dokumente

DTC P0335 CKP Sensor A Circuit Performance: 2000 Cadillac Deville

Hochgeladen von

alis13Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DTC P0335 CKP Sensor A Circuit Performance: 2000 Cadillac Deville

Hochgeladen von

alis13Copyright:

Verfügbare Formate

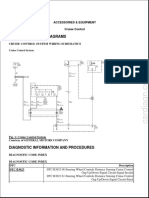

2000 Cadillac DeVille

DTC P0335 CKP Sensor A Circuit Performance

Circuit Description

The PCM uses dual crankshaft position (CKP A and CKP B) sensors to determine crankshaft position. The PCM

supplies an ignition voltage and a ground for each sensor. During engine rotation, a slotted ring, machined into the

crankshaft, causes the sensors to return a series of ON and OFF pulses to the PCM. The PCM uses these pulses to

decode the position of the engine crankshaft.

The PCM uses two basic methods of decoding the engine position: Angle Based and Time Based (using either CKP A

or CKP B sensor input). During normal operation, the PCM uses the angle based method. In order to operate in this

mode, the PCM must receive signal pulses from both CKP sensors. The PCM uses the signal pulses to determine an

initial crankshaft position, and to generate MEDRES (24X reference) and LORES (4X reference) signals. Once the

initial crank position is determined, the PCM continuously monitors both sensors for valid signal inputs. As long as

both signal inputs remain, the PCM will continue to use the angle based mode.

When either CKP signal is lost, the PCM will compare the MEDRES signal to the camshaft position (CMP) sensor

signal. If the PCM detects a valid CMP signal, and the MEDRES to CMP signal correlation is correct, the PCM

determines that CKP sensor A is at fault. However, if the MEDRES to CMP correlation is incorrect, the PCM

determines that CKP sensor B is at fault. If the PCM determines that CKP sensor A is at fault, DTC P0335 will set. The

PCM will switch from angle based mode to Time Based mode B using CKP sensor B signal input.

Conditions for Running the DTC

The engine is cranking or running.

Conditions for Setting the DTC

The PCM detects a loss of CKP sensor A signal.

Action Taken When the DTC Sets

The PCM illuminates the malfunction indicator lamp (MIL) during the second consecutive trip in which the

diagnostic test runs and fails.

The PCM stores the conditions present when the DTC set as Freeze Frame/Failure Records data.

Conditions for Clearing the MIL/DTC

z

z

z

The PCM will turn the MIL OFF after the third consecutive trip in which the diagnostic runs and passes.

The history DTC will clear after 40 consecutive warm-up cycles have occurred without a malfunction.

The DTC can be cleared by using the scan tool Clear DTC Information function.

Diagnostic Aids

Notice

Use the connector test adapter kit J 35616-A for any test that requires probing the following items:

z

z

z

z

The PCM harness connectors

The electrical center fuse/relay cavities

The component terminals

The component harness connector

Using this kit will prevent damage caused by the improper probing of connector terminals.

Ignition system DTCs set with the ignition in the START position if the starter relay or the starter is inoperative. When

the PCM enables starter operation, the PCM also initiates the diagnostic test routines for DTCs P0335, P0340, and

P0385. The PCM will not receive signal input from the CKP and CMP sensors if a condition exists which prevents the

engine from cranking. When this occurs, the DTCs will set.

If DTC P0615 is set, diagnose DTC P0615 first. If DTC P0335, P0340, and/or P0385 are set and no trouble is found,

check for the following conditions:

z

z

Is there a no-crank condition or an intermittent no-crank condition?

Was an attempt made to crank the engine with the shift lever not in P/N?

Procedures for Selecting Crank Position Sensing Decode Mode

When diagnosing the crankshaft position sensors, it may be necessary to enable a specific decode mode (Angle, Time

A, or Time B). To enable a specific crank decode, using the scan tool, perform the following steps:

z

z

z

z

z

Turn the ignition to the RUN/ON position.

Select Engine Output Controls.

Select Crank Position Sensing Decode Mode.

Select the desired mode (Angle, Time A, or Time B) by pressing SELECT STATE.

Command the decode mode by pressing COMMAND STATE.

The commanded state remains valid for the current ignition cycle. A specific decode mode can not be commanded with

the engine running, or after commanding a desired decode mode. To command a different decode mode, you must

cycle the ignition OFF and ON.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2. This step determines if the ignition feed circuit to the CKP A, CKP B, and the CMP is shorted to a ground. If all

three DTCs are set, this indicates the circuit is shorted to a ground or a sensor is internally shorted. All three

DTCs set because the ignition feed circuits are internally connected within the PCM. The engine will not start

with this condition.

3. DTC P0386 indicates an intermittent loss of CKP sensor B signal while in Time B mode. DTC P0386 only sets

after the PCM detects a loss of CKP sensor A signal and has switched to Time B mode.

During normal operation, the PCM uses the Angle Mode to determine engine position. In order to operate in this

mode, the PCM must receive valid input from both CKP sensors. If the PCM detects a loss of CKP sensor A

signal, the PCM switches to a Time B mode using CKP sensor B input to determine engine position. If the PCM

detects a loss of CKP sensor B, the PCM switches to a Time A mode using CKP sensor A input to determine

engine position.

4. During engine operation, if moving the harnesses and connectors related to CKP sensor A results in a switch to

Time B mode, may also cause an engine stall condition, an intermittent condition in the harnesses or connectors

is present. If the harnesses and connectors are OK, CKP sensor A may be the cause of the intermittent condition.

7. In order to test the CKP sensor A signal circuit, the PCM must be commanded to Time A mode using the scan

tool. This allows the PCM to monitor input signals from CKP sensor A. Refer to Diagnostic Aids for the

procedures to selecting the Crank Decode Mode.

11. This step determines if the CMP sensor is shorted internally. If the 12 Volt Reference parameter changes from

Fault to OK, the condition is with the sensor.

12. This step determines if the CKP A sensor is shorted internally. If the 12 Volt Reference parameter changes from

Fault to OK, the condition is with the sensor.

13. This step determines if the CKP B sensor is shorted internally. If the 12 Volt Reference parameter changes from

Fault to OK, the condition is with the sensor.

Step

1

Action

Did you perform the Powertrain On Board Diagnostic (OBD) System

Check?

1. Install a scan tool.

2. Attempt to start the engine.

3. With a scan tool, monitor the DTC information.

Values

--

Yes

Go to

Step 2

No

Go to Powertrain

On Board

Diagnostic (OBD)

System Check

Go to

Step 11

Go to Step 3

Go to

Step 4

Go to Step 5

--

Are DTCs P0335, P0340, and P0385 set?

Important

If DTC P0386 is also set, continue with the diagnostic table for

DTC P0335 before diagnosing DTC P0386.

3

1. Start the engine.

2. With a scan tool, monitor the CKP sensor status parameter in the

Misfire list.

Does the scan tool indicate the CKP sensor status as ANGLE?

1. With the engine running, move the harnesses and connectors

related to CKP sensor A (by hand only).

2. If the CKP sensor status changes or an engine stall occurs, locate

and repair the condition in the harnesses/connectors related to CKP

sensor A. Refer to Testing for Intermittent and Poor Connections

and Connector Repairs in Wiring Systems.

--

--

Did you find and correct the condition?

1. Turn ON the ignition, with the engine OFF.

2. Disconnect the CKP sensor A. Refer to Crankshaft Position (CKP)

Sensor Replacement .

3. Probe the ignition feed circuit of the CKP A sensor with a test

lamp that is connected to a good ground.

Does the test lamp illuminate?

Connect the test lamp between the supply voltage circuit of the CKP A

sensor and the ground circuit of the CKP A sensor.

Does the test lamp illuminate?

1. With a scan tool, clear the DTCs.

2. With the test lamp connected to battery positive voltage, repeatedly

touch the CKP A sensor signal circuit in the harness connector.

3. With a scan tool, observe the 24X crank sensor data parameter.

Does the scan tool indicate an RPM while touching the test lamp to the

signal circuit?

1. Turn OFF the ignition.

2. Disconnect the PCM harness connector C2. Refer to PCM

Replacement/Programming .

3. Test the ignition feed circuit of the CKP A sensor for an open.

Refer to Circuit Testing and Wiring Repairs in Wiring Systems.

Did you find and correct the condition?

1. Turn OFF the ignition.

2. Disconnect the PCM harness connector C2. Refer to PCM

Replacement/Programming .

3. Test the ground circuit of the CKP A sensor for an open. Refer to

Circuit Testing and Wiring Repairs in Wiring Systems.

Did you find and correct the condition?

1. Turn OFF the ignition.

2. Disconnect the PCM harness connector C2. Refer to PCM

Replacement/Programming .

3. Turn ON the ignition, with the engine OFF.

4. Test the CKP A signal circuit for an open, a short to ground, or a

10

short to voltage. Refer to Circuit Testing and Wiring Repairs in

Wiring Systems.

Did you find and correct the condition?

1. Disconnect the CMP sensor harness connector. Refer to Camshaft

Position (CMP) Sensor Replacement .

2.

With a scan tool, monitor the 12 Volt Reference parameter.

11

Does the scan tool display OK?

1. Raise the vehicle. Refer to Lifting and Jacking the Vehicle .

2. Disconnect CKP sensor A harness connector. Refer to Crankshaft

Position (CKP) Sensor Replacement .

12

3. With a scan tool, monitor the 12 Volt Reference parameter.

Go to

Step 21

Go to Diagnostic

Aids

Go to

Step 6

Go to Step 8

Go to

Step 7

Go to Step 9

Go to

Step 15

Go to Step 10

Go to

Step 21

Go to Step 16

Go to

Step 21

Go to Step 16

Go to

Step 21

Go to Step 16

Go to

Step 17

Go to Step 12

--

--

--

--

--

--

--

-Go to

Does the scan tool display OK?

1. Disconnect the CKP B sensor harness connector. Refer to

Crankshaft Position (CKP) Sensor Replacement .

2. With a scan tool, monitor the 12 Volt Reference parameter.

13

Does the scan tool display OK?

1. Turn OFF the ignition.

2. Disconnect the PCM harness connectors. Refer to PCM

Replacement/Programming .

3. Test the ignition feed circuit of the CKP A, CKP B, and the CMP

14

sensor for a grounded circuit. Refer to Circuit Testing and Wiring

Repairs in Wiring Systems.

Did you find and correct the condition?

Inspect for poor connections at the harness connector of the CKP A

sensor. Refer to Testing for Intermittent and Poor Connections and

15 Connector Repairs in Wiring Systems.

Did you find and correct the condition?

Inspect for poor connections at the harness connector of the PCM. Refer

to Testing for Intermittent and Poor Connections and Connector Repairs

16 in Wiring Systems.

17

18

19

Did you find and correct the condition?

Replace the CMP sensor. Refer to Camshaft Position (CMP) Sensor

Replacement .

Is the replacement complete?

Replace the CKP sensor A. Refer to Crankshaft Position (CKP) Sensor

Replacement .

Is the replacement complete?

Replace the CKP sensor B. Refer to Crankshaft Position (CKP) Sensor

Replacement .

Step 18

Go to Step 13

Go to

Step 19

Go to Step 14

Go to

Step 21

Go to Step 20

Go to

Step 21

Go to Step 18

Go to

Step 21

Go to Step 20

Go to

Step 21

--

Go to

Step 21

--

Go to

Step 21

--

Go to

Step 21

--

System

OK

Go to Step 2

--

--

--

--

--

--

--

Is the replacement complete?

Important

The replacement PCM must be programmed.

20

-Replace the PCM. Refer to PCM Replacement/Programming .

Is the replacement complete?

1. Observe and record the scan tool Freeze Frame and/or Fail Records

information.

2. With a scan tool, clear the DTCs.

3. Operate the vehicle within the parameters listed in the Conditions

21

for Running the DTC.

4. With a scan tool, monitor the DTC Information.

Does the scan tool display the DTC ran and passed?

--

Das könnte Ihnen auch gefallen

- DTC p1374Dokument3 SeitenDTC p1374David RosadoNoch keine Bewertungen

- DTC DescriptorDokument3 SeitenDTC DescriptorEngine Tuning UPNoch keine Bewertungen

- DTC C0131 00: ABS Pressure Circuit: Diagnostic Trouble Code (DTC) List - VehicleDokument8 SeitenDTC C0131 00: ABS Pressure Circuit: Diagnostic Trouble Code (DTC) List - Vehiclecccp izcalli-poniente 2017Noch keine Bewertungen

- 2008 Chevrolet HHR DTCDokument6 Seiten2008 Chevrolet HHR DTCTal Benyamin100% (1)

- Accent P0016 Crankshaft Position-Camshaft Position CorrelationDokument8 SeitenAccent P0016 Crankshaft Position-Camshaft Position Correlationflash_24014910Noch keine Bewertungen

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0010Dokument3 SeitenA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0010PeterNoch keine Bewertungen

- No Crank Reference Signal at PCMDokument7 SeitenNo Crank Reference Signal at PCMAO5616Noch keine Bewertungen

- P 0340Dokument3 SeitenP 0340Carlos Medina CastilloNoch keine Bewertungen

- C6 DTC P0806Dokument3 SeitenC6 DTC P0806احمدميدوNoch keine Bewertungen

- P 1464Dokument8 SeitenP 1464Yargen GonzalezNoch keine Bewertungen

- Throttle Position Sensor Circuit TestDokument8 SeitenThrottle Position Sensor Circuit TestDaniel AmanorNoch keine Bewertungen

- 2006 File 15Dokument63 Seiten2006 File 15eurospeed2Noch keine Bewertungen

- 2003 Nissan Altima 2.5 Serivce Manual BcsDokument22 Seiten2003 Nissan Altima 2.5 Serivce Manual BcsAndy Dellinger100% (1)

- Welcome To Today's Presentation Sponsored byDokument47 SeitenWelcome To Today's Presentation Sponsored byfadrique54Noch keine Bewertungen

- Cmpaveo0342 PDFDokument5 SeitenCmpaveo0342 PDFmariodavid1988Noch keine Bewertungen

- Ls1 ManualDokument113 SeitenLs1 ManualMTNoch keine Bewertungen

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0340Dokument3 SeitenA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0340Julio SanchezNoch keine Bewertungen

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0230Dokument2 SeitenA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0230Jose GarciaNoch keine Bewertungen

- Speed Control (Switch) - Test (RENR5096)Dokument4 SeitenSpeed Control (Switch) - Test (RENR5096)Josip MiškovićNoch keine Bewertungen

- Marine Power Usa 5.0L 5.7L MEFI 4 Service ManualDokument206 SeitenMarine Power Usa 5.0L 5.7L MEFI 4 Service ManualJBartley32100% (1)

- P1631 PDFDokument5 SeitenP1631 PDFReinaldo ArrivillagaNoch keine Bewertungen

- P1637Dokument3 SeitenP1637ALEMAN GARAGE AUTOMOTRIZNoch keine Bewertungen

- Rento PDFDokument4 SeitenRento PDFAnonymous Lu6vjikNoch keine Bewertungen

- Speed Control - TestDokument5 SeitenSpeed Control - TestPablo Cesar Poma ArrateaNoch keine Bewertungen

- GM 3.8L Icm Testing PDFDokument4 SeitenGM 3.8L Icm Testing PDFJoeNoch keine Bewertungen

- Speed Timing Sensor PDFDokument5 SeitenSpeed Timing Sensor PDFKashifNoch keine Bewertungen

- HosamDokument3 SeitenHosamahmadshikemohmadNoch keine Bewertungen

- P1660Dokument5 SeitenP1660Frank DiblasiNoch keine Bewertungen

- DTC p1351 Ignition Coil Control Circuit High VoltajeDokument5 SeitenDTC p1351 Ignition Coil Control Circuit High VoltajeBenito LopezNoch keine Bewertungen

- DTC P1705 Throttle Position SensorDokument2 SeitenDTC P1705 Throttle Position SensorEagle TransmissionNoch keine Bewertungen

- P0340Dokument5 SeitenP0340Freddie Kemp100% (1)

- Description & Operation: WarningDokument6 SeitenDescription & Operation: WarningTheJomVz PrNoch keine Bewertungen

- P0562-Battery Voltage LowDokument7 SeitenP0562-Battery Voltage Lowguillermoal539100% (1)

- Dobdsm971 PDFDokument25 SeitenDobdsm971 PDFTecknobites VallenarNoch keine Bewertungen

- Bajo Voltaje en SolenoidesDokument7 SeitenBajo Voltaje en SolenoidesMAXIMILIANO CASTILLO ANTONIONoch keine Bewertungen

- 07 GRP01 All EnginesDokument27 Seiten07 GRP01 All Engineseurospeed2Noch keine Bewertungen

- 6F35N IntroDokument47 Seiten6F35N Introacmemail583Noch keine Bewertungen

- DTC 27 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairDokument6 SeitenDTC 27 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA Repairmuhammad AkramNoch keine Bewertungen

- RAPTORDokument16 SeitenRAPTORp.motortechNoch keine Bewertungen

- CMP (Phase) MuranoDokument8 SeitenCMP (Phase) MuranoGuillermo RojasNoch keine Bewertungen

- Guide For Using The IDS Oscilloscope: For 6.0L, 4.5L, and 6.4L EnginesDokument86 SeitenGuide For Using The IDS Oscilloscope: For 6.0L, 4.5L, and 6.4L EnginesJesus Almanzar SantosNoch keine Bewertungen

- Speed ControlDokument7 SeitenSpeed Controlayman akrabNoch keine Bewertungen

- Standard CANopen V101 01 SpecificationDokument29 SeitenStandard CANopen V101 01 SpecificationJuanma Galindo de PablosNoch keine Bewertungen

- OEM Ford 7.3 Litre Diesel OBD II DiagnosticsDokument26 SeitenOEM Ford 7.3 Litre Diesel OBD II DiagnosticsTigxMig75% (8)

- DTC P0008 or P0009: Diagnostic InstructionsDokument2 SeitenDTC P0008 or P0009: Diagnostic InstructionsJose Luis Velasquez RomeroNoch keine Bewertungen

- 08 GRP01 All EnginesDokument24 Seiten08 GRP01 All Enginescianurel2184Noch keine Bewertungen

- Re95300 2007-12 PDFDokument16 SeitenRe95300 2007-12 PDFrenatNoch keine Bewertungen

- DTC Fallas Caja Automatica OptraDokument64 SeitenDTC Fallas Caja Automatica OptraFernando Jordan BarretoNoch keine Bewertungen

- P 2229Dokument3 SeitenP 2229Doug SmileyNoch keine Bewertungen

- Acce Lera To PedalDokument5 SeitenAcce Lera To PedalEKONoch keine Bewertungen

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135Dokument4 SeitenA L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135PeterNoch keine Bewertungen

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0011Dokument3 SeitenA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0011PeterNoch keine Bewertungen

- Schematic Wiring Diagrams: Accessories & Equipment Cruise ControlDokument51 SeitenSchematic Wiring Diagrams: Accessories & Equipment Cruise ControlMuhammed Douma100% (1)

- P020C-Fuel Injector 3 Performance: Theory of OperationDokument2 SeitenP020C-Fuel Injector 3 Performance: Theory of OperationWillie AustineNoch keine Bewertungen

- Work ProcedureDokument6 SeitenWork ProcedureMani KandanNoch keine Bewertungen

- Cart A Delco Dig Op 0740Dokument2 SeitenCart A Delco Dig Op 0740josepadilla1987Noch keine Bewertungen

- 5R55S Pinpoint TestsDokument21 Seiten5R55S Pinpoint TestsJason Wolfe100% (3)

- GR00004300B 13aDokument274 SeitenGR00004300B 13aEduardo Enrique Rojas Valenzuela100% (1)

- Installation Instructions For 3-3/8" Programmable Speedometer Before You StartDokument2 SeitenInstallation Instructions For 3-3/8" Programmable Speedometer Before You Startjulio797Noch keine Bewertungen

- 15me71 Dec18-Jan19Dokument2 Seiten15me71 Dec18-Jan19Raju GNoch keine Bewertungen

- A Review On Battery Thermal Management System of Electric VehicleDokument5 SeitenA Review On Battery Thermal Management System of Electric VehiclePrafull ShindeNoch keine Bewertungen

- Fiitjee: Answers, Hints & SolutionsDokument10 SeitenFiitjee: Answers, Hints & SolutionsZayanmalikNoch keine Bewertungen

- PHYSICS (CE & ME) (PH-21102) Introduction To Mechanics: Module 1: (8 Lectures)Dokument1 SeitePHYSICS (CE & ME) (PH-21102) Introduction To Mechanics: Module 1: (8 Lectures)Supratim RoyNoch keine Bewertungen

- Performance Task in General Physics 1Dokument3 SeitenPerformance Task in General Physics 1Erica JoyNoch keine Bewertungen

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Dokument255 SeitenD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Agitator Power Requirementand Mixing Intensity CalculationDokument26 SeitenAgitator Power Requirementand Mixing Intensity Calculationkkaranag100% (1)

- A Simple Approach To Truss Deflections: N-Braced TypeDokument6 SeitenA Simple Approach To Truss Deflections: N-Braced Typealbertoxina100% (1)

- Nissan RB Engine - WikipediaDokument60 SeitenNissan RB Engine - WikipediaZedrick Nell100% (2)

- Ajax PresentationDokument34 SeitenAjax PresentationJesus lopezNoch keine Bewertungen

- flowIT FTBGDW-16Dokument1 SeiteflowIT FTBGDW-16technicalsupportNoch keine Bewertungen

- MM PT6T-3B 72-3Dokument24 SeitenMM PT6T-3B 72-3Panca Xp100% (1)

- BRS Manual Rev 4-10Dokument38 SeitenBRS Manual Rev 4-10RondrashNoch keine Bewertungen

- STC-1000 Temperature Controller Operating Manual: or or orDokument1 SeiteSTC-1000 Temperature Controller Operating Manual: or or orziandNoch keine Bewertungen

- FSAE SuspensionDokument37 SeitenFSAE SuspensionDonald MuchemwaNoch keine Bewertungen

- 800 ZCC9800W Catalogue Cummins BenzDokument22 Seiten800 ZCC9800W Catalogue Cummins BenzPhúc Linh NguyễnNoch keine Bewertungen

- CH 5 Kerja Dan EnergiDokument21 SeitenCH 5 Kerja Dan EnergiDey TandirerungNoch keine Bewertungen

- CH2 - Heating System PDFDokument10 SeitenCH2 - Heating System PDFAaron AngNoch keine Bewertungen

- BPW Service Instructions - KLD 08 2010 ECOPLUS IIDokument95 SeitenBPW Service Instructions - KLD 08 2010 ECOPLUS IIpricopdaniel100% (1)

- Martillo Hyd Atlas Copco SB 150Dokument12 SeitenMartillo Hyd Atlas Copco SB 150Nain murilloNoch keine Bewertungen

- 05-Vl996 Vista Series-A4 2010 Intl Application GuideDokument4 Seiten05-Vl996 Vista Series-A4 2010 Intl Application GuideJuan SuarezNoch keine Bewertungen

- NATCO TurbulatorDokument2 SeitenNATCO TurbulatorshansalNoch keine Bewertungen

- Himalaya GasesDokument4 SeitenHimalaya Gasesmitr_mmNoch keine Bewertungen

- Proforma Invoice: Bill ToDokument2 SeitenProforma Invoice: Bill ToExpert Trading & Ttechnical ServicesNoch keine Bewertungen

- Fan ChecklistDokument4 SeitenFan ChecklistfatREVITNoch keine Bewertungen

- Module 3 PDFDokument18 SeitenModule 3 PDFVladimirNoch keine Bewertungen

- Odorizatin UnitDokument4 SeitenOdorizatin UnitSachin VermaNoch keine Bewertungen

- Anchor BoltsDokument1 SeiteAnchor BoltsBert EngNoch keine Bewertungen

- Belt Drive Numerical 1Dokument6 SeitenBelt Drive Numerical 1Prateek ridersNoch keine Bewertungen

- Ecg303-M3-01 Soil Permeability and Seepage PDFDokument20 SeitenEcg303-M3-01 Soil Permeability and Seepage PDFDk AshokNoch keine Bewertungen