Beruflich Dokumente

Kultur Dokumente

Notes On Pre-Stressed Concrete.

Hochgeladen von

Chetan ToliaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Notes On Pre-Stressed Concrete.

Hochgeladen von

Chetan ToliaCopyright:

Verfügbare Formate

PRE-STRESSED CONCRETE STRUCTURES

1. BASIC CONCEPTS

What is pre-stressing?

Pre-stressing can be defined in general terms as the preloading of a structure,

before application of service loads, so as to improve its performance in specific

ways.

Examples of pre-stressed objects are:

Cart wheel and barrels where wooden parts are held in compression by

steel band around them which is in tension.

The bicycle wheel where steel rim is held in compression by spokes in

tension.

The umbrella where membrane is held in tension by ribs in compression.

2. WHY PRESTRESS CONCRETE?

Concrete is a building material that is strong in compression but relatively weak in

tension. In principle, there are two ways of overcoming this deficiency:

Embed within the concrete, reinforcement that is strong in tension

reinforced concrete;

Avoid the tension altogether by arching the structure or pre-stressing the

concrete.

In reinforced concrete construction, steel reinforcing bars are provided in the

regions where tension occurs, compensating for the low tensile strength of the

concrete as shown above.

In Pre-stressed concrete construction, steel tendons are stretched and

anchored at each end so that the compressive forces are applied to the concrete

as shown in the figure above. The forces are transmitted from the tendons to the

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

concrete either by bond created between the concrete and the tendons or by

embedded anchorages, depending up on method of pre-stressing.

3. MECHANICS OF FORCE SYSTEM

PLAIN CONCRETE BEAM

Plain concrete is a brittle material. That is to say having little load carrying

capacity before lower most fibre reaches tensile capacity of the material. But if this

material is reinforced it may take more load. Three different concepts may be applied

to analyse behaviour of pre-stressed concrete.

First, pre-stressing to transform concrete into an elastic material. Concrete,

which is weak in tension and strong in compression, is compressed (generally by

steel under high tension) so that the brittle concrete would be able to withstand

tensile stresses. It is generally believed that if there are no tensile stresses in the

concrete, there can be no cracks, and the concrete is no longer a brittle material but

becomes an elastic material. The tensile pre-stress force F in the tendon produces

an equal compressive force F in the concrete, which also acts at the centroid of the

tendon. Due to the pre-stress F, a uniform compressive stress of f will be produced

across the section that has an area A.

If M is the external moment at a section due to the load on and the weight of the

beam, then the stress at any point across that section due to M is

Where y is the distance from the centroidal axis and I the moment of inertia of the

section. Thus the resulting stress distribution is given by

This is shown below.

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

Second concept is Pre-stressing for combination of High Strength steel with

concrete. This is similar to reinforced concrete concept.

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

In pre-stressed concrete, high tensile steel is used which will have to be elongated a

great deal before its strength is fully utilized. If the high-tensile steel is simply buried

in the concrete, as in ordinary concrete reinforcement, the surrounding concrete will

have to crack very seriously before the full strength of the steel is developed. Hence

it is necessary to prestretch the steel with respect to the concrete. By prestretching

and anchoring the steel against the concrete, one can produce desirable stresses

and strains in both the materials. This combined action permits the safe and

economical utilization of the two materials which cannot be achieved by simply

burying steel in the concrete.

Third concept is using Prestressing to achieve Load Balancing. This concept is

to visualize prestressing primarily as an attempt to balance the loads on a member.

In the overall design of a prestressed concrete structure, the effect of prestressing is

viewed as the balancing of gravity loads so that members under bending such as

slabs, beams and girders will not be subjected to flexural stresses under a given

loading condition. This enables the transformation of a flexural member into a

member under direct stress and thus greatly simplifies both the design and analysis.

The application of this concept requires taking the concrete as a free body and

replacing the tendons with forces acting on the concrete along the span.

If F= prestressing force

L = length of span

h = sag of parabola

The upward uniform load is given by

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

4. DEFINITIONS

The terms used in pre-stressed concrete are explained below:

Forms of Pre-stressing steel:

a) Wires: Pre-stressing wire is a single unit made of steel.

b) Strands: Two, three or seven wires are wound to form a pre-stressing strand.

c) Tendon: A group of strands or wires wound to form a pre-stressing tendon.

d) Cable: A group of tendons form a pre-stressing cable.

e) Bars: A tendon can be made of a single steel bar which is a large diameter

wire.

5. CLASSIFICATION AND TYPES OF PRESTRESSING

a) Externally or Internally Prestressed.

Most of structures designed and constructed as Prestressed are internally

prestressed; however, in externally prestressed structures jacks are used to

provide necessary force externally on the structure to be prestressed.

b) Linear or Circular Prestressing.

Circular prestressing is a term applied to prestressed circular structure such

as round tanks, silos and pipes where the prestressing tendons are wound

around in circles. All other structures are linear prestressed structures.

c) Pre-tensioning or Post Tensioning.

In this type of prestressing, the tendons are tensioned and anchored between

fixed supports before the concrete is places around the tendons. The

concrete is either case in moulds or formed by an extrusion or slip-form

process to provide the required cross section. When the concrete has

achieved sufficient strength, the tendons are slowly released from the support

at one end. The prestressing force is transferred from tendons to the concrete

by the bond existing between the hardened concrete and the tendons.

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

Pre-tensioning may be used on site where large numbers of similar precast

units are required, but is usually carried out in a factory where permanent

stressing beds have been installed.

Post-tensioning is a method where prestressing the tendon is done after the

concrete has hardened.

d) Bonded or Unbonded Tendons.

When there is adequate bond between the pre-stressing tendon and

concrete, it is called a bonded tendon. Pre-tensioned and grouted posttensioned tendons are examples of bonded tendons.

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

When there is no bond between the pre-stressing tendon and concrete, it is

called unbonded tendon. When grout is not applied after post-tensioning, the

tendon is an unbonded tendon.

e) Pre-cast, Cast-in- situ or composite construction.

Precasting involves the placing of concrete away from its final position. The

members being cast either in a permanent plant or somewhere near the site

of the structure and eventually erected at the final location.

Cast in- situ or cast in place concrete requires more formwork and false

work per unit of product but saves the cost of transportation and erection and

it is necessary for large and heavy members.

Sometimes it is economical to precast part of a structure, erect it and then

cast the remaining portion in place. This is composite construction.

f) Partial or Full Prestressing.

When a member is designed so that under the service load there are no

tensile stresses in it, then the concrete is said to be fully prestressed. If some

tensile stresses will be produced in the member under service load, then it is

termed as partially prestressed. For partial prestressing, additional mild steel

bars are frequently provided to reinforce the portion under tension.

6. STAGES OF LOADING

One of the considerations peculiar to prestressed concrete is the multiple stages

of loading to which a member or structure is often subjected.

a) Initial Stage:

The member or structure is under prestress but is not subjected to any

superimposed external load.

Before prestressing: Before the concrete is prestressed, it is quite weak in

carrying load; hence, the yielding of its supports must be prevented. Provision

must be made for the shrinkage of concrete if it might occur.

During prestressing: This is a critical stage for the strength of tendons. The

maximum stress to which the tendons will be subjected throughout their life

occurs at this period. For concrete, the prestressing operations impose a

severe test on the bearing strength at the anchorages. Since the concrete is

not aged at this period while the prestress is at its maximum, crushing of the

concrete at anchorages is possible.

b) Intermediate Stage:

This is the stage during transportation and erection. It is occurs only for

precast members when they are transported to the site and erected in

position.

c) Final Stage.

This is the stage when the actual working loads come on the structure.

7. ADVANTAGES OF PRESTRESSING

1) Section remains uncracked under service loads

Reduction of steel corrosion

o Increase in durability.

Full section is utilised

o Higher moment of inertia (higher stiffness)

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

o Less deformations (improved serviceability).

Increase in shear capacity.

Suitable for use in pressure vessels, liquid retaining structures.

Improved performance (resilience) under dynamic and fatigue

loading.

2) High span-to-depth ratios

Larger spans possible with prestressing (bridges, buildings with large columnfree spaces)

Typical values of span-to-depth ratios in slabs are given below.

Non-prestressed slab 28:1

Prestressed slab 45:1

For the same span, less depth compared to RC member.

Reduction in self-weight

More aesthetic appeal due to slender sections

More economical sections.

3) Suitable for Precast construction

The advantages of precast construction are as follow:

Rapid construction

Better quality control

Reduced maintenance

Suitable for repetitive construction

Multiple use of formwork

Availability of standard shapes.

8. LIMITATION OF PRESTRESSING

Although prestressing has advantages, some aspects need to be carefully

addressed:

Prestressing needs skilled technology. Hence, if it is not as common as

R.C.C.

The use of high strength materials is costly.

There is additional cost in auxiliary equipments.

There is need for quality control and inspection.

9. MATERIALS

a) CONCRETE

The concrete grade required for prestressing is of high strength and

production of concrete is govern by IS 456 and IS 1343. Minimum grades of

concrete are specified as M-30 for post-tensioned members and M-40 for pretensioned members with characteristic of developing strength early.

b) STEEL

The development of prestressed concrete was influenced by the invention of

high strength steel. It is an alloy of iron, carbon, manganese and optional

materials.

In addition to prestressing steel, conventional non-prestressed reinforcement

is used for flexural capacity (optional), shear capacity, temperature and

shrinkage requirements.

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

10.

LOSSES IN PRESTRESS

When stress is applied to concrete, it undergoes dimensional

changes: an immediate elastic deformation followed by a time-related creep

deformation. These changes are in addition to the shrinkage caused by

changes in moisture content. Any shortening of the concrete that occurs after

the tendons have been tensioned and anchored causes a loss of prestress

that must be allowed for in the design of the member.

Concrete shrinks over time by an amount that varies with the initial

water content of the mix, the thickness of the section and the relative humidity

of the environment. The shrinkage develops rapidly at first and continues at a

reducing rate for many years. The resulting loss of prestress that occurs in

the tendons depends on the age of the concrete at transfer, and is greater

with pre-tensioning than with post-tensioning.

The loss of prestress due to the elastic deformation of the concrete

that occurs at transfer is greatest in pre-tensioning, since the tendons are

already anchored by bond, and all the stress is applied to the concrete at the

same time. In post-tensioning, there is no loss if all the tendons are stressed

at the same time, since the elastic deformation takes place before the

tendons are anchored. When the tendons are stressed sequentially, a

progressive loss occurs in any tendons that are already anchored. The total

loss is then intermediate between nil and half the value that occurs in pretensioning.

Concrete under applied stress also undergoes an inelastic creep

deformation. Like shrinkage, creep develops rapidly at first and continues at a

decreasing rate for many years. The creep value depends upon the thickness

of the section, the relative humidity of the environment and the maturity of the

concrete at transfer of prestress. As a result, the loss of prestress that occurs

in the tendons is greater with pre-tensioning than with post-tensioning.

11.

ECONOMICS OF PRESTRESSED CONCRETE

From an economic point of view, conditions favouring pre-stressed construction

can be listed as follows:

a) Long spans, where the ratio of dead to live load is large, so that savings in

weight of structure becomes a significant item in economy. A minimum dead

to live load ratio is necessary in order to permit the placement of steel near

the tensile fibre, thus giving it the greatest possible lever arm for resisting

moment. For long members, the relative cost of anchorages is also lowered.

b) Heavy loads, where large quantities of materials are involved so that saving in

materials becomes worthwhile.

c) Multiple units, where forms can be reused and labour mechanized so that the

additional cost of labour and forms can be minimized.

d) Precasting units, where work can be centralized so as to reduce the

additional cost of labour and to obtain better control of the products.

e) Pre-tensioning units, where the cost of anchorage, sheathing and grouting

can be saved.

CHETAN TOLIA

ST4121301

PRE-STRESSED CONCRETE STRUCTURES

There are other conditions which, for certain situations are not favourable to the

economy of prestressed concrete but which are bound to improve as time goes on.

These are:

a) The availability of contractors experienced with the work of prestressing.

b) The availability of equipments for post-tensioning and of plants for pretensioning.

A pre-stressed concrete structure is different from a conventional reinforced

concrete structure due to the application of an initial load on the structure prior to

its use. The initial load or `pre-stress is applied to enable the structure to

counteract the stresses during its service period.

For concrete, internal stresses are induced for following reasons:

The tensile strength of concrete is only about 8 to 14% of its compressive

strength.

Cracks tend to develop at early stages of loading in flexural members

such as beams and slabs.

To prevent such cracks, compressive force can be suitably applied in the

perpendicular direction of the loading.

Pre-stressing enhances the bending, shear and torsion capacities of the

flexural members.

CHETAN TOLIA

10

ST4121301

Das könnte Ihnen auch gefallen

- NIST Prestressed ConcreteDokument6 SeitenNIST Prestressed Concretepaul machariaNoch keine Bewertungen

- Prestressed ConcreteDokument14 SeitenPrestressed ConcretekomalNoch keine Bewertungen

- Chapter 4 Pre-Stressed ConcreteDokument23 SeitenChapter 4 Pre-Stressed ConcreteDdeqz Elina Bueno INoch keine Bewertungen

- Ce2404 Pcs NotesDokument49 SeitenCe2404 Pcs NotesChockalingamNoch keine Bewertungen

- Terminologies in Prestressed DesignDokument4 SeitenTerminologies in Prestressed DesignMegan FerrarinNoch keine Bewertungen

- Chapter 1 Introduction To PrestressingDokument22 SeitenChapter 1 Introduction To PrestressingJoena LindaNoch keine Bewertungen

- Advantages and Disadvantages of Prestressed ConcreteDokument19 SeitenAdvantages and Disadvantages of Prestressed Concretebhargav reddyNoch keine Bewertungen

- PrestressingDokument26 SeitenPrestressingNupur BhadraNoch keine Bewertungen

- Prestressed General Principles PDFDokument7 SeitenPrestressed General Principles PDFNani CherryNoch keine Bewertungen

- Lesson 2-Flexural Analysis of BeamsDokument15 SeitenLesson 2-Flexural Analysis of Beamsnelson christopher servidaNoch keine Bewertungen

- Pre-Stressed Elective EngineeringDokument7 SeitenPre-Stressed Elective EngineeringJonas FernandezNoch keine Bewertungen

- Pre Tensioning & Post TensioningDokument3 SeitenPre Tensioning & Post TensioningPrasannanjaneya Kumar SanagalaNoch keine Bewertungen

- CE2404 Pre Stressed Concrete StructuresDokument149 SeitenCE2404 Pre Stressed Concrete StructuresPrantik Adhar Samanta100% (1)

- Thesis ManuscriptDokument177 SeitenThesis ManuscriptMaevin WooNoch keine Bewertungen

- Instructions: Analyze and Answer Each of The Following Problems. Show Your Complete Solutions WithDokument8 SeitenInstructions: Analyze and Answer Each of The Following Problems. Show Your Complete Solutions WithMarben Leynes-Cereno Agustin-ViernesNoch keine Bewertungen

- Design of Deck SlabDokument8 SeitenDesign of Deck SlabHussein AlkafajiNoch keine Bewertungen

- ECS226 - Chapter 4 Buckling of ColumnDokument34 SeitenECS226 - Chapter 4 Buckling of ColumnYasmin QashrinaNoch keine Bewertungen

- CEN 308 - Pre-Stressed Concrete PDFDokument112 SeitenCEN 308 - Pre-Stressed Concrete PDFAshish Singh Sengar100% (1)

- Chapter 1 Introduction To Bridge EngineeringDokument110 SeitenChapter 1 Introduction To Bridge Engineeringbooradley31480% (5)

- Introduction to Prestressed Concrete DesignDokument7 SeitenIntroduction to Prestressed Concrete DesignLEONARD DEL ROSARIONoch keine Bewertungen

- 3) T-BeamsDokument4 Seiten3) T-BeamsVanessa Rosal PalerNoch keine Bewertungen

- Sample Assignment of Prestressed Concrete DesignDokument21 SeitenSample Assignment of Prestressed Concrete DesignjrmmansayonNoch keine Bewertungen

- Losses in Prestress ConcreteDokument41 SeitenLosses in Prestress ConcreteourebooksNoch keine Bewertungen

- Failure Investigation of Microwave Towers During Cyclones - A Case StudyDokument11 SeitenFailure Investigation of Microwave Towers During Cyclones - A Case StudyMahaveer Janapala100% (2)

- Concrete Slab Design - Aci 318Dokument4 SeitenConcrete Slab Design - Aci 318Kutty MansoorNoch keine Bewertungen

- Steel Lecture - 1Dokument131 SeitenSteel Lecture - 1vinodh159Noch keine Bewertungen

- Irregular Section of Beams Reinforced For TensionDokument26 SeitenIrregular Section of Beams Reinforced For TensionMadelyn Escaner MorilloNoch keine Bewertungen

- Earthquake Engineering QuizDokument29 SeitenEarthquake Engineering Quizshivanandarcot0% (1)

- 2-CE 305 MOD 2 Singly RCFDokument10 Seiten2-CE 305 MOD 2 Singly RCFLester Khiets RoaNoch keine Bewertungen

- Flexural Analysis of Prestressed ConcreteDokument29 SeitenFlexural Analysis of Prestressed ConcreteGray Fiore FullbusterNoch keine Bewertungen

- Module 03 Part 1 Reinforced Concrete Design For Beams USD FlexureDokument44 SeitenModule 03 Part 1 Reinforced Concrete Design For Beams USD FlexureSteph BruanNoch keine Bewertungen

- Advantages and Disadvantages of Prestressed ConcreteDokument1 SeiteAdvantages and Disadvantages of Prestressed ConcreteMarlou Salazar SabanganNoch keine Bewertungen

- Linear Static Seismic Force Procedures <40Dokument28 SeitenLinear Static Seismic Force Procedures <40alfieNoch keine Bewertungen

- Fund II Assignment 2Dokument3 SeitenFund II Assignment 2Asegid Bezabih50% (2)

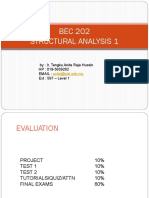

- BEC 202 Structural Analysis 1 Course OutlineDokument92 SeitenBEC 202 Structural Analysis 1 Course OutlineShoby Kesavan Pillai100% (1)

- I Have Chosen This Topic So That I Can Test The Strength and Behaviour of SFRSCDokument3 SeitenI Have Chosen This Topic So That I Can Test The Strength and Behaviour of SFRSCKartik SainiNoch keine Bewertungen

- Possibilities of Pre-Stressed Concrete in Construction (April 2016)Dokument3 SeitenPossibilities of Pre-Stressed Concrete in Construction (April 2016)JaiNoch keine Bewertungen

- 3331 ST7008 Prestressed Concrete QBDokument11 Seiten3331 ST7008 Prestressed Concrete QBsundar100% (1)

- Assignment No. 1Dokument9 SeitenAssignment No. 1Cheryl Lou SantiagoNoch keine Bewertungen

- Portal Frame Method: General AssumptionsDokument4 SeitenPortal Frame Method: General AssumptionsArslan QureshiNoch keine Bewertungen

- Analysis of PSCDokument28 SeitenAnalysis of PSCdrpNoch keine Bewertungen

- Mode of Failure FoundationDokument11 SeitenMode of Failure FoundationFirash ImranNoch keine Bewertungen

- Final Exam Prestressed Concrete SRCR5523Dokument1 SeiteFinal Exam Prestressed Concrete SRCR5523John Rhey Almojallas BenedictoNoch keine Bewertungen

- Reinforced Concrete - I DMU Lecture NotesDokument206 SeitenReinforced Concrete - I DMU Lecture NotesAntenehNoch keine Bewertungen

- Reinforced Concrete I: Lecture-1Dokument54 SeitenReinforced Concrete I: Lecture-1Temesgen BihonegnNoch keine Bewertungen

- TOS I - Chapter 1Dokument27 SeitenTOS I - Chapter 1michael jayNoch keine Bewertungen

- Prestressed Concrete DesignDokument11 SeitenPrestressed Concrete DesignMelchor Jaramilla Oronos100% (1)

- C1-Analytical Methods Assignment 1Dokument2 SeitenC1-Analytical Methods Assignment 1JP de AzevedoNoch keine Bewertungen

- Chapter 5-Prestressed Concrete DesignDokument51 SeitenChapter 5-Prestressed Concrete DesignAzrai AzizNoch keine Bewertungen

- Losses in Prestress: Creep, Shrinkage, RelaxationDokument17 SeitenLosses in Prestress: Creep, Shrinkage, RelaxationSamanvay ChandnaoNoch keine Bewertungen

- Prestressed Concrete StructuresDokument32 SeitenPrestressed Concrete StructuresMâjñù MâjñúNoch keine Bewertungen

- Manuel S. Enverga University Foundation Granted Autonomous StatusDokument8 SeitenManuel S. Enverga University Foundation Granted Autonomous StatusMaria Anthony Macatangay OriolaNoch keine Bewertungen

- Fundamentals of Prestressing ExplainedDokument7 SeitenFundamentals of Prestressing Explainedsankar_rao333Noch keine Bewertungen

- Assignment PrestressedDokument18 SeitenAssignment PrestressedMarzuki Oemar100% (5)

- Prestress Concrete DPDokument20 SeitenPrestress Concrete DPdanielNoch keine Bewertungen

- Prestressed Concrete, Pre-Tension and Post-TensionDokument6 SeitenPrestressed Concrete, Pre-Tension and Post-TensionAjayi PeterNoch keine Bewertungen

- Provide A Brief History of Prestressed ConcreteDokument8 SeitenProvide A Brief History of Prestressed Concretehasif21100% (1)

- Tos Vii Unit 01 & 02dfhtgfijkDokument20 SeitenTos Vii Unit 01 & 02dfhtgfijkKanak YadavNoch keine Bewertungen

- Prestress Lecture NotesfsfsfsDokument153 SeitenPrestress Lecture NotesfsfsfsAlzhammer ManupacNoch keine Bewertungen

- Prestressed ConcreteDokument9 SeitenPrestressed ConcreteDiploma - CE Dept.Noch keine Bewertungen

- Arch Mechanism in Prestressed Concrete Beams With Web OpeningsDokument9 SeitenArch Mechanism in Prestressed Concrete Beams With Web OpeningsChetan ToliaNoch keine Bewertungen

- Reinforcement Detailing For Openings in Beams 103Dokument5 SeitenReinforcement Detailing For Openings in Beams 103stefengoNoch keine Bewertungen

- Openings in BeamsDokument57 SeitenOpenings in BeamsNguyen Ngoc Hoa100% (1)

- NCSCM Campus Tender DocumentsDokument498 SeitenNCSCM Campus Tender Documentssadi3013Noch keine Bewertungen

- Pour StripsDokument2 SeitenPour StripsChetan Tolia100% (1)

- Site Grading Specs PDFDokument2 SeitenSite Grading Specs PDFChetan ToliaNoch keine Bewertungen

- StructuresDokument33 SeitenStructuresChetan ToliaNoch keine Bewertungen

- The Study of The Effects of Web Openings On The Concrete BeamsDokument10 SeitenThe Study of The Effects of Web Openings On The Concrete BeamsChetan ToliaNoch keine Bewertungen

- uPVC Pressure Grey Pipes BS PDFDokument3 SeitenuPVC Pressure Grey Pipes BS PDFChetan ToliaNoch keine Bewertungen

- Specification For Hollow Metal Pressed Steel Doors PDFDokument7 SeitenSpecification For Hollow Metal Pressed Steel Doors PDFChetan ToliaNoch keine Bewertungen

- 27 Shape of ArchesDokument20 Seiten27 Shape of ArchesChetan ToliaNoch keine Bewertungen

- RCC Member Design TipsDokument5 SeitenRCC Member Design TipsChetan ToliaNoch keine Bewertungen

- Basic Functions and The Right TriangleDokument15 SeitenBasic Functions and The Right TriangleChetan Tolia100% (1)

- Dia GridDokument16 SeitenDia GridAshok VarmaNoch keine Bewertungen

- Basics of Engg MechanicsDokument10 SeitenBasics of Engg MechanicsKumar RaviNoch keine Bewertungen

- Bearing Capacity of SoilsDokument138 SeitenBearing Capacity of SoilsMuqeem Khan100% (1)

- Base Isolation For Increased Earthquake Resistance of BuildingsDokument9 SeitenBase Isolation For Increased Earthquake Resistance of BuildingsChetan ToliaNoch keine Bewertungen

- Architects Guide 2010-03-18 PDFDokument47 SeitenArchitects Guide 2010-03-18 PDFSharath JagadeeshanNoch keine Bewertungen

- Greatest Gift TimeDokument21 SeitenGreatest Gift TimeChetan ToliaNoch keine Bewertungen

- Anchor Bolt DesignDokument26 SeitenAnchor Bolt Designdwicahyo_as100% (1)

- JBS Conceptual DesignDokument11 SeitenJBS Conceptual DesignChetan ToliaNoch keine Bewertungen

- Design Criteria For Concrete Foundations & Structures 2Dokument24 SeitenDesign Criteria For Concrete Foundations & Structures 2Chetan ToliaNoch keine Bewertungen

- SL Chan FacadeDokument29 SeitenSL Chan FacadeKayBee DatilesNoch keine Bewertungen

- SL Chan FacadeDokument29 SeitenSL Chan FacadeKayBee DatilesNoch keine Bewertungen

- 42.0 - Pre-Cast Construction v3.0 EnglishDokument20 Seiten42.0 - Pre-Cast Construction v3.0 EnglishchumairabbasNoch keine Bewertungen

- Construction Job Safety AnalysisDokument10 SeitenConstruction Job Safety AnalysisMata RosemarieNoch keine Bewertungen

- Precast Pre Stressed ConcreteDokument6 SeitenPrecast Pre Stressed Concretejack.simpson.changNoch keine Bewertungen

- Flood Protection Method - StatementDokument4 SeitenFlood Protection Method - Statementthowchin100% (1)

- Cement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementDokument4 SeitenCement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementChalamaiah VMNoch keine Bewertungen

- Nitofill Ur63 PDFDokument3 SeitenNitofill Ur63 PDFtalatzahoorNoch keine Bewertungen

- Load Rating of Large Reaction Floor-Wall AssemblyDokument12 SeitenLoad Rating of Large Reaction Floor-Wall Assemblyprashanth palaniNoch keine Bewertungen

- Umri Road Work Done-1Dokument162 SeitenUmri Road Work Done-1DPRE PIU ADILABADNoch keine Bewertungen

- Uses of Steel LintelsDokument2 SeitenUses of Steel LintelsTyrone LanosaNoch keine Bewertungen

- 650 - Standard Sand For Testing CementDokument7 Seiten650 - Standard Sand For Testing CementDebabrata PalNoch keine Bewertungen

- CMA Building Foundation Beams PDFDokument13 SeitenCMA Building Foundation Beams PDFRegie NojaldaNoch keine Bewertungen

- IDEA StatiCa Release 9 HighlightsDokument43 SeitenIDEA StatiCa Release 9 HighlightsSedad SubasicNoch keine Bewertungen

- 40.0 - False Work (Formwork) v3.0 English (Full Permission)Dokument14 Seiten40.0 - False Work (Formwork) v3.0 English (Full Permission)Amal JagadiNoch keine Bewertungen

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14Dokument10 SeitenBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14jklo12Noch keine Bewertungen

- Overview: Behavior of Adhesive Bonded Anchors: Ronald A. Cook Rolf Eligehausen Jörg J. ApplDokument6 SeitenOverview: Behavior of Adhesive Bonded Anchors: Ronald A. Cook Rolf Eligehausen Jörg J. ApplSami SyedNoch keine Bewertungen

- BtechhDokument7 SeitenBtechhcorbitecoNoch keine Bewertungen

- Concrete Surface Preparation GuideDokument18 SeitenConcrete Surface Preparation GuidemadhurajshNoch keine Bewertungen

- IS 7272.1.1974 - Labour Constants PDFDokument19 SeitenIS 7272.1.1974 - Labour Constants PDFVenkatesh KakhandikiNoch keine Bewertungen

- Analisa-Prime MortarDokument14 SeitenAnalisa-Prime Mortarirfan ikhsani wahyuNoch keine Bewertungen

- Repair and RehabilitationDokument115 SeitenRepair and RehabilitationBala Subramanian0% (1)

- Epoxy CatalogDokument38 SeitenEpoxy CatalogMohamed ElMahalaweyNoch keine Bewertungen

- Astm D5340 03 PCI PDFDokument54 SeitenAstm D5340 03 PCI PDFDavid Alonso Quintero HenaoNoch keine Bewertungen

- Supercast EPT PDFDokument2 SeitenSupercast EPT PDFmilanbrasinaNoch keine Bewertungen

- Gps PillarDokument6 SeitenGps PillarKosygin LeishangthemNoch keine Bewertungen

- Asset & Liability Management of Kesoram CementsDokument51 SeitenAsset & Liability Management of Kesoram Cementsaurorashiva1Noch keine Bewertungen

- Engineering Notes For Concrete Block Masonry WallsDokument12 SeitenEngineering Notes For Concrete Block Masonry WallsCristopher VegaNoch keine Bewertungen

- Irr PD 957Dokument63 SeitenIrr PD 957Addie EconarNoch keine Bewertungen

- Is 459Dokument10 SeitenIs 459AmbrishNoch keine Bewertungen

- Astm C1073Dokument3 SeitenAstm C1073mirvahid HOSSiNiNoch keine Bewertungen

- Basic Concrete Principles PDFDokument33 SeitenBasic Concrete Principles PDFOliver BrownNoch keine Bewertungen