Beruflich Dokumente

Kultur Dokumente

Conveyer Screw Stops Bottles for Labeling

Hochgeladen von

Christian MavarezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Conveyer Screw Stops Bottles for Labeling

Hochgeladen von

Christian MavarezCopyright:

Verfügbare Formate

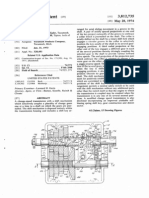

Oct. 21, 1941.

'

w, B, HULLHQRST

2,259,748

CONVEYER

Filed March 29, 1940

INVENTOR

' William .B. Hull/701291;,

2,259,748

Patented Oct. 21, 1941

"UNITED STATES PATENT" OF'FIGE

-

"

'

2,259,748

"

'

CONVEYER

William _B. Hullhorst, Toledo, Ohio, assignor to _

Owens-Illinois Glass Company, a corporation

of Ohio

'

Application March 29, 1940, Serial No. 326,696

4 Claims. (c1.'_19a-s4)

pair of pulleys l5, one of the latter being mounted

upon a shaft It at oneend of the conveyer.

. The present invention relates to improvements

in conveyers and more particularly is concerned

with the, provision of novel and effective means

. - The bottles H are retained against excessive

lateral shifting upon the conveyer H] by means

of a longitudinal guide ll which is positioned

alongside of the conveyer opposite a timing screw

for momentarily retarding advancing movement

of the articles one at a time, upon a continuously

moving conveyer, to permit labeling or any other 1

desired operation upon the articles...

l8, the latter being disposed in parallel relation

An object of my invention is the provision of a

ship to said conveyer.~

I.

This timing screw functions to space the bottles

conveying system including a continuously rotat

ing timing screw which is so formed, that, in 10 apart su?iciently in advance of _ arrival at the

sealing or capping station S to permit complete

conjunction with acontinuously moving horizon

cessation of forward movement of the bottles at

tal conveyer, it will' operate to gradually increase

said station for the'period of time required to- .

the spaced relation between articles that are

beingv delivered to a preselected station by the

> apply and ?rmly attach closures or caps thereto.

conveyer and momentarily hold the articles sta 15 The screw I8 is journaled in bearings 19 and at

least in part overlies a marginal portion of; the

tionary at the station one at a time, vwithout

conveyer so that the thread 2llm'ay engage the

regard to the continued movement of the con

side surfaces of the bottles as they are carried

veyer and other articles, whereby to facilitate the

to the capping station S by said conveyer. At

performance of any desired operation upon the

the inlet or entrance end of the timing screw, the

articles. To this end the.timing screw is so

pitch or lead of the thread is such that to-.

formed that the thread, substantially medially of

gether with rotation of the screw at a predeter-'

its length, accelerates forward'movement of the.

mined speed, it does not have any accelerating

articles one at a time andat the exitend of the

or decelerating effect upon the speed of travel of

screw is so formed that the normal forward

motion of each article is completely stopped until 25 the bottles. Substantially, medially of the length

. of the timing screw the thread,thereof is in

it has been labeled or otherwise treated.

creased in pitch or lead su?iciently to accelerate

Another object of my invention is the provi

the speed of movement of the bottles one-at a

' sion of a'timing screw which is usable with any

time and advance them relative to the following .

of the various types of conveyers and is of such

bottles and conveyer a distance substantially

construction that several _may be'arranged in

equal to the diameter of one of the bottles. By

endto end relation alongside of a.convey'er and

so spacing the bottles prior to arrival thereof at

employed in delivering articles in the desired

spaced relation to a series of stations at which - the capping station, it is practicable to'hold them

stationary at said station during, the capping .

various operations may be performed thereon.

Other objects will be in part apparent and in 35 operation without in any way interrupting nor

1.

part pointed out hereinafter.

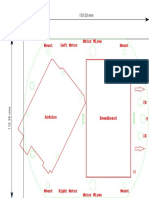

In the drawing:

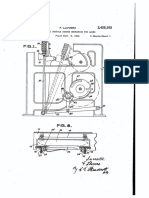

Fig. 1 is. a top plan view of a conveyer system

including the timing screw which embodiesmy

invention.

'

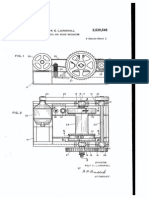

Fig. 2 is a sectional elevational view taken 'sub- _

' stantially along the line 2-2 of Fig. 1.

While the invention iscapa-ble of use with

mal forward travel of the other bottles with the

conveyer Ill.

The bottles are held stationary at the capping .

station due'to the speci?c contour of the thread

of the timing screw in proximity to the exit end

of the latter. The speci?c construction includes

a semi-circular radial ?ange 2| disposed in a

plane at right angles to the axis of said screw,

said ?ange being in e?ect a continuation of the

various types of conveyers and for the purpose of

handling a great variety of articles, I have in 45 main thread 20 and connecting the latter with-a '

relatively short spiral thread 22, the latter at its ,

the accompanying drawing illustrated it in con-

other end merging into an end of aradial ?ange

junction with a horizontal endless belt type con

23 which is formed at the extreme end of the

veyer which is transporting glass containers to

timing screw and extends in a direction circum

ya sealing station._

.

ferentially of the latter for a distance ofapprox- The .endless conveyer I0 is disposed horizon

tally and operates to bring glass bottles H toy'a

capping or sealing station 8.. This conveyer may

' be driven by conventional means including an

_ imately 90?. This end ?ange 23 positively holds

the bottles _one at a time against forward move

ment with the conveyer Ill. The other ?ange 2| '

prevents contact between a container, that is

electric motor l2 operating through a speed re

ducing unit l3 and a belt l4 which connects a 55 being held stationary and the next succeeding

H

2,259,748

2.

container such as might otherwise occur under

some conditions. As the'screw rotates and the

outer end of the radial flange 23 moves out of

contact with a bottle, the latter is engaged by

the spiral thread portion 22, the lead or pitch of

which is such that it functions as a cam and

causes the bottle to resume its forward move

ment, the initial portion of which movement is

slightly faster than the speed of the conveyer

Ill. Thus contact between the containers is pre

vented.

Mechanism for imparting continuous rotation

to the timing screw may well include an electric

?nally release the article for normal travel with

said conveyer.

2. In a conveyer system of the character de

scribed, a horizontal continuously moving con

veyer, a guide arranged along one side thereof, a

timing screw positioned at the opposite side of

the conveyer and in part overlying the latter, said

timing screw having a continuous thread from its

inlet end to a point in proximity to the exit end

thereof, a major portion of the thread remote

from the inlet end being of greater pitch than

the remainder and a pair of longitudinally spaced

radial ?anges forming a part of the exit end of

the screw and extending in a direction circum

unit 25 and a belt 26 or the like which is trained 15 ferentially of the latter, said ?anges being con

nected to and forming a continuation of the

over a pair of pulleys 21. One of these pulleys is

mounted directly upon an end of the timing screw _ thread proper, means for imparting continuous

motor 24 operating through a speed reduction

rotation to the timing screw, and a segmental

For the purpose of illustration I have shown ' spiral thread connecting the opposed ends of said

a capping or sealing unit 28 positioned 'at the 20 ?anges.

from the motor 24. . The construction may in

3. A conveyer system including a horizontal

conveyer adapted to_ carry articles to and away

clude a standard 29 which pivotally supports a

capping head ll. This head is brought into en

partoverlying said conveyer and disposed paral

capping station S. This unit obtains its power

gagement with the bottles at regular intervals by

mechanism including a pair of bell crank levers"

from a preselected station, a timing screw in

lel thereto, a guide spaced from the timing screw

and extending lengthwise of the conveyer, the

thread at the inlet end of said screw being shaped

to engage the articles without accelerating or

Si and a shaft 3 I. supporting them. One lever is

connected through a rod 32 to said head while

decelerating their speed, the adjacent part of the other is secured to a push rod 33. - This latter

the

screw thread being shaped to accelerate move

30

rod carries a cam roll 34 which runs in a closed

ment of the articles relative to the conveyer as

rotary cam 35, the latter being mounted upon a

they approach said station, means at said sta

shaft 36 which is driven by the motor 24 through

tion connected to and forming an extension of

the aforementioned speed reduction unit 25.

the screw thread for effecting momentary cessa

In view of the above it will be apparent that

tion of the advancing movement of the articles,

in operation the mechanism continuously delivers

means for continuously rotating the timing

bottles to the capping unit and just prior to

arrival of the bottles at said station, spaces them

screw and means for moving the conveyer at a

constantspeed.

'

apart sumciently to permit complete cessation

4. In apparatus of the character described, a

of the forward movement thereof during the 40

= timing screw arranged alongside of a continu

' ously moving horizontal conveyer and in part

capping operation.

overlying the latter, said screw having inlet and

Modi?cations may be resorted to within the

exit ends, the lead of the screw thread inter

spirit and scope of the appended claims.

I claim:

1. In a conveyer system of the character de

scribed, a horizontal continuously moving con

veyer, a guide arranged along one side thereof,

mediate the length of the latter being increased

- in pitch, said thread at the inlet end having pitch

to eifect movement of the articles at the same

speed as that of the conveyer, said thread in

proximity to the exitof the screw being formed

and a timing screw positioned at the opposite side

to momentarily retard advancing movement of

of the conveyer and in part overlying the latter,

the thread ot the screw being in part shaped to 50 articles engaged thereby, and means for impart- '

ing continuous rotary movement to the timing

accelerate forward movement of articles on and

relative to the conveyer and thereafter momen

tarily completely stop such forward movement and.

screw.

l,

WILLIAM B. HULLHORST.

Das könnte Ihnen auch gefallen

- Basic Hydraulic SystemsDokument128 SeitenBasic Hydraulic Systemsbeau04297% (35)

- 507 Mechanical Movements: Mechanisms and DevicesVon Everand507 Mechanical Movements: Mechanisms and DevicesBewertung: 4 von 5 Sternen4/5 (28)

- Bulk Material Handling Belt-Conveyor-CatalogDokument21 SeitenBulk Material Handling Belt-Conveyor-CatalogjayNoch keine Bewertungen

- United States "Patents PDFDokument17 SeitenUnited States "Patents PDFTien Nguyen VanNoch keine Bewertungen

- Woodward MFR 13Dokument91 SeitenWoodward MFR 13OryaNoch keine Bewertungen

- Heat Combustion Laboratory ReportDokument8 SeitenHeat Combustion Laboratory ReportSteven Lee100% (1)

- Tow Target Cable Drag Mechanism (1941)Dokument4 SeitenTow Target Cable Drag Mechanism (1941)CAP History LibraryNoch keine Bewertungen

- Agitated Vessel Heat Transfer Design PDFDokument3 SeitenAgitated Vessel Heat Transfer Design PDFmrariffNoch keine Bewertungen

- Feed Mill InfoDokument33 SeitenFeed Mill InfoSapelNoch keine Bewertungen

- DS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1Dokument52 SeitenDS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1AlexandreNoch keine Bewertungen

- 304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFDokument16 Seiten304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFAndressa EgerNoch keine Bewertungen

- Design and Fabricatino of Liquid Dispensing Machine Using Automatic Control For Engg IndustryDokument7 SeitenDesign and Fabricatino of Liquid Dispensing Machine Using Automatic Control For Engg IndustryChristian MavarezNoch keine Bewertungen

- Apron MechanismDokument7 SeitenApron Mechanismgopalpaul0% (2)

- M. Schwafel: Derrick Safety CageDokument4 SeitenM. Schwafel: Derrick Safety CageRodrigoPomaNoch keine Bewertungen

- Rig-E???': Gill!Dokument6 SeitenRig-E???': Gill!luiscremaschiNoch keine Bewertungen

- J. H. Wilson: Inventor.Dokument6 SeitenJ. H. Wilson: Inventor.lfilippiniNoch keine Bewertungen

- 1895 - Us570025Dokument5 Seiten1895 - Us570025Enrico Bruce GioloNoch keine Bewertungen

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Dokument8 SeitenApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiNoch keine Bewertungen

- United States Patent: Dreve, Jr. (45) May 16, 1972Dokument6 SeitenUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNoch keine Bewertungen

- Us2765819 PDFDokument8 SeitenUs2765819 PDFAzri LunduNoch keine Bewertungen

- J.B. HALE'S 1920 BRAIDING MACHINE CARRIERDokument5 SeitenJ.B. HALE'S 1920 BRAIDING MACHINE CARRIERsebastian escobarNoch keine Bewertungen

- Us2351483 PDFDokument7 SeitenUs2351483 PDFbelchior alvaroNoch keine Bewertungen

- Military Searchlight Truck (1937)Dokument8 SeitenMilitary Searchlight Truck (1937)CAP History LibraryNoch keine Bewertungen

- Variable-Speed Gearing Patent from 1901Dokument4 SeitenVariable-Speed Gearing Patent from 1901belchior alvaroNoch keine Bewertungen

- Illlllllllllilllllllllilllllllllli: United States Patent (191Dokument3 SeitenIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNoch keine Bewertungen

- June 24, 1969 R, Manterhelq 3,451,532: Med March 28, 1967 ', Sheet I OfaDokument5 SeitenJune 24, 1969 R, Manterhelq 3,451,532: Med March 28, 1967 ', Sheet I OfabakkaNoch keine Bewertungen

- Sept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1Dokument5 SeitenSept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1cvkkkk1Noch keine Bewertungen

- Us955823 PDFDokument3 SeitenUs955823 PDFSashikant SharmaNoch keine Bewertungen

- Us2371574 PDFDokument5 SeitenUs2371574 PDFbelchior alvaroNoch keine Bewertungen

- Welding FBWDokument13 SeitenWelding FBWRakesh SrivastavaNoch keine Bewertungen

- Shaft Mounting Device Measures and Controls Thrust LoadsDokument7 SeitenShaft Mounting Device Measures and Controls Thrust LoadsNicandroGonzalesNoch keine Bewertungen

- Us2935914 PDFDokument14 SeitenUs2935914 PDFMichael LaneNoch keine Bewertungen

- Tow Target Release Mechanism (1927)Dokument5 SeitenTow Target Release Mechanism (1927)CAP History LibraryNoch keine Bewertungen

- Us2421190 PDFDokument6 SeitenUs2421190 PDFbelchior alvaroNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1Dokument14 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1zbhdzpNoch keine Bewertungen

- Us 1001260Dokument5 SeitenUs 1001260mehdi parsNoch keine Bewertungen

- 8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336Dokument9 Seiten8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336tyrer567899Noch keine Bewertungen

- 1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieDokument3 Seiten1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieVincent Grangé-PradérasNoch keine Bewertungen

- Us 2425103Dokument6 SeitenUs 2425103Muhamad HasanNoch keine Bewertungen

- Us1446763 PDFDokument7 SeitenUs1446763 PDFJin SongNoch keine Bewertungen

- Filed April 2, 1946Dokument4 SeitenFiled April 2, 1946lfilippiniNoch keine Bewertungen

- Kinematic Systems and Working Principles of Semi Automatic LathesDokument4 SeitenKinematic Systems and Working Principles of Semi Automatic Lathes21UME003 TUSHAR DEBNoch keine Bewertungen

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDokument3 SeitenFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNoch keine Bewertungen

- May 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworksDokument10 SeitenMay 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworkslfilippiniNoch keine Bewertungen

- Us2127655 PDFDokument5 SeitenUs2127655 PDFbelchior alvaroNoch keine Bewertungen

- Lifting and transferring apparatus patent from 1945Dokument6 SeitenLifting and transferring apparatus patent from 1945varun mNoch keine Bewertungen

- United States Patent: SchwartzmanDokument4 SeitenUnited States Patent: SchwartzmanJames LindonNoch keine Bewertungen

- US patent for balanced lifting beam craneDokument3 SeitenUS patent for balanced lifting beam cranegibson_sx87Noch keine Bewertungen

- Sept. 2, 1.930. W. Wxlson 1,774,955: Filed De'C. 7, 1929 2 Sheets-Sheet L ADokument5 SeitenSept. 2, 1.930. W. Wxlson 1,774,955: Filed De'C. 7, 1929 2 Sheets-Sheet L Aاحمد عبدالكريمNoch keine Bewertungen

- April 2, 1940.: P. Ravigneaux - 2,195,783Dokument9 SeitenApril 2, 1940.: P. Ravigneaux - 2,195,783Stefan IlicNoch keine Bewertungen

- United States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Dokument8 SeitenUnited States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Stanislas AchardNoch keine Bewertungen

- 1,023,695, Patented Apr. 16, 1912.: G. WaltherDokument3 Seiten1,023,695, Patented Apr. 16, 1912.: G. WaltherdfdfsdNoch keine Bewertungen

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Dokument12 SeitenL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniNoch keine Bewertungen

- Bottle Filler and Capper Unit: June 24, 1930. G. E. Strandt 1,766,962Dokument8 SeitenBottle Filler and Capper Unit: June 24, 1930. G. E. Strandt 1,766,962Luis Enrique Barreto GarciaNoch keine Bewertungen

- Paper Cup Machine Patent from 1921 Details Machine for Making Disposable CupsDokument18 SeitenPaper Cup Machine Patent from 1921 Details Machine for Making Disposable Cupspafredo007Noch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1Dokument9 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1DANESINoch keine Bewertungen

- Tree Climbing Motor Patent from 1903Dokument4 SeitenTree Climbing Motor Patent from 1903monem2014Noch keine Bewertungen

- EP0662572A1Dokument14 SeitenEP0662572A1Rockerss RockerssNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Dokument14 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanNoch keine Bewertungen

- US2128620 - Bending MachineDokument5 SeitenUS2128620 - Bending MachinedevheadbotNoch keine Bewertungen

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDokument10 SeitenUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91Noch keine Bewertungen

- Air Compressor Using Crank and Slotted Link MechanismDokument22 SeitenAir Compressor Using Crank and Slotted Link MechanismSaravanan Viswakarma75% (4)

- Four-Speed Transmission Shift MechanismDokument18 SeitenFour-Speed Transmission Shift MechanismJoão Paulo Canto RibeiroNoch keine Bewertungen

- %WWMD%WM: J. H. Vanderslig-E. Flanging MachineDokument4 Seiten%WWMD%WM: J. H. Vanderslig-E. Flanging MachineOO G-sus OoNoch keine Bewertungen

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedDokument7 SeitenNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaNoch keine Bewertungen

- Us2218760 PDFDokument3 SeitenUs2218760 PDFbelchior alvaroNoch keine Bewertungen

- Us2333680 PDFDokument8 SeitenUs2333680 PDFbelchior alvaroNoch keine Bewertungen

- Braiding MachineDokument7 SeitenBraiding Machinejojaberi100% (1)

- Scientific American Supplement, No. 312, December 24, 1881Von EverandScientific American Supplement, No. 312, December 24, 1881Noch keine Bewertungen

- US4927617 Production of Ammonium NitrateDokument4 SeitenUS4927617 Production of Ammonium NitrateChristian MavarezNoch keine Bewertungen

- Journal of Kones 2014 No. 4 Vol. - 21 Issn 1231-4005 Mlynarczyk111Dokument8 SeitenJournal of Kones 2014 No. 4 Vol. - 21 Issn 1231-4005 Mlynarczyk111Christian MavarezNoch keine Bewertungen

- Car Top FinalDokument1 SeiteCar Top FinalChristian MavarezNoch keine Bewertungen

- Cost Data Analysis For The Food IindustryDokument11 SeitenCost Data Analysis For The Food IindustryChristian MavarezNoch keine Bewertungen

- US4927617 Production of Ammonium NitrateDokument4 SeitenUS4927617 Production of Ammonium NitrateChristian MavarezNoch keine Bewertungen

- Isothermal Quenching of Crusher HammersDokument1 SeiteIsothermal Quenching of Crusher HammersChristian MavarezNoch keine Bewertungen

- The Temperature, Pressure and Time Dependence of LubricantDokument8 SeitenThe Temperature, Pressure and Time Dependence of LubricantChristian MavarezNoch keine Bewertungen

- Cost Standards For A Model Stationary Custom Feed Mill For The MidwestDokument18 SeitenCost Standards For A Model Stationary Custom Feed Mill For The MidwestChristian MavarezNoch keine Bewertungen

- 3-3 THR - Keith Behnke - Feed Milling Milestones - ANC 2010Dokument31 Seiten3-3 THR - Keith Behnke - Feed Milling Milestones - ANC 2010Christian Mavarez100% (1)

- Optimal Sizing of Counterflow Cooler For PelletsDokument72 SeitenOptimal Sizing of Counterflow Cooler For PelletsChristian MavarezNoch keine Bewertungen

- Investigating Limits in Naturally Cooled Systems Using FlothermDokument6 SeitenInvestigating Limits in Naturally Cooled Systems Using FlothermChristian MavarezNoch keine Bewertungen

- Isothermal Quenching of Crusher HammersDokument1 SeiteIsothermal Quenching of Crusher HammersChristian MavarezNoch keine Bewertungen

- Heat Sink Design Optimization Using The Thermal Bottleneck ConceptDokument5 SeitenHeat Sink Design Optimization Using The Thermal Bottleneck ConceptChristian MavarezNoch keine Bewertungen

- Journal of Kones 2014 No. 4 Vol. - 21 Issn 1231-4005 Mlynarczyk111Dokument8 SeitenJournal of Kones 2014 No. 4 Vol. - 21 Issn 1231-4005 Mlynarczyk111Christian MavarezNoch keine Bewertungen

- Animal Feed Compunding ProcessDokument41 SeitenAnimal Feed Compunding ProcessChristian Mavarez100% (1)

- ATTACHMENT A A Weight of Evidence Assessment of TDokument67 SeitenATTACHMENT A A Weight of Evidence Assessment of TChristian MavarezNoch keine Bewertungen

- 605 05 Industrial Screw ConveyorDokument1 Seite605 05 Industrial Screw ConveyorChristian MavarezNoch keine Bewertungen

- Mobile Crushing Plant: Rio Tinto Coal Australia Clermont Coal Mine (Australia) Turn-Key ProjectDokument2 SeitenMobile Crushing Plant: Rio Tinto Coal Australia Clermont Coal Mine (Australia) Turn-Key ProjectChristian MavarezNoch keine Bewertungen

- Mobile CrushersDokument8 SeitenMobile CrushersChristian MavarezNoch keine Bewertungen

- 72Dokument17 Seiten72Christian MavarezNoch keine Bewertungen

- Ds Asphalt THF 1214 EngDokument2 SeitenDs Asphalt THF 1214 EngChristian MavarezNoch keine Bewertungen

- Production Process Analysis On Manufacturing of Hydraulic Gear PumpDokument17 SeitenProduction Process Analysis On Manufacturing of Hydraulic Gear PumpChristian MavarezNoch keine Bewertungen

- Common-Cause Failures of Centrifugal PumpsDokument30 SeitenCommon-Cause Failures of Centrifugal PumpsingrbarrosNoch keine Bewertungen

- Cimbria Conveyor In-Outlets Dimensions GuideDokument1 SeiteCimbria Conveyor In-Outlets Dimensions GuideChristian MavarezNoch keine Bewertungen

- Second Mid Term CE 461: Structural Analysis II: Student Name: Student No.: Section: 9 10 11 12Dokument4 SeitenSecond Mid Term CE 461: Structural Analysis II: Student Name: Student No.: Section: 9 10 11 12David Olorato NgwakoNoch keine Bewertungen

- Final Project Regenerative BrakingDokument6 SeitenFinal Project Regenerative Brakingdims irifiyinNoch keine Bewertungen

- Requirements Elicitation and AnalysisDokument74 SeitenRequirements Elicitation and AnalysisSadam GebiNoch keine Bewertungen

- Expanding Wired Connectivity For SOHO Networks: Plus Gigabit Ethernet SwitchesDokument4 SeitenExpanding Wired Connectivity For SOHO Networks: Plus Gigabit Ethernet SwitchesAndré LinharesNoch keine Bewertungen

- Chemical Equilibrium Updated WorksheetDokument22 SeitenChemical Equilibrium Updated Worksheetmehwish razaNoch keine Bewertungen

- Mste 3.0 Plane Geometry Hand OutsDokument8 SeitenMste 3.0 Plane Geometry Hand OutsJasmine MartinezNoch keine Bewertungen

- Python Notes - 1Dokument364 SeitenPython Notes - 1hopefulantonelliNoch keine Bewertungen

- Cylindrical Plug Gage DesignsDokument3 SeitenCylindrical Plug Gage DesignskkphadnisNoch keine Bewertungen

- Weld CheckDokument6 SeitenWeld CheckArnold c ElverNoch keine Bewertungen

- Unit I The Scientific Approach in EducationDokument4 SeitenUnit I The Scientific Approach in EducationadesaNoch keine Bewertungen

- Product Documentation: Release NotesDokument3 SeitenProduct Documentation: Release NotesArmando CisternasNoch keine Bewertungen

- Essay For Villa Savoye AbstractDokument1 SeiteEssay For Villa Savoye AbstractFrancis PohNoch keine Bewertungen

- WCS1400 / WCS1400S: FeaturesDokument7 SeitenWCS1400 / WCS1400S: FeaturesbahrowiadiNoch keine Bewertungen

- Tut 5. Two-Column Hammerhead Pier PDFDokument35 SeitenTut 5. Two-Column Hammerhead Pier PDFOscar Varon BarbosaNoch keine Bewertungen

- Physics Assignment 1Dokument4 SeitenPhysics Assignment 1Trí Võ PhạmNoch keine Bewertungen

- Martillo Hyd Atlas Copco SB 150Dokument12 SeitenMartillo Hyd Atlas Copco SB 150Nain murilloNoch keine Bewertungen

- Iygb Gce: Mathematics MP2 Advanced LevelDokument7 SeitenIygb Gce: Mathematics MP2 Advanced Levelsingh cos tanNoch keine Bewertungen

- NCERT: Why Is Steel More Elastic Than Rubber?Dokument7 SeitenNCERT: Why Is Steel More Elastic Than Rubber?Satyam RaiNoch keine Bewertungen

- Fulltext PDFDokument454 SeitenFulltext PDFVirmantas JuoceviciusNoch keine Bewertungen

- Homework1 PDFDokument3 SeitenHomework1 PDFYuanhao LiuNoch keine Bewertungen

- Z 80 HelptopicsDokument5 SeitenZ 80 HelptopicsEverly NNoch keine Bewertungen

- Unit - L: List and Explain The Functions of Various Parts of Computer Hardware and SoftwareDokument50 SeitenUnit - L: List and Explain The Functions of Various Parts of Computer Hardware and SoftwareMallapuram Sneha RaoNoch keine Bewertungen

- Unified Modeling Language Class Diagram ..Uml)Dokument20 SeitenUnified Modeling Language Class Diagram ..Uml)Yasmeen AltuwatiNoch keine Bewertungen

- Von-Neumann vs Harvard ArchitecturesDokument3 SeitenVon-Neumann vs Harvard ArchitecturesRalstine Jane IgneNoch keine Bewertungen

- MCB and ELCB PDFDokument35 SeitenMCB and ELCB PDFChris AntoniouNoch keine Bewertungen