Beruflich Dokumente

Kultur Dokumente

Hinopak Production Managment

Hochgeladen von

fujimukazuOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hinopak Production Managment

Hochgeladen von

fujimukazuCopyright:

Verfügbare Formate

PRODUCTION OPERATIONS MANAGEMENT

&

SEC A

TERM REPORT

ON

“HINOPAK”

5th JAN ‘09

Submitted to:

INSTITUTE OF BUSINESS MANAGEMENT 1

INSTITUTE OF BUSINESS MANAGEMENT 2

TABLE OF CONTENTS

OGSM:.......................................................................................................................................................12

How Hinopak Develops Its OGSM:..........................................................................................................13

Benefits Being Reaped By Hinopak..........................................................................................................14

OGSM Next Steps......................................................................................................................................14

A Live Document:......................................................................................................................................15

Some Changes to Focus On.......................................................................................................................37

Reasons to Test Changes...........................................................................................................................38

STEP 1: PLAN......................................................................................................39

STEP 2: DO..........................................................................................................39

Try out the test on a small scale..................................................................................................................39

STEP 3: STUDY...................................................................................................39

Set aside time to analyse the data and study the results...........................................................................39

STEP 4: ACT........................................................................................................40

Refine the change, based on what was learnt from the test......................................................................40

INSTITUTE OF BUSINESS MANAGEMENT 3

LETTER OF ACKNOWLEDGEMENT

We are truly indebted to Dr.

MUFADDAL MIRZA for giving

us this incredible opportunity

to gain exemplary experience

of preparing a Total Quality

Plan for a real world

company. He showed

commendable gesture of

believing in our potentials

and guided us throughout the

completion of this project. He

had faith in us which helped

us overcome all the obstacles

and developed passion with

regard to the project.

INSTITUTE OF BUSINESS MANAGEMENT 4

EXECUTIVE SUMMARY

Hinopak is one of the

matchless manufacturer of

trucks, buses and spare

parts headquartered in

Karachi which launched

itself in a maturing market.

Hinopak’s offering combines

exclusive products and

services at value-added

price.

They have targeted specific

segments in the consumer

and business market, taking

advantages of opportunities

indicated by higher demand

for transportation facilities

and commercial vehicles.

INSTITUTE OF BUSINESS MANAGEMENT 5

INTRODUCTION

• Hino Motors Japan and Toyota Tsusho

Corporation in collaboration with Al-Futtaim

Group of UAE and PACO Pakistan formed

Hinopak Motors Limited in 1986.

• In 1998, Hino Motors Ltd., and Toyota

Tsusho Corporation obtained majority

shareholding in the company after

disinvestments by the other two founding

sponsors. This decision to invest in Hinopak at

a time when the country's

economy was passing through a depression and the sale of commercial

vehicles was at an all time low reflects the confidence their Principals have

in the company and their commitment to the Pakistani market. Hinopak is

the trusted market leader with over 65% share in the Pakistani Truck and

Bus industry. Hinopak is a vital contributor in saving of foreign exchange.

The company was founded in 1985 and is headquartered in Karachi,

Pakistan.

• Hinopak Motors Limited assembles, manufactures and markets world

renowned Hino diesel trucks and buses, and spare parts primarily in

Pakistan. The Company has held the top position in the domestic market

for medium and heavy-duty vehicles for 17 consecutive years and is

highly acclaimed for quality and technological excellence.

• Hinopak is first in commercial vehicles sector to start the

establishment of 3S Dealership network, which offers Sales, Service and

Spare parts facilities all under one roof. This comprehensive network of

offices, 3S Service Dealers and Spare parts Dealers are strategically

located throughout the country. The company primarily operates in

Pakistan, Japan, Australia, New Zealand, Thailand, Canada, and the US. It

is headquartered in Karachi, Pakistan and employs 313 people.

• The company recorded revenues of PKR7, 826.8 million

(approximately $129.3 million) during the fiscal year ended December

2007. The net profit was PKR590 million (approximately $9.7 million) in

fiscal year 2007.

• Hinopak Motors Limited engages in the assembly, manufacture, and

marketing of Hino diesel trucks and buses, and spare parts. It

manufactures bus chassis and various types of bus bodies. The company’s

bus product line includes Roadliner Shangrila luxury bus for long journeys,

Citiliner Intercity buses, Citiliner urban buses, and luxury Senator coach

INSTITUTE OF BUSINESS MANAGEMENT 6

and Rapidliner Deluxe coaches. It also manufactures and sells specialized

vehicles that are used for hauling of various supplies, such as food,

equipment, and machinery. These products include prime movers, high

wall dumpers, cargo carriers, garbage collectors, school buses, mobile

kitchens, beverage carriers, water/fuel browsers, mobile eye clinics, NLC

trucks, and mobile registration vans.

• Hinopak firmly believes:

o In Total Quality Management; a process for managing quality; it

must be a continuous way of life; a philosophy of perpetual

improvement in everything they do

o Everyone can improve. A problem occurs when someone

believes that everyone else, excluding them needs to change.

INSTITUTE OF BUSINESS MANAGEMENT 7

SITUATIONAL ANALYSIS

Backed by Hino's expertise Hinopak has achieved standard of quality and

excellence that rival the best in the region. With over 39,000 vehicles on

road, Hinopak has gained over 65% market share making it the largest

manufacturer in medium and heavy-duty truck and bus industry in Pakistan.

HinoPak's product range has been designed and built in Hino's traditions of

automotive excellence to be the leader in its category and the main emphasis

has been given to passengers' safety & comfort.

Hinopak also offers a complete in-house facility for designing and building

buses, ambulances, cargo trucks, dumpers, water boozers and a wide range

of specialized superstructures. Unlike small body makers who spray paint the

vehicles, Hinopak actually uses baked paint to give a longer life and better

finish to the vehicles. Even the 36-foot long Rampliners and Roadliner buses

are baked in the gigantic ovens at the Body operations plant.

In the face of growing competition, Hinopak is resolved to achieving total

customer satisfaction by providing quality products at competitive prices and

supported by the best after-sales service in the commercial vehicle market.

This quest for excellence is evidenced by the fact that Hinopak is the only

manufacturer to succeed in exporting complete built-up buses to the Middle

East and African countries.

INSTITUTE OF BUSINESS MANAGEMENT 8

Hinopak delivers only the safest most reliable products and remains the

Pioneer in supplying the largest number of Urban Buses those are

successfully facilitating the commuters of Punjab and Sindh. Hinopak is fully-

equipped to design and manufacture a wide range of Bus Chassis and all

types of Bus Bodies.

Hinopak is the first Pakistani commercial vehicle manufacturer to introduce a

complete range of environment friendly vehicles. It has been especially

developed and designed keeping in mind the rugged terrain in order to meet

the requirements of the diverse Pakistani automobile market.

Hinopak is Pakistan’s first automobile company to

export its buses to Middleast and African countries.

After successfully establishing itself as

the market leader at home, Hinopak

proceeded to explore its product

potential for the export market. This

entry into the export market was an

important milestone for Hinopak and

lead Pakistan into an exciting new era

for the automotive industry, fulfilling

Hinopak’s commitment towards the

economic growth of Pakistan.

The year 2007 marked the year of great success, as Hinopak Motors broke

record in three fields: volume of sales, chassis assembly, and body

fabrication.

Following are the highlights of Hinopak's ongoing achievements,

which make Hinopak Motors Limited the leading manufacturer of

trucks and buses in Pakistan.

• 'Market Leader' in Pakistan/ holding over 65% of the Truck & Bus market

share.

• First Pakistani automobile company & Hino affiliate to receive ISO-9001

certificate in 1997. First automobile company in Pakistan to obtain ISO-

14001 Certification on its Environmental Management system.

• Listed among the "Top 25 Companies" at Karachi Stock Exchange.

• First company to export buses from Pakistan.

• First automotive company to introduce "3S" concept in heavy-duty

commercial vehicles market in Pakistan.

• First company to supply buses under "Urban Transport Scheme" in

Pakistan.

INSTITUTE OF BUSINESS MANAGEMENT 9

• Recipient of Employers Federation of Pakistan's Golden Jubilee Award for

best HR/IR practices.

• Recipient of Corporate Excellence Award from Management Association of

Pakistan.

• Recipient of Employer's Federation of Pakistan's Golden Jubilee Award for

"Excellence in Productivity".

Hinopak has modern plants equipped with advance facilities for vehicle

assembly and fabrication of buses and superstructures. These comprise of

modern paint booths and baking ovens, axle assembly shops, chassis

assembly line, trim line, and engine assembly shop, which strictly adheres to

high Japanese standards. Hinopak also houses a comprehensive engineering

and design section with highly qualified professionals, promising the best

solutions to their wide range of customers' requirements.

Hinopak's product line has three distinct segments i.e.

Trucks/ Buses and Specialized vehicles.

INSTITUTE OF BUSINESS MANAGEMENT 10

INSTITUTE OF BUSINESS MANAGEMENT 11

APPLICATION OF ‘OGSM’ PHILOSOPHY AT HINOPAK

Hinopak uses the OGSM methodology to help build a strategic plan for its

automobile business.

OGSM:

A strategic planning framework that uses a top-down approach to define the

Objective, Goals, Strategies & Measures (OGSM) of their business. The

output is a clear, simple and concise (ONE page) strategic plan:

• Objective: The objective / vision for their business

“Total Customer Satisfaction” a set vision for the company.

The mission of Hinopak Motors Limited is: “To provide the society with safe,

economical, comfortable and environment friendly means of transportation by

manufacturing and supplying commercial vehicles and services.”

• Goals: Translation of their vision into specific goals e.g. turnover,

profit, market share, professional organisation etc.

Hinopak’s goals for year 2009:

• Decrease turn over by 6%

• Increase production by 8%

• Increase sales by 11%

• Strategies & Measures: What strategies (i.e. ‘choices’) will be

necessary in order for you to achieve the goals (& ultimately the vision)

and the specific measures (milestones) used to track progress.

INSTITUTE OF BUSINESS MANAGEMENT 12

To achieve the mission they commit themselves:

To their individual, institutional and international customers: to deliver high

quality, safe, durable, reliable, comfortable, environment–friendly and

economical products and services to their total satisfaction.

To their employees: to foster corporate culture of mutual trust; respect for

fundamental human rights at work; opportunities for professional growth and

personal welfare so that they are proud of being a member of the “Hinopak

Family”.

To the community and the nation: to contribute in economic and social

development by providing means of transportation and by progressive

localization of the vehicles.

To the shareholders: to act in compliance with the norms expected of a

subsidiary of the Toyota Group of companies and make a meaningful

financial return to the shareholders.

The OGSM methodology makes a clear distinction between the ‘business’ and

the ‘organisation’ i.e. people. In this respect, goals, strategies & measures

are developed for both the business and organisation (but united under a

single overall objective).

How Hinopak Develops Its OGSM:

Following the philosophy – helping businesses build themselves – Hinopak’s

OGSM is developed in full partnership with themselves:

• 2 day off site ‘event’ (location & logistics to be decided by client)

INSTITUTE OF BUSINESS MANAGEMENT 13

• On your side: representation from every function of your business

(ideally 10-20 people)

• Full OGSM training provided by The Hinopak Group

• Professional facilitator / moderator from Hinopak

• Post event: full write-up by Hinopak – a ONE page OSGM and

recommended ‘next steps’

Benefits Being Reaped By Hinopak

The primary purpose of an OGSM is to guide their business to long-term

success. An OGSM ensures that they have a medium- to long-term strategic

plan that can guide their short-term choices & targets across their total

business e.g. annual sales targets, brand acquisition strategy / portfolio

rationalisation, investments in the organisation etc.

Hinopak also develops multiple OGSMs that all link to one another. This

ensures their different businesses / divisions (3S Dealership) are united

under a single objective and that cohesive strategies exist between them.

OGSM Next Steps

Many actions emerge following an OGSM, such as:

• Deployment to wider organisation: if deployed efficiently, an

OGSM can unite their whole organisation behind a common business

objective. This helps ensure their people are focused on achieving the

big picture and NOT wasting time on non-value-adding work.

Deployment to their wider organisation could take the form of a

deployment ‘event’, or a series of training workshops.

• Deployment to stakeholders: by sharing their OGSM with key

stakeholders e.g. distribution companies, this allows key influences of

their business to be aware of and be aligned to their objectives and

strategies.

INSTITUTE OF BUSINESS MANAGEMENT 14

• Translation in balanced scorecards: using Kaplan / Norton

methods.

• Development & implementation of measuring tools: some goals

are easy to measure e.g. turnover. For other goals e.g. having a

professional organisation, Hinpak designs and implements effective

measuring tools to track progress. For example, cost-effectiveness of

their methods.

• Re-alignment of organisation: once Hinopak is clear on its

objective, goals and strategies, they review their organisation to align

it fully to the developed OGSM.

A Live Document:

Hinopak believes that an OGSM is a live document and should be reviewed

regularly, i.e. annually. The objective of each review is to take into account

progress and any changes in the macro-environment / consumer trends,

then update the goals, strategies and measures accordingly.

HINOPAK MOTORS LTD. - OGSM: Highly Confidential

OBJECTIVE

Be the leading facilitator of commercial vehicles and services

MEASURES (by 2012

GOALS (by 2012) STRATEGIES

latest)

Markets, Channels,

• 8% profitability Categories - ≥60% revenue from

($11M) Canada and USA

Focus on (key priorities): - Focus on Distribution

• $140m sales Pakistan, USA, and Australia operations

• Serve 250M Focus on distribution - 5 year transition plan in

consumers in Pakistan, Grow retail operations place

Japan, Australia, New Exit non-profitable - 15%-20% CAG

Zealand, Thailand, Communications operations (support focus

Canada, and the US (outsource) specialized vehicles

expansion)

• Be facilitator for Focus on luxury (vs prestige

specialized commercial / mastige) - All catogories ≥ 8%

profitability

INSTITUTE OF BUSINESS MANAGEMENT 15

vehicles Actions to Take

- Identify strategic

-Forge strategic partnership partner

to outsource logistics - All logistics &

-Invest in BIC I.T. warehousing outsourced

operations by end 2009 (except US)

-Improve efficiency by - Automated payment for

leveraging technology collectables / receivables

≥90% cash flow

-Understand the consumer (reduction in cash

handling)

-Invest in market data - 0.5% sales revenue

invested in consumer

-Maintain positive cash flow research

- Build telemarketing unit

-Keep inventory at (200 operators) by Q3

manageable levels 2009

- For key markets

-Drive customer and (Japan, Canada, USA)

consumer satisfaction buy data for all

culture categories worth $30M+

(on-going)

-Build, document, - +ve cash flow with no

implement and review BIC external finance (across

systems & processes group) (on-going)

- Max. 45 stock days

-Drive Hinopak brand (group average)

amongst key stakeholders - All business units to

(NOT consumers) have customer

satisfaction measurement

tools in place by End

2009

- Satisfaction (surveys):

90% “satisfied” or “very

satisfied”

- Key systems &

processes reviewed,

documented &

implemented (trained) by

End 2009

Building the Organization

• Efficient, well trained Invest in training - Corporate Training

and motivated Department in place by

organisation end 2009 (with clear

-Comprehensive overview of deliverables)

evaluation & compensation - Minimum 5 working

system days per year per

employee invested in

training

-Leverage diversity as key - Training plan in place &

competitive advantage tracked for 100%

INSTITUTE OF BUSINESS MANAGEMENT 16

employees

-Create healthy work / life - By mid 2009; clear job

balance descriptions / work plans

and reporting lines for

-Review and live “Hinopak 100% employees

Culture” - New system in place by

End 2009

- Compensation directly

-Invest time in creating linked to performance

well-motivated organization that build the business

AND organization

-Leverage Intranet as a key - 50% local talent / 50%

organizational tool expatriate

- 30% women. At band 5

-Activity build / support the and above (inc. Board

communities in which we level) 2/10 positions

serve filled by women

- Maximum 50 hours

working week

- Culture of “take 100%

holiday entitlement –

undisturbed”

- Hinopak culture –

mission, values,

principles etc. reviewed

and approved by board

(mid 2009)

- All senior management

trained to promote

culture across whole

organisation (Q3 2009)

- Employee survey: key

measures (e.g.

perfection, integrity) top

scores (on-going)

- Job satisfaction

(survey): 90% “satisfied”

or “very satisfied”

- Formalise / standardise

informal rewards &

recognition programme

(end 2009) across group

- BIC Intranet tool that

promotes networking and

learning culture in a

transparent environment

- 2% profits donated to

“charitable causes” /

each legal entity to

support charitable cause

BIC = Best In Class

Hinopak is the leading manufacturer of automobiles

INSTITUTE OF BUSINESS MANAGEMENT 17

MARKET SUMMARY

TARGET MARKET:

1. Institutions:

These are the main customers including:

• Educational centers (universities, • MNCs (Shell, Caltex, Coca Cola).

schools and colleges). • Transport Companies.

• Pakistan Army. • Pakistan Cricket board.

• Pakistan Navy. • Town Municipal Administration.

• Pakistan Air Force. • Police.

• Government. • Water supplying corporations.

• Oil Companies.

Order from Coca Cola Beverages

The quality of the vehicle speaks for itself, &

this is the reason why it has been receiving

repeat bulk orders from various institutions

on regular basis. The Company has received

repeat orders from leading Beverage

manufacturer “Coca Cola Beverages Pakistan

Ltd.”, which placed an order of 57 units of

Beverage carriers on Hino Dutro, Hino

FG1JKPB &Hino SG1JDP, truck models.

These repeat orders demonstrate that

existing customers are benefiting from their

adoption of the Hino technology.

Hinopak Delivers Citiliner buses to Institute of

Management Science

Hinopak recently delivered 02 units of Hino

Citiliner buses to Institute of Management

Sciences, Peshawar. Mr. Faridullah Khan

Manager Sales & Product Support handed

over the buses to Mr. Naseer Ali Khan,

INSTITUTE OF BUSINESS MANAGEMENT 18

Director Institute of Management Sciences, comfortable and durable

Peshawar. vehicles like Hino buses.

Dr. Naseer Ali Khan on the occasion said,

their steady growth now calls for expansion

of their transport fleet, where they will

include high performance, high quality,

Hinopak Delivers Hino Senator Coach to

Pakistan Cricket Board

Recently Hinopak delivered Hino

Senator Coach to Pakistan Cricket

Board. The handing over ceremony

of one of these Coaches was held

at National Cricket Stadium,

Karachi. Mr. Mohsin Khan, regional

GM Sindh, PCBreceived the

symbolic key of the vehicle from

Mr.M. Irfan Shaikh, Director Sales

& Marketing.

Order of 10 units of Hino Dutro from TMA, Bin

Qasim

In order to tackle the problem of lasting vehicles will fulfill the

solid waste management demanding task of solid waste

TMA(Town Municipal management in an economical and

Administration) Bin Qasim has efficient manner.

recently placed the order of 10

units of Dumpers on Hino Dutro

Truck Chassis. The Hino Dumper

trucks have been supplied in a very

short time to meet the customer’s

urgent requirement. These

dumpers are specially designed to

carry maximum load and are able

to maneuver in congested and

narrow roads. The robust and long

Repeat Order from Punjab Police

Recently Punjab Police placed an optimum price in previous order,

order of 10 units of Troop Carrier high quality units delivered well in

on Hino DUTRO chassis. The above time and the best product service.

order was awarded to Hinopak

because of the performance and

INSTITUTE OF BUSINESS MANAGEMENT 19

2. Individuals:

The individual customers buy the product to earn money directly by

operating their product. It is their main business.

MARKET NEEDS:

Pakistan is a nation with a diverse economy that includes textiles, chemicals,

food processing, agriculture and other industries. It is the 25th largest

economy in the world.

Approximately 49% of adults are literate, and life expectancy is about 64

years. The population, about 168 million in 2007, is growing at about 1.80%.

Bus is a relatively cheap and easy method of transport, with services run by

both public and private companies.

With the rebuilt of national highways, construction of Makran Coastal

Highway, the construction of Motorways such as M1, M2, M3 etc, grew the

demand of buses and trucks for transportation and commercial purposes.

MARKET TRENDS:

Mobility has been an important objective for mankind since the beginning of

time. The invention of the wheel about the year 3000 B.C. was the first great

achievement. Then in the 18th century the steam engine, one of the greatest

gifts of the Industrial Revolution made a major impact on the life-style of the

human race. The mating of the 'wheel' with the 'engine' made it possible to

transform animal driven carriages into automobile.

From the 18th century to the 20th century the history of the automobile is a

tale of human ingenuity and passion for comfort, fastness, safety and a

better quality of life.

Heavy truck demand is driven by growth in the agriculture,

manufacturing, construction, and retail sectors. Bus demand is driven by

growth in the number of school-aged children and investment in public

transportation systems. The industry is capital-intensive.

INSTITUTE OF BUSINESS MANAGEMENT 20

MARKET GROWTH:

In the year ended December 31, 2007 Hinopak made the highest ever profit

in its history. The production and sales revenue have also been the highest.

While the sale of locally manufactured trucks declined nationally, Hinopak

was able to claim a larger share in the reduced numbers.

National Sales:

The national growth in Large Scale Manufacturing in 2007 fell to 8% from 9%

in 2006 and an average of 11.6% over the last five years. In the automotive

sector it fell more steeply. In 2007, it grew only by 3.8% against the five-

year average of 25.8%.

The increased freight movement because of growth in industrial production

and exports had substantially increased the demand for trucks in recent

years. The benefit of this increase however all went to the second-hand or

illegally imported (later regularized) heavy and medium duty trucks. The sale

of locally produced trucks of this category in 2007, ironically, fell to

2544units from 3154 in2006. The sale of light duty trucks however increased

from 1404 to 1554.

INSTITUTE OF BUSINESS MANAGEMENT 21

The sales of buses increased by 16% from 928 in 2006 to 1078 in 2007 as

the sales tax was reduced to zero towards the end of 2006. However, it still

fell considerably short of the level of 2004 when1411 buses were sold. The

bus sales, it seems, will remain depressed till the time the second-hand

imports are altogether stopped and the policy incentives for urban transport,

under consideration since long, are announced by the federal and provincial

governments.

INSTITUTE OF BUSINESS MANAGEMENT 22

INSTITUTE OF BUSINESS MANAGEMENT 23

OUR RECOMMENDATION TO HINOPAK TO USE “JIT

MANUFACTURING”

Just-in-time (JIT) manufacturing is a way of managing manufacturing

systems that could reduce waste, and lower cost, thus increasing profit. In

its most basic explanation and principle JIT is every component in the

manufacturing system arriving just in time for it to be used. Since the

products arrive just in time there is no need for stock holding facilities of any

kind. The most common industry using JIT manufacturing is the automobile

industries. Therefore, it’s advisable for Hinopak as well to apply JIT principle

in its production system.

The following are more specific areas that could be corrected to improve

efficiency:

• overproduction - waste from producing more than is needed

INSTITUTE OF BUSINESS MANAGEMENT 24

• time spent waiting - waste such as that associated with a worker being

idle whilst waiting for another worker to pass him an item he needs

(e.g. such as may occur in a sequential line production process)

• transportation/movement - waste such as that associated with

transporting/moving items around a factory

• processing time - waste such as that associated with spending more

time than is necessary processing an item on a machine

• inventory - waste associated with keeping stocks

• defects - waste associated with defective items"

Objectives

An overall objective is to limit resources used in the manufacturing system

to only those needed. There are six other objectives that are a key part to

obtain the overall objective.

• The first is to optimize each individual step of the manufacturing

system. In other words make part as efficient as possible to get the

most from the least.

• Second is to make a product with no flaws or defects. This ensures

that each part of the production line will go as planned.

• Third is to reduce the manufacturing cost, the cheaper it is to make

the product the larger the profit for the company.

• Fourth is to make a product that is demanded by consumers. If there

is no demand then there is only money lost.

• Fifth there needs to be flexibility in the system. Things will not always

go as planned and there needs to be a flexible enough system so that

it can be modified easily.

• Sixth, there needs to be a strong and reliable relationship between

customers and suppliers. Since JIT technique has virtually no extra

stock or materials the companies need to rely on each other to be

reliable and on time.

These objectives need to be taken into consideration by Hinopak to

integrate JIT, and are crucial to being successful in the integration.

Keys to Implementation and Integration

Just-in Time manufacturing is difficult to setup because each company

needs to personalize for their type of company to fit their specific needs.

Although many companies seek help from consultant firms for the difficult

task ahead, there are many key points that they can address themselves.

Changing over the current output production in the company’s factories to

limited or constant quantity is a good start in the process to determine

exactly how many resources are going into making a certain amount of

products. Setup time is an issue that each company can look to improve its

INSTITUTE OF BUSINESS MANAGEMENT 25

efficiency. A good rule is to be able to change the setup in a single digit time

frame. Schedule meetings on a regular basis with the workers to gather

information on problems as well as possible solutions, and other suggestions.

This will make the workers feel involved in the implementation, and may

result in a positive attitude about the change over. This could mean

redesigning several areas such as the product or the process itself. Once a

reduced setup time is achieved the system now has the ability to more

efficiently produce smaller batches of products. However, this will require

deliveries of materials to be more often. Reducing time in between the

transportation of the individual parts can also improve the efficiency. To

accomplish this, work stations can be moved closer together. As well as the

amount of time a part is waiting to be processed at an individual station can

be lowered. Finding a supplier closer to the factory or convincing one to

relocate closer will also reduce lead time. Using down time is also another

way to help with productivity and efficiency. While a worker or machine is

waiting for other parts of the system to be used maintenance can be

performed on the machinery. This makes the most of the workers time and

can help to prevent future breakdowns do to lack of maintenance. Provide

the workers with more responsibilities and training. This can include training

on several machines, ability to maintain the machines, and perform correct

inspection. This will make the companies work force more versatile and can

help with issues of absences. Although the kanban system is not required in

a JIT system it is a good organizational tool to help eliminate

misunderstandings and increase communication. These points are things the

company can control and improve to help the successful integration of the

JIT system.

Suppliers

Since JIT is a stockless production and does not allow room for defects or

error having trustworthy reliable suppliers is an important factor. When

choosing a reliable supplier, consider their location and prior occurrences

with labor issues such as strikes. Once a reliable supplier is found, creating a

good relationship is the next step. This is a two way relationship in that both

the company and supplier get some positive out of it. The company gets

products or material with no errors or defects, a quality partnership, and gets

everything on time according to delivery schedules. Also the supplier must

have a back-up plan incase for emergencies such as strike, weather

conditions, and any other problem that many arise. The supplier gets a long

term contract, constant demand for their product, and a good constant

price.

INSTITUTE OF BUSINESS MANAGEMENT 26

Advantages

There are many advantages of that Hinopak can receive from JIT. Listed

below are some of the advantages:

• Possible increase in profits

• Quality products

• Quicker setup

• Eliminates costs of storage facilities

• More flexible employees

• Quality relationships with suppliers

• Elimination of waste

• No down time

Disadvantages

Although the advantages outweigh the disadvantages, the disadvantages

can have a negative effect on the company. Listed below are some of the

disadvantages:

• Long term commitment

• Possible large initial cost with no short term returns

• Problems with supplier can cost company large amounts of money

• Risk of never successfully implementing JIT

Conclusion

Just-in-time manufacturing can be a positive influence on Hinopak.

However there are many risks associated with attempting to implement JIT

manufacturing techniques. When looked at it appears to be a very simple,

quick, and easy thing to do. In reality it is a very complicated technique that

takes long term commitment and a initial cost with no guarantee of success.

If implemented successfully it would eliminate waste, make the company

more productive and more efficient. It does this through shorter

transportation and increased communication. Although there are many

companies that are successful, many companies are not. Even though there

are enormous risks many still consider implementing JIT for it many

advantages.

INSTITUTE OF BUSINESS MANAGEMENT 27

MARKET SEGMENTATION

Hinopak’s customers:

Those people who are looking to make money by operating their product.

Like CNG bus owner will buy CNG bus from them because this bus will carry

INSTITUTE OF BUSINESS MANAGEMENT 28

passengers from one point to another and thus earn money through fares

charged to the passengers.

They have done Behavioral Segmentation. Unlike cars these Buses and

trucks are very expensive. They are bought when there is a special need on

special requirement. It is basically a Procedural segmentation. When there is

a need, customers come to them with different requirements. The Sales force

attracts them and then the customers usually give their specifications and

the structure they want on the chassis. For e.g. a customer might want a

High wall trailer built on FM2PKPA 6X4 Prime mover but with changes in

standard specification.

TWO TYPES OF CUSTOMERS

1. Institutional Customers:

Description:

These are the main customers. They include Pakistan Army, Pakistan Air

Force, Pakistan Navy, Shell, Total, Caltex, City District Government

Karachi, NED, KU, CNG Bus owners and others.

Behavior: These are the customers who buy in Bulk.

They want to add buses to their fleet. For e.g. CNG bus owner

would like to add new CNG buses to his existing fleet.

These customers have different specifications, deals, and different sort

of requirements which is required by their business.

They buy products with customized body. For e.g. some client might

need bowzer with high density.

Special attention is paid to these customers as they buy in bulk

and buying effects their business.

Deliveries are made over a period of time as it requires time to

complete the paperwork, and then assemble the product according to the

demand of the customers. Delivery depends upon who came first and the

number of trucks or buses already in the queue for the production.

What they want and the use of product:

INSTITUTE OF BUSINESS MANAGEMENT 29

The institutional customers buy the product to earn money indirectly by

operating their product. In other words it helps them in their main line of

business.

Reliability & Availability

Customers look for reliability and availability of parts.

The auto parts should be easily available in the market and they

should be able to get service in remote areas.

Objective:

The objective of customers while buying the product is that the cost

should be minimal, the product should be helpful in overall business and

the most important factor is that the operating cost should be low. Also

the initial cost should be low.

Price sensitivity:

Institutional clients are more price sensitive then the individual clients.

You cannot dictate them. The product has to be very good. 80% of the

times customers demand low price and they are looking for lowest tender.

Percentage (%) of sales:

The sales of Hinopak overall increased in the past. The ratio of Institutional

to Individual customers is 80-20 %. As in past the purchases of Institutional

customers increased with the increase in purchases of the government and

the armed forces.

But in the past few months the ratio has changed to 60-40%. This is because

of the increase in the purchase of individual customers and the decline in

government purchases due to political instability. The government is not

building infrastructure as it was in the past. Therefore, they are buying less.

So the sale to this segment, i.e. Institutional customers, is 60-65% of the

total sales.

As in September 2008 Hinopak sold 149 trucks, 89.4 trucks (estimated as

60% of 149) were sold to institutional customers.

Also because of the high inflation all the customers are holding money and

thus the sales of the industry has declined as buying of such vehicles is not

everyday task and involves high investment.

2. Individual Customers:

Description:

INSTITUTE OF BUSINESS MANAGEMENT 30

Dealers, people who want to make money while using the product.

What they want:

The customers in this segment want a product which is profitable. They

look for profitability of the product.

Operating cost should be less.

The auto parts should be easily available in the market and they

should be able to get service in remote areas.

Service:

Hino has specialized mechanics and they are given free training as well

paid training. These mechanics come for training to Hinopak from all

over Pakistan. Since the service is available to customers everywhere in

Pakistan, so customers are happy.

Loading capacity:

The capacity a truck/ bus can carry is also an important factor which is

influencing the customers. As we know that the public Buses

everywhere in city are overloaded and this also happens in the case of

trucks that they are over loaded. So the customers do look for trucks

which have high loading capacity as well as it can take overload.

A product which has a high resale value and can be easily sold.

Use of product:

The individual customers buy the product to earn money directly by

operating their product. It is their main business. They buy these products

for commercial use.

Objective:

The objective of customers while buying the product is that it is profitable

as the use of the product is to make profit out of it by running it,

customers look for profitability. They look for Operating cost. It should be

less.

Percentage (%) of Sales:

The ratio of Institutional to Individual customers is 80-20 %. But due to

decrease in buying of institutional customers as well as the increase in

purchasing of individual customers, who buy from authorized dealers, the

sales ratio has changed to 60-40% recently. This was the ratio some

years back. For example, the sales of trucks in September ’08 were 149

so approximately 60 trucks were sold to individual customers.

Selling Strategy:

INSTITUTE OF BUSINESS MANAGEMENT 31

The selling is done by using the advantage Hino has in the market of being

the market leader and the favorable opinion market has about the products

of Hino.

As the brand image is big, the company uses it in selling the product. Hino is

known for its reliability and availability. They use this image in selling their

product.

Also, the goodwill is high. They have free service camps in which they give

service free of cost to the customers; they are given free oil change and a

new filter. A new filter usually cots around Rs.7000. so it’s a big thing for the

customers.

The price of Hino’s products are relatively higher than their competitors, this

is because their product is of good quality. They easily use this image. The

quality of the competitor’s products is lower mainly because they sell low

quality products

COMPETITIVE ANALYSIS

July'08 Aug'08 Sep'08 Cumulative

Prod. 209 133 155 497

Hino

Sale 180 176 149 505

TRUCKS

July'08 Aug'08 Sep'08 Cumulative

Prod. 209 133 155 497

Hino

Sale 180 176 149 505

Prod. 116 48 54 218

Nissan

Sale 79 34 11 124

Prod. - - - -

Dong Feng

Sale - - - -

Prod. 99 27 26 152

Master

Sale 48 41 24 113

Prod. 68 35 23 126

Isuzu

Sale 40 36 15 91

BUSES

July'08 Aug'08 Sep'08 Cumulative

Hino 84 54 12 150

INSTITUTE OF BUSINESS MANAGEMENT 32

41 64 43 148

- - - -

Nissan

- - - -

- - - -

Dong Feng

- - - -

- - - -

Master

- - - -

24 6 18 48

Isuzu

11 2 1 14

Prod. 108 60 30 198

TOTAL BUSES

Sale 52 66 44 162

ANNUAL PLANT CAPACITY

TRUCK

Hinopak Motors Ltd. 10,000

Ghandhara Industries Ltd. 3,000

Sind Engineering Ltd. 3,000

VPL Limited 500 ****

Master Motor Corporation Ltd. 8,050

BUS

Hinopak Motors Ltd. 2,000

Sind Engineering Ltd. 1,000

Ghandhara Industries Ltd. 1,800 ***

Ghandhara Nissan Ltd. -

Capacity Planning at Hinopak

INSTITUTE OF BUSINESS MANAGEMENT 33

Process Flowchart

APPLICATION OF TOTAL QUALITY MANAGEMENT AT

HINOPAK

1. Pursuing New Strategic Thinking

INSTITUTE OF BUSINESS MANAGEMENT 34

First in commercial vehicles sector to start the establishment of 3S

Dealership network, which offers Sales, Service and Spare parts facilities all

under one roof. This comprehensive network of offices, 3S Service Dealers

and Spare parts Dealers are strategically located throughout the country.

Hinopak's product line has three distinct segments i.e. Trucks/ Buses and

Specialized vehicles.

2. Knowing their Customers

Big vehicles, like trucks and buses, are bought when there is a special need

on special requirement. Hinopak basically has Procedural segmentation.

When there is a need, customers come to them with different requirements.

3. Setting True Customer Requirements

Customers have different specifications, deals, and different sort of

requirements which is required by their business.

Sales force attracts customers and then the customers usually give their

specifications and the structure they want on the chassis. For e.g. a customer

might want a High wall trailer built on FM2PKPA 6X4 Prime mover but with

changes in standard specification.

4. Concentrating on Prevention, Not Correction

Unlike small body makers who spray paint the vehicles and then later receive

numerous customer complaints, Hinopak actually uses baked paint to give a

longer life and better finish to the vehicles.

5. Reducing Chronic Waste

Hinopak Motors Ltd. has reduced its chronic waste by 18% and as a result its

annual plant capacity has increased to 10,000

6. Pursuing a Continuous Improvement Strategy

Hinopak’s approach to continuous improvement:

“The best approach is to dig out and eliminate problems where they are

assumed not to exist.”

7. Using Structured Methodology for Process Improvement

Hinopak believes in using structured methodology for process improvement.

Improvement efforts in Hinopak generally focus on improving process

INSTITUTE OF BUSINESS MANAGEMENT 35

productivity, quality, and cycle time. Intangible customer needs (ease of use,

trust, etc.) are quantified, Critical Success Factors (CSFs) are determined,

and performance is evaluated. The process is mapped and quality issues are

examined. Brainstorming is used to resolve issues, eliminate non-value

added activities, and reduce cycle times. Action plans are developed for high

priority recommendations..

Hinopak applies After-Action Review (ARR) process for continuous

improvement, which is actually Lean Six Sigma (LSS) in disguise.

INSTITUTE OF BUSINESS MANAGEMENT 36

8. Reducing Variation

Hinopak follows the following steps in reducing its undesirable variations

Some Changes to Focus On

• Eliminate Waste

o Remove any activity or resource in the organisation that does not add

value to an external customer/patient

• Improve Work Flow

o This is an important way to improve the quality of service provided by

any process

INSTITUTE OF BUSINESS MANAGEMENT 37

• Stock Control

o Stock of all types is a possible source of waste; understanding where

stock is stored is the first step in finding opportunities for improvement

• Focus on Variation

o Reducing variation improves the predictability of outcomes and

reduces the frequency of poor results

We suggested Hinopak to use PDSA cycle for testing a change.

Once a team has set an aim, established its membership, and developed

measures to determine whether a change leads to an improvement, the next

step is to test a change in the work setting

• The Plan-Do-Study-Act (PDSA) cycle is shorthand for testing a change

• This is a scientific method for action-oriented learning

Reasons to Test Changes

• Increase your belief that the change will result in improvement

• Decide which of several proposed changes will lead to the desired

improvement

• Evaluate how much improvement can be expected

• Decide whether the proposed change will work in the real world

• Decide which combinations of changes will have the desired effects on

the important measures of quality

• Evaluate costs, social impact, and side effects

• Minimise resistance upon implementation

PDSA CYCLE

The "Plan-Do-Study-Act" (PDSA) cycle is shorthand for testing a change — by

planning it, trying it, observing the results, and acting on what is learned.

This is the scientific method, used for action-oriented learning.

Use of PDSA cycles is a way of testing an idea by putting a change into effect

on a temporary basis and learning from its potential impact. This approach is

quite different from the approach traditionally used in healthcare settings,

where new ideas are often introduced without sufficient testing.

A PDSA cycle involves testing change ideas on a small scale. By building on

the learning from these test cycles in a structured and incremental way, a

new idea can be implemented with a greater chance of success.

INSTITUTE OF BUSINESS MANAGEMENT 38

There are four stages to a PDSA cycle:

Step 1: Plan

Plan the test or observation

• State the objective

• Make predictions about what will

happen and why

• Develop a plan to test the change.

(Who? What? When? Where?)

Step 2: Do

Try out the test on a small scale

• Carry out the test

• Document problems and

unexpected observations

• Begin analysis of the data

Step 3: Study

Set aside time to analyse the data and study the results

• Complete the analysis of the data

• Compare the data to your predictions

• Summarize and reflect on what was learned

INSTITUTE OF BUSINESS MANAGEMENT 39

Step 4: Act

Refine the change, based on what was learnt

from the test

• Determine what modifications should be made

• Prepare a plan for the next test

9. Using a Balanced Approach

We also suggested Hinopak to use a balanced

approach by using two systems for improvement.

Two Systems for Improvement

Both the Lean and the Six Sigma methodologies have proven that it is

possible to achieve dramatic improvements in cost, quality and time by

focusing on process performance. Whereas Six Sigma focuses on reducing

variation and improving process yield by following a problem-solving

approach using statistical tools, Lean is primarily concerned with eliminating

waste and improving flow by following the Lean principles and a defined

approach to implement each of these principles. However, using either one of

them alone has limitations: Six Sigma will eliminate defects but it will not

address the question of how to optimize process flow; and the Lean principles

exclude the advanced statistical tools often required to achieve the process

capabilities needed to be truly 'lean'. Most companies embarking on Lean and

Six Sigma create their own combination - picking and choosing which

elements to emphasize. However, we suggest Hinopak to embrace the basic

methodology of each system.

Six Sigma (6σ)

"This big myth is that Six Sigma is about quality control and statistics. It is

that - but it's much more. Ultimately, it drives leadership to be better by

providing tools to think through tough issues. At Six Sigma's core is an idea

that can turn a company inside out, focusing the organization outward on the

customer."

A process that is in Six Sigma control will produce no more than two defects

out of every billion units. Six Sigma uses many statistical tools but applies

them in a clear 5 stage project oriented cycle: Define, Measure, Analyze,

Improve, Control (DMAIC). Tools used in the Six Sigma approach include

Flow charts, Run charts, Pareto charts, Check sheets, Cause and effect

diagrams, Opportunity flow diagrams, Control charts, Failure mode and effect

analysis, Design of experiments

INSTITUTE OF BUSINESS MANAGEMENT 40

Lean

Lean is aimed at the elimination of waste in every area of production

including customer relations, product design, supplier networks and factory

management. Its goal is to incorporate less human effort, less inventory, less

time to develop products, and less space to become highly responsive to

customer demand while producing top quality products in the most efficient

and economical manner possible. The keys to Lean are understanding where

the value in your process lies, identifying all non value adding activities as

waste and devising plans to remove the waste from the process.

Flowcharting is a core tool of Lean - as flowcharting provides a visual image

of a process enabling waste identification to take place. This flowcharting is

known as value stream mapping. Lean considers that there are 7 wastes -

Defects, Overproduction, Transportation, Waiting, Inventory, Motion, and

Processing (DOTWIMP). The worst of all the 7 wastes is overproduction

because it includes in essence all others and was the main driving force for

the Toyota JIT system Ohno and Shingo were smart enough to tackle this

one to eliminate the rest.

| Project Management | Play Factory

INSTITUTE OF BUSINESS MANAGEMENT 41

10. Apply to All Functions

We then recommended Hinopak to apply Continuous improvement strategy,

PDSA cycle, Six sigma and Lean to all functions in order to maintain lifetime

competitive edge in the market place.

SWOT ANALYSIS

HELPFUL HARMFUL

(to achieving objectives) (to achieving objectives)

I STRENGTHS WEAKNESSES

N • Hinopak has 65% market share.

It is already at the pinnacle.

• Has from beginning been

expanding company. In current

an

T •Listed among the "Top 25

Companies" at Karachi Stock

environment it must adapt to

consolidating.

E Exchange.

• Small variations in certain vehicle

• The only Pakistani manufacturer

R to succeed in exporting

models make them redundant and

unnecessary.

completely built-up buses to

N Middle East and Africa.

• Not enough focus for specialized

A • Highly acclaimed for quality and

technological excellence.

vehicle department.

L • Environment friendly low emission

standard engines EURO engines

produced.

• Highly developed state of the art

Technical training centre ranging

O from mechanics to managers.

• 3S Dealership network, which

R offers Sales, Service and Spare

parts facilities all under one roof.

I • First Pakistani automobile

G company & Hino affiliate to

receive ISO-9001 certificate in

1997.

I • Hinopak has modern plants

N equipped with advance facilities

for vehicle assembly and

fabrication of buses and

superstructures.

INSTITUTE OF BUSINESS MANAGEMENT 42

E OPPORTUNITIES THREATS

X

• With infrastructure already in • Oil price fluctuation makes

T place, branching out into other production forecast risky.

E products might be advisable to

R offset low vehicle consumption. • World Economy recession makes

N business tighter than usual.

• Buy other manufactures at low

A cost while economic situation is • Multinationals leaving Pakistan

L gloomy to increase market share. decreasing potential business.

• Construction of China Corridor

O karakoram highway. Highway

R which links China to middle east

I through GWADAR port.

G

I

N

Customer Relationship Management

Organize and make accessible a database of information on individual

customer needs, preferences, contacts, purchase frequency, and satisfaction.

Example: Contact customers every time a new product launch, feature

enhancement, or upgrade is undertaken in a vehicle

Make it easy for customers to reach appropriate company personnel and

express their needs, perceptions and complaints

Customer Relationship Management enables real-time availability checks,

contract management, billing management, fulfillment visibility, and order

tracking, giving the company the features and functions necessary for

marketing planning, campaign management, telemarketing, lead generation,

and customer segmentation. In addition, CRM allows Hinopak to offer

ongoing customer care across all channels – with a customer-interaction

center, Web-based customer self-service capabilities, service and claims

management, field service and dispatch, and installed-base management.

INSTITUTE OF BUSINESS MANAGEMENT 43

CRM helps the business:

• Provide better customer service

• Make call centers more efficient

• Cross-sell products more effectively

• Have sales staff close deals faster

• Simplify marketing and sales

processes

• Discover new customers

• Increase customer revenues

Customer Relationship Management goes

beyond sales, marketing and customer-service applications into business

intelligence, analytics, hosted applications, mobile capabilities and much

more! By thinking more insightfully about what the customers are worth, the

company can focus its resources on attracting and keeping the right type of

customers. This focus, in turn, will make the CRM efforts more productive

and position the company better for innovation and growth.

INSTITUTE OF BUSINESS MANAGEMENT 44

RECOMMENDATION TO APPLY GEMBA AT HINOPAK

Five Golden Rules of Gemba:

Golden Rule One: When a problem (abnormality) arises, go to gemba first'.

So what's gemba? It's the shop floor, or equivalent. Once there, you apply

Rule Two.

Golden Rule Two: check with gembutsu (relevant objects).

Golden Rule Three: take temporary counter-measures on the spot.

Golden Rule Four: find the root cause.

Golden Rule Five: standardise to prevent recurrence.

Standardisation is the managing part of getting good gemba. Hinopak also

needs good housekeeping (that includes cleaning machines) and muda, the

elimination of waste.

To be truly efficient in operations, Hinopak must GO TO GEMBA!

The aim of TPS is to eliminate all muri, mura, muda (overburden,

unevenness, waste) from the operations. It is a system that uses the PDCA

approach to involve everyone in solving problems and improving quality,

cost, delivery, safety, and morale.

INSTITUTE OF BUSINESS MANAGEMENT 45

TPS continues to evolve today. Toyota people are beginning to call TPS the

"Thinking People System" instead of the Toyota Production System. TPS is

always improving.

TPS is the Operational Blueprint for a Lean Enterprise

The organizations that have implemented Lean most successfully have

adopted TPS as their operational blueprint. They have studied

and understood the system, renamed it to take ownership of it as their own

system, and adopted as pure a form of TPS as possible

• Make what the customer needs, when it is needed, and in the right

amount

• Minimize inventories

• Separate machine work from human work and fully utilize both

• Build quality into the process and prevent errors from happening

• Reduce lead-times to allow for rapid, flexible scheduling

• Produce a high mix of low volume products efficiently

The GRPS house shows how to build a world class production system that

continuously improves by eliminating waste.

Just-in-Time (Takt-Flow-Pull)

Left Pillar Eliminate the 7 Wastes of Production

Create a smooth flow of product and information,

minimize inventory and space.

Jidoka (Autonomation)

Build quality into the process, separate man &

Right Pillar machine using intelligent automation.

Implement low-cost automation, error-proofing,

equipment upgrades and reliability improvement.

Heijunka (Leveling)

Foundation Stabilize production schedule variability

Reduce total Lead-time, coordinate sales,

scheduling, and customer needs

INSTITUTE OF BUSINESS MANAGEMENT 46

OUR RECOMMENDATION TO HINOPAK TO APPLY Malcolm

Baldrige Criteria for Performance

The Baldrige Criteria for Performance Excellence provide a systems

perspective for understanding performance management. They reflect

validated, leading-edge management practices against which Hinopak will be

able to measure itself. With their acceptance nationally and internationally as

the model for performance excellence, the Criteria represent a common

language for communication among organizations for sharing best practices.

The Criteria are also the basis for the Malcolm Baldrige National Quality

Award process.

If Hinopak applies for the Baldrige Award, it will be judged by an independent

board of examiners. Recipients will be selected based on achievement and

improvement in seven areas, known as the Baldrige Criteria for

Performance Excellence:

1. Leadership: How upper management leads the organization, and how

the organization leads within the community.

2. Strategic planning: How the organization establishes and plans to

implement strategic directions.

3. Customer and market focus: How the organization builds and

maintains strong, lasting relationships with customers.

4. Measurement, analysis, and knowledge management: How the

organization uses data to support key processes and manage

performance.

5. Human resource focus: How the organization empowers and

involves its workforce.

6. Process management: How the organization designs, manages and

improves key processes.

7. Business/organizational performance results: How the

organization performs in terms of customer satisfaction, finances,

human resources, supplier and partner performance, operations,

governance and social responsibility, and how the organization

compares to its competitors.

We designed a Self-Analysis worksheet for Hinopak, which it can use to

assess itself after adopting Baldrige Criteria for Performance

INSTITUTE OF BUSINESS MANAGEMENT 47

SELF-ANALYSIS WORKSHEET FOR HINOPAK

While insights gained from external Examiners or reviewers are always

helpful, you know your organization better than they will. You are currently

in an excellent position to identify your organization’s key strengths and key

opportunities for improvement (OFIs). Having just completed your responses

to the Baldrige Criteria questions, you can accelerate your improvement

journey by doing a self-analysis of your responses to all seven Criteria

Categories using this worksheet.

Start by identifying one or two strengths and one or two OFIs for each

Criteria category. For those of high importance, establish a goal and a plan of

action.

For High-Importance Areas

Importance

Criteria (High, Stretch

Category Medium, (Strength) or What Action Who Is

Low) By When?

Improvement Is Planned? Responsible?

(OFI) Goal

Category 1—Leadership

Strength

1.

2.

OFI

1.

2.

Category 2—Strategic Planning

Strength

1.

2.

OFI

1.

2.

Category 3—Customer Focus

Strength

1.

2.

INSTITUTE OF BUSINESS MANAGEMENT 48

For High-Importance Areas

Importance

Criteria (High, Stretch

Category Medium, (Strength) or What Action Who Is

Low) By When?

Improvement Is Planned? Responsible?

(OFI) Goal

OFI

1.

2.

Category 4—Measurement, Analysis, and Knowledge Management

Strength

1.

2.

OFI

1.

2.

Category 5—Workforce Focus

Strength

1.

2.

OFI

1.

2.

Category 6—Process Management

Strength

1.

2.

OFI

1.

2.

Category 7—Results

Strength

1.

INSTITUTE OF BUSINESS MANAGEMENT 49

GRADING OUR PM INC. SUBSIDIARY BASED ON MBNQA

We, four members, worked as a team and came up with valuable

recommendations for Hinopak what will assist the company have a life time

competitive edge in the marketplace.

This is how we grade our PM Inc. subsidiary based on MBNQA:

Points

S.No Category Description

Out Of Obtained

1. Category 1 Leadership 120 110

2. Category 2 Strategic Planning 85 80

Customer and Market

3. Category 3 85 83

Focus

Measurement,

Analysis, and

4. Category 4 Knowledge 90 85

Management

Human Resource

5. Category 5 85 80

Focus

6. Category 6 Process Management 85 80

7. Category 7 Business Results 400 390

INSTITUTE OF BUSINESS MANAGEMENT 50

Das könnte Ihnen auch gefallen

- Technology Transfer A Complete Guide - 2020 EditionVon EverandTechnology Transfer A Complete Guide - 2020 EditionNoch keine Bewertungen

- The Beginning of A New Chapter in India's Automotive Saga: Vikas Tiwari Pradeep VermaDokument11 SeitenThe Beginning of A New Chapter in India's Automotive Saga: Vikas Tiwari Pradeep VermaSiddharth GhorpadeNoch keine Bewertungen

- Hazard identification and risk assessment formDokument3 SeitenHazard identification and risk assessment formusman4428Noch keine Bewertungen

- Failure Mode and Effects Analysis (Quality Risks Analysis) FormDokument16 SeitenFailure Mode and Effects Analysis (Quality Risks Analysis) FormgaziahmadNoch keine Bewertungen

- Context of The Organization 4.1. Understanding The Organization and Its ContextDokument2 SeitenContext of The Organization 4.1. Understanding The Organization and Its ContextSelvaraj SimiyonNoch keine Bewertungen

- To Regionalize or Not Optimizing North American Supply ChainsDokument8 SeitenTo Regionalize or Not Optimizing North American Supply ChainsRaúlNoch keine Bewertungen

- Mostafa Mahmoud Soliman CV - March 2023Dokument5 SeitenMostafa Mahmoud Soliman CV - March 2023Mustafa Mahmoud MatarNoch keine Bewertungen

- Retail Store Manager Operations in Modesto CA Resume Catherine BaileyDokument1 SeiteRetail Store Manager Operations in Modesto CA Resume Catherine BaileyCatherineBaileyNoch keine Bewertungen

- Honda Motor CoDokument8 SeitenHonda Motor Cowe are IndiansNoch keine Bewertungen

- Pharmaceutical Industry AnalysisDokument3 SeitenPharmaceutical Industry AnalysisAmeet DaulatNoch keine Bewertungen

- INTERNSHIP REPORT On LatherDokument52 SeitenINTERNSHIP REPORT On LatherSub 1Noch keine Bewertungen

- Sessions EventsDokument459 SeitenSessions Eventspassion777Noch keine Bewertungen

- Novita Wahyu Setyawati (1957-1970) PDFDokument14 SeitenNovita Wahyu Setyawati (1957-1970) PDFvishu_kaNoch keine Bewertungen

- UNIT-II (HR Policies & Strategies)Dokument36 SeitenUNIT-II (HR Policies & Strategies)monika sharmaNoch keine Bewertungen

- Tata MotorsDokument20 SeitenTata MotorsABHISHEK SHARMANoch keine Bewertungen

- DS-16 Capacity-Analysis (Ford Authorized) CAR-5.6Dokument12 SeitenDS-16 Capacity-Analysis (Ford Authorized) CAR-5.6Ahmet SonerNoch keine Bewertungen

- Sample - Global Expanded Polystyrene (EPS) Market - Mordor IntelligenceDokument30 SeitenSample - Global Expanded Polystyrene (EPS) Market - Mordor IntelligenceEnoch Aaron R'GasanaNoch keine Bewertungen

- Fishbone Diagram by YumnaDokument2 SeitenFishbone Diagram by YumnaYumna JawedNoch keine Bewertungen

- Ilovepdf Merged PDFDokument25 SeitenIlovepdf Merged PDFSf BztprkNoch keine Bewertungen

- Strategic MGT MbaDokument80 SeitenStrategic MGT MbaBenard NyakwebaNoch keine Bewertungen

- Application of Value Stream Mapping in Waste Minimisation PDFDokument23 SeitenApplication of Value Stream Mapping in Waste Minimisation PDFSaurav NegiNoch keine Bewertungen

- FDA-ISO QMS Audit Checklist GreenlightDokument3 SeitenFDA-ISO QMS Audit Checklist Greenlightada wangNoch keine Bewertungen

- PESTLE AnalysisDokument13 SeitenPESTLE AnalysisAlzen Marie DelvoNoch keine Bewertungen

- Assignment1 DBA AgilityDokument10 SeitenAssignment1 DBA Agilityأدهم صبريNoch keine Bewertungen

- Environment & AnalysisDokument91 SeitenEnvironment & AnalysisSudeep RegmiNoch keine Bewertungen

- A Report ON Bharti Airtel: Understanding Distribution Issues With AirtelDokument10 SeitenA Report ON Bharti Airtel: Understanding Distribution Issues With AirtelArpita Sharma100% (5)

- Swot and PestelDokument12 SeitenSwot and PestelRuchaNoch keine Bewertungen

- Gati - Gati KWE Corporate Presentation - 2019Dokument23 SeitenGati - Gati KWE Corporate Presentation - 2019Bikash Kumar DashNoch keine Bewertungen

- Pakistan Tobacco Company: Internship ReportDokument22 SeitenPakistan Tobacco Company: Internship ReportHasnat qadirNoch keine Bewertungen

- Reducing Cycle Time and Increasing Margins with an Integrated Product Development ProcessDokument6 SeitenReducing Cycle Time and Increasing Margins with an Integrated Product Development ProcessJoydeep Sen GuptaNoch keine Bewertungen

- PharmaDoc Pharmacy AppDokument109 SeitenPharmaDoc Pharmacy AppUsama Malik100% (1)

- معرفة وابتكار الاردنDokument25 Seitenمعرفة وابتكار الاردنAhmad Smadi100% (1)

- Sample 02 - Strategic Change Management - CompressedDokument17 SeitenSample 02 - Strategic Change Management - CompressedSadaf YousafNoch keine Bewertungen

- Nerolac Sales Force Management ReportDokument52 SeitenNerolac Sales Force Management Reportaneela05Noch keine Bewertungen

- Poster On Emerging Business Trend in BiopharmaceuticsDokument1 SeitePoster On Emerging Business Trend in Biopharmaceuticsrajkunwar97Noch keine Bewertungen

- 3rd Party Manufacturing Pre-Screen Questionnaire - PEPSIDokument26 Seiten3rd Party Manufacturing Pre-Screen Questionnaire - PEPSIDuNoch keine Bewertungen

- Corn StarchDokument2 SeitenCorn StarchDeepthi KurianNoch keine Bewertungen

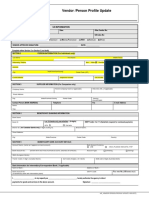

- Vendor Profile-IndividualDokument1 SeiteVendor Profile-IndividualCasana MandalNoch keine Bewertungen

- Bellad Motors Consumer Satisfaction StudyDokument68 SeitenBellad Motors Consumer Satisfaction StudySangeeta S SoppimathNoch keine Bewertungen

- Becg - L1Dokument66 SeitenBecg - L1Chandru JeyaramNoch keine Bewertungen

- Trade Policy in EthiopiaDokument28 SeitenTrade Policy in EthiopiaVivek Raina100% (1)

- CRISIL SME Connect June 09Dokument28 SeitenCRISIL SME Connect June 09shikha1982Noch keine Bewertungen

- Singapore Aerospace Supplier GuideDokument92 SeitenSingapore Aerospace Supplier Guidestrip1Noch keine Bewertungen

- Lupin and Boehringer Ingelheim Announce Strategic Co-Marketing Agreement (Company Update)Dokument2 SeitenLupin and Boehringer Ingelheim Announce Strategic Co-Marketing Agreement (Company Update)Shyam SunderNoch keine Bewertungen

- A Study On Customer Satisfaction at CielDokument87 SeitenA Study On Customer Satisfaction at Cielganesh rajNoch keine Bewertungen

- Pfizer Vaccine PLCDokument8 SeitenPfizer Vaccine PLCHarendra KumarNoch keine Bewertungen

- Minda Kosei - 2019-20 - Rev4Dokument27 SeitenMinda Kosei - 2019-20 - Rev4xmen norNoch keine Bewertungen

- Swot AnalysisDokument45 SeitenSwot AnalysisEr. Hebin RajNoch keine Bewertungen

- 812 MarketingDokument12 Seiten812 MarketingAbhinav SainiNoch keine Bewertungen

- Crisil Sme Connect Aug12Dokument60 SeitenCrisil Sme Connect Aug12Ravindra BagateNoch keine Bewertungen

- MSDS Chalk Powder SafetyDokument4 SeitenMSDS Chalk Powder SafetyMark Evan SalutinNoch keine Bewertungen

- Integrated Marketing Communication of Lux Soap by Hindustan Unilever LimitedDokument50 SeitenIntegrated Marketing Communication of Lux Soap by Hindustan Unilever LimitedMd Wasim Alam0% (1)

- Apollo Tyres LTDDokument27 SeitenApollo Tyres LTDGaurav MadanNoch keine Bewertungen

- TQM OddDokument6 SeitenTQM OddVILLAMAYOR, Kyla Shane A.Noch keine Bewertungen

- SCM Order Fulfillment OutlineDokument6 SeitenSCM Order Fulfillment OutlineBiswaranjan SenapatiNoch keine Bewertungen

- G.S.F.C Financial Analysis (Gujarat State Fertilizers & Chemicals LTD.)Dokument98 SeitenG.S.F.C Financial Analysis (Gujarat State Fertilizers & Chemicals LTD.)viveknegandhiNoch keine Bewertungen

- Boost Juice Bars PDFDokument5 SeitenBoost Juice Bars PDFmaint001100% (1)

- Approved Vendor List (SAI)Dokument10 SeitenApproved Vendor List (SAI)Muhammad Rafique KhokharNoch keine Bewertungen

- Hinopak Production ManagmentDokument53 SeitenHinopak Production ManagmentWaqas AhmedNoch keine Bewertungen

- Hinopak ReportDokument31 SeitenHinopak ReportTauseef Ghauri50% (2)

- FMDokument1 SeiteFMfujimukazuNoch keine Bewertungen

- Pakistan Economy HistoryDokument34 SeitenPakistan Economy HistoryfujimukazuNoch keine Bewertungen

- T C I G S: HE Hallenges OF Mplementing A Lobal TrategyDokument5 SeitenT C I G S: HE Hallenges OF Mplementing A Lobal TrategyfujimukazuNoch keine Bewertungen

- World Bank PakistanDokument17 SeitenWorld Bank PakistanfujimukazuNoch keine Bewertungen

- World Bank PakistanDokument22 SeitenWorld Bank PakistanfujimukazuNoch keine Bewertungen

- Pakistan Pharma IndustryDokument22 SeitenPakistan Pharma IndustryfujimukazuNoch keine Bewertungen

- History Pakistan EconomyDokument32 SeitenHistory Pakistan Economyfujimukazu94% (16)

- Pakistan Monetary Policy 2009Dokument25 SeitenPakistan Monetary Policy 2009fujimukazu0% (1)

- Privatization PakistanDokument16 SeitenPrivatization PakistanfujimukazuNoch keine Bewertungen

- History Pakistan EconomyDokument32 SeitenHistory Pakistan Economyfujimukazu94% (16)

- Pakistan Monetary Policy 2009Dokument15 SeitenPakistan Monetary Policy 2009fujimukazuNoch keine Bewertungen

- Radio: - TOTAL BUDGET: Rs. 34,507,160 - RADIO BUDGET: Rs. 4,034,120 - Percentage For Radio: 12%Dokument9 SeitenRadio: - TOTAL BUDGET: Rs. 34,507,160 - RADIO BUDGET: Rs. 4,034,120 - Percentage For Radio: 12%fujimukazuNoch keine Bewertungen

- Globalization WTODokument1 SeiteGlobalization WTOfujimukazuNoch keine Bewertungen

- Pakistan Economy HistoryDokument34 SeitenPakistan Economy HistoryfujimukazuNoch keine Bewertungen

- Globalization WTODokument3 SeitenGlobalization WTOfujimukazuNoch keine Bewertungen

- Money and Capital MaketDokument1 SeiteMoney and Capital MaketfujimukazuNoch keine Bewertungen

- Swift PakistanDokument24 SeitenSwift Pakistanfujimukazu100% (1)

- Power of Media: Manzoor Ali MemonDokument14 SeitenPower of Media: Manzoor Ali MemonfujimukazuNoch keine Bewertungen

- MC Donalds CaseDokument37 SeitenMC Donalds CasefujimukazuNoch keine Bewertungen

- Pepsi PakistanDokument7 SeitenPepsi PakistanfujimukazuNoch keine Bewertungen

- Training & Development at OgdcDokument20 SeitenTraining & Development at OgdcfujimukazuNoch keine Bewertungen

- Influence of Media On ChildrenDokument11 SeitenInfluence of Media On ChildrenfujimukazuNoch keine Bewertungen

- Media in ChinaDokument16 SeitenMedia in ChinafujimukazuNoch keine Bewertungen

- Isaac Newton S Metaphyssics: Rule of Hazrat Umar Bin Abdul AzizDokument9 SeitenIsaac Newton S Metaphyssics: Rule of Hazrat Umar Bin Abdul AzizfujimukazuNoch keine Bewertungen

- Mobile Monitoring and Wireless Data SynchronizationDokument44 SeitenMobile Monitoring and Wireless Data SynchronizationfujimukazuNoch keine Bewertungen

- New Media, Changing Scenario and The Anchor'S ResponsibilityDokument10 SeitenNew Media, Changing Scenario and The Anchor'S ResponsibilityfujimukazuNoch keine Bewertungen

- Media and TerrorismDokument8 SeitenMedia and TerrorismfujimukazuNoch keine Bewertungen

- InertiaDokument11 SeitenInertiafujimukazuNoch keine Bewertungen

- Unilever Vs P&GDokument5 SeitenUnilever Vs P&GfujimukazuNoch keine Bewertungen

- IMFDokument28 SeitenIMFfujimukazuNoch keine Bewertungen

- 35 (Gyro Bus) ReportDokument40 Seiten35 (Gyro Bus) ReportNehul PatilNoch keine Bewertungen

- Moscow Travel Guide BookDokument28 SeitenMoscow Travel Guide Bookewijayanto1Noch keine Bewertungen

- Shree Cement Ltd-People First - Project-Mobility Questionaire For Assessment of Present SystemDokument3 SeitenShree Cement Ltd-People First - Project-Mobility Questionaire For Assessment of Present SystemStephen BridgesNoch keine Bewertungen

- Impact of Side Friction On Speed-Flow RelationshipsDokument27 SeitenImpact of Side Friction On Speed-Flow RelationshipsMarijan Jakovljevic75% (4)

- Red Bus SampleDokument2 SeitenRed Bus Sampleanon_3874264370% (10)

- Print Control PageDokument1 SeitePrint Control PagecutemmaaNoch keine Bewertungen