Beruflich Dokumente

Kultur Dokumente

Solutions-Focused Manufacturing Leader

Hochgeladen von

sanjay_lingotOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Solutions-Focused Manufacturing Leader

Hochgeladen von

sanjay_lingotCopyright:

Verfügbare Formate

SAMPLE CLIENT

123 Any Street

Wichita, KS 12345

info@greatresumesfast.com

Home: 800.991.5187

Cell: 800.991.5187

Solutions-Focused Manufacturing Manager

Strategic Planning | Plant Engineering & Maintenance | Operations

Personal Profile

Dedicated and knowledgeable manufacturing professional with diverse industry knowledge and special talent for

searching out opportunities for improvement, contributing to cost reduction, increased productivity, and waste

reduction (up to 15% across the board). Provides objective analysis and innovative solutions to a wide range of

manufacturing problems including civil/structural repair needs, cost and productivity optimization, and safety and

environmental issues. Knowledgeable in structural steel, concrete flooring, roofing repair/replacement, roads and

parking lots, river walls, underground utilities, and sprinkler system upgrades.

Demonstration of cross-functional knowledge with proven operational success. Proactive planner with the ability to

nurture credibility and confidence with management and plant personnel. Excellent safety and compliance record with

working knowledge of OSHA, IBC, and environmental regulations.

Facility Maintenance & Planning

Production Planning Strategy

Industrial & Structural Engineering

Personnel Development & Training

Manufacturing Processes

Critical Issue Resolution

Quality Control

Building Code Adherence

Cost Analysis & Accounting

Project Management

Capital Planning & Improvement

Environmental Law & Regulations

Education & Professional Development

Master of Science in Management

Confidential University, Wichita, KS

Bachelor of Science in Industrial Engineering

Confidential University, Portland, OR

Conferences:

Structure Steel Painting/Corrosion Control, Performance of Alternative Coatings in the Environment (PACE), 2005

Concrete Conference, American Concrete Institute, 2005

Key Career Accomplishments

Recognized opportunity and proactively coordinated sale of $400,000 of used equipment, pioneering installation of

overseas import/export shipping system. Received recognition from Confidential Corporation Purchasing VP.

Successfully retained threatened clients and improved equipment reliability and productivity by eliminating offquality printed bag production through clear, effective personnel training and equipment modifications.

Led effort that reduced plant VOC emissions from 69 lbs. to less than 20 lbs. within one year, reducing the cost

to obtain air permits by approximately $78,000.

Saved up to $1.9M annually by creating economic method for analyzing paper purchasing decisions in a capacity

restrained situation by optimizing production by paper grade to minimize overall cost of purchased paper.

Sample Client

Page 2

Key Career Accomplishments (continued)

Created actual savings of $270,000 by developing balancing (scheduling) rationale for multiple paper machines to

maximize production capacity by reducing change-over time between paper grades.

Created innovative solution to build one new, all-inclusive facility rather than replace roofing on two old buildings

for a comparable cost.

Achieved 15 consecutive years of successful construction projects with no recordable incidents.

Established career-long loyalty to single company (Confidential Corporation).

Professional Experience

Confidential Corporation

Infrastructure Maintenance Manager, Wichita, KS location, 1995 Present

Led facility infrastructure management for two large mills (80 and 100 years old), totaling nearly 7 million sq. ft. of

managed space and 900 acres of land. Successfully completed diverse range of capital projects that strengthened mill

infrastructure, increased safety, and saved money. Granted autonomy in planning and execution of all major facility

infrastructure maintenance thanks to proven results and long-standing loyalty. Managed annual budget of up to $8M.

Proactively created a maintenance rating system for determining priorities based on safety, budget, and

effectiveness.

Developed and promoted use of engineered standards for corrosion control.

Facilitated a mill-wide ventilation plan and several multi-million dollar demolition projects.

Gained control of additional facility upon 2004 corporate reorganization, creating entirely new, more proactive

maintenance management system.

Evaluated worker productivity and used observations to eliminate ten unwarranted positions, saving company

approx. $50,000 per person.

Organized cost-effective fleet management program for approximately 80 lift trucks that evaluated replacement

vs. maintenance costs, minimizing total cost of ownership.

Honed knowledge of building code and approval requirements, working to disseminate a working knowledge

to others to help minimize both risk and compliance errors.

Directed shoring activity in ensure long-term employee and equipment safety.

Sr. Industrial Engineer, Wichita, KS location, 1993 1995

Enlisted by senior management to lead development team to modernize entire tissue converting operations.

Providing expertise to mentor newer engineers.

Aided in labor reduction by completing workload evaluation.

Operations Manager , Long Beach, CA location, 1989 1992

Led operations for specialty printing converting plant location with $15M in annual sales and 80 employees. Directed

production, maintenance, shipping, engineering, capital planning and implementation, and environmental compliance.

Primary equipment included Bretting napkin folders with letterpress printing, Beasley French bag machines with

flexographic printing, and a placemat press with gravure printing.

Reduced plant air emissions by researching options and changing plant-wide printing methods and materials.

Improved competitive standing by leading effort to enhance equipment reliability and capability to produce

high-quality product through planned equipment upgrades.

Improved attendance and behavior by initiating programs to reduce absenteeism and disciplinary problems.

Sample Client

Page 3

Operations Manager (continued)

Increased efficiency and operator ownership by re-designing bag department organization and training bagmachine operators to allow them to more fully manage their respective areas (e.g. inventory, purchasing,

maintenance, and scheduling).

Implemented comprehensive environmental compliance program, resulting in savings from potential fines and

possible plant closure.

Industrial Engineering Consultant, Green Bay, WI location, 1988 1989

Served as internal company consultant providing resources to all mills within corporation.

Analyzed problems and recommended practical solutions.

Sought out and advised multiple groups on potential areas of improvement.

Production Planning/Consumer Logistics Manager, Chicago, IL Headquarters, 1986 1988

Managed system-wide production planning and inventory control of national retail towel business.

Coordinated all retail towel production, transfers, and inventory.

Collaborated with marketing, product development, sales, customer service, and multiple manufacturing sites

on a number of large-scale projects.

Served as logistics resource for a new-business team, including development of logistical plans for distribution

and warehousing of new products centered on non-woven technologies.

Industrial Engineer, Green Bay, WI location, 1984 1986

Coordinated paper mill budgeting, capital and strategic planning, and operations improvement projects focused

on waste reduction and increased uptime.

Proactively promoted use of economic analysis in decision-making.

Production Engineer, Portland, OR location, 1981 1984

Worked with mill operations and accounting teams to successfully execute mill projects.

Developed emphasis on productivity improvement in converting and shipping operations.

Das könnte Ihnen auch gefallen

- Plant Manager or Operations ManagerDokument4 SeitenPlant Manager or Operations Managerapi-121389384Noch keine Bewertungen

- VP of Manufacturing or OperationsDokument4 SeitenVP of Manufacturing or Operationsapi-79310704Noch keine Bewertungen

- Lean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichDokument3 SeitenLean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichMichaelMakarewichNoch keine Bewertungen

- Manufacturing CostDokument30 SeitenManufacturing CostPradika WibowoNoch keine Bewertungen

- Total Preventive Maint.Dokument18 SeitenTotal Preventive Maint.No HopeNoch keine Bewertungen

- Statistical Analysis of Cement IndustryDokument10 SeitenStatistical Analysis of Cement IndustryEr Shafique Gajdhar100% (1)

- Reliability Engineer: Organizational RelationshipsDokument6 SeitenReliability Engineer: Organizational RelationshipsJosé David Cruz MahechaNoch keine Bewertungen

- Responsibilities of A FACTORY MANAGERDokument3 SeitenResponsibilities of A FACTORY MANAGERPawan KinnalNoch keine Bewertungen

- Roles of Production ManagerDokument20 SeitenRoles of Production ManagerKaran JaiswalNoch keine Bewertungen

- Maintenance Manager 1598637070Dokument4 SeitenMaintenance Manager 1598637070Alyssa ArdeleanNoch keine Bewertungen

- CV Deepak Purohit PDFDokument2 SeitenCV Deepak Purohit PDFyosharmaNoch keine Bewertungen

- Mechanical ForemanDokument7 SeitenMechanical Foremanbook1616Noch keine Bewertungen

- Operations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsDokument2 SeitenOperations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsPaulRoberts2Noch keine Bewertungen

- Operations ManagerDokument3 SeitenOperations Managerapi-79229412Noch keine Bewertungen

- Plant Manager Operations in Rochester NY Resume Mark AsbrandDokument3 SeitenPlant Manager Operations in Rochester NY Resume Mark AsbrandMark AsbrandNoch keine Bewertungen

- Supplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDDokument29 SeitenSupplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDAdam Andrew OngNoch keine Bewertungen

- PM-Maintenance Plan and Notification - Config PDFDokument96 SeitenPM-Maintenance Plan and Notification - Config PDFanon_88317949Noch keine Bewertungen

- Roles & Responsibility of Billing EngineerDokument7 SeitenRoles & Responsibility of Billing EngineerRaj MNoch keine Bewertungen

- Resume B.tech ME - PurchaseDokument5 SeitenResume B.tech ME - PurchaseSonali YadavNoch keine Bewertungen

- ERP vs actual production reportDokument8 SeitenERP vs actual production reportIam EshwarNoch keine Bewertungen

- Production Manager Resume TemplateDokument2 SeitenProduction Manager Resume TemplateAputMartinNoch keine Bewertungen

- Layout ChecklistDokument2 SeitenLayout Checklistvmohapatra8100% (1)

- AssemblyDokument26 SeitenAssemblySahil GuptaNoch keine Bewertungen

- Failure Mode Effect Analysis FMEADokument42 SeitenFailure Mode Effect Analysis FMEARahman SonowijoyoNoch keine Bewertungen

- Latest Resume Yogesh CharatkarDokument4 SeitenLatest Resume Yogesh CharatkarYogesh CharatkarNoch keine Bewertungen

- Project Management ConceptsDokument25 SeitenProject Management ConceptszamNoch keine Bewertungen

- List of Production ReportsDokument12 SeitenList of Production ReportsSangeeth BhoopaalanNoch keine Bewertungen

- Week 35 - EHS Roles & ResponsibilitiesDokument1 SeiteWeek 35 - EHS Roles & Responsibilitiespl_rajaNoch keine Bewertungen

- SCLM ChecklistDokument38 SeitenSCLM ChecklistMayur GaidhaneNoch keine Bewertungen

- Presentation On Ambuja LTD - Group 2Dokument53 SeitenPresentation On Ambuja LTD - Group 2Nikita BhattNoch keine Bewertungen

- Caterpillar Brazil Facility 28 Pre-Delivery Inspection ChecklistDokument5 SeitenCaterpillar Brazil Facility 28 Pre-Delivery Inspection ChecklistEduardo Alfredo Anchahua HuamaniNoch keine Bewertungen

- Procurement Professional Seeks New OpportunityDokument4 SeitenProcurement Professional Seeks New OpportunityMANIKANDANNoch keine Bewertungen

- Best Practices For WarehousesDokument44 SeitenBest Practices For WarehousesAbraham Siju CherianNoch keine Bewertungen

- New Layout PlanningDokument21 SeitenNew Layout PlanningamuNoch keine Bewertungen

- Key Performance Indicators (KPIs) - WarehousingDokument5 SeitenKey Performance Indicators (KPIs) - WarehousingPerumal DM100% (1)

- Engineering Design Review and ChecklistDokument40 SeitenEngineering Design Review and ChecklistwnaciNoch keine Bewertungen

- Role and Responsibilities of Production ManagerDokument6 SeitenRole and Responsibilities of Production ManagerPrabhu VelidindiNoch keine Bewertungen

- Project: NO. Module (S) Aps Task Description CURRENT (As of Nov-18) 1 System MaintenanceDokument18 SeitenProject: NO. Module (S) Aps Task Description CURRENT (As of Nov-18) 1 System MaintenanceElvera GeorgeNoch keine Bewertungen

- Very Good CV FormatDokument5 SeitenVery Good CV FormatAhmad YaseenNoch keine Bewertungen

- RE140 Section 2 - Maintenance Policies (NXPowerLite)Dokument39 SeitenRE140 Section 2 - Maintenance Policies (NXPowerLite)Ahmed FaragNoch keine Bewertungen

- Titan ADX DatasheetDokument4 SeitenTitan ADX Datasheetmiguelrccosta100% (1)

- Rupesh Kumar: Management, Vendor Management, Project ManagementDokument4 SeitenRupesh Kumar: Management, Vendor Management, Project Managementrakeshkumar8010690Noch keine Bewertungen

- My HR SuzlonDokument105 SeitenMy HR Suzlonkaushik makwana100% (2)

- ValtekDokument20 SeitenValtekhugolm9-1100% (1)

- Return On Value (ROV) - An Imperative For Next-Generation ROI in High Tech Executive SummaryDokument4 SeitenReturn On Value (ROV) - An Imperative For Next-Generation ROI in High Tech Executive Summarypramod.mitraNoch keine Bewertungen

- Electric Actautor Valve Damper Technical Catalog PDFDokument5 SeitenElectric Actautor Valve Damper Technical Catalog PDFCair Euromatic Automation Pvt. Ltd.Noch keine Bewertungen

- Welding Dept. (En15085-2) Calibration Status: Least CountDokument1 SeiteWelding Dept. (En15085-2) Calibration Status: Least CountAMIT SHAHNoch keine Bewertungen

- Kundan Kumar Mechanical Engineer ManufacturingDokument4 SeitenKundan Kumar Mechanical Engineer ManufacturingMelinda WaltersNoch keine Bewertungen

- Red Flags SurveyDokument6 SeitenRed Flags Surveyhmp90Noch keine Bewertungen

- Production Report Shift Wise - AddaDokument1 SeiteProduction Report Shift Wise - AddaOBSC PerfectionNoch keine Bewertungen

- Resume VikasDokument4 SeitenResume VikasBaljeetNoch keine Bewertungen

- Top Maintenance KPIs For The Optimal CMMS DashboardDokument12 SeitenTop Maintenance KPIs For The Optimal CMMS DashboardLaam MeemNoch keine Bewertungen

- Supply Planning Demand Plan Sales and Operations Planning (S&OP)Dokument3 SeitenSupply Planning Demand Plan Sales and Operations Planning (S&OP)ranga.ramanNoch keine Bewertungen

- Topics To Be Covered in Materials ManagementDokument91 SeitenTopics To Be Covered in Materials ManagementPratik DhruvNoch keine Bewertungen

- Production Planning ManagerDokument2 SeitenProduction Planning ManagerNitin Verma100% (1)

- Master Production ScheduleDokument18 SeitenMaster Production Schedulerafazel hardyNoch keine Bewertungen

- Manufacturing Manager Resume SummaryDokument3 SeitenManufacturing Manager Resume SummarySiddiquiNoch keine Bewertungen

- Executive Director Facilities Management in NYC Resume Scott KeithDokument3 SeitenExecutive Director Facilities Management in NYC Resume Scott KeithScottKeith100% (2)

- Sales Manager Solar Engineer in Dallas FT Worth TX Resume John JohnsonDokument2 SeitenSales Manager Solar Engineer in Dallas FT Worth TX Resume John JohnsonJohnJohnsonNoch keine Bewertungen

- VP Director Facilities Management in Kansas City MO Resume Chris GardnerDokument2 SeitenVP Director Facilities Management in Kansas City MO Resume Chris GardnerChrisGardner2Noch keine Bewertungen

- Ignited MindsDokument9 SeitenIgnited MindsMeenu Mathur0% (3)

- Carbide K20Dokument1 SeiteCarbide K20hadeNoch keine Bewertungen

- Products Requirement RequestDokument2 SeitenProducts Requirement Requestsanjay_lingotNoch keine Bewertungen

- Products Purchase RequestDokument2 SeitenProducts Purchase Requestsanjay_lingotNoch keine Bewertungen

- Cross Members AssemblyDokument1 SeiteCross Members Assemblysanjay_lingotNoch keine Bewertungen

- Part and Mold Design Guide (2005)Dokument174 SeitenPart and Mold Design Guide (2005)naitikpanchal100% (4)

- Feed Manufacturing Costs and Capital Requirements: Economic Research Service United States Department of AgricultureDokument91 SeitenFeed Manufacturing Costs and Capital Requirements: Economic Research Service United States Department of Agriculturemy_khan20027195Noch keine Bewertungen

- Learning SpanishDokument1 SeiteLearning Spanishsanjay_lingotNoch keine Bewertungen

- CVB Table Booklet Feeding of Poultry - Website VersionDokument34 SeitenCVB Table Booklet Feeding of Poultry - Website Versionsanjay_lingot80% (5)

- Casting PDFDokument48 SeitenCasting PDFsanjay_lingotNoch keine Bewertungen

- Model Project Report On Fruit & Vegetable Processing UnitDokument24 SeitenModel Project Report On Fruit & Vegetable Processing UnitSuhas Ninghot100% (1)

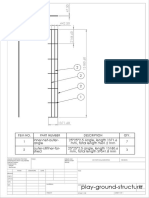

- Play Ground StructureDokument1 SeitePlay Ground Structuresanjay_lingotNoch keine Bewertungen

- FINAL - Layer Poultry Estate-OrissaDokument14 SeitenFINAL - Layer Poultry Estate-OrissaSrinivas RaoNoch keine Bewertungen

- Hongkong QMAS VisaDokument5 SeitenHongkong QMAS Visasanjay_lingotNoch keine Bewertungen

- Properties Function PlasticsDokument15 SeitenProperties Function Plasticssanjay_lingotNoch keine Bewertungen

- CG Scheme ImplementationDokument2 SeitenCG Scheme Implementationsanjay_lingotNoch keine Bewertungen

- Inner Short Structure AssemblyDokument1 SeiteInner Short Structure Assemblysanjay_lingotNoch keine Bewertungen

- Mech - Adjustable Hospital BedsDokument7 SeitenMech - Adjustable Hospital Bedssanjay_lingotNoch keine Bewertungen

- Cross Members AssemblyDokument1 SeiteCross Members Assemblysanjay_lingotNoch keine Bewertungen

- Inner-Net-Structure: Item No. Part Number Description Qty. 1 2 2 7 3 1Dokument1 SeiteInner-Net-Structure: Item No. Part Number Description Qty. 1 2 2 7 3 1sanjay_lingotNoch keine Bewertungen

- Inner-Net-Structure: Item No. Part Number Description Qty. 1 2 2 7 3 1Dokument1 SeiteInner-Net-Structure: Item No. Part Number Description Qty. 1 2 2 7 3 1sanjay_lingotNoch keine Bewertungen

- Goat Farm Shed AssemblyDokument1 SeiteGoat Farm Shed Assemblysanjay_lingot100% (1)

- Catalano Coolidge MQP Report 10-3-2006Dokument111 SeitenCatalano Coolidge MQP Report 10-3-2006Jagdeep SinghNoch keine Bewertungen

- 04 01 004 Masterate DissertationDokument170 Seiten04 01 004 Masterate DissertationahmedzulfiqarNoch keine Bewertungen

- Hot Forged Bolts & Nuts Project ProfileDokument10 SeitenHot Forged Bolts & Nuts Project Profilesanjay_lingotNoch keine Bewertungen

- Sample Resume-Mechanical EngineerDokument1 SeiteSample Resume-Mechanical Engineersanjay_lingotNoch keine Bewertungen

- Technical: & Letter WritingDokument50 SeitenTechnical: & Letter WritingFarhan Khan NiaZiNoch keine Bewertungen

- Resume SamplesDokument13 SeitenResume Samplessanjay_lingotNoch keine Bewertungen

- Technical: & Letter WritingDokument50 SeitenTechnical: & Letter WritingFarhan Khan NiaZiNoch keine Bewertungen

- HR Admin DutiesDokument2 SeitenHR Admin Dutiesdtr17Noch keine Bewertungen

- Human Resource Development ManagementDokument1 SeiteHuman Resource Development ManagementlogicballiaNoch keine Bewertungen

- Jetlheee Report 2Dokument3 SeitenJetlheee Report 2Maria Lucy MendozaNoch keine Bewertungen

- Event ManagementDokument3 SeitenEvent ManagementAlexandru Dan GheorghiuNoch keine Bewertungen

- Audit and Internal Control Policy - CPCEMPC Updated As of 30 January 2020Dokument18 SeitenAudit and Internal Control Policy - CPCEMPC Updated As of 30 January 2020Rhododendron ButterflyNoch keine Bewertungen

- BCG Analysis Is Mainly Used For Multi CategoryDokument2 SeitenBCG Analysis Is Mainly Used For Multi CategoryVankishKhoslaNoch keine Bewertungen

- Al Ain Farms Company ProjectDokument6 SeitenAl Ain Farms Company ProjectMohammad NaumanNoch keine Bewertungen

- Seminar Topic: Software Reuse, Reengineering, Reverse EngineeringDokument29 SeitenSeminar Topic: Software Reuse, Reengineering, Reverse EngineeringSHAIK CHAND PASHANoch keine Bewertungen

- Guide To The Completion of A Personal Development PlanDokument8 SeitenGuide To The Completion of A Personal Development PlanSpot BobNoch keine Bewertungen

- Case Study - Tackling ROI Requests With MoxeDokument2 SeitenCase Study - Tackling ROI Requests With MoxeMohammed ImamuddinNoch keine Bewertungen

- Badrinathraju Vysyaraju: Professional SkillsDokument3 SeitenBadrinathraju Vysyaraju: Professional SkillsVeera Manikanta GNoch keine Bewertungen

- Character Formation Through PlanningDokument3 SeitenCharacter Formation Through PlanningMicaella MunozNoch keine Bewertungen

- JIT FinalDokument10 SeitenJIT FinalMarie Antoinette HolandaNoch keine Bewertungen

- Job Vacancy 2024Dokument10 SeitenJob Vacancy 2024Kurnia AljufriNoch keine Bewertungen

- Strategic Change NokiaDokument8 SeitenStrategic Change NokiaMinhNoch keine Bewertungen

- Superior Strategy Execution in Eight ComponentsDokument70 SeitenSuperior Strategy Execution in Eight ComponentsHàn Nguyệt CátNoch keine Bewertungen

- Strategic Management CH-2Dokument7 SeitenStrategic Management CH-2padmNoch keine Bewertungen

- Reward Management Literature ReviewDokument9 SeitenReward Management Literature Reviewc5sq1b48100% (1)

- UNIT 2 - Human Resource PlanningDokument26 SeitenUNIT 2 - Human Resource PlanningPreeti BhaskarNoch keine Bewertungen

- BECO505 Advance Managerial Economics PDFDokument13 SeitenBECO505 Advance Managerial Economics PDFpoona ramwaniNoch keine Bewertungen

- Working Capital Management at BEMLDokument20 SeitenWorking Capital Management at BEMLadharav malikNoch keine Bewertungen

- Harpic Case Study AnalysisDokument13 SeitenHarpic Case Study AnalysisSujit80% (5)

- IMD MBA 2015 Class ProfileDokument16 SeitenIMD MBA 2015 Class ProfileHoya ChiangNoch keine Bewertungen

- ESS and Hotel IndustryDokument20 SeitenESS and Hotel Industryparul198731100% (1)

- Managment Learning OutlineDokument38 SeitenManagment Learning OutlineAamir RazaNoch keine Bewertungen

- Low Cost AutomationDokument2 SeitenLow Cost AutomationTejas shastrakarNoch keine Bewertungen

- Understanding The Spiral Model As A Tool For Evolutionary AcquisitionDokument15 SeitenUnderstanding The Spiral Model As A Tool For Evolutionary AcquisitionksmohanaNoch keine Bewertungen

- KFUPM Maintenance Management SyllabusDokument10 SeitenKFUPM Maintenance Management SyllabusNoman Ullah ChoudharyNoch keine Bewertungen

- MIS Implementation Challenges and Sucess Case - MSC ThesisDokument67 SeitenMIS Implementation Challenges and Sucess Case - MSC Thesisbassa741100% (1)

- Chapter-3 Research Methodology and Survey Instrument: 3.1 Need For The StudyDokument28 SeitenChapter-3 Research Methodology and Survey Instrument: 3.1 Need For The StudyArun Kumar SatapathyNoch keine Bewertungen