Beruflich Dokumente

Kultur Dokumente

Tool Steel - Wikipedia, The Free Encyclopedia

Hochgeladen von

Sohail ShaikhCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tool Steel - Wikipedia, The Free Encyclopedia

Hochgeladen von

Sohail ShaikhCopyright:

Verfügbare Formate

3/2/2016

Tool steel - Wikipedia, the free encyclopedia

Tool steel

From Wikipedia, the free encyclopedia

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools. Their

suitability comes from their distinctive hardness, resistance to abrasion and deformation and their ability to hold a

cutting edge at elevated temperatures. As a result tool steels are suited for their use in the shaping of other materials.

With a carbon content between 0.5% and 1.5%, tool steels are manufactured under carefully controlled conditions

to produce the required quality. The presence of carbides in their matrix plays the dominant role in the qualities of

tool steel. The four major alloying elements in tool steel that form carbides are: tungsten, chromium, vanadium and

molybdenum. The rate of dissolution of the different carbides into the austenite form of the iron determines the high

temperature performance of steel (slower is better, making for a heat resistant steel). Proper heat treatment of these

steels is important for adequate performance.[1] The manganese content is often kept low to minimize the possibility

of cracking during water quenching.

There are six groups of tool steels: water-hardening, cold-work, shock-resisting, high-speed, hot-work, and special

purpose. The choice of group to select depends on cost, working temperature, required surface hardness, strength,

shock resistance, and toughness requirements.[2] The more severe the service condition (higher temperature,

abrasiveness, corrosiveness, loading), the higher the alloy content and consequent amount of carbides required for

the tool steel.

Tool steels are used for cutting, pressing, extruding, and coining of metals and other materials. Their use, such as the

production of injection molds, is essential, due to their resistance to abrasion, which is an important criterion for a

mold that will be used to produce hundreds of thousands of moldings of a product or part.

The AISI-SAE grades of tool steel is the most common scale used to identify various grades of tool steel.

Individual alloys within a grade are given a number; for example: A2, O1, etc.

Contents

1 Water-hardening group

2 Cold-work group

2.1 Oil-hardening: the O-series

2.2 Air-hardening: the A-series

2.3 High carbon-chromium: the D-series

2.4 1.2767 type

3 Shock-resisting group

https://en.wikipedia.org/wiki/Tool_steel

1/7

3/2/2016

Tool steel - Wikipedia, the free encyclopedia

4 High speed group

5 Hot-working group

6 Special purpose group

7 Comparison

8 See also

9 References

10 Bibliography

11 External links

Water-hardening group

W-group tool steel gets its name from its defining property of having to be water quenched. W-grade steel is

essentially high carbon plain-carbon steel. This group of tool steel is the most commonly used tool steel because of

its low cost compared to others. They work well for small parts and applications where high temperatures are not

encountered; above 150 C (302 F) it begins to soften to a noticeable degree. Its hardenability is low, so Wgroup tool steels must be subjected to a rapid quenching, requiring the use of water. These steels can attain high

hardness (above HRC 66) and are rather brittle compared to other tool steels. W-steels are still sold, especially for

springs, but are much less widely used than they were in the 19th and early 20th centuries. This is partly because

W-steels warp and crack much more during quench than oil-quenched or air hardening steels.

The toughness of W-group tool steels are increased by alloying with manganese, silicon and molybdenum. Up to

0.20% of vanadium is used to retain fine grain sizes during heat treating.

Typical applications for various carbon compositions are for W-steels:

0.600.75% carbon: machine parts, chisels, setscrews; properties include medium hardness with good

toughness and shock resistance.

0.760.90% carbon: forging dies, hammers, and sledges.

0.911.10% carbon: general purpose tooling applications that require a good balance of wear resistance and

toughness, such as rasps, drills, cutters, and shear blades.

1.111.30% carbon: files, small drills, lathe tools, razor blades, and other light-duty applications where more

wear resistance is required without great toughness. Steel of about 0.8% C gets as hard as steel with more

carbon, but the free iron carbide particles in 1% or 1.25% carbon steel make it hold an edge better.

However, the fine edge probably rusts off faster than it wears off, if it is used to cut acidic or salty materials.

Cold-work group

https://en.wikipedia.org/wiki/Tool_steel

2/7

3/2/2016

Tool steel - Wikipedia, the free encyclopedia

The cold-work tool steels include the O-series (oil-hardening), the A-series (air-hardening), and the D-series (high

carbon-chromium). These are steels used to cut or form materials that are at low temperatures. This group

possesses high hardenability and wear resistance, and average toughness and heat softening resistance. They are

used in production of larger parts or parts that require minimal distortion during hardening. The use of oil quenching

and air-hardening helps reduce distortion, avoiding the higher stresses caused by the quicker water quenching.

More alloying elements are used in these steels, as compared to the water-hardening class. These alloys increase

the steels' hardenability, and thus require a less severe quenching process and as a result are less likely to crack.

They have high surface hardness and are often used to make knife blades. The machinability of the oil hardening

grades is high but for the high carbon-chromium types is low.

Oil-hardening: the O-series

This series originally included an O2 type and an O7 type, but only O1 remains in production.

Grade

O1

Composition

0.90% C, 1.01.4% Mn,

0.50% Cr, 0.50% W

Notes

It is a very good cold work steel and also makes very good knives and

forks. It can be hardened to about 57-61 HRC.

Air-hardening: the A-series

The first air-hardening grade tool steel was mushet steel, which was known as air-hardening steel at the time.

Modern air-hardening steels are characterized by low distortion during heat treatment because of their highchromium content. Their machinability is good and they have a balance of wear resistance and toughness (i.e.

between the D- and shock-resistant grades).[3]

https://en.wikipedia.org/wiki/Tool_steel

3/7

3/2/2016

Grade

Tool steel - Wikipedia, the free encyclopedia

Composition

Notes

A2[4]

1.0% C, 1.0% Mn, 5.0% A common general purpose tool steel; it is the most commonly used variety of

Cr, 0.3% Ni, 1.0% Mo, air-hardening steel. It is commonly used for blanking and forming punches,

0.150.50% V

trimming dies, thread rolling dies, and injection molding dies.[3]

A3[5]

1.25% C, 0.5% Mn,

5.0% Cr, 0.3% Ni, 0.9

1.4% Mo, 0.81.4% V

A4[6]

1.0% C, 2.0% Mn, 1.0%

Cr, 0.3% Ni, 0.91.4%

Mo

A6[7]

0.7% C, 1.82.5% Mn,

0.91.2% Cr, 0.3% Ni,

0.91.4% Mo

A7[8]

2.002.85% C, 0.8%

Mn, 5.005.75% Cr,

0.3% Ni, 0.91.4% Mo,

3.95.15% V, 0.51.5

W

A8[9]

0.50.6% C, 0.5% Mn,

4.755.50% Cr, 0.3%

Ni, 1.151.65% Mo,

1.01.5 W

This type of tool steel air-hardens at a relatively low temperature

(approximately the same temperature as oil-hardening types) and is

dimensionally stable. Therefore it is commonly used for dies, forming tools,

and gauges that do not require extreme wear resistance but do need high

stability.[3]

0.5% C, 0.5% Mn,

0.951.15% Si, 4.75

[10]

5.00% Cr, 1.251.75%

A9

Ni, 1.31.8% Mo, 0.8

1.4% V

1.251.50% C, 1.6

2.1% Mn, 1.01.5% Si,

A10[11]

1.552.05% Ni, 1.25

1.75% Mo

This grade contains a uniform distribution of graphite particles to increase

machinability and provide self-lubricating properties. It is commonly used for

gauges, arbors, shears, and punches.[12]

High carbon-chromium: the D-series

The D-series of the cold-work class of tool steels, which originally included types D2, D3,D6, and D7, contains

between 10% and 13% chromium (which is unusually high). These steels retain their hardness up to a temperature

of 425 C (797 F). Common applications for these tool steels include forging dies, die-casting die blocks, and

drawing dies. Due to their high chromium content, certain D-type tool steels are often considered stainless or semistainless, however their corrosion resistance is very limited due to the precipitation of the majority of their chromium

and carbon constituents as carbides.

https://en.wikipedia.org/wiki/Tool_steel

4/7

3/2/2016

Tool steel - Wikipedia, the free encyclopedia

Grade

D2

Composition

Notes

1.5% C, 11.013.0% Cr;

additionally 0.45% Mn,

0.030% P, 0.030% S, 1.0%

V, 0.9% Mo, 0.30% Si

D2 is very wear resistant but not as tough as lower alloyed steels. The

mechanical properties of D2 are very sensitive to heat treatment. It is

widely used for the production of shear blades, planer blades and industrial

cutting tools; sometimes used for knife blades.

1.2767 type

ISO 1.2767, also known as DIN X 45 NiCrMo 4, AISI 6F7, and BS EN 20 B, is an air-hardening tool steel with

a primary alloying element of nickel. It possesses good toughness, stable grains, and is highly polishable. It is

primarily used for dies in plastic injection molding application that involve high stresses. Other applications include

blanking dies, forging dies, and industrial blades.[13]

Shock-resisting group

The high shock resistance and good hardenability are provided by chromium-tungsten, silicon-molybdenum, siliconmanganese alloying. Shock-resisting group tool steels (S) are designed to resist shock at both low and high

temperatures. A low carbon content is required for the necessary toughness (approximately 0.5% carbon).

Carbide-forming alloys provide the necessary abrasion resistance, hardenability, and hot-work characteristics. This

family of steels displays very high impact toughness and relatively low abrasion resistance and can attain relatively

high hardness (HRC 58/60). In the US, toughness usually derives from 1 to 2% silicon and 0.5-1% molybdenum

content. In Europe, shock steels often contain 0.5-0.6 % carbon and around 3% nickel. 1.75% to 2.75% nickel is

still used in some shock resisting and high strength low alloy steels (HSLA), such as L6, 4340, and Swedish saw

steel, but it is relatively expensive. An example of its use is in the production of jackhammer bits.

High speed group

Hot-working group

Hot-working steels are a group of steel used to cut or shape material at high temperatures. H-group tool steels

were developed for strength and hardness during prolonged exposure to elevated temperatures. These tool steels

are low carbon and moderate to high alloy that provide good hot hardness and toughness and fair wear resistance

due to a substantial amount of carbide.[1] H1 to H19 are based on a chromium content of 5%; H20 to H39 are

based on a tungsten content of 9-18% and a chromium content of 34%; H40 to H59 are molybdenum based.

Special purpose group

P-type tool steel is short for plastic mold steels. They are designed to meet the requirements of zinc die

casting and plastic injection molding dies.

L-type tool steel is short for low alloy special purpose tool steel. L6 is extremely tough.

F-type tool steel is water hardened and substantially more wear resistant than W-type tool steel.

Comparison

https://en.wikipedia.org/wiki/Tool_steel

5/7

3/2/2016

Tool steel - Wikipedia, the free encyclopedia

AISI-SAE tool steel grades [14]

Defining property AISI-SAE grade Significant characteristics

Water-hardening

Cold-working

Shock resisting

W

O

Oil-hardening

Air-hardening; medium alloy

High carbon; high chromium

S

T

Tungsten base

Molybdenum base

Hot-working

H1H19: chromium base

H20H39: tungsten base

H40H59: molybdenum base

Plastic mold

High speed

Special purpose

Low alloy

Carbon tungsten

See also

Crucible Industries

List of steel producers

Silver steel

References

1. Verhoeven, John. Steel Metallurgy for the Non-Metallurgist. ASM International. p. 159. ISBN 978-0-87170-858-8.

Retrieved 9 November 2014..

2. Baumeister, Avallone, Baumeister. "6". Marks' Standard Handbook for Mechanical Engineers, 8th ed. McGraw

Hill. pp. 33, 34. ISBN 9780070041233.

3. Oberg et al. 2004, pp. 466467.

4. AISI A2, Efunda, archived from the original on 2010-12-25, retrieved 2010-12-25.

5. AISI A3, Efunda, archived from the original on 2010-12-25, retrieved 2010-12-25.

6. AISI A4, Efunda, archived from the original on 2010-12-25, retrieved 2010-12-25.

7. AISI A6, Efunda, archived from the original on 2010-12-25, retrieved 2010-12-25.

8. AISI A7, Efunda, archived from the original on 2010-12-25, retrieved 2010-12-25.

9. AISI A8, Efunda, archived from the original on 2010-12-25, retrieved 2010-12-25.

10. AISI A9, Efunda, archived from the original on 2010-12-25, retrieved 2010-12-25.

11. AISI A10, Efunda, archived from the original on 2010-12-25, retrieved 2010-12-25.

12. A-10 Tool Steel Material Information, archived from the original on 2010-12-25, retrieved 2010-12-25.

13. Plastid Mould Steel / Cold Working Steel, archived from the original (PDF) on 2010-11-27, retrieved 2010-11-27.

14. Oberg et al. 2004, p. 452.

Bibliography

https://en.wikipedia.org/wiki/Tool_steel

6/7

3/2/2016

Tool steel - Wikipedia, the free encyclopedia

Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003), Materials and Processes in Manufacturing

(9th ed.), Wiley, ISBN 0-471-65653-4.

Oberg, Erik; Jones, Franklin D.; McCauley, Christopher J.; Heald, Ricardo M. (2004), Machinery's

Handbook (27th ed.), Industrial Press, ISBN 978-0-8311-2700-8.

External links

Software to compare different tool steel grades based on their properties: Steel-guide EU based on A.I.S.I.

norm (http://www.steel-guide.eu) and Steel-guide GB based on British Steel norm (http://www.steelguide.co.uk).

Suggested tool steel selections for various purposes

(http://web.archive.org/web/20061121035638/http://www.pvsteel.com/docs/Tsb-093.pdf)

Comparison of tool steel standards (http://www.westyorkssteel.com/steel-specifications/internationalstandards/tool-steel/)

Tool Steel Chemical Composition (http://www.sousacorp.com/ts-comp.htm)

Retrieved from "https://en.wikipedia.org/w/index.php?title=Tool_steel&oldid=695844025"

Categories: Steels Metalworking

This page was last modified on 19 December 2015, at 01:25.

Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may apply.

By using this site, you agree to the Terms of Use and Privacy Policy. Wikipedia is a registered trademark

of the Wikimedia Foundation, Inc., a non-profit organization.

https://en.wikipedia.org/wiki/Tool_steel

7/7

Das könnte Ihnen auch gefallen

- Duplex Stainless Steel 2d Edition PracticalDokument64 SeitenDuplex Stainless Steel 2d Edition Practicalmahmoud_allam3Noch keine Bewertungen

- PC SG Grand Theft Auto 5Dokument308 SeitenPC SG Grand Theft Auto 5Sohail ShaikhNoch keine Bewertungen

- List of Blade MaterialsDokument19 SeitenList of Blade MaterialsAnie Ummu Alif & SyifaNoch keine Bewertungen

- Types of Steel AlloyDokument47 SeitenTypes of Steel AlloyArpit Thumar100% (2)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkVon EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNoch keine Bewertungen

- StoichiometryDokument16 SeitenStoichiometryVel MuruganNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- Acid, Base and Salt - C-AA - DoneDokument14 SeitenAcid, Base and Salt - C-AA - DoneVinod AgrawalNoch keine Bewertungen

- Testing of Austenitic Stainless SteelsDokument64 SeitenTesting of Austenitic Stainless SteelsmirelamanteamirelaNoch keine Bewertungen

- Tool Steel Grade and Standard DesignationDokument7 SeitenTool Steel Grade and Standard DesignationMustafa SevimliNoch keine Bewertungen

- Ferrous Metal & AlloysDokument30 SeitenFerrous Metal & AlloysRed ReidNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonBewertung: 4 von 5 Sternen4/5 (1)

- SAE Steel GradesDokument21 SeitenSAE Steel Gradescal2_uniNoch keine Bewertungen

- Ch-27.7 Alloying Element of Steel and Alloy SteelDokument51 SeitenCh-27.7 Alloying Element of Steel and Alloy SteelSmruti Ranjan PattanayakNoch keine Bewertungen

- Alloy Steels: Dr. Indika de SilvaDokument25 SeitenAlloy Steels: Dr. Indika de SilvaChandima K PriyamalNoch keine Bewertungen

- Agitated Vessel Heat TransferDokument6 SeitenAgitated Vessel Heat TransferSohail Shaikh100% (1)

- Aircraft Materials, Processes and Hardware PDFDokument189 SeitenAircraft Materials, Processes and Hardware PDFregina marie100% (1)

- The Australian Welding Guide PDFDokument220 SeitenThe Australian Welding Guide PDFThành Nguyễn XuânNoch keine Bewertungen

- Valve Material EquivalentsDokument3 SeitenValve Material EquivalentsAndre Villegas Romero100% (1)

- Lec 02Dokument19 SeitenLec 02أمير حامد100% (1)

- Engg - Materials - Effect of Alloying ElementDokument22 SeitenEngg - Materials - Effect of Alloying ElementSmruthi SuvarnaNoch keine Bewertungen

- EN 1092-1-Flange PDFDokument18 SeitenEN 1092-1-Flange PDFSimona Adriana100% (1)

- Ferrous Alloys GuideDokument56 SeitenFerrous Alloys Guidejayakrishnan psNoch keine Bewertungen

- Think and Grow Rich in Your CareerDokument14 SeitenThink and Grow Rich in Your CareerSohail ShaikhNoch keine Bewertungen

- Ferrous Alloys GuideDokument11 SeitenFerrous Alloys Guidekalaivananmek100% (1)

- Welding Module #2 PDFDokument112 SeitenWelding Module #2 PDFHARSH SHARMANoch keine Bewertungen

- Stainless Steels Guide - Properties, Applications & GradesDokument16 SeitenStainless Steels Guide - Properties, Applications & GradesAndika RizalNoch keine Bewertungen

- The 4 Main Types of Steel: Carbon, Alloy, Tool, and StainlessDokument4 SeitenThe 4 Main Types of Steel: Carbon, Alloy, Tool, and StainlessVivek KambleNoch keine Bewertungen

- The Stainless Steel Family - An Overview - Campbell Tip of The MonthDokument5 SeitenThe Stainless Steel Family - An Overview - Campbell Tip of The Monthpeach5Noch keine Bewertungen

- ASM Metals HandBook Volume 4 - Heat TreatingDokument15 SeitenASM Metals HandBook Volume 4 - Heat TreatingK.s. Raghavendra KumarNoch keine Bewertungen

- Tool Steel: AISI-SAE GradesDokument4 SeitenTool Steel: AISI-SAE GradesarienissaNoch keine Bewertungen

- Aalco Metals LTD Aluminium Alloy en Standards For Rolled Aluminium 51Dokument13 SeitenAalco Metals LTD Aluminium Alloy en Standards For Rolled Aluminium 51kartik spectomsNoch keine Bewertungen

- Aisi: O1 UNS: T31501 Component: Cold-Work SteelsDokument2 SeitenAisi: O1 UNS: T31501 Component: Cold-Work SteelsnaufalmametNoch keine Bewertungen

- Tool SteelsDokument31 SeitenTool SteelsMaheswaran MuthuNoch keine Bewertungen

- Designation of The Types of SteelsDokument6 SeitenDesignation of The Types of SteelsDavid FernandezNoch keine Bewertungen

- Bench Fitting: Name - W.M.S.P. Weerasingha Course - N.D.T Field - CIVIL Reg. No - 09/IT/CI/100 Date of Sub - 2010/11Dokument27 SeitenBench Fitting: Name - W.M.S.P. Weerasingha Course - N.D.T Field - CIVIL Reg. No - 09/IT/CI/100 Date of Sub - 2010/11malith kml100% (2)

- MATS4084 Specialty Alloys Assignment: Tool & Die SteelsDokument9 SeitenMATS4084 Specialty Alloys Assignment: Tool & Die SteelsLinda LyNoch keine Bewertungen

- Classification of Steels for Engineering Materials AssignmentDokument9 SeitenClassification of Steels for Engineering Materials AssignmentZarak MirNoch keine Bewertungen

- Engineering Materials Assignment SummaryDokument14 SeitenEngineering Materials Assignment SummaryJoseph JoelNoch keine Bewertungen

- SAE Steel GradesDokument8 SeitenSAE Steel GradesbugmenotNoch keine Bewertungen

- Tool SteelsDokument53 SeitenTool SteelsMuhamad KahfaNoch keine Bewertungen

- 014 ToolsteelDokument36 Seiten014 ToolsteelSamrat SinghNoch keine Bewertungen

- Low Alloy Steel - An OverviewDokument10 SeitenLow Alloy Steel - An OverviewhaharameshNoch keine Bewertungen

- Properties and applications of carbon and alloy steelsDokument12 SeitenProperties and applications of carbon and alloy steelsananda narayananNoch keine Bewertungen

- Types of Steel-Grades of SteelDokument7 SeitenTypes of Steel-Grades of SteelmabroukNoch keine Bewertungen

- 300 Series Austenitic: Austenite Face Centered Cubic Alloys Chromium Nickel Molybdenum NitrogenDokument3 Seiten300 Series Austenitic: Austenite Face Centered Cubic Alloys Chromium Nickel Molybdenum NitrogenMohamad AzuwanNoch keine Bewertungen

- Machining Titanium AlloysDokument22 SeitenMachining Titanium AlloysSarswati SuryawanshiNoch keine Bewertungen

- Hss Tools and AppilcationDokument17 SeitenHss Tools and AppilcationMeena SivasubramanianNoch keine Bewertungen

- 304 316 Stainless SteelDokument3 Seiten304 316 Stainless Steelnetuno9999Noch keine Bewertungen

- Stainless Steel - WikipediaDokument14 SeitenStainless Steel - Wikipediaramthecharm_46098467Noch keine Bewertungen

- MEE 511 Course WorkDokument10 SeitenMEE 511 Course WorktornakingstonNoch keine Bewertungen

- Aalco Stainless SteelDokument45 SeitenAalco Stainless SteelswaminathanNoch keine Bewertungen

- Report Stainless SteelDokument6 SeitenReport Stainless SteelAhmed ShokryNoch keine Bewertungen

- Ch-27.7 Alloying Element of Steel and Alloy SteelDokument50 SeitenCh-27.7 Alloying Element of Steel and Alloy SteelPARESHNoch keine Bewertungen

- Chapter 5Dokument3 SeitenChapter 5Dufton MusiliNoch keine Bewertungen

- Stainless Steel Properties GuideDokument3 SeitenStainless Steel Properties GuidebabeNoch keine Bewertungen

- Tool SteelsDokument35 SeitenTool SteelsHandrizaHanifAsyrafiNoch keine Bewertungen

- 14 Material and Heat Treatment of Jigs &Dokument18 Seiten14 Material and Heat Treatment of Jigs &GV RagunathanNoch keine Bewertungen

- Effects of Steel Alloys on PropertiesDokument9 SeitenEffects of Steel Alloys on PropertiesMina RemonNoch keine Bewertungen

- CH 05Dokument113 SeitenCH 05hammad khalidNoch keine Bewertungen

- SAE Steel GradesDokument14 SeitenSAE Steel GradesSiva BhaskarNoch keine Bewertungen

- Stainless SteelDokument24 SeitenStainless SteelsmrutiNoch keine Bewertungen

- C18Dokument24 SeitenC18combinationdieNoch keine Bewertungen

- Define Stainless OKDokument12 SeitenDefine Stainless OKabasoudaNoch keine Bewertungen

- Materials For Engine: © 2016 Scrivener Publishing LLC. Published 2016 by John Wiley & Sons, IncDokument8 SeitenMaterials For Engine: © 2016 Scrivener Publishing LLC. Published 2016 by John Wiley & Sons, IncDzaky ArizsaNoch keine Bewertungen

- Iron and Steel Railway WagonsDokument35 SeitenIron and Steel Railway Wagonsrajbir_singhNoch keine Bewertungen

- Quiz LetDokument3 SeitenQuiz LetSohail ShaikhNoch keine Bewertungen

- Lec 1Dokument17 SeitenLec 1Sohail ShaikhNoch keine Bewertungen

- 1&2 RTDokument2 Seiten1&2 RTSohail ShaikhNoch keine Bewertungen

- LM6 Alloy DetailDokument4 SeitenLM6 Alloy DetaildsoNoch keine Bewertungen

- Inverter Split Air ConditionerDokument2 SeitenInverter Split Air ConditionerSohail ShaikhNoch keine Bewertungen

- LM6 Alloy DetailDokument4 SeitenLM6 Alloy DetaildsoNoch keine Bewertungen

- LM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsDokument3 SeitenLM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsSohail ShaikhNoch keine Bewertungen

- Equivalent Cross Valve Cast PDFDokument2 SeitenEquivalent Cross Valve Cast PDFshaonaaNoch keine Bewertungen

- Practical Guide To Pressure Vessel Manufacturing by Sunil Kumar Pullarcot PDFDokument366 SeitenPractical Guide To Pressure Vessel Manufacturing by Sunil Kumar Pullarcot PDFSohail Shaikh100% (1)

- Standard Pipe Sizes ME303-4.1.1Dokument5 SeitenStandard Pipe Sizes ME303-4.1.1manashbdNoch keine Bewertungen

- Ins Cad WDokument1 SeiteIns Cad WzarcherNoch keine Bewertungen

- Texas Flange Product Catalog ANSI B16.5 Class 150 & 300 Forged FlangesDokument48 SeitenTexas Flange Product Catalog ANSI B16.5 Class 150 & 300 Forged Flangeslink2u_007Noch keine Bewertungen

- Is 15839 2009Dokument15 SeitenIs 15839 2009Sohail ShaikhNoch keine Bewertungen

- BS10 Flanges PDFDokument10 SeitenBS10 Flanges PDFManpreet SinghNoch keine Bewertungen

- Nominal Size (NB) Outside Diameter Wall Thickness Weight (MM) (MM) (MM) KG/M M/tonne KG/M M/tonne Black GalvanisedDokument1 SeiteNominal Size (NB) Outside Diameter Wall Thickness Weight (MM) (MM) (MM) KG/M M/tonne KG/M M/tonne Black GalvanisedVisas SivaNoch keine Bewertungen

- Induction Sealing - Wikipedia, The Free EncyclopediaDokument6 SeitenInduction Sealing - Wikipedia, The Free EncyclopediaSohail ShaikhNoch keine Bewertungen

- Mechanical CoursesDokument8 SeitenMechanical CoursesSohail ShaikhNoch keine Bewertungen

- PE Pipes - Pressure GradesDokument5 SeitenPE Pipes - Pressure GradesSohail ShaikhNoch keine Bewertungen

- CIS677 4 ReengineeringDokument14 SeitenCIS677 4 ReengineeringSohail ShaikhNoch keine Bewertungen

- Emerging Steelmaking TechnologiesDokument5 SeitenEmerging Steelmaking TechnologiesSohail ShaikhNoch keine Bewertungen

- Water-Tube Package WDokument12 SeitenWater-Tube Package W김윤환Noch keine Bewertungen

- Application For Bonafide CertificateDokument1 SeiteApplication For Bonafide CertificateSohail ShaikhNoch keine Bewertungen

- RRB Tecnical AbilityDokument32 SeitenRRB Tecnical AbilitySohail ShaikhNoch keine Bewertungen

- Alloy 400 PDFDokument12 SeitenAlloy 400 PDFwasatiah05Noch keine Bewertungen

- Chemistry - Revision - Grade - 8 - 1st - Term Answer KeyDokument9 SeitenChemistry - Revision - Grade - 8 - 1st - Term Answer KeyWaLkiEs TaLkIeSNoch keine Bewertungen

- 4CH1 2CR Que 20220118Dokument20 Seiten4CH1 2CR Que 20220118Mohamed MuhajireenNoch keine Bewertungen

- The Importance of Iron in Our Daily LifeDokument38 SeitenThe Importance of Iron in Our Daily Lifelamia97100% (1)

- Acids Bases WS 1689573034Dokument6 SeitenAcids Bases WS 1689573034shreyasNoch keine Bewertungen

- Transition Metals LabDokument3 SeitenTransition Metals LabGordon ForsythNoch keine Bewertungen

- Year 11 IGCSE Question PaperDokument17 SeitenYear 11 IGCSE Question PaperMaitrey TelangNoch keine Bewertungen

- MIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)Dokument20 SeitenMIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)ccorp0089Noch keine Bewertungen

- Science Checkpoint Exam RevisionDokument14 SeitenScience Checkpoint Exam RevisionMark ZuckerburgNoch keine Bewertungen

- Cambridge O Level: CHEMISTRY 5070/21Dokument20 SeitenCambridge O Level: CHEMISTRY 5070/21Fasih RazaNoch keine Bewertungen

- Kobel CoDokument4 SeitenKobel CoCesar ZarateNoch keine Bewertungen

- Chapter 10 Practice 1wsDokument3 SeitenChapter 10 Practice 1wsPranav BulusuNoch keine Bewertungen

- Microstructure and mechanical properties of dissimilar AISI 347 and A335 welded jointDokument8 SeitenMicrostructure and mechanical properties of dissimilar AISI 347 and A335 welded jointBurhanuddin As-SirajNoch keine Bewertungen

- Year 9 F Worksheet SC2 a.5 Mixtures and melting point dataDokument2 SeitenYear 9 F Worksheet SC2 a.5 Mixtures and melting point dataMohamed Elshadi Elshaikh Mohamed Ahmed YassinNoch keine Bewertungen

- Mystery Powders 1Dokument10 SeitenMystery Powders 1api-373282629Noch keine Bewertungen

- Obejctive Questions: Revision For Science Chapter 8 7/12/2020Dokument11 SeitenObejctive Questions: Revision For Science Chapter 8 7/12/2020Ziyi EngNoch keine Bewertungen

- Coal Spec Wahana 6300 GarDokument1 SeiteCoal Spec Wahana 6300 GarAmatơ Hà ThànhNoch keine Bewertungen

- Lesson Plan - July Class 10Dokument5 SeitenLesson Plan - July Class 10Pravita K dasNoch keine Bewertungen

- Leaching Kinetics of Bastnaesite Concentrate in HCL SolutionDokument5 SeitenLeaching Kinetics of Bastnaesite Concentrate in HCL Solutionmtanaydin100% (1)

- Co CR Mo AlloyDokument7 SeitenCo CR Mo AlloyRe ZanoNoch keine Bewertungen

- Refractory Metals, Noble Metals & Misc. - KirimDokument11 SeitenRefractory Metals, Noble Metals & Misc. - KirimRachmat HermawanNoch keine Bewertungen

- ISO834 Fire Resistance TestsDokument4 SeitenISO834 Fire Resistance TestsVictor Hugo0% (1)

- Chemical Formulae and EquationDokument12 SeitenChemical Formulae and EquationKiTTyNoch keine Bewertungen

- Solvent Extraction of Aluminium from Sulphate Solutions Using Cyanex 272Dokument8 SeitenSolvent Extraction of Aluminium from Sulphate Solutions Using Cyanex 272Leda HidalgoNoch keine Bewertungen

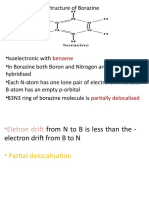

- Structure and Properties of Borazine, SN, and ClathratesDokument14 SeitenStructure and Properties of Borazine, SN, and ClathratesgirishNoch keine Bewertungen

- Daftar PustakaDokument4 SeitenDaftar PustakaRafika RahmawatiNoch keine Bewertungen