Beruflich Dokumente

Kultur Dokumente

Solar Boat Launched

Hochgeladen von

Marcelo Moya Cajas0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

35 Ansichten1 Seitesolar

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldensolar

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

35 Ansichten1 SeiteSolar Boat Launched

Hochgeladen von

Marcelo Moya Cajassolar

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

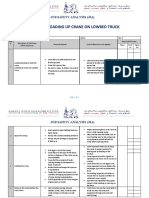

APPLICATIONS

Solar boat launched

NEXT YEAR, the Tranor

PlanetSolar composite catamaran will set out to become

the rst solar-powered boat

to sail around the world.

The 30 m long, 5 m wide

catamarans deck is covered

with photovoltaic panels with

a surface area of over 530 m2.

The solar power will be stored

in a lithium ion battery, which

will power an electric motor.

The boat was constructed by

Knierim Yacht Club, in Kiel,

Germany, in 14 months. It is an

extremely lightweight carbon/

epoxy composite sandwich

design. It required approximately 20.6 tons of carbon

bre, 23 tons of epoxy resin

and 11.5 tons of AIREX C70

structural foam core material

in various densities. One of the

challenges for this sandwich

construction was to take into

account the weight of the

solar panels, battery and motor,

while designing the boat as

light and as robust as possible.

In 2011, PlanetSolar will

set out to circumnavigate

the world powered only

by the sun. It will travel at

average speeds of 7.5 knots

and the 50 000 km journey

will take about 160 days.

Planet Solar;

www.planetsolar.org

PlanetSolar, the worlds biggest solar-powered boat, was launched at the end of

March. The project aims to promote the use of renewable technologies as the main

energy source of the future.

AAR wins CSeries contract

AAR CORP has been selected

by Bombardier Aerospace,

Belfast, to design and manufacture composite ap track

fairings for the wings of Bombardiers new CSeries aircraft.

The contract could be worth

more than US$90 million over

the life of the programme.

The work will be performed

by AAR Composites, which

develops and fabricates advanced

composite structures for aviation

and aerospace applications.

Located in Clearwater, Florida,

USA, AAR Composites recently

expanded its manufacturing

capabilities with the opening of

a west coast facility in Sacramento, California. The expansion

REINFORCEDplastics

provides additional capacity for

autoclave, oven, resin transfer

moulding (RTM) and vacuum

assisted resin transfer moulding

(VARTM) composites processes.

Bombardier Aerospace, Belfast,

is responsible for the development, design and manufacture

of the composite wings for the

CSeries aircraft family, which is

designed for the 100- to 149-seat

market. It has already assembled

a pre-production demonstrator

wing using its resin transfer

infusion process (see page 8).

AAR;

www.aarcorp.com

Bombardier;

www.bombardier.com

MAY/JUNE 2010

Composites strengthen

Melbourne bridge

The West Gate bridge.

CARBON COMPOSITES are

being used to strengthen

the West Gate Bridge in

Melbourne, Australia.

The West Gate Bridge crosses

the Yarra River and is part

of a freeway that traverses

the city of Melbourne. It is a

2.5 km long suspension bridge

(approximately 6 km long

including approach roads), with

a 336 m main river span, 58 m

high above the water, with

its two towers culminating at

102 m above river level. The

current trac volume across

the bridge of 160 000 vehicles

per day includes 20 000 trucks.

The renovation of the bridge

includes expanding the bridge

from four to ve lanes and

installing a public safety barrier.

The strengthening work

started in October 2009 on

the east side of the bridge,

using MBrace carbon bre

sheets and fabrics supplied by

EPSILON Composite, France, and

epoxy resins supplied by BASF,

Australia. The MBrace plates (up

to 4 mm thick) have a peel ply

on both sides.

The original design required

more than 100 km of high

strength standard carbon bre

plates, more than 10 000 m of

carbon bre fabric, including

more than 65 tons of adhesive and more than 20 tons

of resin. According to EPSILON

Composite, this makes it by far

the largest carbon composite

strengthening project ever,

by a factor of at least three

compared to previous jobs.

The project is being funded

by the Victorian State Government and the Australian Federal

Government to the value of

$240 million.

EPSILON Composite;

www.epsilon-composite.com

BASF; www.basf.com

The strengthening work.

www.reinforcedplastics.com

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- NHTSA DWI/DUI Field Sobriety Test Student Manual 2006 OCRDokument321 SeitenNHTSA DWI/DUI Field Sobriety Test Student Manual 2006 OCRMark W. Bennett100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Right To Travel FlyerDokument3 SeitenRight To Travel Flyersolution4theinnocent100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- ColtoDokument448 SeitenColtoPhumlani Kunene75% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- InfrastructureDokument32 SeitenInfrastructureDr Sarbesh Mishra100% (2)

- Norman "Destin Landing" PUD NarrativeDokument39 SeitenNorman "Destin Landing" PUD NarrativeKeaton FoxNoch keine Bewertungen

- Paver SUPER 1800-3 BrochureDokument22 SeitenPaver SUPER 1800-3 BrochureMohammad Younes100% (1)

- SAB-JSA - Loading Crane On The TruckDokument3 SeitenSAB-JSA - Loading Crane On The TruckaymenmoatazNoch keine Bewertungen

- Bitumen Road ConstructionDokument40 SeitenBitumen Road Constructionsai kiranNoch keine Bewertungen

- Civil Engineer Resume - Sample 1Dokument4 SeitenCivil Engineer Resume - Sample 1anandkumarrs6Noch keine Bewertungen

- MaritimeReporter 2001 09Dokument76 SeitenMaritimeReporter 2001 09Marcelo Moya CajasNoch keine Bewertungen

- Alternative PowerDokument1 SeiteAlternative PowerMarcelo Moya CajasNoch keine Bewertungen

- Neural Network For PLC PDFDokument7 SeitenNeural Network For PLC PDFMarcelo Moya CajasNoch keine Bewertungen

- LaTeX TutorialDokument11 SeitenLaTeX TutorialMarcelo Moya CajasNoch keine Bewertungen

- Labview State Diagram Toolkit User Guide: © 2003 National Instruments Corp. All Rights ReservedDokument23 SeitenLabview State Diagram Toolkit User Guide: © 2003 National Instruments Corp. All Rights ReservedMarcelo Moya CajasNoch keine Bewertungen

- VRML Pag 29Dokument61 SeitenVRML Pag 29Marcelo Moya CajasNoch keine Bewertungen

- Vic Rider HandbookDokument96 SeitenVic Rider HandbookTom GiulyanNoch keine Bewertungen

- Vehicle Speed Affects Both Pre-Skid Braking Kinematics and Average Tire/roadway FrictionDokument12 SeitenVehicle Speed Affects Both Pre-Skid Braking Kinematics and Average Tire/roadway FrictionKuldeep SinghNoch keine Bewertungen

- Merlin Road Roughness Machine User GuideDokument18 SeitenMerlin Road Roughness Machine User GuidePablo José Farfan GuerreroNoch keine Bewertungen

- LKPD XiiDokument4 SeitenLKPD XiiSri Wahyuni BasmanNoch keine Bewertungen

- VicRoads 2019-Road Design Note 0613 Guidelines For The Protection of Gantry and Cantilever Sign Supports-DoneDokument19 SeitenVicRoads 2019-Road Design Note 0613 Guidelines For The Protection of Gantry and Cantilever Sign Supports-DoneMineaNoch keine Bewertungen

- Preliminary Vehicle Diagnosis WorksheetDokument4 SeitenPreliminary Vehicle Diagnosis Worksheetways4successNoch keine Bewertungen

- Borivali Railway Station (E) - Thane Railway Station (E) : 65 AC Bus Time Schedule & Line MapDokument5 SeitenBorivali Railway Station (E) - Thane Railway Station (E) : 65 AC Bus Time Schedule & Line MapwdcwoNoch keine Bewertungen

- Divyadesams Near ThanjavurDokument6 SeitenDivyadesams Near ThanjavursaaigeeNoch keine Bewertungen

- BrakesDokument15 SeitenBrakesSheshu GeddiNoch keine Bewertungen

- RP 0801 Heli DeckDokument19 SeitenRP 0801 Heli DeckBrian DunaganNoch keine Bewertungen

- Tamil Nadu 04092012Dokument65 SeitenTamil Nadu 04092012Nikhil PatilNoch keine Bewertungen

- SU14 Norway TripDokument4 SeitenSU14 Norway TripJaslynNgHuiShanNoch keine Bewertungen

- Assignment IIDokument3 SeitenAssignment IItedy yidegNoch keine Bewertungen

- BW MapDokument2 SeitenBW MapDamon MeddingsNoch keine Bewertungen

- Fleet Management LegislationDokument17 SeitenFleet Management LegislationNurul AduraNoch keine Bewertungen

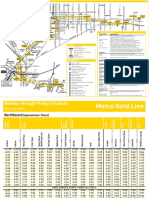

- Metro Gold Line Metro Gold Line: Saturday, Sunday & Holiday Schedule Saturday, Sunday & Holiday ScheduleDokument5 SeitenMetro Gold Line Metro Gold Line: Saturday, Sunday & Holiday Schedule Saturday, Sunday & Holiday ScheduleSherri BerryNoch keine Bewertungen

- Flyer E-BIKE int2018LOWDokument16 SeitenFlyer E-BIKE int2018LOWJulieta OliveraNoch keine Bewertungen

- Public Private Partnership - Project ReportDokument44 SeitenPublic Private Partnership - Project ReportKamlesh GuptaNoch keine Bewertungen

- Intermediate Polish Wordlist: File 1Dokument32 SeitenIntermediate Polish Wordlist: File 1Monika ChudzińskaNoch keine Bewertungen

- ETAG N° 032: Guideline For European Technical Approval ofDokument51 SeitenETAG N° 032: Guideline For European Technical Approval ofShamaNoch keine Bewertungen

- DMRC NotificationDokument4 SeitenDMRC NotificationMalhotraSoniaNoch keine Bewertungen