Beruflich Dokumente

Kultur Dokumente

736

Hochgeladen von

jorgeCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

736

Hochgeladen von

jorgeCopyright:

Verfügbare Formate

Coupled AbioticBiotic Mineralization of 2,4,6-Trinitrotoluene (TNT)

Thomas F. Hess* and Paul S. Schrader

ABSTRACT

Fentons reaction is the catalyzed decomposition of

hydrogen peroxide by transition metals, resulting in the

generation of hydroxyl radicals (Haber and Weiss, 1934).

The standard Fenton reaction proceeds by adding dilute

hydrogen peroxide to a degassed solution of iron(II),

resulting in nearly stoichiometric generation of hydroxyl

radicals. Most environmental applications of Fenton

chemistry involve reaction modifications, including use

of higher concentrations of hydrogen peroxide, phosphate-buffered medium, heterogeneous catalysts, or iron.

These conditions, although not as stoichiometrically efficient as the standard Fentons reaction, are often necessary to treat sorbed contaminants in soils and ground

water (Tyre et al., 1991).

Hydroxyl radical has high reactivity with many environmental contaminants at or near diffusion-controlled

rates (109 M1 s1 ). The degradation of xenobiotic

chemicals by hydroxyl radical is typically due to either

hydroxylation or hydrogen atom abstraction. Some biorefractory compounds such as perchloroethylene, hexachlorocyclopentadiene, and hexachlorobenzene have

been effectively destroyed by hydroxyl radicals within

minutes (Leung et al., 1992; Sato et al., 1993; Watts et

al., 1994). The use of Fentons reagent (29.4 mM H2O2

and 40 mM Fe2 ) for the destruction of TNT in aqueous

solutions (0.31 mM) resulted in complete degradation

within 8 h and 40% mineralization within 24 h (Li et

al., 1997a).

Anaerobic and aerobic biodegradation processes

have been investigated for the destruction of TNT.

While aerobic TNT biodegradation has been demonstrated, problems such as accumulation of metabolic

intermediates (Vorbeck et al., 1994, Ramos et al., 1995),

inhibitory intermediate compound formation (Michels

and Gottschalk, 1995), and low mineralization (Fernando et al., 1990) limit process effectiveness. Additionally, reductive microbial transformation of TNT is the

thermodynamically favorable pathway due to the aromatic ring stabilization and electron-withdrawing effect

of the nitro groups (Bruhn et al., 1987). The consensus

of recent research is that anaerobic biological processes

hold the most promise for stand-alone bioremediation

of TNT (Funk et al., 1993; Preuss and Rieger, 1995,

Crawford, 1995; Regan and Crawford, 1994; Lewis et

al., 1997). The research has indicated, however, that

substantial mineralization of TNT may not be achieved

although the parent compound can be entirely transformed to intermediary metabolites (Crawford, 1995).

Combined technologies for the destruction of hazardous wastes have received research attention (Carberry

and Benzing, 1991; Koyama et al., 1994; Scott and Ollis,

1995; Ravikumar and Gurol, 1991). In these studies, the

authors investigated sequential processes, using abiotic

Munitions wastes such as TNT are widespread contaminants in

soils and ground waters. We investigated a coupled abioticbiotic

treatment scheme for remediation of aqueous solutions of TNT. Mineralization of aqueous TNT (0.22 mM ) was initially optimized with

minimum reactant use (Fe3 and H2O2 ) in light-assisted and dark,

modified Fenton reactions at acidic and neutral pH. Complete TNT

degradation occurred under all reaction conditions within 24 h. Using

the optimum reactant concentrations, coupled abioticbiotic reactions

showed an increase in TNT mineralization, from 47 to 80%, after

biomass addition to the acidic, dark Fenton-like reaction. Comparable

increases of TNT mineralization were observed under neutral pH

with similar reaction conditions. In light-assisted Fenton-like reactions

at neutral pH, no increase in cumulative TNT mineralization (66%)

was seen in coupled abioticbiotic reactions. Abiotic photo-Fentonlike reactions alone, at acidic pH, produced complete TNT mineralization and required no biotic assistance. While light-enhanced Fenton

reactions alone can provide high levels of TNT mineralization, the

dark abioticbiotic reaction scheme has perhaps a wider use due to

a similar extent of TNT mineralization in the absence of light, leading

to possible applications in soil slurry and in situ processes in the subsurface.

aste generated during the past manufacture of

2,4,6-trinitrotoluene (TNT) and decommissioning

of military ordnance has contributed to widespread environmental contamination at many current and former

Department of Defense (DOD) facilities located

throughout the United States (Urbanski, 1964; Spalding

and Fulton, 1988). More than 1200 explosives-contaminated DOD sites have been identified with almost 90%

of these sites containing TNT-contaminated ground water (Schmelling and Gray, 1995). Because TNT is acutely

toxic to humans and animals even in low concentrations

(Watts, 1998), mutagenic in the Ames test (Won et al.,

1976), and listed as a priority pollutant by the USEPA

(Schuster and Gratzfeld-Huesgen, 1993), remediation

of TNT-contaminated soils and ground waters is legally mandated.

The numerous technologies investigated for remediation of waters contaminated with TNT and related compounds principally have been based on chemical or biological processes. Studies of chemical treatment have

focused on advanced oxidative processes (AOPs), while

those related to biological transformation have used

either bacterial or fungal systems under aerobic or anaerobic conditions. The AOPs previously applied to the

treatment of TNT include ozone-catalyzed decomposition of TNT (Lang et al., 1998), TiO2mediated photocatalysis (Schmelling et al., 1996; Schmelling and Gray,

1993, 1995), and Fenton chemistry (Li et al., 1997a,b).

Center for Hazardous Waste Remediation and Research, Univ. of

Idaho, Moscow, ID 83844-0904. Received 14 May 2001. *Corresponding author (tfhess@uidaho.edu).

Abbreviations: DNP, 2,4-dinitrophenol; NTA, nitrilotriaceticacid;

TNT, 2,4,6-trinitrotoluene; WAS, waste-activated sludge.

Published in J. Environ. Qual. 31:736744 (2002).

736

HESS & SCHRADER: COUPLED ABIOTICBIOTIC MINERALIZATION OF TNT

reactions as a pretreatment step for a separate, followon biological reaction. Such technologies were developed to overcome the biorecalcitrance of a particular

compound inherent with stand-alone biological processes. Our own research into sequential, coupled processes has indicated that TiO2mediated photocatalysis

followed by biological degradation (Hess et al., 1998)

and coexistent abiotic and biotic transformations (Buyuksonmez et al., 1998, 1999; Howsakeng et al., 2002)

can be used to treat biorefractory compounds.

This research was designed to test the efficacy of

coupled abioticbiotic reactions for a high extent of

TNT destruction in simple, aqueous matrices, thus

avoiding complications of soil solutions, yet provide a

basis for future work in soil. A modified Fentons system

(Fe3 catalyst) was used in the abiotic reaction and two

different, uncharacterized aerobic biomasses were tested for their potential to degrade any Fenton-degradation products. The specific objectives of this research

were fourfold: (i) explore the efficacy of the chemical

treatment under a variety of environmental conditions,

(ii) optimize the chemical mineralization of TNT under

these conditions, (iii) explore the use of an aerobic microbial biomass as a subsequent treatment, and (iv) determine the kinetics of each treatment.

MATERIALS AND METHODS

Chemical Reagents

Iron(III) sulfate pentahydrate (97%) and nitrilotriaceticacid (NTA, 99%) were purchased from Aldrich Chemical

Company (Milwaukee, WI). Reagent-grade H2O2 (30% v/v)

was obtained from J.T. Baker (Phillipsburg, NJ). The 2,4,6trinitrotoluene (99%) was purchased from Chem Service

(West Chester, PA). Ecolite () scintillation cocktail was purchased from ICN Biomedicals (Costa Mesa, CA). Uniformly

ring-labeled 2,4,6-trinitrotoluene with a specific activity of 2.18

MBq mM1 (99%) was synthesized by Dr. Stefan Goszczyn-

737

ski of the Environmental Biotechnology Institute, University

of Idaho (Moscow, ID). All other chemicals used in the project

were of the highest available purity. Double-deionized water

(18 M-cm) was used for preparation of all chemical solutions.

Experimental Design

Several sets of experiments were conducted for this research: abiotic, optimization experiments to determine maximum TNT mineralization occurring at minimum reactant concentrations; combined abioticbiotic kinetic experiments

(conducted at optimum reactant concentrations determined

above) to determine any increase in TNT mineralization due

to biotic reactions; abiotic degradation experiments conducted

to determine extent of TNT degradation using optimum reactant concentrations; and abiotic experiments to determine

the effect of metal chelate concentrations on overall TNT

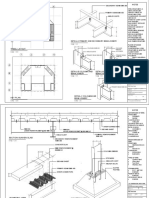

mineralization (Fig. 1). Modified Fenton reactions were used

for all abiotic TNT mineralization and degradation studies.

Optimization experiments were originally conceived as twolevel, rotatable, central composite designs (Table 1) but later

converted to factorial designs when early data (dark-Fenton

reactions, pH 3) did not show rotatability (Table 2) (Cochran

and Cox, 1992). The two-level designs (Tables 1 and 2) included Fe3 and H2O2 concentrations as experimental variables with TNT mineralization as the response. The factorial

experimental design was used to quantify the effects of the

individual experimental variables, iron and hydrogen peroxide, on the response. This was done by analyzing the response

when testing one experimental variable over a range of concentrations while leaving the other constant. The same was

then done for the other variable. Optimality was determined

graphically based on the maximum response achieved using

the lowest reactant concentrations.

Abiotic TNT Mineralization Experiments

Abiotic TNT mineralization was measured in both optimization and kinetic experiments by capture and quantification

of 14CO2 produced during the modified Fenton reactions. All

Fig. 1. Diagram of experimental setup showing incremental use of results (arrows) between various stages of experimentation.

738

J. ENVIRON. QUAL., VOL. 31, MAYJUNE 2002

Table 1. Experimental designs and results of 14C-labeled experiments for investigation of the effects of iron and hydrogen

peroxide on the mineralization of aqueous TNT (0.22 mM ) in

dark-Fenton reactions at pH 3. Optimum iron and hydrogen

peroxide concentrations that produced maximum TNT mineralization are in italic type.

Fe3

H2O2

mM

2.93

2.93

17.07

17.07

0.00

20

10

10

10

10

10

10

10

0.01

0.05

0.1

0.5

1

2

3

5

0.01

0.05

0.1

0.5

1

2

3

5

1

2

3

5

0.01

0.05

0.1

0.5

1

2

3

5

TNT mineralization

%

Central composite design

43

251

43

251

147

147

0

294

147

147

147

147

147

Factorial design

15

15

15

15

15

15

15

15

29

29

29

29

29

29

29

29

44

44

44

44

74

74

74

74

74

74

74

74

30.73

37.79

27.61

33.54

0

31.73

0

34.09

31.58

32.65

33.02

33.08

33.84

0.32

0.55

1.52

31.03

27.45

29.85

27.53

24.47

0.36

0.98

1.87

29.75

31.60

34.56

28.47

27.51

37.33

32.87

32.44

29.19

0.52

1.58

2.31

24.70

42.68

32.35

33.97

31.33

experiments were conducted with 30-mL solutions of TNT

(0.22 mM ) using mixtures of nonlabeled TNT and enough 14C

uniformly labelled TNT to provide approximately 1.67 103

Bq per flask. Mineralization reactions were conducted in 500mL biometer flasks each sealed with a rubber stopper and

containing a glass cup (holding base solution) suspended in

the atmosphere of the flask and a piece of glass tubing extending from the atmosphere of the flask through the stopper.

Attached to the outside end of the glass tubing was an expandable bladder used to hold the gasses evolved from the reaction

and allow free exchange with the flask atmosphere. The glass

cup contained 1 mL of a 0.1 M NaOH solution used to capture

CO2 from the flask atmosphere. For optimization experiments,

the 1-mL NaOH sample was collected, as well as two successive 1-mL H2O-rinsates, at the end of the experiment. For

kinetic experiments, the sample and rinsates were collected

at timed intervals during the course of the experiment. The

samples were added directly to 15 mL of Ecolite () liquid

scintillation cocktail and analyzed by scintillation counting as

described below to quantify the amount of 14CO2 generated

from the reaction. Knowing the original quantity of 14C-TNT

in solution, we determined the extent (percent) of TNT miner-

Table 2. Experimental design and results of 14C-labeled experiments for investigation of the effects of iron and hydrogen

peroxide on the mineralization of aqueous TNT (0.22 mM ) in

dark-Fenton reactions at pH 7 and light-Fenton reactions at

pH 3 and pH 7. Experiments at pH 7 used NTA to Fe molar

ratios of 10:1 to chelate iron. Optimum iron hydrogen peroxide

concentrations that produced maximum TNT mineralization

are in italic type.

Factorial design

Fe

H2O2

TNT mineralization

Light, pH 3

Dark, pH 7

Light, pH 7

1.29

5.84

81.16

89.26

84.21

80.94

75.29

63.19

59.28

4.40

6.56

94.67

95.00

92.05

88.11

82.83

79.35

71.57

5.31

9.56

94.05

99.35

97.63

93.44

90.75

82.88

81.88

5.31

7.98

80.34

99.15

97.93

96.67

91.31

76.86

78.28

2.40

5.99

53.74

91.78

84.42

88.67

87.84

85.49

79.57

%

3.72

6.05

17.55

16.72

10.41

7.66

4.01

2.48

1.76

1.83

4.97

22.81

17.78

16.70

10.90

5.23

2.74

0.38

2.83

3.03

24.88

20.49

21.21

19.13

12.99

5.48

1.82

7.76

14.49

23.95

16.25

14.47

12.21

8.96

7.27

2.25

5.24

9.69

20.77

15.16

11.15

9.64

6.01

4.55

2.25

9.57

19.08

33.44

23.11

12.75

7.53

3.46

1.13

0.00

15.93

24.58

29.44

36.34

25.17

16.60

7.92

3.03

0.87

25.76

28.40

28.01

22.07

32.69

25.98

16.11

5.84

1.76

18.28

23.88

27.72

16.63

14.55

11.91

10.48

7.95

2.32

12.05

15.91

23.12

16.25

9.73

9.47

7.29

4.24

2.02

mM

0.05

0.1

0.5

1

2

3

5

10

20

0.05

0.1

0.5

1

2

3

5

10

20

0.05

0.1

0.5

1

2

3

5

10

20

0.05

0.1

0.5

1

2

3

5

10

20

0.05

0.1

0.5

1

2

3

5

10

20

15

15

15

15

15

15

15

15

15

29

29

29

29

29

29

29

29

29

74

74

74

74

74

74

74

74

74

147

147

147

147

147

147

147

147

147

294

294

294

294

294

294

294

294

294

alization. A 1-mL sample of the aqueous portion of the reaction was collected at the end of the experiment and analyzed

similarly to determine a mass balance on 14C.

Procedurally, the mineralization experiments were set up

by initially adding Fe3 to the TNT solution and the Fentonlike reaction was then begun by adding H2O2 to the TNTFe3

solution. Hydrogen peroxide and Fe3 concentrations varied

between 15 and 294 mM (1%) and 0.05 and 20 mM, respectively, for optimization experiments (Tables 1 and 2) and were

constant for kinetic experiments, based on results found during

optimization (values listed in italic type in Tables 1 and 2).

The iron used in neutral pH reactions was chelated with nitrilotriaceticacid (NTA) at either equimolar concentrations (1:1)

or ten times more NTA than iron (10:1), depending on the

experiment. The pH of the NTAFe3 solution was adjusted

to 7.0 using NaOH. All experiments were monitored for pH

using a meter and probe, and calibrated prior to each use with

standard buffer solutions (Accument Basic; Fisher Scientific,

HESS & SCHRADER: COUPLED ABIOTICBIOTIC MINERALIZATION OF TNT

Pittsburgh, PA). Experiments performed in the dark (darkFenton) were conducted after covering the reaction vessels

in aluminum foil. Those experiments run in the light (lightFenton) were put under a light box containing six, 24-inch

full-spectrum (380750 nm, peak intensity at 610 nm) 20-watt

light bulbs, 16-inches above the flasks, giving a light intensity

of 54.2 cd m2.

Biotic Reactions

Kinetic experiments that received biotic treatment subsequent to the Fenton reaction were first brought to neutral pH

by the addition of 1 mL of M9 salts (Provence and Curtiss,

1994). The addition of the salts resulted in a final concentration

of Na2HPO4 (42.3 mM ), KH2PO4 (22 mM ), NaCl (8.5 mM ),

and NH4Cl (18.7 mM ). Two uncharacterized biomasses from

aerobic, bench-scale sequencing batch reactors (SBRs), described previously (Hess et al., 1993), were used in separate

experiments. The first SBR was seeded with waste-activated

sludge (WAS) from the Pullman, Washington Wastewater

Treatment Facility, fed daily a synthetic waste (Kennedy et

al., 1990) with an organic carbon content of approximately

130 mg L1, and maintained at an average total suspended

solids (TSS) concentration of 2800 mg L1. The WAS was

added to the biometer flasks at 24 h after the initiation of the

abiotic, modified Fenton reaction (after solution neutralization) at an average concentration of either 467 or 93 mg L1,

depending on the experiment, and allowed to react for an

additional 6 d with base samples, containing 14CO2, taken at

regular intervals. The second SBR was seeded with a consortium of 2,4-dinitrophenol (DNP)degrading bacteria, fed daily

with a DNPglucose waste (Hess et al., 1990) with an organic

carbon content of approximately 45 mg L1, and maintained

at an average TSS concentration of 2000 mg L1. This DNP

biomass was added to biometer flasks similar to the WAS

biomass at concentrations of 333 and 67 mg L1, depending

on the experiment.

Liquid Scintillation Analysis

All samples from mineralization studies were counted with

a liquid scintillation analyzer (Tri-Carb Model 2100TR; Packard Bioscience, Meriden, CT) using a 14C protocol. Counts

per minute were converted to disintegrations per minute by

using an efficiency plot for known 14C quench standards and

appropriate blanks to eliminate background chemiluminescence.

TNT Degradation Sample Quenching

and Preparation

For analyses of each TNT degradation experiment, a 2-mL

sample of the modified Fenton reaction mixture was combined

with 100 L of sodium bicarbonate (approximately 0.9 M ) in

a test tube in order to stop the reaction (Glaze and Kang,

1988). A 1-mL aliquot of the quenched material was prepared

for high performance liquid chromatography (HPLC) analysis

by filtering through a 0.2-m nylon filter and placed into 1.5mL amber vials with Teflon-lined septa.

Chemical Analyses

The TNT concentrations were determined using HPLC

(Model 1090, Series II; Hewlett Packard, Palo Alto, CA)

equipped with a security guard column containing a C18 (ODS

octadecyl) filter connected to a C18 reverse-phase column

(250 mm 2.0 mm 5 m; Phenomenex, Torrance, CA). A

binary solvent, gradient elution methodology was used and

739

consisted of (i) acetonitrile and (ii) 0.5 mM lithium phosphate

buffer, pH 4.0 0.1, at a flow rate of 0.22 mL min1. Initial

conditions were 5% acetonitrile (0 to 3 min), to 51% acetonitrile (3 to 21 min, held 12 min), to 70% acetonitrile (21 to 29

min, held 4 min), with a return to initial setup conditions by

32 min. A 10-L injection of each sample collected was analyzed with the temperature of the HPLC column held constant

at 40C. The HPLC was equipped with a diode array UV/

Visible light detector (DAD) monitoring A230 with continuous

scanning of the absorption spectrum of each peak from 190

to 600 nm. Compounds detected were identified by a comparison of their retention times and UV/Visible light spectra with

those of authentic standards.

Identification of nitrate and oxalate ions was determined

by ion chromatography using conductivity detection (Dionex

Corporation, Sunnyvale, CA). A binary solvent, isocratic elution methodology was used for separation and consisted of

89.5% double distilled deionized water and 11.5% 100 mM

NaOH solution. Total run time for each sample was 9 min.

An IonPac AG-11 (Dionex) guard column connected to an

IonPac AS11 column with an IonPac ATC-1 filter for carbonate removal were used for all separations. Anions detected

were identified and quantified based on comparison with known

reference standards.

RESULTS AND DISCUSSION

Two major groups of experiments were conducted in

this project: (i) optimization experiments, using abiotic

Fenton reactions, designed to find minimum reactant

concentrations resulting in maximum TNT mineralization; and (ii) kinetic experiments, using abiotic Fenton reactions (conducted at reactant concentrations as

found in optimization experiments) coupled with follow-on biotic reactions, to determine the increase in

TNT mineralization due to biological treatment. Both

groups of experiments were conducted with four different reaction conditions: light-Fenton and dark-Fenton

reactions at pH 3 and light-Fenton and dark-Fenton

reactions at pH 7. Two additional minor groups of experiments were conducted, based on optimization results: (i) determination of the effects of iron chelate

concentrations on TNT mineralization extent and (ii)

overall TNT degradation kinetics. All experiments used

0.22 mM aqueous TNT solutions with varying concentrations of Fe3 and H2O2 in the modified Fenton reactions. The biotic portion of kinetic experiments used

varying concentrations of two uncharacterized biomasses, previously described.

Abiotic TNT Mineralization Optimization

Optimal concentrations of reactants, Fe3 and H2O2,

in aqueous, modified Fenton reactions were determined

from the results of experiments in factorial designs (Tables 1 and 2) for the four reaction conditions described

above. Initial experiments were based on rotatable, central composite designs (dark-Fenton reactions at pH 3)

but, upon failing to show rotatability, were converted

to factorial designs more appropriate for investigating

the resulting maximal responses (Chochran and Cox,

1992). Iron(III) and hydrogen peroxide were tested over

concentration ranges of 0.05 to 20 mM and 15 to 294

mM, respectively. Optimal reactant concentrations, the

740

J. ENVIRON. QUAL., VOL. 31, MAYJUNE 2002

Table 3. Percent recovery of 14C in optimization (Tables 1 and 2) and kinetic (Fig. 35) experiments related to aqueous TNT (0.22 mM )

mineralization. Data are means standard error (P 0.05).

14

Kinetic experiments (n 3)

Optimization

experiments

Abiotic biotic (WAS)

Abiotic

Dark, pH 3

Dark, pH 7

Light, pH 3

Light, pH 7

Biotic control

92.8

91.7

89.3

90.0

5.5

2.0

1.7

1.7

(n

(n

(n

(n

Abiotic

C recovery

41)

45)

45)

45)

89.4

100.25

103.4

100.0

0.9

0.8

4.6

0.4

93 mg

L 1

%

88.7 1.4

97.4 0.3

93.8 1.7

Abiotic biotic (DNP)

L 1

67 mg L1

300 mg L1

81.7 6.8

90.1 1.4

90.5 4.8

92.9 1.8

75.7 1.2

85.3 6.7

93.9 1.7

99.5 0.7

94.3 2.1

93.9 0.9

97.8 2.1

467 mg

Waste-activated sludge.

2,4-Dinitrophenol biomass.

lowest concentrations of reactants producing the highest

extent of TNT mineralization (shown in italic type in

Tables 1 and 2) were determined graphically (not

shown) for each experiment. These reactant concentrations were used for all subsequent experimentation. Experimental error for the data (Tables 1 and 2) was approximately 0.8% mineralization, based on the standard

deviation of the mean of center point replicates of the

central composite experiment (Table 1). Carbon balances, based on recovery of 14C (Table 3), were done

for all optimization data (Tables 1 and 2) and averaged

approximately 90% recovery for each reaction condition.

Several phenomena were observed upon examination

of the results. In all of the optimization experiments,

TNT mineralization extent declined with reactant concentrations above optimal (Table 1), presumably due

to competitive reactions between the reactive oxygen

radical species and excess Fe3 (De Laat and Gallard,

1999). Greater TNT mineralization extent in light-Fenton reactions (Table 2) than in dark-Fenton reactions

(Table 1), under similar conditions, was attributed to

photo-assisted Fenton oxidation, mechanistically described by others (Sun and Pignatello, 1993; Li et al.,

1997a). Overall TNT mineralization extent in dark-Fenton reactions was considerably less under neutral pH

conditions than under acidic conditions. This was attributed to either or both (i) a lowered efficiency of hydroxyl

radical formation at neutral pH or (ii) a higher reactivity

of hydroxyl radical with the ironchelate complex than

with TNT. The chelating agent (NTA) was required to

prevent formation of iron oxide precipitates at neutral

pH, thus removing the soluble iron catalyst from solution and limiting the Fenton-like reaction.

to iron ratio resulted in the greatest TNT mineralization

extent of 66%, whereas the same reaction with a 10:1

ratio produced 44% TNT mineralization (data not

shown). Similarly, with dark-Fenton reactions, the lower

molar ratio of NTA produced 45% TNT mineralization

versus 28% for the reaction with a 10:1 molar ratio of

NTA to Fe (data not shown).

TNT Degradation

Degradation of TNT has been a common benchmark

for success of a treatment process (Schmelling and Gray,

1993; Schmelling et al., 1996) and a good complement

to measuring the mineralization of TNT. By using both

measurements, one may determine how much of the

TNT parent molecule remains as well as the fraction

mineralized. Degradation experiments were performed

for the four light- and dark-Fenton reactions using the

optimal reactant and chelate concentrations defined

previously. Two additional light- and dark-Fenton reactions, at neutral pH, were also conducted with optimal

reactant concentrations and excess chelate to iron concentrations (10:1). It was observed (Fig. 2) that 100% of

Effect of Chelate Concentration

As mentioned above, the efficiency of Fenton reactions with TNT at neutral pH was lowered, presumably

due to the use of a chelate. We therefore explored the

effects of different chelate (NTA) concentrations on

TNT mineralization in light- and dark-Fenton reactions

at neutral pH. Optimal concentrations of iron(III) and

hydrogen peroxide (Tables 1 and 2) were used in these

experiments. A 1:1 molar ratio of chelate to iron was

the lowest concentration of NTA that maintained iron

in solution. The light-Fenton reaction with a 1:1 NTA

Fig. 2. Degradation of aqueous TNT (0.22 mM ) in dark- or lightFenton reactions: dark, pH 3 (); light, pH 3 (); light, pH 7 (Fe3

to nitrilotriaceticacid [NTA] ratio 1:1) (); dark, pH 7 (Fe3 to

NTA ratio 1:1) (); light, pH 7 (Fe3 to NTA ratio 1:10) ();

dark, pH 7 (Fe3 to NTA ratio 1:10) (). See text for description

of dark- and light-Fenton reactions. Error bars on symbols indicate

standard error of means (n 3, P 0.05); where absent, bars fall

within symbols.

HESS & SCHRADER: COUPLED ABIOTICBIOTIC MINERALIZATION OF TNT

the TNT was transformed under each reaction condition

within 24 h and, in most cases, within 6 h. The effect of

lowering the chelate concentration was seen in these

degradation experiments. The dark-Fenton reaction at

neutral pH, and containing a 10:1 chelate to iron ratio,

required nearly 24 h for complete TNT degradation

as compared with 10 h for an experiment with similar

reaction conditions, but with a 1:1 chelate to iron ratio.

Photo-Fenton effects were also observed (Fig. 2). More

time was required for complete TNT degradation in all

dark-Fenton reactions (624 h) compared with lightFenton reactions (26 h).

Coupled AbioticBiotic TNT

Mineralization Kinetics

The kinetics of a treatment process must be known

prior to assessing its overall viability, cost, and usefulness in an engineered system (Grady et al., 1999).

We therefore conducted several sets of experiments to

determine (i) the kinetics of the abiotic, modified Fenton reaction and (ii) the kinetics of a combined, sequential abioticbiotic reaction scheme using modified

Fenton reactions followed by biological treatment. All

Fenton reactions were investigated using the optimal

reactant concentrations previously determined. The abi-

741

otic reaction was run for 24 h at the pH tested with

subsequent addition of biomass after solution neutralization.

Capture and analysis of 14CO2 resulting from biological or chemical transformation of radiolabeled compounds is widely regarded as incontrovertible evidence

of compound mineralization (Bartha and Pramer, 1965;

Code of Federal Regulations, 1996). Using modified

biometer flasks, described above, we conducted kinetic

studies on the abiotic mineralization of TNT in darkFenton reactions, at both pH 3 and 7. The cumulative

TNT mineralization achieved in each reaction condition,

47 and 45% respectively, was approximately 85% complete within 24 h (Fig. 3). The extent of TNT mineralization in dark-Fenton reactions at neutral pH (45%) was

greater than that seen in the optimization experiments

(25%) due to the lowered NTA to Fe ratio (1:1) found

during chelate optimization studies. Kinetic studies using dark-Fenton reactions with a NTA to Fe ratio of

10:1 (similar to the initial optimization studies), at neutral pH, yielded an ultimate TNT mineralization extent

of 28% (data not shown).

In an effort to increase TNT mineralization using a

coupled abioticbiotic scheme, experiments were conducted with the addition of biotic treatment after the

abiotic, modified Fenton treatments previously investi-

Fig. 3. Mineralization of aqueous TNT (0.22 mM ) in dark-Fenton reactions comparing abiotic with coupled abioticbiotic treatments at high

and low biomass (waste-activated sludge [WAS] or 2,4-dinitrophenol [DNP] biomass) concentrations: (A ) pH 3, WAS biomass; (B ) pH 3,

DNP biomass; (C ) pH 7, WAS biomass; (D ) pH 7, DNP biomass. Abiotic reaction (); high biomass concentration, either 467 mg WAS

L1 or 333 mg DNP L1 (); low biomass concentration, either 93 mg WAS L1 or 67 mg DNP L1 (). Abiotic, pH 7, reactions conducted

with Fe3 to nitrilotriaceticacid (NTA) ratio 1:1. Biotic reactions for (A ) and (B ) were conducted after solution neutralization. Error bars

on symbols indicate standard error of means (n 3, P 0.05); where absent, bars fall within symbols.

742

J. ENVIRON. QUAL., VOL. 31, MAYJUNE 2002

gated. Two different biomasses were tested, a waste-activated sludge (WAS) biomass and a 2,4-dinitrophenol

(DNP)degrading biomass, both cultivated in benchscale sequencing batch reactors (Hess et al., 1993). Experiments were conducted with the four reaction conditions based on pH, acidic and neutral, and presence or

absence of light during the abiotic Fenton reactions.

The timing of biomass addition to the abiotic TNT reaction was critical and several time intervals after abiotic

reaction initiation (6, 10, and 14 h) were initially tested.

In all tests, TNT mineralization increased with the addition of biomass (data not shown). However, presumably

due to abiotic reaction quenching by the biotic, cellular

constituents (catalase and peroxidase), the overall coupled abioticbiotic TNT mineralization extent increased

with increasing time interval prior to biomass addition,

indicating improper timing of the addition. We therefore conducted further experiments with biomass addition 24 h after abiotic reaction initiation (Fig. 3). Overall

TNT mineralization increased from 47%, in the darkFenton reaction, pH 3, to 75 and 80% in the coupled

abioticbiotic system with WAS and DNP biomasses,

respectively (Fig. 3A,B). In reactions conducted at neutral pH, an increase in TNT mineralization from 45% in

the dark-Fenton reaction to 78% in both of the coupled

abioticbiotic systems (WAS or DNP biomasses) was

also seen (Fig. 3C,D). Direct TNT mineralization due

to biological action was negligible (less than 2%) based

on results from biotic controls (Fig. 4). Analysis of 14C

for all kinetic experiments indicated adequate carbon

balances (Table 3) with most experiments achieving at

least 90% recovery of radioactivity. Lower recovery percentages (90%) in some experiments were attributed

to experimental error.

The mechanism of increased TNT mineralization in

the coupled abioticbiotic system over that of the abiotic

reaction alone was probably due to biotic assimilation

of the abiotic TNT transformation products. As recently

reported by others (Li et al., 1997a), dicarboxylic acids,

Fig. 4. Biotic mineralization of aqueous TNT (0.22 mM ) with two

different biomasses, 467 mg waste-activated sludge (WAS) L1

() and 333 mg 2,4-dinitrophenol (DNP) L1 (). Error bars on

symbols indicate standard error of means (n 3, P 0.05); where

absent, bars fall within symbols.

principally oxalic acid, and nitrate are the primary end

products of dark-Fenton reactions with TNT. We also

found accumulation of oxalate and nitrate in solution

after abiotic reactions in approximate 1.4 and 3.1 molar

ratios to TNT, respectively (data not shown). In such

reaction conditions (low pH, dark reaction), oxalate is

essentially unreactive with hydroxyl radical (KOH

4.7 107 mol s1; Buxton et al., 1988) and would persist

in solution. Oxalate is readily usable by many aerobic

organisms, entering their metabolic pathways after breakdown via oxalate decarboxylase (Tanner and Bornemann, 2000; Hokama et al., 2000). In our abioticbiotic

experiments, there was no statistical difference (P

0.05) between ultimate TNT mineralization extent (approximately 78 3%) for WAS or DNP biomasses, at

both acidic and neutral pH and low biomass concentrations (Fig. 3A,B and Fig. 3C,D, respectively), indicating

that both consortia of organisms probably used a common enzyme and/or pathway to degrade the byproducts

of Fenton-mediated transformation of TNT. Analysis

of the data in two experiments (Fig. 3B,C), however,

showed statistical differences between mineralization

kinetics in the biotic reaction for low and high concentrations of similar biomasses. In both experiments, the

low biomass concentrations (67 or 93 mg L1 as TSS)

produced a higher extent of TNT mineralization in a

shorter length of time than did the higher concentrations

of biomass (333 or 467 mg L1 as TSS). This phenomenon may have been due to quenching, by the biomass, of

the Fenton reaction, only approximately 85% complete

(Fig. 3), thereby slowing the biotic reaction and lowering

the overall TNT mineralization extent. Such solution

interactions probably also resulted in coexistent abiotic

and biotic reactions, recently shown to exist in combined

Fentonbiological reactions degrading perchloroethylene and its transformation products (Buyuksonmez et

al., 1999) and perchloroethylene and oxalate (Howsawkeng et al., 2002).

Results of kinetics studies on TNT mineralization in

light-Fenton reactions were quite different from those

in dark-Fenton reactions. Abiotic, modified Fenton reactions at pH 3, using optimal reactant concentrations

(Table 2) previously found, resulted in near-complete

mineralization of TNT (95%) within 48 h (data not

shown). The high extent of TNT mineralization, in

photo-assisted reactions, was similar to that found by

Li et al. (1997a), with the exception of our lower reactant

concentrations. Because of the essentially complete

mineralization of TNT at acidic pH when photo-assisted,

abiotic Fenton reactions were used, no follow-on biotic

reactions were necessary. However, at neutral pH, the

abiotic light-Fenton reaction (using optimal reactant

concentrations from Table 2 and a 1:1 ratio of NTA to

Fe3 ) resulted in only approximately 65% TNT mineralization (Fig. 5), presumably due to lowered efficiency

of hydroxyl radical formation as compared with acidic

pH. Surprisingly, when biomass was added to the abiotic

reaction mixture after 24 h of reaction (at approximately

90% of reaction completion), no significant increase in

TNT mineralization occurred. As seen in Fig. 5, two

different concentrations of WAS biomass and DNP bio-

HESS & SCHRADER: COUPLED ABIOTICBIOTIC MINERALIZATION OF TNT

743

Fig. 5. Mineralization of aqueous TNT (0.22 mM ) in light-Fenton reactions at pH 7 comparing abiotic with coupled abioticbiotic treatments

at high and low biomass (waste-activated sludge [WAS] or 2,4-dinitrophenol [DNP]) concentrations: (A ) WAS biomass; (B ) DNP biomass.

Abiotic reaction (); high biomass concentration, either 467 mg WAS L1 or 333 mg DNP L1 (); low biomass concentration, either 93

mg WAS L1 or 67 mg DNP L1 (). Abiotic reactions conducted with Fe3 to nitrilotriaceticacid (NTA) ratio 1:1. Error bars on symbols

indicate standard error of means (n 3, P 0.05); where absent, bars fall within symbols.

mass, respectively, failed to appreciably alter the abiotic

TNT mineralization kinetics.

The lack of biotic activity after abiotic light-Fenton

reactions was probably due to photo Fentoninduced

destruction of oxalate (or other Fenton transformation

products of TNT), the only microbially assimilable carbon in solution. Other researchers have found high a

extent of oxalate mineralization in photo-Fenton systems (Zuo and Hoigne, 1992; Li et al., 1997a). Such

phenomena are reportedly due to photodissociation of

the chelate in solution by ligand-to-metal charge transfer excitation followed by reaction of the photoreduced

iron with peroxide in the Fenton reaction (Sun and Pignatello, 1993).

CONCLUSIONS

Abiotic reactions were optimized for maximum TNT

mineralization using minimum reactants, Fe3 and H2O2,

under acidic pH and neutral pH conditions in modified

light- and dark-Fenton reactions. We demonstrated that

100% degradation could be obtained under each reaction condition, but the observed mineralization varied

widely. At acidic pH, light-Fenton reactions yielded

near complete mineralization of TNT (99%) versus

43% in dark-Fenton reactions. At neutral pH, light- and

dark-Fenton reactions produced a TNT mineralization

extent of 36 and 25%, respectively. Upon reducing the

chelate to iron molar ratio (from 10:1 to 1:1) in solution,

TNT mineralization was increased to 66% and 45% in

the light- and dark-Fenton reactions, respectively.

Addition of biomass to the abiotic reaction products

increased overall TNT mineralization extent at both

acidic and neutral pH in the modified dark-Fenton reactions. Using this coupled reaction process, abiotic (darkFenton reaction) TNT mineralization at pH 3 was increased from 47 to 75 or 80% using WAS biomass or

DNP biomass, respectively. Under neutral pH conditions (dark-Fenton reaction), TNT mineralization was

increased from 45 to 78% by both biomasses. The increase in TNT mineralization was probably due to the

abiotic formation of organic acids as intermediate prod-

ucts that were subsequently transformed by microorganisms.

Kinetics of the coupled abioticbiotic reactions were

comparatively rapid. The abiotic reaction required 24 h

while the addition of the biomass required an additional

4 d including the 10-h lag between the time of addition

of the biomass and an increase in the mineralization

of TNT. These kinetics are competitive with chemical

treatments and much faster than most stand-alone biological treatments.

Application of the coupled abioticbiotic process may

have the most utility when using the dark-Fenton reaction. In aqueous, reactor-based processes, a high extent

of TNT mineralization is achievable, comparable with

photo-Fenton reactions, with no additional power input

or concern for light penetration. A wider use of the

process, however, may be for the remediation of soils

contaminated with TNT, in both slurry reactor and in

situ treatments, where photo-Fenton processes are not

applicable. We are currently investigating the use of

these coupled processes for remediation of contaminated soils.

ACKNOWLEDGMENTS

Appreciation is expressed to NSF EPSCoR Cooperative

Agreement OSR-9350539 for funding assistance on this project.

REFERENCES

Bartha, R., and D. Pramer. 1965. Features of a flask and method for

measuring the persistence and biological effects of pesticides in

soil. Soil Sci. 100:6870.

Bruhn, C., H. Lenke, and H.J. Knackmuss. 1987. Nitrosubstituted

aromatic compounds as nitrogen sources for bacteria. Appl. Environ. Microbiol. 52:11171122.

Buxton, G.V., C.L. Greenstock, W.P. Helman, and A.B. Ross. 1988.

Critical review of rate constants for reactions of hydrated electrons,

hydrogen atoms and hydroxyl radicals (OH/O ) in aqueous solution. J. Phys. Chem. Ref. Data 17:513886.

Buyuksonmez, F., T.F. Hess, R.L. Crawford, A. Paszczynski, and R.J.

Watts. 1998. Simultaneous abioticbiotic mineralization of perchloroethylene (PCE). p. 277282. In G.B. Wicramanayake and R.E.

Hinchee (ed.) Designing and applying treatment technologies: Re-

744

J. ENVIRON. QUAL., VOL. 31, MAYJUNE 2002

mediation of chlorinated and recalcitrant compounds. Battelle

Press, Columbus, OH.

Buyuksonmez, F., T.F. Hess, R.L. Crawford, A. Paszczynski, and R.J.

Watts. 1999. Optimization of simultaneous chemical and biological

mineralization of perchloroethylene. Appl. Environ. Microbiol. 65:

27842788.

Carberry, J.B., and T.M. Benzing. 1991. Peroxide pre-oxidation of

recalcitrant toxic waste to enhance biodegradation. Water Sci. Technol. 23:367376.

Cochran, W.G., and G.M. Cox. 1992. Experimental designs. 2nd ed.

John Wiley & Sons, New York.

Code of Federal Regulations. 1996. Aerobic aquatic biodegradation

shake flask protocol. U.S. Gov. Print. Office, Washington, DC.

Crawford, R.L. 1995. Biodegradation of nitrated munition compounds

and herbicides by obligately anaerobic bacteria. p. 8798. In J.C.

Spain (ed.) Biodegradation of nitroaromatic compounds. Plenum

Press, New York.

De Laat, J., and H. Gallard. 1999. Catalytic decomposition of hydrogen

peroxide by Fe(III) in homogeneous aqueous solution: Mechanism

and kinetic modeling. Environ. Sci. Technol. 33:27262732.

Fernando, T., J.A. Bumpus, and S.D. Aust. 1990. Biodegradation

of TNT (2,4,6-trinitrotoluene) by Phanerochaete chrysosporium.

Appl. Environ. Microbiol. 56:16661671.

Funk, S.B., D.J. Roberts, D.L. Crawford, and R.L. Crawford. 1993.

Initial-phase optimization for bioremediation of munition compound-contaminated soil. Appl. Environ. Microbiol. 59:21712177.

Glaze, W.H., and J.W. Kang. 1988. Advanced oxidation processes for

treating groundwater contaminated with TCE and PCE: Laboratory studies. J. Am. Water Works Assoc. 5:5762.

Grady, C.P.L., G.T. Daigger, and H.C. Lim. 1999. Biological wastewater treatment. 2nd ed. Marcel Dekker, New York.

Haber, F., and J. Weiss. 1934. The catalytic decomposition of hydrogen

peroxide by iron salts. Proc. Royal Soc. London, Ser. A 147:332

351.

Hess, T.F., T.A. Lewis, R.L. Crawford, S. Katamneni, J.H. Wells, and

R.J. Watts. 1998. Combined photocatalytic and fungal treatment

for the destruction of 2,4,6-trinitrotoluene (TNT). Water Res. 32:

14811491.

Hess, T.F., S.K. Schmidt, J. Silverstein, and B. Howe. 1990. Supplemental substrate enhancement of 2,4-dinitrophenol mineralization

by a bacterial consortium. Appl. Environ. Microbiol. 56:15511558.

Hess, T.F., J. Silverstein, and S.K. Schmidt. 1993. Effect of glucose

on 2,4-dinitrophenol degradation kinetics in sequencing batch reactors. Water Environ. Res. 65:7381.

Hokama, S., Y. Honma, C. Toma, and Y. Ogawa. 2000. Oxalatedegrading Enterococcus faecalis. Microbiol. Immunol. 44:235240.

Howsawkeng, J., R.J. Watts, D.L. Washington, T.F. Hess, and R.L.

Crawford. 2002. Evidence for simultaneous abioticbiotic oxidations in a microbial-Fentons system. Environ. Sci. Technol. (in

press).

Kennedy, M.S., J. Grammas, and W.B. Arbuckle. 1990. Parachlorophenol degradation using bioaugmentation. J. Water Pollut. Control Fed. 62:227233.

Koyama, O., Y. Kamagata, and K. Nakamura. 1994. Degradation

of chlorinated aromatics by Fenton oxidation and methanogenic

digester sludge. Water Res. 28:885899.

Lang, P.S., W.K. Ching, D.M. Willberg, and M.R. Hoffman. 1998.

Oxidative degradation of 2,4,6-trinitrotoluene by ozone in an electrohydraulic discharge reactor. Environ. Sci. Technol. 32:31423148.

Leung, S.W., R.J. Watts, and G.C. Miller. 1992. Degradation of perchloroethylene by Fentons reagent: Speciation and pathway. J.

Environ. Qual. 21:377381.

Lewis, T.A., M.M. Ederer, R.L. Crawford, and D.L. Crawford. 1997.

Microbial transformation of 2,4,6-trinitrotoluene. J. Ind. Microbiol.

Biotechnol. 18:8996.

Li, Z.M., S.D. Comfort, and P.J. Shea. 1997a. Destruction of 2,4,6trinitrotoluene by Fenton oxidation. J. Environ. Qual. 26:480487.

Li, Z.M., P.J. Shea, and S.D. Comfort. 1997b. Fenton oxidation of

2,4,6-trinitrotoluene in contaminated soil slurries. Environ. Eng.

Sci. 14:5566.

Michels, J., and G. Gottschalk. 1995. Pathway of 2,4,6-trinitrotoluene

(TNT) degradation by Phanerochaete chrysosporium. p. 135149.

In J.C. Spain (ed.) Biodegradation of nitroaromatic compounds.

Plenum Press, New York.

Preuss, A., and P.-G. Rieger. 1995. Anaerobic transformation of 2,4,6trinitrotoluene and other nitroaromatic compounds. p. 6985. In

J.C. Spain (ed.) Biodegradation of nitroaromatic compounds. Plenum Press, New York.

Provence, D.L., and R. Curtiss, III. 1994. Gene transfer in gramnegative bacteria. p. 317347. In P. Gerhardt (ed.) Methods for

general and molecular bacteriology. Am. Soc. for Microbiol., Washington, DC.

Ramos, J.L., A. Hadour, O. Delgado, E. Duqu, M. Faudila, M. Gil,

and G. Piear. 1995. Potential of toluene-degrading systems for the

construction of hybrid pathways for nitrotoluene metabolism. p.

5368. In J.C. Spain (ed.) Biodegradation of nitroaromatic compounds. Plenum Press, New York.

Ravikumar, J.X., and M.D. Gurol. 1991. Effectiveness of chemical

oxidation to enhance the biodegradation of pentachlorophenol in

soils: A laboratory study. p. 211221. In R.D. Neufeld and L.W.

Casson (ed.) Hazardous and industrial wastes. Proc. of the 23rd

Mid-Atlantic Ind. Waste Conf. Technomic Publ. Co., Lancaster,

PA.

Regan, K.M., and R.L. Crawford. 1994. Characterization of Clostridium bifermentans and its biotransformation of 2,4,6-trinitrotoluene

(TNT) and 1,3,5-triaza-1,3,5-trinitrcyclohexane (RDX). Biotechnol. Lett. 16:10811086.

Sato, C., S.W. Leung, H. Bell, W.A. Burkett, and R.J. Watts. 1993.

Decomposition of perchloroehylene and polychlorinated biphenyls

with Fentons reagent. p. 343256. In D.W. Tedder and F.G. Pohland (ed.) Emerging technologies in hazardous waste management

III. Am. Chem. Soc., Atlanta, GA.

Schmelling, D.C., and K.A. Gray. 1993. Feasibility of photocatalytic

degradation of TNT as a single or integrated treatment process.

p. 625631. In D.F. Ollis and H. Al-Ekabi (ed.) Photocatalytic

purification and treatment of water and air. Elsevier, Amsterdam.

Schmelling, D.C., and K.A. Gray. 1995. Photocatalytic transformation

and mineralization of 2,4,6-trinitrotoluene (TNT) in TiO2 slurries.

Water Res. 29:26512662.

Schmelling, D.C., K.A. Gray, and P.V. Kamat. 1996. Role of reduction

in the photocatalytic degradation of TNT. Environ. Sci. Technol.

30:25472555.

Schuster, R., and A. Gratzfeld-Huesgen. 1993. HPLC analysis of explosive constituents in soil samples. Company Application Note,

Publ. no. 12-5091-7626E. HewlettPackard, Palo Alto, CA.

Scott, J.P., and D.F. Ollis. 1995. Integration of chemical and biological

oxidation processes for water treatment: Review and recommendations. Environ. Progress 14:88103.

Spalding, R.F., and J.W. Fulton. 1988. Groundwater munitions residues and nitrate near Grand Island, Nebraska, U.S.A. J. Contam.

Hydrol. 2:139153.

Sun, Y., and J.J. Pignatello. 1993. Photochemical reaction involved

in the total mineralization of 2,4-D by Fe3/H2O2/UV. Environ.

Sci. Technol. 27:304310.

Tanner, A., and S. Bornemann. 2000. Bacillus subtilis YvrK is an acidinduced oxalate decarboxylase. J. Bacteriol. 182:52715273.

Tyre, B.W., R.J. Watts, and G.C. Miller. 1991. Treatment of four

biorefractory contaminants in soils using catalyzed hydrogen peroxide. J. Environ. Qual. 20:832838.

Urbanski, T. 1964. Chemistry and technology of explosives. Macmillan, New York.

Vorbeck, C., H. Lenke, P. Fischer, and H.J. Knackmuss. 1994. Identification of a hydride-Meisenheimer complex as a metabolite of 2,4,6trinitrotoluene by a Mycobacterium strain. J. Bacteriol. 176:932

934.

Watts, R.J. 1998. Hazardous wastes: Sources, pathways, receptors.

John Wiley & Sons, New York.

Watts, R.J., S. Kong, M. Dipre, and W.T. Barnes. 1994. Oxidation

of sorbed hexachlorobenzene in soils using catalyzed hydrogen

peroxide. J. Hazard. Mater. 39:3347.

Won, W.D., L.H. DiSalvo, and J. Ng. 1976. Toxicity and mutagenicity

of 2,4,6-trinitrotoluene and its microbial metabolites. Appl. Environ. Microbiol. 31:576580.

Zuo, Y., and J. Hoigne. 1992. Formation of hydrogen peroxide and

depletion of oxalic acid in atmospheric water by photolysis of

iron(III)oxalato complexes. Environ. Sci. Technol. 26:10141022.

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Welding Code Exam Version D1.1Dokument13 SeitenWelding Code Exam Version D1.1Liyakathalikhan Shahjahan100% (4)

- 01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsDokument18 Seiten01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsWHWEN100% (1)

- Chapter 4 Shear Force Bending Moment and Deflection of Beams 28012015 For StudentsDokument26 SeitenChapter 4 Shear Force Bending Moment and Deflection of Beams 28012015 For StudentsccipNoch keine Bewertungen

- 600MW Training Manual of Boiler 20110326 PDFDokument94 Seiten600MW Training Manual of Boiler 20110326 PDFReda NariNoch keine Bewertungen

- KemixDokument8 SeitenKemixjadetorres100% (1)

- Tivar 88-2: Drop-In Liners Solve Flow ProblemsDokument1 SeiteTivar 88-2: Drop-In Liners Solve Flow Problemsacas35100% (1)

- Integrated Passive Component TechnologyDokument392 SeitenIntegrated Passive Component TechnologyMohammad ElmiNoch keine Bewertungen

- 3 PDF TestsDokument3 Seiten3 PDF Testssaif aliNoch keine Bewertungen

- The Benefits of Waste Management 1.better EnvironmentDokument4 SeitenThe Benefits of Waste Management 1.better EnvironmentSally DailyNoch keine Bewertungen

- Synthesis of Carbon Nanotubes by Chemical Vapor DepositionsDokument24 SeitenSynthesis of Carbon Nanotubes by Chemical Vapor DepositionsGovarthananNoch keine Bewertungen

- Damage Detection Using Ansys نهائيDokument86 SeitenDamage Detection Using Ansys نهائيAHMAD GHARABLINoch keine Bewertungen

- Performance of RC Frame Structure With Various Beam To Column Flexural Capacity Ratio - A Case Study Sudip KaranjitDokument7 SeitenPerformance of RC Frame Structure With Various Beam To Column Flexural Capacity Ratio - A Case Study Sudip KaranjitBinod ManandharNoch keine Bewertungen

- Study of Interfacial Area in Rectification of Two-Component MixturesDokument7 SeitenStudy of Interfacial Area in Rectification of Two-Component MixturesIJAR JOURNALNoch keine Bewertungen

- Xanthan Gum E415Dokument4 SeitenXanthan Gum E415sharemwNoch keine Bewertungen

- How To Build An Orgone Generator: InstructionsDokument2 SeitenHow To Build An Orgone Generator: InstructionsRadulescu Eugen100% (1)

- Module 3 (Lesson 1 and 2)Dokument10 SeitenModule 3 (Lesson 1 and 2)rocky.mercado2Noch keine Bewertungen

- Bamboo Mesh Reinforced Cement CompositesDokument21 SeitenBamboo Mesh Reinforced Cement CompositesKurnia BijaksanaNoch keine Bewertungen

- Steam and Gas Turbine Materials Used For Fasteners & Hardware Supplied by PpiDokument4 SeitenSteam and Gas Turbine Materials Used For Fasteners & Hardware Supplied by PpidislocationNoch keine Bewertungen

- Tips & Techniques NOVA-8 Rev00Dokument10 SeitenTips & Techniques NOVA-8 Rev00AntWonxxxNoch keine Bewertungen

- FlexEJ Catalogue Full SDokument87 SeitenFlexEJ Catalogue Full S1arun_nehru100% (1)

- Concrete Column Schedule: CC1 CC2 CC3 CC4 CC5 CC6 CC7 CC8 CC9 CC10 CC11 CC12 CC13Dokument1 SeiteConcrete Column Schedule: CC1 CC2 CC3 CC4 CC5 CC6 CC7 CC8 CC9 CC10 CC11 CC12 CC13Rolly Marc G. SoteloNoch keine Bewertungen

- Concrete Drain Tile: Standard Specification ForDokument6 SeitenConcrete Drain Tile: Standard Specification ForEligio Antonio CerdaNoch keine Bewertungen

- Steel BW 2Dokument2 SeitenSteel BW 2Kuladeep YalamanchiliNoch keine Bewertungen

- IsoplatonDokument1 SeiteIsoplatonikahashimNoch keine Bewertungen

- AE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BDokument3 SeitenAE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BRahul100% (1)

- Periodicity All QuestionsDokument32 SeitenPeriodicity All Questions한서현Noch keine Bewertungen

- Collapse Modes in Aluminium Honeycomb Sandwich Panels Under Bending and Impact LoadingDokument10 SeitenCollapse Modes in Aluminium Honeycomb Sandwich Panels Under Bending and Impact LoadingSURESHNoch keine Bewertungen

- Bernoulli Gripper: ZNC-CDokument20 SeitenBernoulli Gripper: ZNC-Ckissbt7Noch keine Bewertungen

- ms1314-2004 - Compress 2Dokument28 Seitenms1314-2004 - Compress 2Robbie LimbiNoch keine Bewertungen

- Study of Marble Waste and Its UtilizationDokument5 SeitenStudy of Marble Waste and Its UtilizationJP MarzoniaNoch keine Bewertungen