Beruflich Dokumente

Kultur Dokumente

Jacket Weighing Procedure

Hochgeladen von

BolarinwaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Jacket Weighing Procedure

Hochgeladen von

BolarinwaCopyright:

Verfügbare Formate

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING PROCEDURE

MOBIL

P RODUCING

NIGERIA

Prepared, Reviewed, Endorsed and Approved by:

Person

Description

Gordon Dunthorne

NIGERDOCK Engineer

Manager

Prepared

by

Melchor Yaun

NIGERDOCK Lead Engineer

Checked

by

Jagba Smart

NIGERDOCK QA/QC

Engineer

Edward York

NIGERDOCK Project

Manager

Endorsed

by

MPN Representative

NGTA-NK-NPZZZ-00-XXXXXXX Rev. A

Signature

Approved

by

Approved

by

ii

Date

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING PROCEDURE

MOBIL

P RODUCING

NIGERIA

REVISION MODIFICATION LOG

Revision

Section

Rev. A

ALL

ACTION

Description

Initial Document

NGTA-NK-NPZZZ-00-XXXXXXX Rev. A

Issued for Review/Comments

iii

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING PROCEDURE

MOBIL

P RODUCING

NIGERIA

TABLE OF CONTENTS

1.0

SCOPE OF WORK

2.0

INTRODUCTION

3.0

CONCLUSION

4.0

SAFETY

5.0

EQUIPMENT

6.0

ORGANIZATIONAL CHART

7.0

PERSONNEL

8.0

COMMUNICATION

9.0

METHOD

10.0

ANALYSIS

10

11.0

DATA ANALYSIS

13

12.0

REFERENCES

13

APPENDIX A

APPENDIX B

NGTA-NK-NPZZZ-00-XXXXXXX Rev. A

iv

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

1.0

MOBIL

P RODUCING

NIGERIA

SCOPE OF WORK

This procedure describes the method that will be utilized for the weighing of

SFDP Jackets pertaining to NDs Scope of work for Mobil Producing Nigeria.

This procedure is based on SFDP Jackets, SFDP Jacket Weight is 258.2 Mt

(as of estimate 27-01-).

2.0

INTRODUCTION

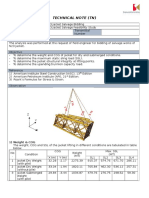

This document describes the weighing of ITUT Jacket Structural Analysis of the

Jacking point currently being fabricated at Nigerdock Nigeria FZE, located at

Snake Island Apapa Lagos.

The method of weighing will be firstly place sheets of 30mm thick steel plate

under the jacket grillage points, then insert jacking stool frames in position

directly under the centre of each platform support leg and to place the enerpac

load cells immediately on top of this jacking stool support frame (shimmed to

suit) This will enable 4 enerpac load cells wires to be run and utilized along with

the enerpac control panel ensuring accurate recording of the weighing exercise.

Drawing ND-ITT-710-GA-200-A1 Below clearly shows enerpac locations and

wiring connected to the main control panel

The structural analysis on the jacking stool was carried out using Staad Pro

2004, the design and checking is in accordance with AISC ASD 9th Edition and

API RP2A All Dimensions used in this procedure are based on SI units and

weight calculation in Mtons.

3.0

CONCLUSION:

The analysis performed on the jacking stool satisfies the structural integrity to

withstand the stresses and that the deflection is within the allowable limits

Maximum stress ratios for weighing are listed below:

-

0.608 for load cell C3

0.649 for all other load cells

Page 1

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

Page 2

MOBIL

P RODUCING

NIGERIA

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

Page 3

MOBIL

P RODUCING

NIGERIA

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

MOBIL

P RODUCING

NIGERIA

4.0 SAFETY

Before the Weighing operations commence, risk assessments followed by Job

safety analysis (JSA) will be completed for all work undertaken by NDs personnel,

and any subcontractor employed in the work. The approved JSA will be discussed

among the workforce prior to commencing any Jacking activity.

The Gantry side where the intended structure for Weighing will be temporarily

positioned must be cordoned off from unauthorized persons and visitors. Barrier

control will be strictly enforced. No personnel will be allowed in the vicinity of

suspended loads.

Only authorized persons shall partake in the JSA meeting

ND shall ensure all procedures are understood and workers are briefed as to any

potential worksite hazards. All identified hazards or potential hazards shall be

promptly eliminated or controlled.

ND shall ensure all works related to the Weighing are carried out in a safe and

efficient manner and that safe systems of work are prepared and implemented.

ND shall ensure all equipment are safe, suitable for the operation, kept in good

condition and that defects are identified and follow up action initiated to repair

defective equipment or withdraw it from site.

All Weighing Equipment shall be inspected prior to use and will have an up to date

certification.

A pre-weighing checklist shall be used to verify safe systems of work are in place,

the check list shall be endorsed by MPN Heavy Lift Advisor.

ND shall ensure all places of work, including work at heights, etc are safe and

where necessary adequate control measures shall be implemented through JSA,

Risk Assessment or Toolbox talks.

Risk assessment will be carried out by ND and Company and will be developed by

the Risk Charter Group as per required procedures.

JSA will be developed based on the RA findings.

Page 4

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

MOBIL

P RODUCING

NIGERIA

An emergency response plan will be developed by the Safety Group.

All personnel involved in this operation shall:

Avoid harm to themselves and prevent harm to others

Utilize and maintain all issued protective equipment in the correct

manner.

Be aware of, and comply with all relevant project HSE procedures.

Make appropriate suggestions for the improvement of safety within the

operations.

ND shall ensure all personnel involved in the Weighing campaign are PPE

compliance at all times (Coveralls, steel toe shoes, Hard hat, Safety Glasses)

as minimum requirements..

5.0

EQUIPMENT:

This section describes the minimum equipment needed to perform this

operation. All Equipment to be used in this procedure shall be checked and

certified by a recognized certifying authority. Equipments required for the

Weighing operation are not limited to the following list:

ENERPAC

4 off ENERPAC 500t LOAD CELLS complete with central control panel

JACKING STOOL

As fabricated by Nigerdock

Page 5

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

6.0

ORGANIZATIONAL CHART (FOR WEIGHING OPERATION)

MPN Rigging Supt.

Mr. Allistair Thompson

Construction Support

Mgr James Cunningham

Enerpac Load Cell operator

7.0

MOBIL

P RODUCING

NIGERIA

Watch Over Assistant

Odom Anefiok

Stand-by Team

plus

Maintenance

Group:

Scaffolders

Welders

Electrician

Helpers

Fitters

Forklift

Safety Officer In charge

Mr. Kayode Omojagbara

PERSONNEL AND RESPOSIBILITIES

7.1.1

CONSTRUCTION SUPPORT MANAGER (1) He is in charge of the

Over all Operation during weighing. All personnel involved in this

operation will report to him. He gives the instructions to any Load Cell

Operators, and Assistance Personnel. He is also responsible to have all

certification to hand over to Company for review prior to weighing.

7.1.2 MPN Rigging Superintendent (1) He is responsible for checking that

the overall approved methodology has been followed before, during and

after the weighing.

7.1.4

SAFETY PERSONNEL Responsible for all works related to the

Weighing are carried out in a safe and efficient manner and that safe

systems of work are prepared and implemented. During Operation one

single Safety Officer will be inside the Barricaded area for

communication with Safety Personnel on the outside of the barrier.

Page 6

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

7.1.5

MOBIL

P RODUCING

NIGERIA

STANDBY TEAM A support team for any immediate fabrication

required or assistance in related matters. It comprises of the following:

The number of personnel will be determined by Construction Support

Manager.

Scaffolders

Welders

Electrician

Helpers

Fitters

Forklift Operators

Load Cell Maintenance Personnel (1) Part of the support team to assist

on any mechanical fault on cranes during operation.

8.0

COMMUNICATION

A communication exercise between the involving personnel will be established

prior to Weighing Operation. A minimum of two (2) days is expected for this

exercise before the final Weighing operation and one (1) day prior to Pre-Weigh

meeting.

During the operation the Hand Signaling, Verbal and Radio will be the means of

communication. Spare radio equipment will be made available.

All the Instructions will come from the Construction Support Manager; he gives

the instructions and receives the information from his subordinates. This

coordination will come from Load Cell Operators and Safety In charge.

The communication between the involved personnel will be by means of one

radio channel in order to ensure clear communication.

The Load Cell Operators and any assistant will communicate to the

Construction Support Manager whenever the event or situation of the Load Cell

is in dangerous position. The instruction will be three STOPS, ex. STOP!

STOP!! STOP!!!.

The four (4) Load Cells used in the operation will be named and identified as

follows:

Load Cell C1

Load Cell C2

Load Cell C3

Load Cell C4

Page 7

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

MOBIL

P RODUCING

NIGERIA

Name tags will be placed on each load cell for identification.

A co-ordination exercise will be undertaken 3 days prior to the operation with

Load Cell operators if the Construction Support Manager feels they are not

experienced enough.

9.0

METHOD

9.1

PREPARATION:

All Rigging and Weighing Appliances should have all certifications checked

prior to use.

Remove all obstructions that will hinder the operations.

During operation the area shall be limited to nominated yard personnel only.

All other personnel shall observe operation from outside the taped area.

Load Cells shall be positioned as specified in the drawings.

Any Required Rigging equipment shall be positioned in accordance to the

specified drawings.

All radio communication shall be checked if working properly.

The Over all control of the operation shall be Construction Support Manager

who will be in touch with the personnel as defined by Communication

sections of the procedures.

During Weighing Operation, all client communicate shall be addressed

through Project Manager or his deputy.

A pre-weighing meeting shall be held between ND Team and Company to

discuss the procedure and issues concerned. All procedure shall be clear to

both parties and pass JSA (Job Safety Analyses) prepared by the

Construction Support Manager with support from the Safety Department.

9.2

A pre weighing meeting shall be held to ensure that everyone involved

understand the procedure. This will also ensure that the coordination

between load cell operator, Construction Support Manager and safety

personnel is achieved.

9.3

During weighing a 50% load shall be tested on each load cell as

specified on the above theoretical value of each load point, and measurement

shall be taken and recorded. All loads in the load cells will be measured. When

the 50% load is achieved, the structure will be lifted gradually until a full 100%

load is achieved at a height of 100mm from the support and this operation is to

be repeated a minimum of 3 times and readings recorded for each lift

operation.

Page 8

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

MOBIL

P RODUCING

NIGERIA

9.4

Acceptance criteria of the final recorded value of the 3 weighing

operations shall be the average of the 3 recorded values and this value should

not differ from the maximum of any of the 3 values by more than 0.7%. The

tolerance of the enerpac load cell should be equal to or less than 1%.

9.5 The maximum load on any one load cell shall between 20-80% of their

total load capacity.

9.6

10.0

If the weighing is achieved and satisfies the operation, the structure will

be put back in original position otherwise the weighing operation will be

repeated again.

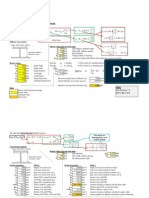

ANALYSIS:

This section explains the procedure performed for the analysis of the ITUT

jacking stool.

The data for the model was taken from the weight control and CofG report

produced by Nigerdock and analysis was performed on Staad-pro

See attachements in Appendix A

11.0 DATA ANALYSIS

The following members are included in this analysis are:

LOAD LIST

SELF WEIGHT

C.O.G.

LOAD CELL REACTIONS

CODE CHECK AISC LFRD

12.0

REFERENCES:

Nigerdock Shop Drawings Reference:

1. ND-ITT-710-GA-200-A1

2. ND-ITT-710-GA-201-A1

The reports of the analysis are based on the following specifications:

Page 9

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

1. AISC 9th Edition

2. API 2A (RP2A)

APPENDIX A

SFDP-TOPSIDE WEIGHING-BEAM-1

SFDP-TOPSIDE WEIGHING-BEAM-2

APPENDIX B

CURRENT JACKET WEIGHT CONTROL SUMMARY

Page

10

MOBIL

P RODUCING

NIGERIA

SATELLITE FIELD DEVELOPMENT PROJECT

(PHASE I)

ITUT AND ABANG JACKET WEIGHING

PROCEDURE

Page

11

MOBIL

P RODUCING

NIGERIA

Das könnte Ihnen auch gefallen

- Practice For Dynamic Analysis of Fixed Offshore Platform - Petronas Technical StandardsDokument32 SeitenPractice For Dynamic Analysis of Fixed Offshore Platform - Petronas Technical StandardsJaga Nath100% (3)

- Load-Out and Sea-Fastening ProcedureDokument17 SeitenLoad-Out and Sea-Fastening ProcedureAdaghara100% (2)

- 0001 CatDokument108 Seiten0001 CatJorge CabreraNoch keine Bewertungen

- Leg Penetration Analysis AD-G34-1041-R2658 - Seafox 8 LPA at Zulf 246-251Dokument8 SeitenLeg Penetration Analysis AD-G34-1041-R2658 - Seafox 8 LPA at Zulf 246-251SinojKumarMalipronNoch keine Bewertungen

- Lifting Analysis Report - Rev BDokument31 SeitenLifting Analysis Report - Rev BDicky Pramono100% (1)

- The Pentester BlueprintDokument27 SeitenThe Pentester Blueprintjames smith100% (1)

- Noble Denton Guidelines For LoadoutsDokument36 SeitenNoble Denton Guidelines For LoadoutsBoyNoch keine Bewertungen

- Grillage&Seafastening DesignExampleDokument66 SeitenGrillage&Seafastening DesignExamplefelipecmello100% (1)

- StruCalc 80 ManualDokument124 SeitenStruCalc 80 ManualBolarinwaNoch keine Bewertungen

- P314.414 Cranes and Mobile Cranes PDFDokument11 SeitenP314.414 Cranes and Mobile Cranes PDFJahel LootiNoch keine Bewertungen

- 1000 Business IdealsDokument43 Seiten1000 Business IdealsBolarinwaNoch keine Bewertungen

- Floatover - Installation - Final (Compatibility Mode) Quiz2 PDFDokument27 SeitenFloatover - Installation - Final (Compatibility Mode) Quiz2 PDFChinmaya Ranjan JenaNoch keine Bewertungen

- Scaffolding Bin Structural Integrity ReportDokument27 SeitenScaffolding Bin Structural Integrity ReportBolarinwaNoch keine Bewertungen

- PE-PP-10-1-F3 Rev. 7.0 PLNG SSI Check List Confirmation ListDokument22 SeitenPE-PP-10-1-F3 Rev. 7.0 PLNG SSI Check List Confirmation ListLuis Enrique LavayenNoch keine Bewertungen

- Ballasting Calculation For The Transportation of PLEMsDokument17 SeitenBallasting Calculation For The Transportation of PLEMsBolarinwa100% (1)

- Lifting AnalysisDokument14 SeitenLifting Analysisruhul72Noch keine Bewertungen

- 05 Loadout of Offshore PlatformDokument70 Seiten05 Loadout of Offshore Platformardikurniawan100% (8)

- Barge 180Ft Deck Load Capacity & Strength-Rev1Dokument52 SeitenBarge 180Ft Deck Load Capacity & Strength-Rev1Wahyu Codyr86% (7)

- 4-Week Weight Loss ChallengeDokument6 Seiten4-Week Weight Loss ChallengeTammy JacksonNoch keine Bewertungen

- 7234 M RP 1002 Ver C0100 PDFDokument601 Seiten7234 M RP 1002 Ver C0100 PDFbaskaran ayyapparaj100% (1)

- 0003 Mi20 00S1 0240 0Dokument15 Seiten0003 Mi20 00S1 0240 0Galih Suksmono AdiNoch keine Bewertungen

- Miscellaneous Calculations: 1 Sea Transport Forces On CargoDokument4 SeitenMiscellaneous Calculations: 1 Sea Transport Forces On CargoAgarry EmmanuelNoch keine Bewertungen

- BS Civil EngineeringDokument138 SeitenBS Civil EngineeringBolarinwaNoch keine Bewertungen

- Offshore Mooring Risk AnalysisDokument109 SeitenOffshore Mooring Risk Analysisbubbly_blu2Noch keine Bewertungen

- BS 2X 33 Two Part EpoxyDokument13 SeitenBS 2X 33 Two Part EpoxyBolarinwaNoch keine Bewertungen

- 05-1 - EPC-SV-ALE-N-CA-10006 - Rev B2 Barge Deck Strength Check PDFDokument63 Seiten05-1 - EPC-SV-ALE-N-CA-10006 - Rev B2 Barge Deck Strength Check PDFBill BenNoch keine Bewertungen

- Calculation Barge StabilityDokument31 SeitenCalculation Barge StabilityMoch Ardiansyah67% (3)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityVon EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNoch keine Bewertungen

- Age Discrimination PDFDokument20 SeitenAge Discrimination PDFMd. Rezoan ShoranNoch keine Bewertungen

- On-Bottom Stability AnalysisDokument3 SeitenOn-Bottom Stability AnalysisBolarinwaNoch keine Bewertungen

- Quayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)Dokument35 SeitenQuayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)cliff1234Noch keine Bewertungen

- DANA-Technical Note (TN)Dokument8 SeitenDANA-Technical Note (TN)Samsul Imran BahromNoch keine Bewertungen

- Mudmat Bearing CapacityDokument11 SeitenMudmat Bearing CapacityMathew Simon100% (1)

- Longitudinal Strength Analysis of Barge During CPP2 Jacket LoadoutDokument106 SeitenLongitudinal Strength Analysis of Barge During CPP2 Jacket LoadoutSanieBurhan100% (3)

- DNV-OS-H206 Transport and Installation of Subsea ObjectsDokument54 SeitenDNV-OS-H206 Transport and Installation of Subsea ObjectsPatranNoch keine Bewertungen

- Lifting Analysis Report - TemplateDokument31 SeitenLifting Analysis Report - TemplateLukman Hakim100% (2)

- Method Statement For Scaffolding ActivitiesDokument8 SeitenMethod Statement For Scaffolding ActivitiesMohsen KeramatiNoch keine Bewertungen

- Offshore Installation ProcedureDokument14 SeitenOffshore Installation ProcedureMichael Enrico100% (1)

- Ffs-pu-5116-A-transportation of Cargo by Barge or ShipDokument28 SeitenFfs-pu-5116-A-transportation of Cargo by Barge or ShipBolarinwaNoch keine Bewertungen

- Sea TransportationDokument8 SeitenSea TransportationMark Samsel RohanNoch keine Bewertungen

- Ffs Su 5218Dokument33 SeitenFfs Su 5218BolarinwaNoch keine Bewertungen

- Idbc-Ts-Vcstr-T100639-Ng0028 - Lir-12 - Weight Control ReportDokument9 SeitenIdbc-Ts-Vcstr-T100639-Ng0028 - Lir-12 - Weight Control ReportWallen Jusri SihotangNoch keine Bewertungen

- Gen S A JK S PR 0024 G02Dokument45 SeitenGen S A JK S PR 0024 G02e100% (1)

- Grillage Seafastening DesignExampleDokument66 SeitenGrillage Seafastening DesignExampleeNoch keine Bewertungen

- Civ-Su-6001-C - Design of BuildingsDokument37 SeitenCiv-Su-6001-C - Design of BuildingsBolarinwaNoch keine Bewertungen

- Pigging Head and Spool InstallationDokument38 SeitenPigging Head and Spool InstallationWilliam O OkolotuNoch keine Bewertungen

- Guide Marine Operations LoadoutDokument20 SeitenGuide Marine Operations Loadoutpssrijit100% (3)

- 23 Mooring Analysis During ShorepullDokument53 Seiten23 Mooring Analysis During ShorepullNoverdo Saputra100% (1)

- B. Equivalent Axial (N) and Lateral (Q) Loads: SD SDDokument2 SeitenB. Equivalent Axial (N) and Lateral (Q) Loads: SD SDRahul Malani100% (1)

- MWA ReportDokument75 SeitenMWA ReportCyrus HongNoch keine Bewertungen

- LOCG-GEN-Guideline-006 Rev 0 - Lift-Off Transportation + Inshore Mating of TopsidesDokument26 SeitenLOCG-GEN-Guideline-006 Rev 0 - Lift-Off Transportation + Inshore Mating of TopsidesTomkel VoonNoch keine Bewertungen

- Mac-Su-7.01 - Offshore Lattice Boom Pedestal CranesDokument31 SeitenMac-Su-7.01 - Offshore Lattice Boom Pedestal CranesBolarinwaNoch keine Bewertungen

- 2343242Dokument102 Seiten2343242Tran Van DaiNoch keine Bewertungen

- PLEM Pile Drivability PDFDokument49 SeitenPLEM Pile Drivability PDFTharach JanesuapasaereeNoch keine Bewertungen

- Method of Statement For MV&LV SwitchgearsDokument12 SeitenMethod of Statement For MV&LV SwitchgearsUtku Can Kılıç100% (1)

- Suction PileDokument3 SeitenSuction PileIwan Renadi Soedigdo100% (1)

- Load OutDokument239 SeitenLoad OutDeepak Kumar100% (2)

- "EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionDokument23 Seiten"EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionBolarinwaNoch keine Bewertungen

- Hospital & Clinical Pharmacy Q&ADokument22 SeitenHospital & Clinical Pharmacy Q&AKrishan KumarNoch keine Bewertungen

- Microsoft Word - PRELIMINARY MOORING ANALISYS DSV TS504Dokument48 SeitenMicrosoft Word - PRELIMINARY MOORING ANALISYS DSV TS504halimNoch keine Bewertungen

- ANSYS Manual StudentDokument215 SeitenANSYS Manual StudentBolarinwaNoch keine Bewertungen

- Healthcare Financing in IndiADokument86 SeitenHealthcare Financing in IndiAGeet Sheil67% (3)

- 48'' Pipeline Shore Approach Reportpdf PDFDokument22 Seiten48'' Pipeline Shore Approach Reportpdf PDFvpandya1981100% (2)

- Ffs-su-5217-A - Design of Fixed Platform StructuresDokument134 SeitenFfs-su-5217-A - Design of Fixed Platform StructuresBolarinwa100% (1)

- Supplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDDokument29 SeitenSupplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDAdam Andrew OngNoch keine Bewertungen

- Ffs-su-5216-A - Structural Welding and Inspection For Offshore PlatformsDokument28 SeitenFfs-su-5216-A - Structural Welding and Inspection For Offshore PlatformsBolarinwaNoch keine Bewertungen

- Civ-su-1.24-A - Design and Fabrication of BuildingsDokument35 SeitenCiv-su-1.24-A - Design and Fabrication of BuildingsBolarinwaNoch keine Bewertungen

- Jacket Topside Transportation Sea Fastening InstallationDokument5 SeitenJacket Topside Transportation Sea Fastening InstallationMermaid co100% (1)

- 14 - NRG - Pipe Installation - Davit LiftDokument16 Seiten14 - NRG - Pipe Installation - Davit LiftBalanNoch keine Bewertungen

- Existing Pipeline Cable Under Crossings - ADDENDUM To PROCEDURE - RO3Dokument8 SeitenExisting Pipeline Cable Under Crossings - ADDENDUM To PROCEDURE - RO3MitchellgranyNoch keine Bewertungen

- Civ Du 5009 H Structural Design CriteriaDokument28 SeitenCiv Du 5009 H Structural Design CriteriaBolarinwaNoch keine Bewertungen

- MS002 ST Rep 076 00016Dokument78 SeitenMS002 ST Rep 076 00016DavisTranNoch keine Bewertungen

- SACS Checklist Latest VersionDokument9 SeitenSACS Checklist Latest VersiontaddeoNoch keine Bewertungen

- Boatlanding and Riser Protecter Design-2Dokument15 SeitenBoatlanding and Riser Protecter Design-2samiransmitaNoch keine Bewertungen

- Inspection and Test Plan: Flow Chart Start IncomingDokument1 SeiteInspection and Test Plan: Flow Chart Start IncomingSinden AyuNoch keine Bewertungen

- Redefining Riser-Guard System For Fixed Offshore PlatformsDokument5 SeitenRedefining Riser-Guard System For Fixed Offshore PlatformsJACKNoch keine Bewertungen

- Procedure For LoadoutDokument17 SeitenProcedure For Loadoutnaeimeslami100% (2)

- Procedure For LiftingDokument7 SeitenProcedure For LiftingAbideen RaheemNoch keine Bewertungen

- Civ-su-1.10-A Design and Installation of Living QuartersDokument86 SeitenCiv-su-1.10-A Design and Installation of Living QuartersBolarinwa100% (1)

- D Formation Damage StimCADE FDADokument30 SeitenD Formation Damage StimCADE FDAEmmanuel EkwohNoch keine Bewertungen

- 3423Dokument12 Seiten3423Tran Van DaiNoch keine Bewertungen

- Orcaflex Training ScopeDokument3 SeitenOrcaflex Training ScopeGodwinNoch keine Bewertungen

- 02-Lifting Operation Planning Checklist - Lifting Freon Bottle To E-House Roof TopDokument6 Seiten02-Lifting Operation Planning Checklist - Lifting Freon Bottle To E-House Roof TopImam Saja DechNoch keine Bewertungen

- SACS Advanced Offshore Structure Design AnalysisDokument2 SeitenSACS Advanced Offshore Structure Design Analysisspyji99Noch keine Bewertungen

- Pole Lifting ProceduresDokument17 SeitenPole Lifting ProceduresCH AsiaNoch keine Bewertungen

- Equipment Numeral Calculator For A ShipDokument16 SeitenEquipment Numeral Calculator For A ShipBolarinwaNoch keine Bewertungen

- Risk AssessmentDokument8 SeitenRisk AssessmentBolarinwaNoch keine Bewertungen

- Crosby Shackles G-2130 PDFDokument2 SeitenCrosby Shackles G-2130 PDFBolarinwaNoch keine Bewertungen

- 101 Ways To Make Money in Africa PDFDokument17 Seiten101 Ways To Make Money in Africa PDFBolarinwaNoch keine Bewertungen

- Onbottom ThailandDokument30 SeitenOnbottom ThailandBolarinwaNoch keine Bewertungen

- Afes StripDokument27 SeitenAfes StripBolarinwaNoch keine Bewertungen

- Mac Su 7.03Dokument8 SeitenMac Su 7.03BolarinwaNoch keine Bewertungen

- Ffs Su 5221Dokument12 SeitenFfs Su 5221BolarinwaNoch keine Bewertungen

- Ffs Su 5221Dokument12 SeitenFfs Su 5221BolarinwaNoch keine Bewertungen

- Civ-su-1.28-A Helidecks On Offshore InstallationsDokument12 SeitenCiv-su-1.28-A Helidecks On Offshore InstallationsBolarinwaNoch keine Bewertungen

- Mac Su 7.02Dokument10 SeitenMac Su 7.02BolarinwaNoch keine Bewertungen

- Gen-Su-5227 - Units of MeasurementDokument4 SeitenGen-Su-5227 - Units of MeasurementBolarinwaNoch keine Bewertungen

- Indg 449Dokument12 SeitenIndg 449Nissam SidheeqNoch keine Bewertungen

- Sunflower Herbicide ChartDokument2 SeitenSunflower Herbicide ChartpapucicaNoch keine Bewertungen

- CHAPTER 15 Managing Current AssetsDokument26 SeitenCHAPTER 15 Managing Current AssetsAhsanNoch keine Bewertungen

- App 17 Venmyn Rand Summary PDFDokument43 SeitenApp 17 Venmyn Rand Summary PDF2fercepolNoch keine Bewertungen

- Understanding Anxiety Disorders and Abnormal PsychologyDokument7 SeitenUnderstanding Anxiety Disorders and Abnormal PsychologyLeonardo YsaiahNoch keine Bewertungen

- Deadline Anchors BrochureDokument3 SeitenDeadline Anchors Brochurejlmunozv100% (2)

- Corn Pulao Recipe With Sweet CornDokument2 SeitenCorn Pulao Recipe With Sweet CornSudharshanNoch keine Bewertungen

- Separation/Termination of Employment Policy SampleDokument4 SeitenSeparation/Termination of Employment Policy SampleferNoch keine Bewertungen

- Schneider - Cptg010 en (Print)Dokument16 SeitenSchneider - Cptg010 en (Print)el_koptan00857693Noch keine Bewertungen

- Jee Main Sample Paper 5Dokument19 SeitenJee Main Sample Paper 5DavidNoch keine Bewertungen

- Specialized Connective TissueDokument15 SeitenSpecialized Connective TissueSebNoch keine Bewertungen

- Mole Concept: Chemfile Mini-Guide To Problem SolvingDokument18 SeitenMole Concept: Chemfile Mini-Guide To Problem SolvingNaren ParasharNoch keine Bewertungen

- Test Units and Accessories: Sinteso™Dokument22 SeitenTest Units and Accessories: Sinteso™Imad QsnNoch keine Bewertungen

- To 1 BUMN 2023 Bahasa Inggris StructureDokument5 SeitenTo 1 BUMN 2023 Bahasa Inggris StructureKukuh Perkasa WirayudaNoch keine Bewertungen

- Bespoke Fabrication Systems for Unique Site SolutionsDokument13 SeitenBespoke Fabrication Systems for Unique Site Solutionswish uNoch keine Bewertungen

- Report Experiment 5 STK1211Dokument9 SeitenReport Experiment 5 STK1211NurAkila Mohd YasirNoch keine Bewertungen

- EDSP Quantitative and Qualitative FormDokument2 SeitenEDSP Quantitative and Qualitative FormTalal SultanNoch keine Bewertungen

- Fiitjee JEE Adv p1 Phase II SolDokument10 SeitenFiitjee JEE Adv p1 Phase II SolPadamNoch keine Bewertungen

- RJ Bensingh Pub Composites CoatingsDokument5 SeitenRJ Bensingh Pub Composites CoatingsFakkir MohamedNoch keine Bewertungen

- Disha Symbiosis 20th JulyDokument2 SeitenDisha Symbiosis 20th JulyhippieatheartbalewadiNoch keine Bewertungen

- IOSA Self Evaluation Form - 31 October 2014Dokument45 SeitenIOSA Self Evaluation Form - 31 October 2014pknight2010Noch keine Bewertungen