Beruflich Dokumente

Kultur Dokumente

A330 Non Normals

Hochgeladen von

pontooOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A330 Non Normals

Hochgeladen von

pontooCopyright:

Verfügbare Formate

A330 NON-NORMALS LAND ASAP - red..

mayday call and land as soon as possible

- amber.. pan call and land without undue delay

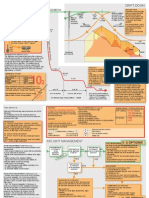

ENGINE-OUT APPROACH Systems

FLT LAW = alternate

- Consider overweight landing (many protections lost, eg. no speed protection)

- CAT 3 single with autothrust available - "CAT 3 DUAL" indicates on the Some control surfaces lost (either fixed or floating.. worst case for

PFD with APPR selected and the APU running, however the autoland controllability)

equipment monitor does not observe everything that requires CAT 3 "ECAM ACTIONS"

dual. The inop list still should say CAT 3 dual inoperative. The procedures are lengthy and take at least half an hour to follow and

- Landing distance x 1.1 (consult QRH 2.40) set up for the landing.

- Reverser inoperative (don't even select to interlock – may this change Work through the whole ECAM process and when "ECAM actions

soon) complete" go to the "hydraulic summary CRUISE section and follow that

- Manual thrust may be used as coordination with manual rudder is procedure.

easier The HYD SUMMARY page includes landing distance calculation and

- A/THR is probably preferred. It may be unsatisfactory in gusty or aids the decision to divert

turbulent conditions.. Vapp is VLS+5 (+ a further 3 kts for gear The increment to Vls is also determined from the summary. NOTE: use

allowance), G/SPD mini varies. the yellow temporary revision page in the summary. MANUALLY

- If rudder trim is used, trim out on short final for correct sense of rudder INSERT THE APPROACH SPEED into the MCDU

when landing or for go-around. The HYDRAULIC ARCHITECTURE on page 5.02 shows what is still

- CONF 3 (reset MCDU perf landing figure) available with certain system losses.

- Delay gear down - especially if heavy, hot and high. Can run out of When briefing the approach, use the QRH HYD summary (landing & GA)

thrust on 1 engine when flying level and fully configured. CONFIG 2 and the STATUS page to talk about what is to come in the approach and

and level flight, heavy-weight requires 80-90% N1 when not even hot. landing phase.

- @ half dot to go on G/S, call for gear down. AT G/S intercept call for

FLAP 3 (final stage). A/THR will work out speed. Rudder trim will be Speeds

automatically coordinated with AP engaged. (QRH 2.40)

- Consider gaining certain landing clearance if go-around is performance RAT only useful above 140 kts. Above this speed the controls still move

limited. slower due to less hydraulic pressure (2500 psi). The approach speed is

increased due to limited control deflection/effectiveness. Better handling

ENGINE-OUT GO AROUND results.

The speed increment to Vls is 15-30 kts depending on flap configuration

- Pitch is 12.5 deg (at loss and also what you can extend).

- Neutralise B target for rudder input (slow and steady - FBW should take Also lost:

care of bank) - antiskid and nosewheel steering

- If speed goes below SRS, be careful about lowering the nose too much - partial spoilers

to regain SRS speed. V/S could easily go to negative – PNF calls

“sink rate”. Monitor V/S as part of the instrument scan in the GA. Handling & Holding

- At engine-out acceleration altitude - select ALT and retract flaps on - continuous control input required

schedule. - manoeuvre with care

- Remember to call FMA – now do so after gear is up and a nav mode - if the ailerons are off-centre then consider use of rudder trim

(NAV or HDG) is selected. This ensures that a nav mode is actually - easier to maintain control with small pitch and bank angles. This also

engaged. eases the load on the hydraulic system

- Remember after takeoff checklist. - if holding, ask for 3 minute patterns (check above MSA); less turns,

less workload

CRM Aspects - configure when straight and level. In turns the Vls come up and could

get a nuisance stall warning

A timely PA to the cabin lets passengers and crew know that you are - hold at an approach fix so when ready for the approach you can

aware of, and in control of the problem. configure and get straight into it.

On diversion or return:

- tell flight crew Go Around

- tell ATC (fire services?) - Status page states use SLAT/FLAP jammed procedure

- tell cabin crew - the hydraulic summary states to maintain slats/flap configuration,

- tell passengers therefore landing with slat/flap jammed procedure is not required.

- tell company - the gear will not retract (if green system lost)

ENGINE DAMAGE INDICATIONS BLUE and YELLOW System Loss

- THS not available; trim is locked in the current position (possibly flare

N1 and N2 windmill speeds, following a failure, are linked to TAS. early or flare more)

It may happen that N2 is zero at low altitude and low IAS and N1 if trim setting greater than 8 then max speed is 180 kts (not enough

remains turning (larger surface area). This does not necessarily mean forward elevator pressure to maintain descent or fly level)

damage. Tests have shown N2 zero at 10,000’ and 20,000’ with IAS at - autotrim operates by deflecting actual elevators

150 kts (very slow). This may occur at 3 minutes after shutdown - park brake may not be available due loss of accumulator (checks

(certainly not immediately). Engine damage is better observed by other required at stop)

indications:

GREEN & YELLOW System Loss

- visual nacelle check

- no autobrakes

- high vibration (meters and airframe)

- alternate (blue) brakes only with antiskid

- high EGT with airframe vibration - no NWS

- N1 = zero (seized main rotor) - slats slow

- no flaps

DUAL HYDRAULIC FAILURE - no yaw damper

- single elevator

- A/P not available - gravity gear extension only

- F/D available - RAT MAN ON (should auto-deploy with G & Y LO LVL)

- A/THR available (nothing hydraulic) >140 kts and 2500 psi system

- Manually fly the aircraft - do not use speedbrake

SLOW DOWN

PF: "I have control, I have the radio" GREEN & BLUE System Loss

PNF: cancel any warnings and cautions - no autobrakes

Check navigation - no slats

“ABNORM” (NOV 07) NOT AN OFFICIAL DOCUMENT

PAGE 1

- flaps slow DOUBLE PROBE HEAT FAILURE

- single elevator DISPLAY UNIT FAILURE

- no brakes - only accumulator - max 7 applications ECAM SINGLE DISPLAY

- no antiskid so max brake pedal pressure 1,000 psi DISPLAY DISCREPANCY

- spoilers 4 & 6 only L/G GRAVITY EXTENSION

- RAT MAN ON (should auto-deploy with G & B LO LVL) LANDING WITH ABNORMAL L/G

>140 kts and 2500 psi system RESIDUAL BRAKING PROC

- do not use speedbrake IR ALIGNMENT IN ATT MODE

- park brake may be inoperative due lost accumulator pressure FM/GPS POS DISAGREE

ADR 1+2+3 FAULT

System Recovery ADR DISAGREE/ADR CHECK PROC

Some systems may be recoverable at the approach phase. UNRELIABLE SPEED INDICATION

- If OVHT or RSVR LO AIR PR was the initial condition and the OVHT DUAL BLEED FAULT

light is now out or the reservoir pressure had restored, the hydraulic ENG RELIGHT IN FLIGHT

pump may be turned back on. ENG STALL

ENG HIGH VIBRATION

Other Systems ENG TAILPIPE FIRE

- GPWS system is turned off due to unusual flap configuration OVERWEIGHT LANDING

- if 1 green pump fails, the other can pressurise the whole system COCKPIT WINDSHIELD /WINDOW CRACKED

- the yellow electric pump runs with an engine failure at takeoff to ensure VOLCANIC ASH ENCOUNTER

the flaps retract properly. It runs continuously provided the green elec BOMB ON BOARD

pump is not running for gear retraction. RESET OF COMPUTERS

(the paper checklist adds to turn it off) ECAM ADVISORY CONDITIONS

- the electric pumps are only 18% the flow capacity of the engine pumps. Vapp DETERMINATION

They assist to retract surfaces but cannot replace the EDPs LDG CONF/APP SPD/LDG DIST FOLLOWING FAILURES

System Sources FCU FAILURE

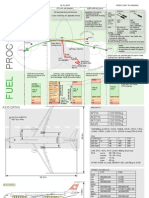

FLAPS G &Y

SLATS G&B ECAM message is

Normal brakes G AUTO FLT FCU FAULT

Alternate brakes & park brake B Autopilots (including FDs) and autothrust may be lost depending on the

RUDDER GYB failure.

LH ELEVATOR G&B Total loss of FCU

RH ELEVATOR G&Y Baro ref STD is only available therefore a pilot correction to altitude must

Pitch Trim 1 Y be made (30’ per hPa).

Pitch Trim 2 B The STBY altimeter and baro reference will still be available.

Landing Gear G * All FCU selections are lost

NWS G * SPEED SEL flag is displayed on the PFD

* ALT SEL flag is displayed on the PFD

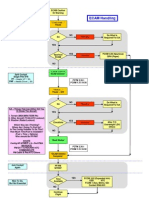

Decision Process * CAT 1 can still be performed manually

Control aircraft - FLY & NAVIGATE Default displays are:

Confirm problem * PFD with ILS

Checklist * track/FPA is also lost

Decision AFOTW, ETOPS + commercial * ND with 80 nm scale range

Communication - Flight Crew * ND weather radar is lost (WXR RANGE flag displayed on ND)

- ATC * Needle 1 is VOR 1

- Cabin Crew * Needle 2 is ADF 2

- Passengers Note: DDRMI selections are not affected

- Company In Practice

* the BIRD comes on automatically (supplied by IRs)

UNANNUNCIATED CHECKLISTS * the green track diamond on the PFD is still available (supplied

by IRs)

EMERGENCY * there is no blue track line on the PFD when the FDs are turned

off

ELEC EMER CONFIG & SUMMARY * there is no speed bug so speeds are manually flown by

SMOKE/TOXIC FUMES REMOVAL reference to the IAS tape

SMOKE/AVIONICS SMOKE * there is no altitude box on the PFD

DUAL HYDRAULIC FAILURE SUMMARY * there is no track or heading bugs available

LOSS OF BRAKING * green dot, F and S speeds are still available from the FMGEC

EGPWS ALERTS Some of these may be available with only partial loss of FCU.

TCAS WARNINGS Consider FCU R/B for reset

ALL ENG FLAME OUT

DITCHING DUAL RA FAILURE

EMER DESCENT

FORCED LANDING System Information

ON GROUND EMER/EVACUATION * GPWS inoperative - switch OFF

* Lost CAT II / III - CAT 1 single available only and manual landing

ABNORMAL * Both PFDs will have a red RA flag

* Lost autocallouts - “1000”, “500”, “50”, “30”, “10”, “RETARD”

MCDU FAILURE * “hundred above” and “minima” callouts remain as these are off the

COCKPIT DOOR FAULT pressure altimeter

RUDDER JAM/RUDDER PEDAL JAM * No flight director approach to CAT ceiling OK but must increase

RUDDER RUNAWAY TRIM visibility minima to 1200m

LANDING WITH SLATS/FLAPS JAMMED * APPR unable to be selected, therefore a raw data approach is required

NO FLAPS NO SLATS LANDING * AP (and FDs) not available in APPR mode but available in other modes

LOW ENERGY WARNING (procedurally) down to 500’

FUEL LEAK * LOC mode is available down to 400’. Below 400’ the AP and/or FDs

GRAVITY FUEL FEEDING guide for overcontrol in roll

FUEL IMBALANCE * When gear down and AP disconnected the pitch law reverts to “FLARE

TRIM TANK FUEL UNUSABLE LAW” (damped direct law with no autotrim)

“ABNORM” (NOV 07) NOT AN OFFICIAL DOCUMENT

PAGE 2

* Roll mode remains normal law

* With flap selection will get a nuisance GPWS “gear not down warning” - RESETTING FMGECS

cancel and clear.

How To Fly It (3.04.24 P2) Supplementary Tech - electrical

* Use the autopilot in LOC / FPA mode. The system will automatically attempt some form of FMGEC reset and

* Establish full landing configuration with AP engaged (trim still occurs) resync.

* Disconnect the autopilot when visual - nominally at 800’ AGL (by It is recommended to use the FMGEC R/B rather than the FM R/B (reset

altimeter) button)

* Select FDs OFF and BIRD ON Ensure the APs are disconnected prior the reset and reset BOTH

* Fly the remainder of the ILS in raw data and manually trim if necessary FMGECs (left and right side of o/head panel)

(generally not required) If one FMGEC is recovered. Deselect NAV backup function on all RMPs

* PNF cannot call “radalt alive” so that AUTO tuning is restored to the MCDU RAD/NAV page.

* PF calls “1000”, “500 stable”, “100”, “50”, “30” and if necessary

“RETARD”. These calls are made off the pressure altimeter, GROUND PROXIMITY WARNING SYSTEM

adjusted for elevation. They assume that the QNH is correct

* The PF conducts the flare primarily by visual reference as the QNH- EGPWS

based calls from the PF may not be accurate CAUTION

During night or IMC conditions, apply the procedure immediately. Do not

COMING OUT OF TOGA LK delay reaction for diagnosis.

During daylight VMC conditions, with terrain obstacles clearly in sight,

- move the thrust levers so that doughnut = actual thrust the alert may be considered cautionary. Take positive corrective action

- disengage the autothrust (instinctive disengage p/b) until the alert ceases, or a safe trajectory is ensured.

- engage autothrust

- move the thrust levers to the CLB detent + "PULL UP" - "TERRAIN TERRAIN PULL UP" - "TERRAIN AHEAD

PULL UP"

DUAL FMGEC FAILURE

Simultaneously :

FMGEC COMPONENTS

- AP ……………………..…. OFF

* Flight Management (FM) - PITCH ……………….…… PULL UP

Navigation Pull up to full backstick and maintain.

Flight Planning - THRUST LEVERS ……… TOGA

Performance - SPEEDBRAKE LEVER … CHECK RETRACTED

* Flight Guidance (FG) - BANK ………………….… WINGS LEVEL or adjust

AP For "TERRAIN AHEAD PULL UP" only, in addition to climbing, a if the

FD crew concludes that turning is the safest way of action, a turning

A/THR manoeuvre can be initiated.

* Flight Envelope (FE)

VLS and VMAX computation * When flight path is safe, and GPWS warning ceases :

Aft CG monitoring Decrease pitch attitude and accelerate.

Windshear detection * When speed is above VLS, and vertical speed is positive :

* Fault Identification and Display Systems (FIDS) - maintenance use Clean up aircraft as required.

only

+ "TERRAIN TERRAIN" - "TOO LOW TERRAIN" :

FAILURE MODES Adjust the flight path, or initiate a go-around.

Parts of the FMGEC may fail or it may fail completely. Inoperative + "TERRAIN AHEAD" :

systems are displayed on ECAM and may include: adjust the flight path. Stop descent. Climb and/or turn as necessary

based on analysis of all

* AP 1 & 2 (only lost if FG function is lost) available instruments and information.

* FD 1 & 2 (turn them off!)

* A/THR (THR LK indication on PFD) + "SINK RATE" "DON'T SINK" :

* VLS & VMAX on PFDs Adjust pitch attitude, and thrust to silence the alert.

* FM functions on MCDU (including landing elevation feed to CPCs)

* GPWS Terrain function + "TO LOW GEAR" - "TOO LOW FLAPS" :

Correct the configuration, or perform a go-around.

ALTERNATIVE METHODS

+ "GLIDESLOPE" :

* FPV is available (provided by the IRs) Establish the aeroplane on the glideslope, or switch OFF the G/S

* Selected modes available mode pushbutton, if flight

* Navaid tuning is conducted through the RMPs below the glideslope is intentional (non precision approach)

* NAV backup mode may be available in the MCDUs (the FM SOURCE

Switch must be in NORM) FAM STUFF

* A reset of the FMGECs may be available Crew immediately:

* Landing elevation is set manually by the knob on the overhead panel - acknowledge alert

(take out of detent and set landing elevation (the figures are in - correct flight path or configuration to eliminate the cause of the alert.

thousands of feet, not hundreds) “terrain terrain pull-up” and “whoop whoop pull-up”. PF immediately take

* ILS CAT 1 available over controls and execute the recovery manoeuvre. (if S/O is PF, pilot on

watch takeover and execute manoeuvre).

NAV BACKUP MODE Only if: DAY VMC and it is immediately obvious to the PF that the

aircraft is not in a dangerous situation can the aircraft continue

Stores the existing flight plan in the MCDU. Gathers the aircraft position without the recovery manoeuvre.

from the onside IR. Recover to MSA, LSALT with maximum climb gradient unless the cause

The only functions available are; of the warning has been identified and the warning ceases.

- DIR TO

- F-PLN

- PROG

The flight plan still sequences. Any new waypoints must be entered as a

lat/long.

“ABNORM” (NOV 07) NOT AN OFFICIAL DOCUMENT

PAGE 3

MANUAL ENGINE STARTING

See FCOM “SUPPL TECH” procedures.

Manual engine start is recommended over automatic engine start (even

when auto start is functional) when:

* after an aborted start because of engine stall, Engine EGT overlimit,

low starter pressure.

* expecting an aborted start due to degraded bleed performance - hot or

high airfield, engine with reduced EGT margin - hot or high airfield,

marginal performance of external pneumatic air.

FADEC passively monitors:

- engine parameters

FADEC controls:

- high EGT start abort

- ignition

- start valve cutout (after start)

Other procedures available:

* Starting with external pneumatic power

* Cross bleed start

* Start Valve manual operation (ground crew)

* Engine start on batteries (with external air)

With an autostart and EGT approaching limit, the FADEC will stop fuel

into the engine well before the limit (750°) is reached. After a short delay

the less is introduced (7% less). If there is a further abort, 7% less fuel

again is introduced. The FADEC autostart gives up after 3 attempts to

start the engine. A manual start is then required procedurally.

COMMUNICATIONS FAILURE

* Check correct frequency

* Check RMP settings

* Check ACP settings

* Try hand mic and speaker up

* Try another comm. Set (eg. VHF 2 or 3, HF, SATCOM or CPDLC/ADS

link)

* Try relay with other aircraft on 121.5 or via company on ACARS

* Full communications is unlikely but if so:

- monitor 121.5, navaids for voice – eg. VOR, NDB

- squawk 7600

- non-radar environment: maintain speed and level for at least 20

minutes

- radar environment: maintain speed and level for at least 7 minutes

- proceed as per flightplan and land ….(TBC)

TAILPIPE FIRE

On the ground.

It is not an “engine fire” so the engine fire extinguisher is strictly not used

(this does not go through the core of the engine). A tailpipe fire comes

from the core.

Fuel is removed from the engine with the ENG MASTER SWITCH.

If the ENG FIRE pushbutton is used -the FADEC will become

unpowered and the engine will not be able to be cranked.

PROCEDURAL ELEMENTS

- ENG MASTER switch OFF

- ensure a bleed source (other engine or APU bleed). If neither, airport

fire services must attend promptly or the engineer can use a portable fire

extinguisher.

- crank the engine (ENG START SEL to CRANK and MAN START P/B

ON). When N2 below 30%

Note: this procedure is in the QRH “ABNORMALS” not the emergency

section.

“ABNORM” (NOV 07) NOT AN OFFICIAL DOCUMENT

PAGE 4

Das könnte Ihnen auch gefallen

- A320 Abnormal NotesDokument12 SeitenA320 Abnormal NotesCheck Singh100% (1)

- Dual Hydraulic Loss Notes A320Dokument10 SeitenDual Hydraulic Loss Notes A320ZORAWAR SINGH HAZURIA -Noch keine Bewertungen

- Airbus Flight Control Laws: The Reconfiguration LawsVon EverandAirbus Flight Control Laws: The Reconfiguration LawsBewertung: 4.5 von 5 Sternen4.5/5 (16)

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveVon EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveBewertung: 5 von 5 Sternen5/5 (2)

- A330 Emergency Electrical ConfigurationDokument2 SeitenA330 Emergency Electrical Configurationpontoo86% (7)

- A340 A330 HydraulicsDokument2 SeitenA340 A330 Hydraulicspontoo100% (5)

- A 330 FactsDokument2 SeitenA 330 FactsVinay Singh83% (6)

- A 330 Elec Power SummaryDokument2 SeitenA 330 Elec Power Summarypontoo75% (4)

- A320 - A330 QRH Abnormal and Emergency Procedures SummaryDokument8 SeitenA320 - A330 QRH Abnormal and Emergency Procedures SummaryAlexander Sturm50% (2)

- A330 Etops DataDokument1 SeiteA330 Etops DataMiroslav Stoyanov67% (3)

- AirBus 330 OralDokument62 SeitenAirBus 330 OralIYIBIRI100% (2)

- A330 OralDokument19 SeitenA330 Oralsaudia686100% (8)

- Airbus Descent MonitoringDokument29 SeitenAirbus Descent Monitoringapi-3805097100% (7)

- A330 Rec TRNG 1-C Apr.2013Dokument16 SeitenA330 Rec TRNG 1-C Apr.2013Rocky2488100% (4)

- A320 MEMORY ITEMS FOR WINDSHEAR AND EMERGENCIESDokument1 SeiteA320 MEMORY ITEMS FOR WINDSHEAR AND EMERGENCIESDale Jordan67% (3)

- A330-Dual ADR FaultDokument9 SeitenA330-Dual ADR Faultkelvinko0% (1)

- A320 Essensial DataDokument1 SeiteA320 Essensial DataKrystal Yeoh100% (1)

- A330 Emer PDFDokument1 SeiteA330 Emer PDFStephanie Johnson67% (3)

- A330Dokument6 SeitenA330Jay France50% (2)

- A320 Limitations Summary Aug 2012Dokument2 SeitenA320 Limitations Summary Aug 2012Bobi Guau100% (14)

- A330 Limitations Crosswind Alt Speed Landing GearDokument22 SeitenA330 Limitations Crosswind Alt Speed Landing GearMoataz Mohammad Naguib78% (9)

- A330-Elec Emer ConfigDokument13 SeitenA330-Elec Emer Confighoatrebg100% (1)

- A330 HydDokument1 SeiteA330 HydElias Iruela100% (7)

- A320-Dual ADR FaultDokument10 SeitenA320-Dual ADR FaulttugayyoungNoch keine Bewertungen

- A320 Quick ReferencesDokument4 SeitenA320 Quick ReferencesRohit Joshi60% (5)

- A330-200 Panel Frntg2zDokument1 SeiteA330-200 Panel Frntg2zpontoo100% (1)

- A320 Airbus Laws HexagonsDokument1 SeiteA320 Airbus Laws HexagonsRohit Joshi100% (4)

- A330 CBT NotesDokument137 SeitenA330 CBT NotesHoon Lee83% (6)

- A340 A330 ElectricalDokument2 SeitenA340 A330 Electricalpontoo75% (4)

- Flashcard List For Airbus A320 Memory Items Abnormal FlowsDokument2 SeitenFlashcard List For Airbus A320 Memory Items Abnormal FlowsMert Gönül85% (13)

- ECAM HandlingDokument1 SeiteECAM Handlingapi-380509783% (6)

- Airbus Engin Out and Auto RelightDokument43 SeitenAirbus Engin Out and Auto RelightIYIBIRI100% (4)

- Airbus A320 FactsDokument2 SeitenAirbus A320 FactsJoao Melo50% (4)

- Wet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Dokument1 SeiteWet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Jehad Badawi100% (12)

- A-320 Performance Question PaperDokument6 SeitenA-320 Performance Question PaperKarthikeyan Ramaswamy0% (1)

- Flight Mode Annuciator EFIS PFD NDDokument51 SeitenFlight Mode Annuciator EFIS PFD NDdarkdatkomNoch keine Bewertungen

- A330 Memory ItemsDokument1 SeiteA330 Memory Itemscrossfantasy100% (1)

- A320-Engine Start Failure (CFM)Dokument5 SeitenA320-Engine Start Failure (CFM)Ganesh ChoudharyNoch keine Bewertungen

- CamScanner Document ScansDokument52 SeitenCamScanner Document ScansKhurram Naseem75% (4)

- A320 CruiseDokument1 SeiteA320 CruiseZMHQS83% (12)

- INSTRUCTOR SUPPORT Airbus A330Dokument202 SeitenINSTRUCTOR SUPPORT Airbus A330pontoo95% (40)

- Engine FailureDokument2 SeitenEngine Failuresaudia686100% (18)

- A320 LimitationsDokument19 SeitenA320 LimitationsRodolfoNoch keine Bewertungen

- MFTD 1 PreparationDokument52 SeitenMFTD 1 PreparationJavier Castaños RuizNoch keine Bewertungen

- A320 LimitationsDokument18 SeitenA320 LimitationsGhardaddou YasserNoch keine Bewertungen

- A320.Normal Procedures Self Study - lpc.V001.130101Dokument29 SeitenA320.Normal Procedures Self Study - lpc.V001.130101Tony Paco100% (2)

- A 0 Rejected Takeoff NotesDokument3 SeitenA 0 Rejected Takeoff NotessuriyaNoch keine Bewertungen

- A340 Emergency Procedures Quick Reference HandbookDokument196 SeitenA340 Emergency Procedures Quick Reference HandbookGraham WaterfieldNoch keine Bewertungen

- A320 Limitations: Last UpdatedDokument19 SeitenA320 Limitations: Last UpdatedAmine ChabchoubNoch keine Bewertungen

- A320 Limitations: Last UpdatedDokument18 SeitenA320 Limitations: Last Updatedjontis jasoliyaNoch keine Bewertungen

- Updated ADIRS and Inertial Reference System FunctionsDokument51 SeitenUpdated ADIRS and Inertial Reference System FunctionsJehad Badawi100% (2)

- A320 LimitationsDokument19 SeitenA320 LimitationsTomas HezNoch keine Bewertungen

- C L - Memento A320 211 Rev 17 Aug 21Dokument2 SeitenC L - Memento A320 211 Rev 17 Aug 21Marwan TorkhaniNoch keine Bewertungen

- 22년 전반기sim 구술Dokument10 Seiten22년 전반기sim 구술JuKyung ParkNoch keine Bewertungen

- Red Triangle Productions LLC - Class Notes For Airbus A320: Phases of FlightDokument15 SeitenRed Triangle Productions LLC - Class Notes For Airbus A320: Phases of FlightMa Jo100% (3)

- A330 Rec TRNG 1-C Apr.2013Dokument14 SeitenA330 Rec TRNG 1-C Apr.2013Rocky2488100% (2)

- A340 Memory ItemsDokument3 SeitenA340 Memory ItemsPunthep Punnotok100% (3)

- A346qrh PDFDokument196 SeitenA346qrh PDFRayNoch keine Bewertungen

- QCM Aigle AzurDokument9 SeitenQCM Aigle Azurektal3aNoch keine Bewertungen

- B737NG QRCDokument2 SeitenB737NG QRCpaulbowes100% (4)

- SPD HDG LAT ALT monitoring aircraft instrumentsDokument44 SeitenSPD HDG LAT ALT monitoring aircraft instrumentspontoo86% (7)

- CAR 66 Module 5.11 Electronic DisplaysDokument13 SeitenCAR 66 Module 5.11 Electronic DisplayspontooNoch keine Bewertungen

- Airbus A320 - Ata 31 Ata 24 Ata 33Dokument19 SeitenAirbus A320 - Ata 31 Ata 24 Ata 33pontoo67% (3)

- Basic Avionics PresentationDokument148 SeitenBasic Avionics Presentationpontoo100% (14)

- CAR 66 Module 5.13 Software Management ControlDokument10 SeitenCAR 66 Module 5.13 Software Management ControlpontooNoch keine Bewertungen

- CAR 66 Module 5.5 Logic CircuitDokument21 SeitenCAR 66 Module 5.5 Logic CircuitpontooNoch keine Bewertungen

- CAR 66 Module 5.12 Electrostatics Sensitive DeviceDokument12 SeitenCAR 66 Module 5.12 Electrostatics Sensitive Devicepontoo100% (1)

- CAR 66 Module 5.10 Fibre OpticDokument25 SeitenCAR 66 Module 5.10 Fibre OpticpontooNoch keine Bewertungen

- Aircraft Radio Navigation Communication SystemsDokument192 SeitenAircraft Radio Navigation Communication Systemspontoo100% (16)

- CAR 66 Module 5.3 Data ConversionDokument9 SeitenCAR 66 Module 5.3 Data ConversionpontooNoch keine Bewertungen

- CAR 66 Module 5.14 Electromagnetic EnvironmentDokument17 SeitenCAR 66 Module 5.14 Electromagnetic EnvironmentpontooNoch keine Bewertungen

- CAR 66 Module 5.6 Basic Computer StructureDokument34 SeitenCAR 66 Module 5.6 Basic Computer StructurepontooNoch keine Bewertungen

- Airbus A320 ATA 31 EIS PresentationDokument101 SeitenAirbus A320 ATA 31 EIS Presentationpontoo94% (31)

- CAR 66 Module 5.2 Numbering SystemsDokument25 SeitenCAR 66 Module 5.2 Numbering SystemspontooNoch keine Bewertungen

- CAR 66 Module 5.1 Electronic Instrument SystemDokument26 SeitenCAR 66 Module 5.1 Electronic Instrument Systempontoo100% (2)

- Aircraft InstrumentsDokument38 SeitenAircraft InstrumentspontooNoch keine Bewertungen

- CAR 66 Module 5.4 Data BusesDokument24 SeitenCAR 66 Module 5.4 Data Busespontoo100% (1)

- CAR 66 B1 Lic Module 11.5.1 Instrument System (ATA 31)Dokument107 SeitenCAR 66 B1 Lic Module 11.5.1 Instrument System (ATA 31)pontoo100% (3)

- CAR 66 Module 5.15 Typical Aircraft Instrument SystemsDokument44 SeitenCAR 66 Module 5.15 Typical Aircraft Instrument Systemspontoo100% (1)

- FAQ Frequently Asked Questions CAR66Dokument60 SeitenFAQ Frequently Asked Questions CAR66pontooNoch keine Bewertungen

- A330 CBT NotesDokument137 SeitenA330 CBT NotesHoon Lee83% (6)

- Airbus A320 Flight Controls LawsDokument74 SeitenAirbus A320 Flight Controls Lawspontoo97% (78)

- Camo and AmoDokument2 SeitenCamo and Amopontoo100% (2)

- Radio Navigation Question RN MCQDokument85 SeitenRadio Navigation Question RN MCQpontoo56% (9)

- ATR Electrical System Push Button DescriptionDokument22 SeitenATR Electrical System Push Button Descriptionpontoo100% (12)

- Inside The Cockpit of An AirplaneDokument111 SeitenInside The Cockpit of An Airplanepontoo100% (1)

- Avionics Flying Instructor S SchoolDokument353 SeitenAvionics Flying Instructor S Schoolisamilio100% (1)

- Electrical Fundamental - Question Bank For AME CourseDokument32 SeitenElectrical Fundamental - Question Bank For AME Coursepontoo94% (32)

- SummaryDokument35 SeitenSummaryM.H.Hoiting100% (1)

- INSTRUCTOR SUPPORT Airbus A340Dokument200 SeitenINSTRUCTOR SUPPORT Airbus A340pontoo50% (2)

- API 570 Part 1 - Pipe ComponentsDokument41 SeitenAPI 570 Part 1 - Pipe Componentspeach5100% (18)

- Airbus A380: A Double Deck, Wide-Body, Four-Engine Airliner Manufactured by The European Corporation AirbusDokument19 SeitenAirbus A380: A Double Deck, Wide-Body, Four-Engine Airliner Manufactured by The European Corporation Airbuspseudonomous actualityNoch keine Bewertungen

- Uniform Circular MotionDokument6 SeitenUniform Circular MotionShekhar YaduvanshiNoch keine Bewertungen

- Cf34-8 CMM Index PDFDokument12 SeitenCf34-8 CMM Index PDFHaithem BrebishNoch keine Bewertungen

- BlueprintDokument42 SeitenBlueprintYagmurNoch keine Bewertungen

- Seginus Inc New PMA RS823-1EH Seal Assembly (OEM RS823-1 Seal Assembly)Dokument2 SeitenSeginus Inc New PMA RS823-1EH Seal Assembly (OEM RS823-1 Seal Assembly)PR.comNoch keine Bewertungen

- Modules of Earth StationsDokument4 SeitenModules of Earth StationsKaaz El DeNoch keine Bewertungen

- Hegn/Hrg Hurghada, Egypt: .Radar - Minimum.AltitudesDokument21 SeitenHegn/Hrg Hurghada, Egypt: .Radar - Minimum.AltitudesOsama GhareebNoch keine Bewertungen

- TM Arc Triarc 2020h209Dokument2 SeitenTM Arc Triarc 2020h209santyagoNoch keine Bewertungen

- Design of A Lateral Motion Controller For A Small Unmanned Aerial Vehicle (SUAV)Dokument6 SeitenDesign of A Lateral Motion Controller For A Small Unmanned Aerial Vehicle (SUAV)Adrian DincaNoch keine Bewertungen

- Load Calculation For Stair CaseDokument2 SeitenLoad Calculation For Stair CaseSantosh Bapu100% (1)

- Iran Air Flight 655Dokument11 SeitenIran Air Flight 655Elizabeth SmithNoch keine Bewertungen

- 2 Combustion Systems - PPTDokument21 Seiten2 Combustion Systems - PPTVăn Thành NguyễnNoch keine Bewertungen

- Fea Analysis of A Caliper Bracket For Disk BrakeDokument5 SeitenFea Analysis of A Caliper Bracket For Disk Brakesuraj dhulannavar100% (1)

- Indianapolis International Airport HistoryDokument6 SeitenIndianapolis International Airport HistoryCAP History Library100% (1)

- Air Force GuideDokument7 SeitenAir Force GuideImperiusTheGreatrblxNoch keine Bewertungen

- Plane Power Lightweight Alternator ReplacementsDokument1 SeitePlane Power Lightweight Alternator ReplacementsAndrea MacaudaNoch keine Bewertungen

- Notice: Fuel Flowmeter Technical Standard Order TSO-C44d RevisionDokument2 SeitenNotice: Fuel Flowmeter Technical Standard Order TSO-C44d RevisionJustia.comNoch keine Bewertungen

- Pub - Soviet Secret Projects Bombers Since 1945 Vol 1 PDFDokument179 SeitenPub - Soviet Secret Projects Bombers Since 1945 Vol 1 PDFBepis83% (6)

- Copernicus Programme Fact SheetDokument2 SeitenCopernicus Programme Fact SheetSunStar Philippine NewsNoch keine Bewertungen

- GPS - NMEA Sentence InformationDokument14 SeitenGPS - NMEA Sentence InformationNazly TeranNoch keine Bewertungen

- EPPODokument38 SeitenEPPOJohn CatlowNoch keine Bewertungen

- AITP-L02 Appendix 04-03 PDFDokument75 SeitenAITP-L02 Appendix 04-03 PDFNaveen SoysaNoch keine Bewertungen

- 01 045 FDSDokument10 Seiten01 045 FDSJaveria NaseemNoch keine Bewertungen

- EASA Part 66 ConsolidatDokument237 SeitenEASA Part 66 ConsolidatBogdan Bobocea100% (1)

- W6A W6A: Hor-Stab Elevator FuselageDokument2 SeitenW6A W6A: Hor-Stab Elevator FuselageTri SusantoNoch keine Bewertungen

- Mtoe User GuideDokument28 SeitenMtoe User GuidepravinNoch keine Bewertungen

- Rocket: History Types DesignDokument22 SeitenRocket: History Types DesigncruzleenoNoch keine Bewertungen

- Cryogenic ReportDokument18 SeitenCryogenic ReportAbhijeet MishraNoch keine Bewertungen

- Advancement On The Solar SystemDokument2 SeitenAdvancement On The Solar SystemLaijanie Claire Gonzales AlvarezNoch keine Bewertungen