Beruflich Dokumente

Kultur Dokumente

HH220i Smaster Manual

Hochgeladen von

jacklyn ade putraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HH220i Smaster Manual

Hochgeladen von

jacklyn ade putraCopyright:

Verfügbare Formate

Customer :

Reference :

W/O

Sykes HH220i Installation, Operation & Maintenance Manual

TABLE OF CONTENTS

1.

CUSTOMER SPECIFICATION

2.

TECHNICAL DATA SHEET

3.

HOW TO READ A PERFORMANCE CURVE

3.1

Example Sykes CP150 Pump Curve

3.2

Generalisations

3.3

Radial Thrust

3.4

Cavitation

4.

RISK ASSESSMENT GUIDE

5.

RISK ASSESSMENT HH220i

6.

PUMP OPERATING INSTRUCTIONS

6.1

Description of Pump Unit

6.2

Procedure Prior to Pump Start Up

6.3

Failure to Prime Pump

6.3.1

Air Leaks

6.4

Pump Dynamic Test

6.5

Ejector Test

6.5.1

7.

Dri-Prime Ejector Pack Assembly

PUMP MAINTENANCE INSTRUCTIONS

7.1

General Pump Inspection Procedure

7.2

Pump Assembly Instructions

7.2.1

Pump Bearing Bracket

7.2.2

Centrifugal Pump

7.2.3

Ejector Package

7.2.4

Mechanical Seal

7.2.5

Non Return Valve Inspection Procedure

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

7.3

Air Compressor

7.3.1

Description of Compressor

7.3.2

Fitting Instructions Compressor Assembly

7.3.3

Compressor Belt Replacement

7.3.4

Compressor Kit

8.

PUMP DIAGNOSTICS

8.1

Trouble Shooting Guide

9.

PUMP UNIT SUB-ASSEMBLY

10.

PARTS LIST

10.1

Recommended HH220i Pump Spare Parts

10.2

Volute Parts List

10.3

Bearing Bracket and Shaft Parts List

10.4

Separation Tank and Ejector Package

10.5

Oil Reservoir

10.6

Compressor

11.

PUMP UNIT ACCESSORIES

12.

DIESEL ENGINE MANUAL (if applicable)

13.

ELECTRIC MOTOR MANUAL (if applicable)

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

1 CUSTOMER SPECIFICATION

General Unit Information

Customer

Sykes Job Number

Sykes Serial Number

Plant Number

Pump Information

Pump Type

Pump Size

Impeller Diameter

HH220i

200mm x 150mm

432mm

Engine Information

Engine Make

Engine Serial Number

Tacho Serial Number

Electric Motor Information

Motor Make

Motor Serial Number

Chassis Information

Dry Weight

Wet Weight

Fuel Capacity

Trailer Information

VIN Number

Tyre Type

Axle Set Up

Pump Extras

Additional Information

Grease Lubricated Bearings

Oil Lubricated Bearings

Sykes Group Pty Ltd

Valvoline Multi Lube Lithium

grease EP Additives NLGI # 3

or Equivalent (high temperature

grease)

Valvoline Hydraulic oil 68 or

Equivalent Hydraulic oil

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

2 TECHNICAL DATA SHEET

!

MATERIALS OF CONSTRUCTION

Pump Casing:

SG Iron To AS1831 Grade 400/12

Suction Cover:

SG Iron To AS1831 Grade 400/12

Tee Piece:

Bearing Bracket:

Pump Shaft:

Impeller:

Wear Plates:

Air Injector:

Mechanical Seal:

Non Return Valve

Compressor Pulley:

Drive Pulley:

Belt Section:

Compressor Details:

SG Iron To AS1831 Grade 400/12

SG Iron To AS1831 Grade 400/12

431 Stainless Steel

316 Stainless Steel

316 Stainless Steel

316 Stainless Steel

Silicon Carbide / Silicon Carbide

150mm Reflux Box NRV

40H150 Pitch Heavy

32H150 Pitch Heavy

390H150 Timing Belt

Bendix 2W 440 R Twin-in-line

cylinders 75mm x 50mm stroke, air

cooled 15cfm (410L/min) at 1000rpm

Lubrication from engine oil system.

Ejector Details:

Jet:

23-0415-2016S

Nozzle: 23-0414-2036S

Sykes Group Pty Ltd

DESIGN DETAILS

Pump Designation:

Pump Description:

Suction Flange:

Delivery Flange:

Nominal Casing Thickness:

Nominal Shaft Diameter:

Impeller Eye Diameter:

Maximum Impeller O.D.:

Minimum Impeller O.D.:

Solids Handling Size:

Operating Speed:

Maximum Head:

Maximum Capacity:

Bearing Sizes:

HH220i

Centrifugal Single Stage, Volute

Type, 4 bladed fully open

200mm Table E

200mm Table E

16mm

75mm

200mm

432mm

380mm

75mm

MIN: 1400rpm MAX: 2200rpm

139m

1030 l/s

DRIVE END: 7317 BALL

PUMP END: NU318 ROLLER

Bearing Lubrication:

Grease or oil. Please refer to

customer specification page for

additional information

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

3 HOW TO READ A PERFORMANCE CURVE

3.1

Example Sykes CP150 Pump Curve

The lines sloping downwards from left to right represent the varying quantities of

liquid delivered by the pump with variations in head. The intersection of this line at

2000rpm with the zero flow line shows the shut off head (41m) of pressure developed

by the pump.

Total Dynamic Head (m) = Static Suction lift (m) + Static Discharge Head (m) +

Friction Head (m)

Where:

Static Suction Lift:

Static Discharge Head:

Friction Head:

Sykes Group Pty Ltd

Difference in elevation between liquid level of the

suction and the centre line of the pump.

Difference in elevation between liquid levels of the

centre line of the pump and the discharge.

Equivalent head necessary to overcome friction on the

interior surfaces of the pipework system including all

valves, bends and fittings.

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Duty Point: A pump operating at 95l/s at 29m (Total Dynamic Head).

1)

Draw a line upwards from Flow (x-axis) at 95l/s (point A).

2)

Draw a line across from Total Head (y-axis) at 29m (point C)

3)

Where the vertical line of 95l/s intersects the horizontal line of 29m

(point B) determines the pump rpm speed and power required at this

duty.

4)

Pump Speed Curve = 2000rpm.

5)

Power Requirement = 45kW to run the whole of the 2000rpm curve.

6)

To obtain NPSHR (Net Positive Suction Head Required), draw a line

across from where the vertical line of the 95l/s intersects the NPSHR

curve (point D).

7)

8)

Dynamic Suction Lift Available (DSLA)

NPSHR = 1.1m (point E).

DSLA = Atmosphere (m) Velocity Head (allow 1m) NPSHR (m)

= 10.3m 1m 1.1m

= 8.2m

To determine the actual dynamic lift of pump, it is recommended to fit a vacuum

gauge on the suction side of the pump to obtain a vacuum reading. The vacuum

gauge, for this example, should read no more than 80.4kPa (8.2m). If the vacuum

gauge reading is greater than 80.4kPa then the pump will experience cavitation.

Note:

To ensure minimal losses to the total suction lift:

Keep suction pipes as short and straight as possible.

Eliminate all possibility of air pockets being trapped in suction pipework.

When choosing foot valves, strainers, bends etc, select those, which will

provide minimal restriction to the flow.

The diameter of the suction pipe should be equal in diameter to the pump inlet

connection.

It is recommended to fit eccentric reducer in conjunction with pipe diameters

larger than the pump inlet to avoid the possibility of air pockets in the suction

pipework.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

3.2

Generalisations

(1) Flow (l/s) decreases, as Total Head (m) increases.

(2) Flow (l/s) increases, Power used increases.

It is not recommended to operate the pump outside the recommended pump

operating range. To operate outside this area will lead to cavitation, vibration and

non-uniform radial forces present in the pump. This drastically reduces the operating

life of the mechanical seal, bearings and efficiency of the pump. In addition, the pump

alignment will also be adversely effected due to excessive vibration. All this will result

in an increase of maintenance cost of the pump.

3.3

Radial Thrust

When a pump is operated at its best efficiency flow rate the velocities and hence the

pressures acting on the impeller are uniform around the volute. This is shown in

Figure A.

At flow rates other than best efficiency point, the pressure distribution is no longer

uniform. At reduced flow rates, the pressures increase spirally towards the cutwater

resulting in a radial reaction F as shown Figure B.

This will lead to the following operating problems:

Low efficiency of pump.

Noise vibration, reduced life of pump.

Increased radial loads on bearings due to unbalanced volute

pressures.

Temperature rise due to dissipated energy created by low efficiency.

A similar situation exists at flow rates beyond best efficiency flow rates, with an

approximate opposite (in direction) reaction.

This also will lead to similar problems associated with the reduced flow rates with an

addition of poor suction performance (high NPSHR).

Figure C shows typical variation of radial thrust with flow rate.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Figure A 100% Best Efficiency Flow

Figure B Reduced Flow

Figure C Radial Thrust

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

3.4

Cavitation

If the Net Positive Head Available of the pump is less than the Net Positive Head

Required, the pumpend liquid will vaporize in the region of the impeller eye i.e. where

the local pressure is less then the vapour pressure.

In this region, the fluid will consist of a liquid plus vapour cavities. This can, in the

extreme, result in the formation of a vapour lock and the prevention of the fluid

entering the impeller.

This phenomenon is called cavitation. The cavitation cycle comprises therefore of

two phase changes; one from liquid to vapour during the initiation and the other from

vapour back to liquid during cavity collapse.

Cavitation may be caused by excessive suction lift, insufficient NPSHA or operation

at too high a speed. The resulting effects include:

(1) Pitting of material surfaces due to the continual hammering action of the

collapsing vapour cavities.

(2) Significant reduction of performance due to vapour formation.

(3) The crackling noise (like gravel going through the pump) caused by vapour

cavity collapse.

Severe cavitation usually results in excessive noise, vibration and damage to pump,

whereas mild cavitation may produce nothing more than a small reduction in pump

efficiency and moderate wear of pump components.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

4 RISK ASSESSMENT GUIDE

The following RISK CLASSIFICATION table should be used to assess the degree of risk presented by

hazardous situations identified when carrying out the assessment.

Consider:

Electrical

Thermal

Noise

Mechanical

Pressure

Chemical

Radiant

Biochemical

Gravity

The numbers indicate how important it is to do something.

1 = Top priority do something immediately

6 = Low priority do something when possible

The table does not provide for control actions to be taken to minimise the risk and it is very important

that these are documented, along with time frame and responsibilities.

How severely

could it hurt

someone or how

ill could it make

someone

How likely is it to happen?

(A) VERY LIKELY

(B) LIKELY

(C) UNLIKELY

(D) VERY UNLIKELY

could happen

any time

could happen

sometime

could happen but

very rarely

could happen but

probably never will

(1) Kill or cause

permanent

disability or ill

health

(2) Long term

illness or

serious injury

(3) Medical

attention and

several

days off work

(4) First aid

needed

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

5 RISK ASSESSMENT HH220i

No.

Activity

Hazard & Type of Injury Risk

Likelihood

Consequence

Risk

Rating

Eliminate / Reduce / Control the risk by

Lifting of

Pumpset by

single point

lifting frame

Excessive lateral movement of unit - crushing

Setting up the

Pumpset

Slips, trips, strain, sprains and pinch points

Operation of

Pumpset

Excessive Noise hearing loss

Sykes Group Pty Ltd

Only qualified personnel to use lifting

equipment

Hoisting acceleration should not exceed

2

0.4m/sec

Ensure lifting equipment is in good

condition

Keep all personnel away from Pumpset

when it is suspended

Do not lift Pumpset by any other method

than the central lifting eye

Do not lift in extreme weather conditions

Stop & think

Correct PPE

Wear correct PPE

Stop and think

Inspect area to ensure safe working

conditions

Set up on level ground

Communicate with personnel

located/working in vicinity of Pumpset

Clean up any spillages causing trip

hazards

Do not operate Pumpset in known

unsafe conditions

Do not use Pumpset in any classification

of hazardous environment unless it has

been specifically designed to do so

Do not operate within a confined space

Wear hearing protection at all times

when working or operating around the

Pumpset

Stop & think

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

No.

Activity

Hazard & Type of Injury Risk

Likelihood

Consequence

Risk

Rating

Eliminate / Reduce / Control the risk by

Operation of

Pumpset

Boom movement (Suction Hose Boom) pinch

points & crushing

Operation of

Pumpset

Running engine & Pump Unit moving parts,

hot pump parts, hot exhaust and manifolds on

engine possible burns, pinch points, cuts and

abrasions

Sykes Group Pty Ltd

Wear correct PPE

Stop & think

Do not operate Pumpset in known

unsafe conditions

Do not use Pumpset in any classification

of hazardous environment unless it has

been specifically designed to do so

Do not operate within a confined space

Keep all personnel away from Pumpset

when boom is tilted, raised or lowered

Do not move Pumpset whilst operating

the boom

Ensure boom lifting equipment is in good

condition

Do not operate Boom in known unsafe

conditions

Communicate with personnel

located/working in vicinity of Pumpset

Wear correct PPE

Stop & think

Educate employees of burn hazards on

engines

Keep access door on enclosures closed

and locked when not required to be open

Ensure that the engine is operated only

from the control panel or from the

operators position by one person only

Keep hands, arms, long hair, loose

clothing and jewelry away from pulleys,

belts and other moving parts

Do not remove any safety guards or

panel

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

No.

Activity

Operation of

Pumpset

Hazard & Type of Injury Risk

Hydraulic, fuel, grease, oil, radiator coolant,

water pressure, movement of pump water

hose and battery electrolyte leaks

environmental pollution, poisoning, burns &

skin irritation

Likelihood

Consequence

Risk

Rating

Eliminate / Reduce / Control the risk by

Operation of

Pumpset

Possible electrocution electric shock and

burns

Sykes Group Pty Ltd

Stop & think

Wear correct PPE

Check all hoses for cracks and leaks

Check that all covers and caps are

secure on alternator, cooling

fan/radiator, engine & fuel tank

Ensure spillages are contained

MSDS available for all items used in

Pumpset

Educate employees of burn hazards

Wear correct PPE

Stop & think

Only Authorised Personnel to work on

electrical equipment

Check all conduits for splits, bare wires

or unsecured conduit fitting prior to

operation of Pumpset

Check all circuit breaker boards are

secure and sealed

Check all guards covering electrical

section are secured correctly

Do not attempt to connect or disconnect

load while standing in water or on wet or

soggy ground

Ensure all electrical power is isolated

from electrical equipment being serviced

Keep all electrical equipment clean and

dry

Keep terminals clean and tight

Test earth leakage equipment regularly

Ensure correct fire extinguisher is

available

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

No.

Activity

Hazard & Type of Injury Risk

Likelihood

Consequence

Risk

Rating

Eliminate / Reduce / Control the risk by

Operation of

Pumpset

Possible fire and explosion burns, bodily

injuries and possible death

Maintenance Battery charging

Possible explosion burns and bodily injuries

Sykes Group Pty Ltd

Wear correct PPE

Stop & think

Ensure correct fire extinguisher is

available

Do not refill the fuel tank while engine is

running

Never store oily rags in metal covered

containers

Do not smoke or allow sparks, flames or

other sources of ignition around fuel or

batteries

To avoid arcing keep grounded

conductive objects, such as tools, away

from exposed live electrical parts, such

as terminals

Do not operate the Pumpset system with

any known leaks in the fuel system

Open exhaust system drain plugs after

repeated failed start attempts

Wear correct PPE

Stop & think

Correctly isolate equipment

Do not smoke or allow sparks, flames or

other sources of ignition around batteries

To avoid arcing keep grounded

conductive objects, such as tools, away

from exposed live electrical parts, such

as terminals

When disconnecting battery disconnect

the negative battery terminal first

When reconnecting battery connect the

negative battery terminal last

Ensure adequate ventilation

Turn off power or disconnect the power

to the battery charger before making or

breaking connections with the battery

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

No.

Activity

Hazard & Type of Injury Risk

Likelihood

Consequence

Risk

Rating

Eliminate / Reduce / Control the risk by

Maintenance Electrical

Possible electrocution electric shock and

burns

Maintenance

refilling fuel tank

Fuel leaks environmental pollution,

poisoning, burns & skin irritation

Sykes Group Pty Ltd

Wear correct PPE

Stop & think

Correctly isolate equipment

Only Authorised Personnel to work on

electrical equipment

Do not attempt to connect or disconnect

load while standing in water or on wet or

soggy ground

Ensure all electrical power is isolated

from electrical equipment being serviced

Keep all electrical equipment clean and

dry

Keep terminals clean and tight

Test earth leakage equipment regularly

Ensure correct fire extinguisher is

available

Stop & think

Wear correct PPE

Correctly isolate equipment

Check all hoses and fittings for cracks

and leaks

Ensure spillages are contained

MSDS available for fuel used in lighting

tower

Educate employees of burn hazards

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

No.

Activity

Hazard & Type of Injury Risk

Likelihood

Consequence

Risk

Rating

Eliminate / Reduce / Control the risk by

Maintenance mechanical

Engine, hydraulic pump and centrifugal

pumpend maintenance explosion, burns,

pinch points, skin irritation

Sykes Group Pty Ltd

Stop & think

Wear correct PPE

Correctly isolate equipment

MSDS available for items used in

Pumpset

Ensure spillages are contained

Check all hoses and fittings for cracks

and leaks

Correctly de-energise hydraulic system

Ensure guarding is in place and secure

after maintenance is finished

Do not remove the radiator filler cap until

the coolant has cooled. Then loosen the

cap slowly to relieve any excess

pressure before removing the cap

completely

Educate employees on hazards of hot

coolant and oil under pressure

Educate employees of burn hazards

Ensure correct fire extinguisher is

available

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

6 PUMP OPERATING INSTRUCTIONS

6.1

Description of Pump Unit

The pump is basically a simple end suction pump which has a completely automatic

priming system built into the design. This enables the pump to self-prime from a

completely dry condition even with a long suction line. No liquid of any nature is

required to prime the pump and therefore in temporary dry trench conditions the pump

will '

snore'until such time as liquid is available.

It can handle unscreened sewage, trade effluents, thick slurries and solids up to a

normal limitation of 75mm.

The impeller is a 4 bladed, 316 Stainless Steel construction, design fully open. It is

mounted on a shaft made from 431 stainless steel fitted in an SG iron bearing bracket;

which also provides concentric location for the pump body.

The pump body is SG iron construction fitted with Stainless Steel wear plates secured

by high tensile steel screws.

The mechanical seal is leak tight using a silicon carbide face on a silicon carbide seat.

The arrangement incorporates glycol lubricated seal housing.

Guards are fitted as standard to all moving parts.

Suction flange 200mm Table E.

Delivery flange 200mm Table E.

Note

If your HH220i pumpset has been mounted on a trailer chassis, it is recommended that

after approximately 5 km of travel that all wheel nuts be inspected and re-tightened.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

6.2

Procedure Prior to Pump Start Up

The pump should be placed on a level area of ground.

In order to put the pump to work the following procedure should be undertaken.

1. Ensure that the pump turns freely.

2. Ensure bearings are adequately lubricated.

3. Ensure oil level in bearing bracket is filled to centre line of pump shaft indicated by

the sight gauge and oil level label.

4. The incline angle of pump should not to be greater than 10.

5. Check pump runs without excessive noise, heat or vibration.

6. Position hoses to avoid unnecessary stress. Sharp bends should be eliminated and

protective measures taken where hoses are exposed to abrasive surfaces.

Collapsible type hoses MUST NOT be used on the suction side of the pump.

7. For diesel prime movers:Check engine fuel supply level and top up if necessary.

(The fuel tank is built into the chassis).

8. Check engine oil level on dipstick and top up with recommended oil if necessary.

The pump will prime automatically once the suction hose intake is submerged.

Note

For engine starting instructions or starting difficulties, refer to the manufacturer's

handbook.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

6.3

Failure to Prime Pump

6.3.1 Air Leaks

To test for air leaks, disconnect suction hose from pump and blank off suction entry. If

the vacuum gauge registers a satisfactory reading, i.e. 9.14 metres, the leak will be in

the suction hose. Re-couple hose to pump; remove intake and blank-off entry to hose.

It should then be possible to locate leak.

If the air leak is in the pump:a) Check that all drain plugs are screwed tightly in position

b) Remove NRV Inspection cover and make sure that the valve is seating

correctly.

6.4

Pump Dynamic Test

1. Before starting the engine, check that the shaft, pulleys and belt are free to rotate

with the guards in position.

2. Start pump and run completely dry for a minimum period of 10 minutes (initial run up

speed at 900rpm increasing during test to 1100rpm). During this period, generally

check and observe for any unusual vibrations, overheating, fuel, oil or air leaks.

3. These faults must be rectified immediately to prevent a possible engine seizure.

4. After the dry running period, check that the pump unit will raise a minimum vacuum

of 81kPa (8.3m).

Special Note

Consult engine manufacturers handbook for oil, fuel, speed control and stop details.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

6.5

Ejector Test

6.5.1 Dri-Prime Ejector Pack Assembly

1. Check ejector and jet sizes:

Nozzle

Jet

23-0414-2036S

23-0415-2016S

2. Clean the jet and nozzle with paraffin or similar cleaner. On no account should

stiff wire be used as this will enlarge the bores.

3. Check the nozzle and jet bores for any sharp edges, burrs or rough surfaces. If

damaged and no replacement is readily available, smooth and polish as well as

possible to original form.

4. Alignment of jet and nozzle is important but this is preset by machining

tolerances.

5. Assemble ejector unit and check performance on test unit. Operation Air

Pressure: 40 psi approx. Minimum Pass Vacuum: 81kPa (8.3m).

6. A satisfactory arrangement for carrying out the performance test on the ejector

unit is a plate fitted with a vacuum gauge as illustrated.

Figure 1 Ejector Exploded Assembly Drawing

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

7 PUMP MAINTENANCE INSTRUCTIONS

7.1

General Pump Inspection Procedure

1. Drain the water from the pump and the non-return valve.

2. Remove the non-return valve and inspect the valve and seat for wear.

3. Drain the oil from the engine and the pump.

4. Dismantle the pump end completely.

5. If there is a mechanical seal problem, return to supplier for reconditioning.

6. Check that the shaft rotates freely with no end float.

7. Clean and inspect all components and renew where necessary. Do not use

abrasive materials or solutions to clean the ejector assembly. Renew all nyltite

seals.

8. Reassemble the complete pump end and non-return valve (refer to Fitting

Instructions).

9. Drain the fuel tank.

10. Detach fuel, oil and air hoses. Clean and ensure that they are not blocked. Test

the relief valve at 3 to 5 PSI.

11. Check pulley alignment and belt condition. Check the security of pulleys and

flexible couplings.

12. Re-assemble the complete unit.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

7.2

Pump Assembly Instructions

7.2.1 Pump Bearing Bracket (for oil lubricated bearings)

1. Ensure all items are free from burrs and rust.

2. Visually check for porosity and blow holes in the castings and clean out any

casting sand and swarf which may be present.

3. Ensure that all items are clean and that the seal faces are free from score or

wear marks.

4. Check surface finish on shaft where oil seals run and polish if required.

5. Check shaft thread, retaining nut threads & lock washer tab slots.

6. Fit inner angular contact ball bearing to shaft (large inner race face to shaft

shoulder).

Retain with spacer tool and bearing lock nut.

Allow to cool.

7. Fit inner race of roller bearing to shaft.

Fit lock ring to shaft

Loctite grub screws

Wipe off excess loctite

8. Fit roller bearing outer race to bearing housing.

9. Fit inner bearing covers.

10. After bearings are cooled on shaft, oil bearings, fit assembly into housing.

11. Position angular contact ball bearing slightly recessed into housing enough to

position outer bearing spacer.

12. Remove temporary spacer tool from shaft.

13. Fit inner and outer bearing spacer.

14. Heat outer angular contact ball bearing.

Fit bearing to shaft (large inner race face to bearing locknut)

Fit locknut and lock washer

Tighten until both bearings move together than bend over lock tab on lock

washer

Allow to cool

15. Fit lip seals to bearings covers.

16. When bearing is cooled oil and position shaft in bearing bracket.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

17. Bolt rear outer bearing cover onto the bearing bracket using bolts, spring

washers, flat washers, sealing washers and O-rings. This will locate shaft in

bearing bracket. Ensure shaft turns freely.

18. Fit bearing bracket cover plate.

19. Fit mechanical seal as per instructions outlined in this manual.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

7.2.2 Centrifugal Pump

1. Slide Mechanical Seal onto shaft. Ensure the locking grub screws are screwed

back clear of shaft refer to mechanical seal section for complete installation

instructions.

2. Before fitting seal onto shaft ensure that all surfaces are clean and that all edges

over which the seal has to pass are rounded off. All working faces must be free

from any foreign matter.

3. Fit rear wear plate to volute using bolts, sealing washers and o-rings

respectively.

4. Fit volute onto Bearing Bracket using studs, nuts and washers. Apply antisieze

grease between mating surfaces.

5. Fit Spacer Ring onto shaft.

6. Before fitting the impeller apply anti-seize compound onto the threads. Screw

impeller onto shaft in a clockwise motion. The recommended grades of anti

seize is: - GA50 Molybond or equivalent (Molybdenum Disulphide).

7. Locate front wearplate onto front adaptor plate using bolt, sealing washer and

o-ring.

8. Fit studs into volute then locate front adaptor plate onto volute, then by

tightening nuts move the front adaptor plate until the impeller starts to rub on the

front wear plate. When this has been achieved measure the distance between

the front adaptor plate and the volute then add 0.040 (1.00mm / 1.10mm). This

will give you the amount of shims that have to be added to give you correct

clearance between the impeller and front wear plate.

9. Once this measurement has been achieved, remove front adaptor plate and add

appropriate shims. Then re-tighten front adaptor plate onto volute, than re-check

clearances by measuring the distance between the impeller and front wearplate

using feeler gauges. If the clearance is not 0.030 (0.70mm/0.85mm) then

repeat steps 9 & 10 until correct.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

7.2.3 Ejector Package

1. Check that all items are clean and free from burrs. The jet and nozzle should

only be cleaned with paraffin or similar cleaner. Wire should not be used, as this

will enlarge the bores.

2. Do not use excessive jointing compound when fitting these items and ensure

that it does not enter the bores. This may cause a blockage in the ejector.

3. Screw by hand the jet and the nozzle to the carrier plate.

4. Fit elbow to nozzle.

5. Place the ball in the carrier plate, and then secure ball seat.

6. Fit the carrier plate to the tee piece with gasket filters and fasteners.

7. Push exhaust hose onto the elbow. Fasten using clamp.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

7.2.4 Mechanical Seal

Assembly

Installation Instructions for a P3F Cartridge Seal

Prepare Pump for Mechanical Seal Installation

1. Clean pump parts:

a) Shaft

d) Pump Frame

b) Shaft Sleeve

e) Impeller

c) Stuffing Box Back Plate

f) Studs, Nuts & Bolts

2. Inspect and de-burr pump parts:

a. Replace shaft or repair shaft if worn in secondary sealing area under orings.

b. Remove all burrs that would cut secondary seals or cause misalignment.

(Pay attention to old set-screw marks.)

c. Check shaft run out (to be within 0.025mm (0.001)) TIR per 25mm of

shaft dia) end play (not to exceed 0.13mm (0.005)) stuffing box face

mis-alignment (square to shaft to within 0.13mm TIR and a good surface

to seal, 1.60UMRA max) and condition of bearings. Replace if necessary.

d. Drain & flush glycol reservoir.

Installation of the Mechanical Seal

1. Lubricate the shaft before sliding on seal. Slide the seal on the shaft by pushing

on the collar & sleeve, making sure that the set screws are engaged in the

sleeve without touching the shaft.

2. Make all necessary impeller or rotor adjustments as required.

3. Tighten the gland bolts evenly.

4. Tighten grub screws (3off s/s std grub screws, use Locktite 243)

5. Dimpling shaft: Drill into shaft through remaining grub screw holes (3off) to suit

spear point grub screws. (Use Locktite 243)

6. Tighten remaining M6 x 6 Umbrako Grubscrews directly on top of the 6 grub

screws in place. (Use Locktite 243)

7. Remove setting clips and cap head screws.

8. Turn shaft by hand, there should be no metal to metal contact between the

sleeve and the seal.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

9. Make all necessary pump connections and alignments. Hook up appropriate

tangential flush port depending on shaft rotation. (Connect flush in the direction

of shaft rotation, eg; if the shaft is rotating clockwise, connect the flush (marked)

clockwise).

10. Fill tank with Ethylene Glycol (mixture 30% Glycol, 70% Water), bled barrier fluid

line free of air.

11. The seal is ready for pump start-up procedures.

Warning! Ensure once pump is operation that the barrier fluid is circulating. If

barrier fluid does not seem to be circulating, remove return line to bled

remaining air out of it. Reconnect and re-check flow.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

7.2.5 Non Return Valve Inspection Procedure

1. Ensure that all items are clean and free from burrs.

2. Visually check for porosity and blow holes in the castings and for scores or chaffing

of the seat.

3. Ensure all bolts on inspection cover are secure.

4. Clean the delivery flange on the pump body and secure the valve to it with

fasteners.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

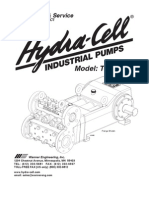

7.3

Air Compressor

7.3.1 Description of Compressor

BENDIX AIR

COMPRESSOR

TYPE 2W 440 R.

Introduction: The very high air output of this twin cylinder

single stage air compressor makes it eminently suitable for

use on buses and special purpose heavy duty vehicles. It

has a balanced crankshaft and reed type air inlet and

delivery valves for greater efficiency and reliability at high

operating speeds.

It is available in either base or flange mounted versions

which are suitable for gear, belt, or shaft drive from the

vehicle engine.

The crankcase and cylinders form a single rigid weight

saving casting. The cylinder barrels are air cooled while

the cylinder head is cooled by water circulated from the

vehicle engine cooling system. The compressor may be

run in either direction of rotation at speeds of up to 2400

r.p.m. to deliver up to 9 bar pressure (130 p.s.i.) For

sustained operation at higher delivery pressures please

consult our Technical Services Department.

An unloader mechanism may be incorporated in the

cylinder head. In its absence, pressure regulation is by an

air delivery line mounted unloader valve, or by a D2

Governor used in conjunction with an AD2 Air Dryer. The

air inlet and delivery valves are contained in a valve plate

fitted between the cylinder barrels and the cylinder head.

The compressor lubricating oil is circulated under pressure

from the vehicle engine lubricating oil system.

Every effort has been made to ensure that the information in this

leaflet is correct but we reserve the right to amend or change this

information without notice.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Construction: Refer to Figs. 1 and 4. In Fig. 1 A is the

reed valve plate and B is the cast aluminium cylinder head

which is partially finned to assist cooling. C is the air

delivery connection and there are cooling water connections

at the two positions D. E is the air inlet connection.

Each cylinder has an air delivery valve F and an air inlet

valve G. Three gaskets are fitted at H, one between the

cylinder head and valve plate, and two between the valve

plate and the finned cast iron cylinder/crankcase unit J.

The two aluminium pistons K each have two piston rings L

and an oil control ring M. The piston pins N are retained by

the circlips P. The front end of the forged steel crankshaft Q

runs in the ball bearing R. The front end cover S also carries

the crankshaft oil seal T.

The connecting rods U are made from a forged light alloy

which forms an excellent bearing surface. The rods run

directly on the crankshaft journals and piston pins. This

eliminates the need for separate bearing inserts.

The rear end of the crankshaft carries a thrust washer V and

runs in a white metal bearing bush W. The rear end cover X

is threaded at Y for a lubricating oil connection from the

vehicle engine. Engine oil under pressure then flows

through drillings in the crankshaft to the main bearing at W

and to the big end bearings. The ball bearing R and the

other internal surfaces are lubricated by oil splash and mist.

The oil drains back to the vehicle engine through the open

bottom of the compressor crankcase.

General Specification:

Bore

Stroke

Swept Volume

Maximum Recommended Speed

Maximum Recommended Delivery

Pressure

Operating temperature Range

Maximum Continuous delivered

Air Temperature

(See '

Installation'

)

Weight

75mm

50mm

3

441.6 cm

2400 r.p.m.

9bar (130 p.s.i.)

-40C to + 80C

220C

19.5 kg

Also refer to the performance charts in Fig. 2.

Installation:

Standard ISO and DIN symbols for air

compressors in pnuematic circuit diagrams are shown in Fig.

3. Because of the range of mounting and driving options the

dimensions in Fig. 4 are typical only. Our Technical

Services Department will supply detailed dimensions and

information for each particular application. The Department

should also be consulted if it is desired to mount the

compressor at an appreciable angle. The compressor

should be mounted where the maximum air flow will pass

over it to help in ensuring that the delivered air temperature

does not exceed 220C.

The cylinder/crankcase unit may be flange mounted instead

of base mounted as in Fig. 4. Details are available on

request.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Maintenance: Before working on or around air

brake systems and components always observe the

following precautions:

a)

b)

c)

d)

e)

f)

g)

Stop the engine before working under a

vehicle.

Always chock the vehicle wheels,

because depleting the vehicle air system

pressure may cause the vehicle to roll.

Keep hands away from actuator push rods

and slack adjusters. They may apply as

the system pressure drops.

Never connect or disconnect a hose or

line containing air pressure. It may whip

as air escapes.

Never remove a component or pipe plug

unless you are certain all system pressure

has been depleted.

Never exceed recommended air pressure.

Always wear safety glasses when working

with air pressure. Never look into air jets

or direct them at anyone.

Sykes Group Pty Ltd

h)

i)

j)

Never attempt to dismantle a component

until you have read and understand

recommended procedures.

Some units contain powerful springs and

injury can result if not properly dismantled.

Use only the correct tools and observe all

precautions pertaining to the use of these

tools.

At vehicle service intervals check the compressor

for any leakages of water, oil, or air. If the

compressor is slow to build up pressure the

cylinder head and valve plate may be removed.

The condition of the valve assemblies and the

cylinder bores may then be checked and any

excessive build up of carbon removed. Service

Kits of replaceable items are available on request.

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

7.3.2 Fitting Instructions Compressor Assembly

1

Ensure all items are clean and that the hoses are free from foreign matter.

Do not use excessive jointing compound (eg. Stag, Neolite, Non-Adhesive

Hermatite etc) when fitting these items and ensure that it does not enter the

bores. This may cause a blockage in the oil or air lines.

Fit gasket to the compressor position on adaptor and secure with fasteners.

Secure the compressor pulley to the compressor with the nut and spring

washer. Remove the taperlock bush from the pump pulley then pass the

pulley over the shaft. Ease the belt over the pulleys, and fit the key. Align

the pulleys then refit the taperlock bush to the pump pulley and secure it to

the shaft.

Remove and discard four cylinder head screws from the compressor and

ensure the compressed air port is located at the opposite end to fan.

Connect the compressed air hose between the compressor and the jet

sleeve.

Fit the oil pipe fittings to the compressor.

Connect air intake fittings.

Secure the guard with screws. Ensure that the belt and pulleys are free to

rotate.

7.3.3 Compressor Belt Replacement

Timing Belt Procedure

1.

Remove pulley guard set screws and pump support nuts and draw pump

assembly away from engine flywheel housing

2.

Remove old belt and taper lock bush from pump pulley.

3.

Ease replacement belt over pulleys, realign pulleys and refit taper lock bush.

4.

Check belt tension then refit pump unit onto engine.

5.

The compressor tooth belt drive has fixed centres so no adjustment is

necessary. The normal operating air pressure is 3.44 - 5.17 bar (50-75psi).

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Link Belt Procedure

1

Remove pulley guard and old belt.

Place belt around pulleys without creating any tension.

Count the number of links and remove 7% (1 in 14).

Place belting around pump shaft and link up.

Fit around drive pulley and over compressor pulley rotating the drive shaft

slowly.

The normal operating air pressure is 2.75 - 4.13 bar (40-60psi).

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

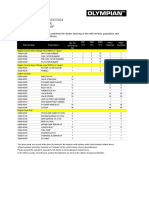

7.3.4 Compressor Parts List

Ref.

Description

Part Number

Bendix Air Compressor 2W 440 R KZ1087/14

49-0523-9915

A

B

C

D

E

F

G

H

Valve Plate Assembly c/w Reed Valve Kit & Air Inlet Valve

Cylinder Head

BSP Threaded Air Delivery Connection

Threaded Water Cooling Ports

BSP Threaded Air Inlet

Reed Valve Kit

Air Inlet Valve 229502

Valve Plate & Head Gasket Kit

KY2331/1SP

KZ1160/3

Cylinder Body

Piston Assembly (STD)

(KW5172/1SP)

Piston Assembly

Piston Assembly

Piston Ring Set (STD)

Piston Ring Set (0.010 o/s)

Piston Ring Set (0.020 o/s)

Piston Ring Set (0.030 o/s)

L

M

N

P

Q

R

S

T

U

V

W

X

Y

Comprising: Cyl.Head Gasket KX2466/2

Top Plate Gasket KX2799/2

Lower Plate Gasket KX2280/2

Oil Control Ring

Set

Connecting Rod Pin Rod Pin Snap Pin

-

Sykes Group Pty Ltd

SK2997/1

KZ1094/1

1189082SP

(KW5172/2SP)

(KW5172/3SP)

(SKR2790/00)

(SKR2790/10)

(SKR2790/20)

Included in Piston Assy & Piston Ring

Included in Piston Assembly

Included in Piston Assembly

Crankshaft

Ball Bearing (NSK-6307-CE)

Front End Cover

O-Ring, Inner Bearing Cover

Crankshaft Oil Seal (CR13938)

Con Rod Complete

(KW4785/1SP)

Thrust Washer

White Metal Bearing Bushing

End Cover Assembly c/w Bushing

C Ring - End Cover

Lubricating Oil Inlet 1/8 BSP

Base Mount Gasket 0.8mm

Base Mount Gasket 0.4mm

SK2955/1

1189255SP

1189256SP

SKR2962/00

SKR2962/10

SKR2962/20

SKR2962/30

KY2258/1SP

1194120SP

KX2491/1

1189619

267805

1194120SP

KY2372/1

I811560066

KX1223/13SP

1189571

KX2542/1

KX2542/2

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

8 Pump Diagnostics

8.1

Trouble Shooting Guide

Pump System Problems

Likely Cause

Pump Does Not Prime

- Suction lift too great

- Inlet of suction pipe insufficiently

submerged

- Suction inlet or strainer blocked

- Excessive amount of air or gas in liquid

- Viscosity and / or S.G. of liquid being

pumped too high

- Suction line not air tight

- Suction hose collapsed

- Non return valve ball not seating

- Mechanical seal / Packing drawing air

into pump

- Pumps priming system blocked or badly

worn

- Separation tank cover blocked

- Pumps priming hose leaking air

- Pumps priming system not delivering

sufficient air

- Pumps priming system belt drive faulty

Not Enough Liquid

Sykes Group Pty Ltd

Incorrect engine speed

Discharge head too high

Suction lift too great

Suction inlet or strainer blocked

Suction line not air tight

Suction hose collapsed

Mechanical seal drawing air into pump

Obstruction in pump casing / impeller

Impeller excessively worn

Delivery hose punctured or blocked

Pump not primed

Air pockets in suction line

Inlet of suction pipe insufficiently

submerged

- Excessive amount of air or gas in liquid

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Pump System Problems

Not Enough Pressure

Likely Cause

Speed too low

Excessive amount of air or gas in liquid

Incorrect direction of rotation

Viscosity and / or S.G. of liquid being

pumped too high

- Impeller Damaged

- Impeller out of balance

Pump Ceases to Deliver

Liquid After a Time

Pump Takes Excessive

Power

- Engine speed too high

- Obstruction between impeller and casing

- Viscosity and / or SG of liquid being

pumped too high

- Incorrect direction of rotation

- Misalignment

- Shaft bent

Pump Leaking at

Mechanical Seal Housing

- Mechanical seal damaged or worn

Pump Bearings Have Short

Life

Suction lift too great

Insufficient water at suction inlet

Suction inlet or strainer blocked

Suction hose collapsed

Excessive air leak in suction line

Mechanical seal / Packing drawing air

into pump

- Obstruction in pump casing / impeller

- Delivery hose punctured or blocked

Sykes Group Pty Ltd

Obstruction in pump casing / impeller

Impeller out of balance

Shaft bent

Shaft running of centre because of worn

bearings or misalignment

Misalignment

Bearings worn

Excessive thrust caused by mechanical

failure inside pump

Lack of bearing lubrication

Incorrect assembly of stacked bearings,

i.e. angular contact ball bearings fitted

front-to-front instead of back-to-back

Dirt in bearings

Rusting of bearings from water in

housing

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Pump System Problems

Pump Vibrating or

Overheating

Likely Cause

-

Sykes Group Pty Ltd

Engine speed too high

Obstruction in pump casing / impeller

Impeller damaged

Cavitation due to excessive suction lift

Impeller out of balance

Shaft bent

Shaft running of centre because of worn

bearings or misalignment

Misalignment

Bearings worn

Pump not primed

Pump or suction pipe not completely

filled with water

Inlet of suction pipe insufficiently

submerged

Suction or discharge re-circulation in

volute

Excessive thrust caused by mechanical

failure inside pump

Lack of bearing lubrication

Incorrect assembly of stacked bearings,

i.e. angular contact ball bearings fitted

front-to-front instead of back-to-back

Dirt in bearings

Rusting of bearings from water in

housing

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

9 PUMP UNIT SUB-ASSEMBLY

H

Volute

BB

Bearing Bracket

ST

Separation Tank

EP

Ejector Pack

OR

Glycol Reservoir

AC

Compressor Assembly

AC

EP

OR

ST

BB

Figure 19 Typical HH220i Pumpend

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Figure 20 HH220i General Assembly Drawing

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

10 PARTS LIST

10.1 Recommended HH220i Pump Spare Parts

Description

Impeller

Front Wear Plate

Stuffing Box Plate

Stuffing Box Plate Gasket

Shim - 0.25mm

Shim - 0.40mm

Shim - 0.80mm

Shim - 1.60mm

Mechanical Seal

Shaft Sleeve

Roller Bearing

Ball Bearing Angular Contact

Shaft

Sykes Group Pty Ltd

Part Number

12-0325-3015

12-0185-0115

12-0196-0115

98-430-807-162

38-0200-5413

38-0200-5423

38-0200-5433

38-0200-5443

001-1007JC

28-0210-3215

39-0094-9912

39-0091-9912

16-0200-8011-BU

Quantity

1

1

1

1

2

2

2

2

1

1

1

2

1

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

10.2 Volute Parts List

Figure 21 Volute Mechanical Seal Exploded Assembly Drawing

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

VOLUTE PARTS LIST

Illustration

number

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H13a

H13b

H16

H18a

H18b

H18c

H18d

H19

Not Shown

Description

Volute Body

Impeller

Front Wear Plate

Stuffing Box Plate

Adaptor Plate

Stud (M16 x 50)

Nut (M16)

Seal Washer (M16) & O Ring

Part Number

Quantity

11-0200-0115

12-0325-3015

12-0185-0115

12-0196-0115

10-0200-0000

1

1

1

1

1

4

4

4

38-0790-4412

38-0792-4412

Capscrew (M24 x 40)

Spring Washer (M24)

Flat Washer (M16) S/S

Spring Washer (M16)S/S

Gasket

Shim 0.25mm

Shim 0.4 mm

Shim 0.8 mm

Shim 1.6mm

Plug BSP

Epoxy Adhesive

98-430-807-162

38-0200-5413

38-0200-5423

38-0200-5433

38-0200-5433

P12

AC-068

12

12

2

2

1

A/R

A/R

A/R

A/R

2

1

MECHANICAL SEAL

Illustration

Description

number

H11

Shaft Sleeve (modified)

H12

Mechanical Seal

H14

Bolt (M16 x 20) S/S

Part Number

Quantity

28-0210-3215

001-1007JC

1

1

2

Part Number

Quantity

28-0200-3215

14-0300-0115

1

1

2

2

1

PACKED GLAND

Illustration

number

H11

H12

H14

H15

H17

Description

Shaft Sleeve

Gland followers (set of 2 halves)

Nut (M16) S/S

Stud (M16 x 65) S/S

Gland packing -

Sykes Group Pty Ltd

638-4003G

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

Figure 22 Volute Packed Gland Exploded Assembly Drawing

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

VOLUTE PARTS LIST

Illustration

number

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H13a

H13b

H16

H18a

H18b

H18c

H18d

H19

Not Shown

Description

Volute Body

Impeller

Front Wear Plate

Stuffing Box Plate

Adaptor Plate

Stud (M16 x 50)

Nut (M16)

Seal Washer (M16) & O Ring

Part Number

Quantity

11-0200-0115

12-0325-3015

12-0185-0115

12-0196-0115

10-0200-0000

1

1

1

1

1

4

4

4

38-0790-4412

38-0792-4412

Capscrew (M24 x 40)

Spring Washer (M24)

Flat Washer (M16) S/S

Spring Washer (M16)S/S

Gasket

Shim 0.25mm

Shim 0.4 mm

Shim 0.8 mm

Shim 1.6mm

Plug BSP

Epoxy Adhesive

98-430-807-162

38-0200-5413

38-0200-5423

38-0200-5433

38-0200-5443

P12

AC-068

12

12

2

2

1

A/R

A/R

A/R

A/R

2

1

MECHANICAL SEAL

Illustration

Description

number

H11

Shaft Sleeve (modified)

H12

Mechanical Seal

H14

Bolt (M16 x 20) S/S

Part Number

Quantity

28-0210-3215

001-1007JC

1

1

2

Part Number

Quantity

28-0200-3215

14-0300-0115

1

1

2

2

1

PACKED GLAND

Illustration

number

H11

H12

H14

H15

H17

Description

Shaft Sleeve

Gland followers (set of 2 halves)

Nut (M16) S/S

Stud (M16 x 65) S/S

Gland packing -

Sykes Group Pty Ltd

638-4003G

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

10.3 Bearing Bracket and Shaft Parts List

Figure 23 Bearing Bracket Exploded Assembly Drawing

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

BEARING BRACKET & SHAFT PARTS LIST

Illustration

Number

BB1

BB2

BB3

BB4

BB5

BB6

BB7

BB8A

BB8B

BB9

BB10

BB11

BB12

BB13

BB14

BB15

BB16

BB17

BB18

BB19

BB20

BB21

BB22A

BB22B

BB23

BB24

BB25

BB26

BB27

BB28A

BB28B

BB29

BB30

Description

Bearing Bracket

Bearing Cover Outer Rear

Bearing Cover Outer Front

Bearing Cover Inner

Roller Bearing 90 X 190

Angular Ball Bearing 85 X 180

Bolt (M12 x 160)

Flat Washer (M12)

Spring Washer (M12)

Bolt (M12 x 100)

Bolt (M12 x 40)

Bolt (M12 x 180)

Spiroseal 90 x 110

Clamp Ring

Socket Capscrew (M6 x 20)

Shaft

Lock Nut Bearing

Lockwasher Bearing

Bearing Spacers (Pair)

Spiroseal 75 x 95 x 10

Bearing Bracket Cover Joint 1.6mm

Stud (M20 x 70)

Flat Washer (M20)

Spring Washer (M20)

Nut (M20)

Plug 3/8 BSP

Plug 1/8 BSP

Bearing Bracket Cover Plate

Bolt (M12 x 40)

Flat Washer (M12)

Spring Washer (M12)

Sealing Washer (M12)

O-Ring 10.69 x 3.53 Viton

Part Number

Quantity

13-0164-0115

13-0169-0125-BU

13-0162-0115

13-0170-0115-OIL

39-0094-9912

39-0091-9912

1

1

1

1

1

2

3

9

9

3

3

3

1

1

1

1

1

1

1

1

1

8

8

8

8

1

1

1

4

4

4

4

4

38-1331-9912

28-0252-8811

16-0200-8011-BU

39-0096-9912

39-0097-9912

24-0093-8831

38-1328-9912

XH80BBJ-160

P06

P02

27-0200-8211-OIL

* Notes:

1. When ordering Shaft state pump engine type so correct type of shaft length can be

supplied.

2. Ensure that the angular ball bearings (BB6) are fitted back-to-back either side of

bearing spacers (BB18). The set up is obtained by fitting the smaller shoulders of

the inner races facing each other.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

10.4 Separation Tank / Ejector Package Parts List

Figure 24 Separation Tank & Ejector Package

Exploded Assembly Drawing

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

EJECTOR PACKAGE PARTS LIST

Illustration

Number

EP1

EP2

Description

Ejector Nozzle

Ejector Jet

Part Number

Quantity

23-0414-2036S

23-0415-2016S

1

1

SEPARATION TANK PARTS LIST

Illustration

Number

ST1

ST2

ST3

ST4

ST5

ST6

ST7

ST8

ST9

ST10

ST11

ST12

ST13

ST14

Description

T Piece

Tank/Body Joint

Stud (M20 x 70)

Nut (M20)

Lockwasher (M20)

Carrier Plate

Carrier / Tank Stud (M12x 50)

Springwasher (M12)

Nut (M12)

Ball Seat

Ball

Carrier Plate Plug 1 B.S.P.

Fitter

BSP Elbow - Hosetail

Sykes Group Pty Ltd

Part Number

Quantity

348-4008

500-5003

1

2

8

8

8

1

4

4

4

1

1

1

1

1

23-0411-0115

23-0412-2011

39-0641-4113

P16

23-0413-2113

E12SBF

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

10.5 Glycol Reservoir Parts List

Figure 25 Glycol Reservoir Exploded Assembly Drawing

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

GLYCOL RESERVOIR PARTS LIST

Illustration

Number

OR1

OR2

OR3

OR4

OR5

OR6

OR7

OR8

OR9

OR10

OR11

Description

Part Number

Quantity

Glycol Reservoir Assembly

Lid

Sight & Temperature Gauge

Hydraulic Nipple BSP

Reservoir Gasket

Nut (M12)

Springwasher (M12)

Plug (with breather)

Glycol Reservoir Hose Length 1

Glycol Reservoir Hose Length 2

Hose Clamps to suit reservoir hose

Nut & Hose Tails to suit

reservoir hose

Bolt (M10 x 30)

Flat Washer (M10)

Spring Washer (M10)

27-5000-8211

1

1

1

Sykes Group Pty Ltd

40-0000-0060

N04H

38-0350-5443

P08

1-319-0006

1-319-0006

OTK1011

HT0404

1

1

1

1

650mm

550mm

4

4

4

4

4

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

10.6 Compressor Parts List

Figure 26 - Compressor Assembly Drawing

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

COMPRESSOR PARTS LIST

Illustration

Number

AC1

AC2

AC3

AC4

AC5

AC6

AC7

AC8

AC9

AC10

AC11

AC13

AC14

AC15

Description

Compressor (Bendix)

Gasket

Stud M10 x 40

Springwasher M10

Pulley (Pump) bored to 75mm shaft

Pulley (Compressor)

Belt 38wide x 78 teeth (1/2 Heavy Pitch)

Fan Washer

Relief Valve

Air Cleaner

Adaptor (Air Cleaner)

Compressed Air Hose

Nipple BSP x BSP

Pulley / Belt Guard

Sykes Group Pty Ltd

Part Number

Quantity

49-0523-9915

KX2542/1

1

1

4

4

1

1

1

1

1

1

1

1

1

1

10-0000-0037

26-0830-0243

26-0840-9912

36-0556-8111

10-0000-0004

54-0556-9912

A1212

42-0000-0015

N1208H

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

10.7 Non Return Valve Parts List

Figure 27 Non Return Valve Explode Assembly Drawing

NON RETURN VALVE PARTS LIST

Illustration

Number

V1

V2

Description

Flexi-Check Valve 200mm

Flexi-Check Valve Flap 200mm

Sykes Group Pty Ltd

Part Number

Quantity

10-0000-0480

10-0000-0485

1

1

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

11 PUMP UNIT ACCESSORIES

Your HH220i pumpset has been mounted on a robust custom built skid

chassis and comes complete with extras include.

Description

Part Number

14 Flywheel Stub Shaft (3 shaft)

2

3

RFC280 Flex Coupling c/w 3535TLB to

suit shaft 75mm & 3

Inbuilt 24 hour Fuel Tank (2350 litres)

Discharge Pressure Gauges

8 Non Return Valve

6

7

6 Crane Geared Operated Butterfly

Valve

Hydro Flow Valve (Fuel)

Night Lights 2 only

Green Flashing Light (Pump Operating)

10

Loss of Low Shutdown

11

9 kg Fire Extinguisher 2 only

AC-034

12

9 kg Fire Extinguisher Bracket 2 only

AC-035

13

14

Traffolyte Pump Operating Sign

(Recommended Pump Operating

Pressures at Various Speeds)

Jump Start Receptacle

15

Lockable Battery Isolator

AC-017 & AC-017-NEW

16

8 Suction Bauer

8-319-4830

17

Suction Bauer O Ring

8-319-4850

18

8 Split Intake

8-181-4022

19

8 Wire Armoured Suction Hose x 6 m

9-319-6186

20

Wiggins Fast Fill Fittings (Oil & Water)

AC-057

For further information please refer to the manufacturer's Operation and

Maintenance Manuals.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

12 DIESEL ENGINE MANUAL

Your HH220i pumpend is driven by a ?? Liquid Cooled Diesel Engine

and comes complete with the following.

Description

Part Number

Mines Wiring to MDG-15

Water Separator Filter

Emergency Stop

Murphy Control Panel Gauges

Clip Type Lagging on Exhaust Pipes

For further information please refer to the manufacturer's Operation and

Maintenance Manuals.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Sykes HH220i Installation, Operation & Maintenance Manual

13 ELECTRIC MOTOR MANUAL

Your HH220i pumpend is driven by a ??kW / ?Pole / IP?? / ?Phase /

???V Electric Motor and comes complete with the following.

Description

Part Number

For further information please refer to the manufacturer's Operation and

Maintenance Manuals.

Sykes Group Pty Ltd

Spare Parts & Service 24 hours: 1800 131950

Website: www.sykesgroup.com

Das könnte Ihnen auch gefallen

- HD150 Pump Maintenance ManualDokument35 SeitenHD150 Pump Maintenance Manualjacklyn ade putraNoch keine Bewertungen

- CP220i Manual Standard Part Numbers Complete - MasterDokument67 SeitenCP220i Manual Standard Part Numbers Complete - Masterjacklyn ade putra100% (1)

- WO23465 HH160i X Cat C-7 - Phu Bia MiningDokument117 SeitenWO23465 HH160i X Cat C-7 - Phu Bia MiningTego_903779395100% (1)

- HH220 IDokument2 SeitenHH220 Iprimelly0% (1)

- Etanorm KSBDokument28 SeitenEtanorm KSBAlusine Tarawally100% (1)

- WMM MF-385G SS Spare PartDokument41 SeitenWMM MF-385G SS Spare PartJeniverRanyC.Awombo100% (1)

- Air Control 685 Part Locations With Part NumbersDokument41 SeitenAir Control 685 Part Locations With Part NumbersArielJimenezMillalenNoch keine Bewertungen

- Vermeer D220x300Dokument4 SeitenVermeer D220x300Suryantoro Wono NarodoNoch keine Bewertungen

- High-pressure multistage centrifugal pumpsDokument8 SeitenHigh-pressure multistage centrifugal pumpsgaryiandersonNoch keine Bewertungen

- Cat 3306B DITA PropulsionDokument40 SeitenCat 3306B DITA PropulsionStroe VladNoch keine Bewertungen

- Sykes Pump BookletDokument105 SeitenSykes Pump BooklethipsterzNoch keine Bewertungen

- C18 Fire Pump 597 BKW 800 BHP 1750 RPM PDFDokument5 SeitenC18 Fire Pump 597 BKW 800 BHP 1750 RPM PDFDenis JimenezNoch keine Bewertungen

- CS1000 P6L Parts ManualDokument133 SeitenCS1000 P6L Parts Manualhofer jonathan100% (2)

- JWS 400Dokument2 SeitenJWS 400николайNoch keine Bewertungen

- Intruction Manual FSADokument10 SeitenIntruction Manual FSAtrantuan74Noch keine Bewertungen

- C15 Acert Spec SheetDokument4 SeitenC15 Acert Spec SheetMalasquez Leon XavierNoch keine Bewertungen

- PDF Editor: Multi-Purpose DrillsDokument5 SeitenPDF Editor: Multi-Purpose DrillsTalabarteria RaygozaNoch keine Bewertungen

- Air Compressor XAS 186 CDokument2 SeitenAir Compressor XAS 186 CAsad AijazNoch keine Bewertungen

- Mud Pump NOV 8-P80Dokument1 SeiteMud Pump NOV 8-P80jonhyto14100% (1)

- Manual - Wat - Sykes Parts - HH160i - Rev00 Sept12 PDFDokument27 SeitenManual - Wat - Sykes Parts - HH160i - Rev00 Sept12 PDFmuahdibNoch keine Bewertungen

- Enerpac L2596 GDokument108 SeitenEnerpac L2596 GGabriel OniszczukNoch keine Bewertungen

- KTAA19-G6A Cummins Engine & PartsDokument10 SeitenKTAA19-G6A Cummins Engine & PartsServicios y Repuestos Jeremy Azhael 2320 C.ANoch keine Bewertungen

- HH150 Smanual - MasterDokument43 SeitenHH150 Smanual - Masterjacklyn ade putra80% (5)

- B Motor Catalog PDFDokument70 SeitenB Motor Catalog PDFUsama PopatiaNoch keine Bewertungen

- Eight Position Cylinders Service Information: Warnings-Installation and MountingDokument10 SeitenEight Position Cylinders Service Information: Warnings-Installation and MountingyelmustafaaliNoch keine Bewertungen

- GEH300-1 Generating Set Parts ListDokument2 SeitenGEH300-1 Generating Set Parts ListairtupasNoch keine Bewertungen

- Kit Basico Overhaul PerkinsDokument3 SeitenKit Basico Overhaul PerkinsGabriel Andres ValenciaNoch keine Bewertungen

- Alfa Laval PHE Part Numbers PDFDokument686 SeitenAlfa Laval PHE Part Numbers PDFcbienst0% (1)

- MF420EXDokument2 SeitenMF420EXYolanda100% (2)

- HYVA GEAR PUMP ALPHA BI-4H5 SPECSDokument2 SeitenHYVA GEAR PUMP ALPHA BI-4H5 SPECSRidlon PrimatamaNoch keine Bewertungen

- PG 1200 - 350 Combo OMM ManualDokument150 SeitenPG 1200 - 350 Combo OMM ManualAlfiya AnamNoch keine Bewertungen

- Manual - Wat - Sykes XH200 - Pumpset Specification - 2Dokument9 SeitenManual - Wat - Sykes XH200 - Pumpset Specification - 2antonio rodriguesvieiraNoch keine Bewertungen

- BOM 10214 B4-41-1000 - Lowres - tcm261 - 900685Dokument92 SeitenBOM 10214 B4-41-1000 - Lowres - tcm261 - 900685Nuno PaivaNoch keine Bewertungen

- Motobomba SykesDokument144 SeitenMotobomba Sykesmuahdib100% (1)

- Gardner-Denver@: Triplex PlungerDokument38 SeitenGardner-Denver@: Triplex PlungerLibardo Alfonso Cadena Rodriguez100% (1)

- SB Sand Pump Specs & ModelsDokument7 SeitenSB Sand Pump Specs & Modelsscribind100% (1)

- Atlas Copco Top Hammer Drills t25,30,35.Dokument4 SeitenAtlas Copco Top Hammer Drills t25,30,35.dineshbabu1980100% (1)

- Salient Features:: Crawler DozerDokument4 SeitenSalient Features:: Crawler DozerJackson Phinni100% (2)

- High Pres Comp BK 1 PDFDokument58 SeitenHigh Pres Comp BK 1 PDFGerald Boy100% (1)

- KSB Centrifugal EtanormDokument36 SeitenKSB Centrifugal Etanormatmoko2100% (2)

- DM-45 Sales BrochureDokument4 SeitenDM-45 Sales Brochurejuancaf773557100% (1)

- SSW10 Spinning Wrench Assembly GuideDokument10 SeitenSSW10 Spinning Wrench Assembly GuideGeorge Hans SterlingNoch keine Bewertungen

- Parts List For Hydraulic Drifter Model: YH80: CPN 51793800 PL6036Dokument56 SeitenParts List For Hydraulic Drifter Model: YH80: CPN 51793800 PL6036Sergio Andres100% (1)

- Parts List: KewpumpDokument11 SeitenParts List: KewpumpAriel Espinoza100% (1)

- Manual Valvula de Lodos Top DriveDokument13 SeitenManual Valvula de Lodos Top DriveMauricio GarciaNoch keine Bewertungen

- Honghua Hydraulic Power Unit Parts ListDokument29 SeitenHonghua Hydraulic Power Unit Parts Listcmrig74Noch keine Bewertungen

- HH125 Pump Installation ManualDokument41 SeitenHH125 Pump Installation Manualjacklyn ade putra0% (1)

- Funk™ 23000 HMD Transmission: Industrial Drivetrain SpecificationsDokument1 SeiteFunk™ 23000 HMD Transmission: Industrial Drivetrain SpecificationsNoe Melgarejo PonceNoch keine Bewertungen

- Hurricane B7-41/1000: Product ReferenceDokument8 SeitenHurricane B7-41/1000: Product ReferenceY.EbadiNoch keine Bewertungen

- Pompa Kew Pump Tipe CM, FM, KSDokument5 SeitenPompa Kew Pump Tipe CM, FM, KSPurnomo NugrohoNoch keine Bewertungen

- Free Download Here: Service Manuals For Tamrock Drill PDFDokument2 SeitenFree Download Here: Service Manuals For Tamrock Drill PDFTimo Kaartinen100% (4)

- 385 Multiflow Ops Manuas March 2010Dokument32 Seiten385 Multiflow Ops Manuas March 2010lao florentinoNoch keine Bewertungen

- 2010 Specs 1035ac - CanrigDokument4 Seiten2010 Specs 1035ac - Canrigaldino020203100% (1)

- Hawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223Dokument155 SeitenHawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223MASAGUS MANGKU GAMANoch keine Bewertungen

- Engineering Encyclopedia: Centrifugal PumpsDokument70 SeitenEngineering Encyclopedia: Centrifugal PumpsMajdi Belguith67% (3)