Beruflich Dokumente

Kultur Dokumente

Samsung ML-2165W (MLT-D101S) : Toner Cartridge Remanufacturing Instructions

Hochgeladen von

Noel J. Vera G.Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Samsung ML-2165W (MLT-D101S) : Toner Cartridge Remanufacturing Instructions

Hochgeladen von

Noel J. Vera G.Copyright:

Verfügbare Formate

SAMSUNG ML-2165W (MLT-D101S)

TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

SAMSUNG MLT-D101S TONER CARTRIDGE

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

REMANUFACTURING THE SAMSUNG

ML-2165W (MLT-D101S) TONER CARTRIDGE

By Enrique Stura, Daniel Reyes, Mike Josiah, and the Technical Staff at UniNet

TECHNICAL TIP: HOW TO CIRCUMVENT SAMSUNGS ML-2160/2165 CARTRIDGE REPLACEMENT LIMITATION

UniNet offers solutions for optimal performance powered by our Award Winning Technical Team.

On this opportunity we will touch on the Samsung ML-2160, 2165, SCX-3405 printers with cartridge part number MLT-D101S.

Samsung has built in a very devious cartridge replacement limitation on this printer series in which there is a maximum

limitation of 250 cartridges per machine allowed.

There are two issues to consider with this system, one is that a testing bed can be rendered useless after testing 250 cartridges;

the second is that an end users machine can be rendered useless (or dramatically reduced) if the final chip is used

during testing.

- This means only 250 new cartridges (the OEM are included on the count) in total can be installed into the printer.

- Whenever you insert a new cartridge (to be recognized by chip serial number) to the printer, the printer will count "+1" for

the replacement. At the same time, the total accumulated number will be recorded to both the printer and chip of the cartridge.

Now comes the sneaky part: If you take this recorded cartridge to another printer, the install count record in the chip will be written

to the printer and of course "+1" will be counted, and so on...

In other words, if you take a cartridge from a machine that has run 240 cartridges and install it in a brand new machine, that new

machine will have a total life left of nine cartridges (240+1)!

Once the replacement limitation of 250 has been reached, the printer will stop its functionality.

As a result, our technical team strongly recommends: Do not test the toner cartridges with a new chip before delivery." Use an

in-house testing chip (marked with bright paint) to run all the cartridge testing and then after it has passed, install a new chip on

the cartridge.

Otherwise, customer printers would be counted up to the number on the cartridge (from your testing printer), and once changed,

it is unrecoverable.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

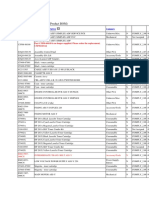

BASIC SAMSUNG ML-2165W PRINTER SPECIFICATIONS

Printing

Speed (black):

21 ppm

First print out time:

Less than 8.5 seconds (black)

Print resolution:

1200 dpi

Emulation:

SPL (Samsung Printing Language)

Duplex printing:

Manual

Paper Handling

Paper input capacity:

Output capacity:

Media sizes:

Media types:

150 sheets

100 pages

3 x 5 in 8.5 x 14 in

Plain, Envelope, Labels, Cardstock, Thick, Cotton, Color, Preprinted, Recycled, Bond, Archive

General

Display:

Processor:

Memory:

Interface:

Noise level:

Monthly duty cycle:

OS compatibility:

Power consumption:

Energy Star compliant:

Dimensions:

Weight:

LED (toner/status)

300MHz

32MB

Hi Speed USB 2.0, wireless 802.11 b/g/n

Less than 50 dBA while printing, less than 26 dBA (standby)

10,000 pages

Windows 7, Vista, XP, 2008, 2003, 3200, Various Linux, Unix, Mac 10.4 and later

Standby mode - less than 1.2W; Ready mode - less than 30W; Peak - less than 310W

Yes

(W x D x H inches) 13" x 7" x 8.5"

8.8 lbs.

TONER CARTRIDGE SPECIFICATIONS

Consumables

Cartridge type:

One-piece toner

Toner load:

Starter Cartridge:

55g (700 pgs)

Replacement Cartridge: 70g (1,500 pgs)

Consumable Yield

As stated by Samsung, the MLT-D101S cartridge, shipped with the machine (starter), will print 700 pages while the replacement

cartridge will print 1,500 pages as per ISO/IEC 19752 specs.

The starter cartridge shipped with the machine can only be identified by its serial number and the word Initial printed in its label.

The aspects of the cartridge are rapidly recognized as a Samsung product, however as with prior releases, the presence of plastic

rivets instead of classic screws to secure end plates, does create the need to carefully drill all seven positions and replace the

rivets with standard self-tapping cartridge screws for proper removing, remanufacturing and assembling.

In the following figures, we can see the relevant details in both end covers.

The real surprise is inside the cartridge as soon as it is removed and separated into its two sections. First, we find that the developer

roller is no longer made of controllably conductive urethane as with prior models but replaced by a aluminum sleeve set at a

particular non-contact distance marked by the presence of bushings at each end of the roller. This metal roller is treated at a given

rugosity and does not have any resistant coating as we find in a cartridge working with magnetic toner, except that in this case the

toner is non-magnetic and there is no magnet inside the roller.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

The separation between the roller and the surface of the OPC is about 0.14mm, meaning in effect there is a jump of the toner

from the roller surface to the OPC surface in the moment of development of the latent image in the photoreceptor. The surprise

does not end there and we see that the doctor blade working at a tangential position is made of stainless steel instead of

polyurethane. This metal to metal contact with toner as intermediate can only mean severe degrading or wear of the surface with

use, particularly if a non-specific toner is used, such as the Universal being offered by suppliers.

Our lab tests have shown that the actual MLT-D101S toner is of a new design and might not be exactly as in previous models.

The use of a non-specific toner could accelerate the wear of the developer roller surface treatment and a rapid decay of the print

quality offered by the cartridge.

REQUIRED TOOLS

1. Toner approved vacuum

2. Small common screwdriver

3. Phillips head screwdriver #3

4. Needle nose pliers

5. Chisel blade X-Acto style knife

6. Small drill bit 5/64 (to match self-tapping screws) and small electric drill

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

REQUIRED SUPPLIES

1. New replacement toner for use in Samsung ML-2165W / MLT-D101S

2. New replacement chip for use in ML-2165W to match region

3. New OPC drum (optional)

4. New developer roller (optional)

5. New PCR (optional)

6. New doctor blade (optional)

7. Self-tapping cartridge screws 1/8 x 1/4 (7 pieces)

8. Conductive grease

9. 99% isopropyl alcohol

10. Wiper blade lubricating powder

1. Place the cartridge in position, and with the chisel blade section, the head of each plastic rivet holding the left end cover.

2. Mark the center of each cut and drill a hole with the small

drill bit no deeper that 3/16.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

3. Tap the four screws into position.

4. Repeat the work sectioning the heads of the rivets on the opposite end cover (marking the center of the rivets, drilling and

tapping the three screws).

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

5. Proceed now to remove the screws of the end cover on the right (contact side) and pry open with the small screwdriver at

different consecutive points until separation is accomplished. Even though the cover seems to be formed by two sections, it is a

unit with a rather thin centerpiece. Worth noting also the way the chip is internally held and the need to be replaced prior to

reinstalling the cover.

6. Repeat the removal of the left end covers in its two parts, starting with the top one and then the lower one.

This will allow separation of the cartridge in two sections.

Begin working in the image section.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

7. Slide the OPC drum axle out just enough to allow the opposite end of the drum to be lifted out of position and remove it.

Leave the drum axle inside the OPC.

8. Remove the PCR, applying slight leverage to both holders with the small screwdriver.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

9. Remove both Phillips screws and remove the wiper blade by prying it out.

10. Vacuum the waste bin and surrounding areas. Inspect also

the state of the wiper and the recovery blade seals.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

11. Lubricate the wiper blade with lubricating powder and install with the two Phillips screws.

12. Wipe the PCR surface with a soft cloth to remove all traces of toner, and if need be, use a PCR cleaning liquid. Most marks and

even fingerprints can be removed with a damp cloth containing a few drops of neutral detergent and fractioning the surface with

axial strokes. Then, use a damp cloth to remove the rest of detergent and dry completely before installing the PCR. Clean the PCR

saddles with isopropyl alcohol and apply a slight coating of conductive grease to both ends. Continue to install the PCR observing

the proper location of each saddle. The green end to the right saddle and the white end to the left saddle.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

13. Clean the OPC surface and proceed to install it in the cartridge, moving the shaft inside just enough to seat the OPC

drum properly. Cover the drum section away from light and set aside. Begin work on the developer section.

14. Remove the black gear from the developer roller, using the small screwdriver as leverage.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

15. At the opposite end, remove the screw holding the contact end plate. It must be noted that there is NO conductive spring or

blade doing the electrical work. Instead, a conductive plastic tip at the plate can be found. This is further confirmed by the use of

fair amount of conductive grease both at this bearing and the inside of the metal developer roller.

16. Slide the developer roller out and be particularly careful with

both plastic bushings acting as separators at each end of the

roller. Clean the roller with a soft cloth and use isopropyl alcohol

if needed, to remove all traces of dirt and grease from the

surface. Replenish with conductive grease as needed.

17. Vacuum the area carefully, and avoid touching the

doctor blade.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

18. Remove the two Phillips screws and doctor blade from its place, then clean with a soft cloth.

19. Vacuum the hopper completely, including the feed roller, and remove the fill plug to facilitate the work.

Inspect the seals for the developer roller and the blade.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

20. Install the doctor blade in its place, securing it with the proper screws.

The figure show the plate for the gears removed, but normally this is not required.

21. Install the developer roller, ensuring the positioning of the red plastic bushing first.

Apply conductive grease if not done before.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

22. On the other end, install the bushing and the contact plate, securing it with the corresponding Phillips screw.

23. Fill the hopper with dedicated toner for use in MLT-D101,

and place the filling plug back to close the hole. Check for leaks.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

24. Now take the image section and place it on top of the developer section as shown, positioning the compression

springs properly.

25. While holding both sections together, place the lower part of the end cover in place, matching the chamfered shaft of the OPC

with the right hole. Screw the cover in place and proceed to install to larger cover in place.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

26. Work on the opposite end by taking the end cover and lubricating all contact points, and replacing the chip as shown.

When installing the cover, ensure proper insertion of the metal contact point through the square hole of the cover.

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

SAMSUNG ML-2165W (MLT-D101S) TONER CARTRIDGE REMANUFACTURING INSTRUCTIONS

27. Screw on the cover with the chip and proceed to check the cartridge in the machine.

For proper protection, use inflatable air bag packaging to transport this cartridge.

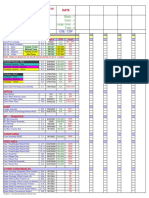

REPETITIVE DEFECT CHART

OPC

62.83 mm

PCR

25.45 mm

Developer Roller

37.70 mm

www.uninetimaging.com

2014 UniNet Imaging Inc. All trademark names and artwork are property of their respective owners. Product brand names mentioned are intended to show compatibility only.

UniNet Imaging does not warrant downloaded information. Unauthorized sale, reproduction or distribution of this article is prohibited. For additional support, please contact techsupport@uninetimaging.com

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Promotii: Categorie Grupa Subgrupa Producator Cod AgisDokument333 SeitenPromotii: Categorie Grupa Subgrupa Producator Cod Agisluca_123Noch keine Bewertungen

- Office Machine NoteDokument54 SeitenOffice Machine Noteኮኾብ ጽባሕNoch keine Bewertungen

- Error Code ContinuationDokument272 SeitenError Code ContinuationYttep Navarro GannabanNoch keine Bewertungen

- Manula de Usuario Ir1435Dokument32 SeitenManula de Usuario Ir1435Angel AvilaNoch keine Bewertungen

- Alignment and Adjustments: 4.1 User ModeDokument26 SeitenAlignment and Adjustments: 4.1 User Mode1122qqwwaasszzxxNoch keine Bewertungen

- HP Laserjet 3015 3020 3030 Aio MFP - Parts and DiagramDokument51 SeitenHP Laserjet 3015 3020 3030 Aio MFP - Parts and DiagramEdon SurfistNoch keine Bewertungen

- Epson Aculaser c1900 c900 SMDokument269 SeitenEpson Aculaser c1900 c900 SMKlema Hanis0% (1)

- Ibm 4019Dokument2 SeitenIbm 4019Jan SoukupNoch keine Bewertungen

- Konica Minolta 1600f - DTS - LFF3 - 4 EN PDFDokument168 SeitenKonica Minolta 1600f - DTS - LFF3 - 4 EN PDFionutkokNoch keine Bewertungen

- Lexmark - OEM Cartridge - Consumable - GeMDokument3 SeitenLexmark - OEM Cartridge - Consumable - GeMNitish KumarNoch keine Bewertungen

- Batch Asphalt Mixing Plants Brochure Ppb-1591-04-En 221009Dokument17 SeitenBatch Asphalt Mixing Plants Brochure Ppb-1591-04-En 221009Mohammad Rabnawaz imamNoch keine Bewertungen

- CSCX72x - CSCX8xx Combined Classroom r1.2Dokument28 SeitenCSCX72x - CSCX8xx Combined Classroom r1.2Henry CarrilloNoch keine Bewertungen

- Certificate of Non-Availability of StocksDokument6 SeitenCertificate of Non-Availability of StocksCarlo Ray DiaseNoch keine Bewertungen

- Spare BOM (HP Orderable Product BOM) : Spare Part Number Spare Part Description CategoryDokument2 SeitenSpare BOM (HP Orderable Product BOM) : Spare Part Number Spare Part Description CategoryAurelian CristeaNoch keine Bewertungen

- DP 220113Dokument68 SeitenDP 220113NurZul HealMeNoch keine Bewertungen

- Sharp Ar m355n Ar m455nDokument264 SeitenSharp Ar m355n Ar m455n19jayster84Noch keine Bewertungen

- Bizhubc650i C550i C450iInstallInstrDokument16 SeitenBizhubc650i C550i C450iInstallInstrM. SalmanNoch keine Bewertungen

- WC7400 Service Log v2 PDFDokument1 SeiteWC7400 Service Log v2 PDFChaipat WansiriNoch keine Bewertungen

- ServiceManual SP4100NDokument294 SeitenServiceManual SP4100NMohamed Reda KasemNoch keine Bewertungen

- 2.MABESAD Ekatalog 20.02.2024 NewDokument78 Seiten2.MABESAD Ekatalog 20.02.2024 Newpratamadifa524Noch keine Bewertungen

- 1203634Dokument40 Seiten1203634Nuong NguyenNoch keine Bewertungen

- Bekalan Toner Adtec Taiping SaeDokument8 SeitenBekalan Toner Adtec Taiping Saeahmad maariffNoch keine Bewertungen

- Catalogue: Corporate Printers & StationersDokument72 SeitenCatalogue: Corporate Printers & StationersMarkNoch keine Bewertungen

- Gestetner 1502 - 1802 - 1802d Copy Ref Part 1Dokument56 SeitenGestetner 1502 - 1802 - 1802d Copy Ref Part 1Klema HanisNoch keine Bewertungen

- MSDS Catridge HPDokument7 SeitenMSDS Catridge HPdp abdullahNoch keine Bewertungen

- Samsung SS 1400 Service ManualDokument104 SeitenSamsung SS 1400 Service ManualwcualumniNoch keine Bewertungen

- Catalog: Printer ConsumablesDokument18 SeitenCatalog: Printer ConsumablesoscarpeNoch keine Bewertungen

- Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDokument4 SeitenCertificate of Non-Availability of Stocks: Product Code Product Description UOM PriceNaye TomawisNoch keine Bewertungen

- Samsung ML 1865Dokument70 SeitenSamsung ML 1865Phillip DarnellNoch keine Bewertungen