Beruflich Dokumente

Kultur Dokumente

Installation of Underground GRP Pipeline

Hochgeladen von

anishdev6Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Installation of Underground GRP Pipeline

Hochgeladen von

anishdev6Copyright:

Verfügbare Formate

Public Works Authority

DRAINAGE AFFAIRS

DOHA WEST SEWAGE TREATMENT WORKS

EXTENSION # 05

CONSULTANT

egis

CONTRACTOR

Suez Environment- Marubeni JV

SUB CONTRACTOR

Gulf East Engineering, Contg. & Trading Co.

Method Statement for the Installation & Tie-In of UG-GRP

Pipe- 533__ESA103_

00

15-03-2016

21

AJIT CHACKO

ANISH DEV

SHASHI PILLAI

REV.

DATE

PAGES

PREPARED

CHECKED

REVIEWD

APPROVED

CLIENT APPRD

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

TABLE OF CONTENTS

1.

PURPOSE

2. SCOPE

3. APPLICABLE CODES, STANDARDS AND REFERENCES

4.

DEFINITIONS AND ABBREVIATIONS

5. RESPONSIBILITY

6. TRAINING

7. MATERIALS HANDLING AND STORAGE

8. MANPOWER, TOOLS AND EQUIPMENT

9. PROCEDURE

10. SEQUENCE OF INSTALLATION

11. SAFETY PRECAUTIONS

12. LIFTING PLAN

13. ATTACHMENTS

Rev. 0

Page 2 / 21

Date: 15/03/2016

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

1.

Rev. 0

Page 3 / 21

Date: 15/03/2016

PURPOSE

This Method Statement is prepared to define the procedures that Gulf East Engineering will implement in

process of Tie-in Connection (Tie-in No.38 & 39) for line no. 533__ESA103_. These Tie-Ins are done to

avoid clash with the pipes 539__EFI018_ & 589B_ETT001_, which shall be laid in future.

Where and when required, all the revisions, modifications and additions to this Method statement shall be

submitted to the consultant for information and/or approval.

Area highlighted yellow in Fig 1. below shows the area of work.

Fig 1.

2.

SCOPE

The scope of this method statement covers the minimum requirements, Procedures and Standards that

must be adhered to while installing the UG Pipelines. The activities include material reception from Stores,

Loading, Shifting the material to area of work, Unloading and Installation.

The Scope is limited to the following category of pipelines identified as listed hereunder.

a) 533__ESA103_

- Dirty Water from Existing UF to inlet works.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

3.

Rev. 0

Page 4 / 21

Date: 15/03/2016

APPLICABLE CODES, STANDARDS AND REFERENCES

3.1. DOCUMENTATION

1.

QCS 2010

2.

PROJECT HSE PLAN

3.

PROJECT QUALITY PLAN

3.2. INTERCONNECTING PIPE DRAWINGS

1.

DGT-M-DR-000-801-C

2.

DGT-M-DR-000-805-C

3.

DGT-M-DR-000-821-C

4.

DGT-M-DR-000-827-A

3.3. ISOMETRIC DRAWINGS

1.

533__ESA103_ Rev 2

3.4. FLOWTITE Installation guide for buried pipes AWWA.

3.5. Pipe List DGT-X-LT-000-801

4.

DEFINITIONS AND ABBREVIATIONS

4.1. Definition

Pipes

: Circular tubes through which fluid can flow

Installation

: Material transport and handling, pipe laying including the complete operation

of laying, jointing and testing pipes in trenches.

Pipeline

: long, continuous line of pipes and fittings including valves and ancillary structures

Plant

: Doha West STP

Client

: Suez Environment Marubeni JV

Consultant

: Egis.

Contractor

: Gulf East Engineering, Contracting & Trading

4.2. Abbreviation

SUEZ

: Suez Environment

GE

: Gulf East Engineering, Contracting & Trading

HSE

: Health, Safety & Environment

BLDG.

: Building

GRP

: Glass Reinforced Plastic

UG

: Under Ground

PTW

: Permit To work

QA/QC

: Quality Assurance / Quality Control

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 5 / 21

Date: 15/03/2016

5. RESPONSIBILITY

MATTHEIU PILLOT

CONSTRUCTION

MANAGER

SUEZ

MANDAL JAGESHWAR

QC INSPECTOR

GUILHEM JOLY

HSE MANAGER

AHMED SHAWKY SITE

ENGINEER UNDERGROUND

NETWORK

KHALED YOUSSEF

GRP ERECTION PIPING

SUPERVISOR

GULF EAST

SAISH K PILLAI

PROJECT MANAGER

SHASHI KUMAR PILLAI

CONSTRUCTION

MANAGER

VISHNU K.V

HSE OFFICER

ANISH DEV.S

PROJECT ENGINEER

SITE SUPERVISORS

WORKERS

AJIT CHACKO

DOC.

CONTROLLER

QA/QC

PLANNING

ENGINEER

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 6 / 21

Date: 15/03/2016

The Project Manager- GULFEAST

a) Supervise and coordinate between the project teams.

b) Attend site meetings on regular basis.

c) To ensure the effective implementation for the Quality management system

d) Coordination and comply with project work program.

e) To ensure the overall progress of project to the agreed program.

f)

To ensure availability of the required resources on time.

g) To supervise the Project engineers.

The Construction Manager- GULFEAST

a) Manage and oversee the day to day construction management of the Project.

b) Plan, Develop and Organise the construction effort to formulate the most effective plan for the

timely completion of each activity and in effect the Project.

c) Responsible for implementation of scope of work fabrication, erection, testing, hook-up in

conformance with the project requirements.

d) Monitor and report to PM the project details including progress, risks, Pull backs and Open

opportunities.

e) Investigate reasons for unsatisfactory performance and provide recommendation and institute

measures for improvement.

The Project Engineer- GULFEAST

a) Act as the main contact for the Construction Manager

b) Ensure the progress of Project to agreed Program

c) To coordinate with the design team dedicated to the Project

d) To check all technical details in liaise with the QA QC.

e) To Supervise the Site in all.

QA/QC Engineer/Inspector- GULFEAST

a) Ensure work has been done as per the specification and drawings, inspections are done as per

Quality Control Procedure and the Inspection and Test plan are up to date.

b) Prepare all quality documents and procedures as required.

c) Perform random site inspections on regular basis.

d) Raise RFIs through Site Query (SQ) systems.

e) To raise non- Conformances for any deviations in the materials, installation procedures,

workmanship.

f)

To follow up all non-conformance notices till the closure and maintain logs of all these items.

g) Ensure that the latest approved drawings are being used by the site personnel.

HSE Officer- GULFEAST

a) Confirm that all people working at site are safety inducted.

b) To make sure that all personnels are wearing the proper required PPEs

c) Identify the hazards involved in each work activity and advice the workforce the correct safety

measures to be followed.

d) Perform routine checks for validation of Certificates of trained Manpower and machines utilized

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 7 / 21

Date: 15/03/2016

e) Attend weekly meeting with the Client HSE Manager.

f)

Observe that the working hours are strictly followed during Summer.

Construction Manager SUEZ

Will be in charge to ensure that the works are done in accordance with the project

requirements. He will also make sure about proper between site engineer carrying out simultaneous

activities such as Piping , Equipment etc.. He will be attending the construction meeting with the client

representative and will report to his team the client expectation.

Site Engineer SUEZ

Shall be responsible of the coordination of the works. He will be the one making sure proper

interfaces with civil work partner as well as with the client representative. He will also check and solve the

technical concerns.

Site Supervisor -SUEZ

Is responsible to follow the work at site and to make sure that works happen

according to method statement and project requirements. The site Supervisor will attend to all site

inspection.

QC Inspector -SUEZ

Is responsible to organize and attend site inspection in accordance with the project

specification, QCS and ITP. He will be responsible to follow the inspection up the issuance of the

inspection report dully signed.

HSE Manager -SUEZ

Will make sure that safety requirement as HSE project plan and procedure are fulfilled.

6. TRAINING

6.1. Safety Induction shall be provided to any employee/ Visitor entering the site.

6.2. Before start of any work, VIGIMINUTE to be performed by all work Crew members on a daily basis.

6.3. Only trained and certified personnels shall be engaged in activities demonstrating high risk rate or in

situations where the presence of a trained personnel is mandatory.

7. MATERIALS HANDLING AND STORAGE

7.1. All materials shall be inspected for any fabrication defects, In-transit defects such as deep scratches,

cracks etc.. prior to reception of materials from Stores. Further the person in charge for accepting the

materials should assure that the permanent identification tags denoting the nominal diameter, name of

manufacturer, Spool number etc. are present on each material received.

7.2. Any Visible defects beyond the agreed tolerances shall not be accepted and the anomaly shall be

immediately reported to the concerned Engineer.

7.3. Coordination with the installation team and logistics should go hand in hand to avoid trouble handling

and reduce unnecessary material transfer and time wastage.

7.4. Transportation, Handling and Storage shall be strictly in accordance with the manufacturers

recommendation.

7.5. During Transport

a) Pipes and fittings shall be well secured and adequately supported along their length.

b) Nesting of pipes may be permitted.

c) No pipe shall overhang the end of a vehicle.

7.6. Handling shall be carried out as follows:

a) Pipes should be lifted singly and not handled as bunches

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 8 / 21

Date: 15/03/2016

b) Pipes shall be handled only by means of approved hooks or fabric slings

c) Use of wire ropes, chains will not be permitted.

d) Pipes and fittings of diameter smaller than 300mm may be handled manually.

e) Pipes and fittings shall not be dropped or bumped.

f)

6.

Pipes shall not be dragged over the ground.

Storage of jointing material shall be as follows:

a) Under cover

b) Rubber ring gaskets shall be stored in their original packing and not be exposed to sunlight.

c) Rubber ring gaskets must be protected from exposure to grease and oils.

d) Gasket lubricant shall be stored in shade and in the original container.

8. MANPOWER, TOOLS AND EQUIPMENT

8.1. Direct Manpower

-

Supervisor

- 01

Safety Officer

- 01

QA/QC Inspector

- 01

Surveyor

- 01

Fitter

- 04

Helper

- 04

Rigger

- 01

8.2. Tools & Equipment

-

Trailer / Truck

- 01

Crane 25T

- 01

Total Station

- 01

Hand Tools

- Lot

Chain puller

- As per requirement

Webbing slings

- As per requirement

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 9 / 21

Date: 15/03/2016

9. PROCEDURE

9.1.1.Preparation for work

- Obtain PTW prior to start of any work.

- Barricade the area to avoid unauthorized/unwanted entry and encroachment.

- Conduct topographic survey of existing pipelines and mark the area for tie-in 38 & 39 as

shown in Fig2.

- As-Built drawings shall be prepared based on this survey. Variations if any with the

isometric drawings shall be noted down and the drawings revised accordingly. The new

drawing shall be submitted to the consultant for approval.

- Check the bottom level and width of trench and make sure it meets the requirements.

- List out the required tools and tackles to carry out the shutdown activity and accumulate

those items in the reserved tool box.

- When all the above requirements are met shift all pipes of portion A to A as shown in Fig3.

- The pipes and fittings shall be transported by using trailer/ Truck and will be offloaded to

the trench using crane in a safe and proper way.

Fig 2.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 10 / 21

Date: 15/03/2016

Fig 3.

9.1.2.Joining of GRP pipes:

Joining of pipes shall be made as per the procedure and directions of pipe supplier. The

following steps to be followed during installation of GRP pipes. There are different types method

of joining and the following joining method and procedure shall be applied;

All the pipes as per the required length shall be joined with coupling, which is called as double

bell coupling joint. The following steps shall be followed;

- Foundation & Bedding: The bed must be over excavated at each joint location to ensure

that the pipe will have continuous support and does not rest on the coupling. The

coupling area must be properly bedded and backfilled after the joint assembly completed.

- Cleaning of Coupling: All the coupling grooves and other parts shall be thoroughly

cleaned to ensure no dirt, presence of oil and any other unwanted particles inside the

coupling and its groove. (see below cleaning method)

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 11 / 21

Date: 15/03/2016

Install Gaskets: Insert the rubber gasket in to the coupling groove leaping loops (typically

two to four) of rubber extending out of the groove. And it is restricted to apply any kind of

lubricants in the groove or on the gasket at this stage of assembly. Water may be used to

moisten the gasket and groove to ease positioning and insertion of the gasket. (See below

picture). Apply uniform pressure and push each loop of the rubber gasket in to the gasket

groove. After insertion pull carefully in the radial direction around the circumference to

distribute compression of the gasket.

Lubricate Gaskets: Apply a thin layer of lubricant to the rubber gaskets (see below picture)

in order to get flexibility and easiness to insert the pipe.

Clean and Lubricate Spigots: Clean thoroughly the pipe spigots to remove any dirt, grit,

grease and other unwanted/foreign materials (see below picture). Inspect the spigot sealing

surface for possible damage and apply a thin layer of lubricant to the spigots from the end to

the black alignment stripe. Keep clean both the coupling and spigot until completion of

insertion.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 12 / 21

Date: 15/03/2016

Coupling shall be mounted on one pipe, prior join two pipes together, by using clamp or

sling around the pipe at a distance of 1 to 2 meter from the spigot on to which the

coupling will be mounted.

Make sure that the coupling as well as the pipe should have enough gaps from the

ground or at least 100 mm above the ground level to keep away from dirt. Other

techniques may also be used to joining the coupling/pipes.

Fixing of Clamps: Clamp/slings shall be fixed on the first pipe or left in the position from

the previous joint. (See below pictures). Clamp contact with the pipe shall be padded or

otherwise protected to prevent damage to the pipe surface.

Join Coupling: Come alone jacks or any other alternative mechanism placed on the pipe

and connected to the clamps. Pipe shall be pulled into position in to the coupling until it

reaches the home line or touches the centre register. Then it shall be moved on to the

next pipe to be joined.

Home line = (Width of coupling- Gap between adjacent pipes)/2.

Normally the pipes we are using at site have either single spigot (SP) or double

spigot (DSP).

Refer the Table 1 below for spigot dimensions

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 13 / 21

Date: 15/03/2016

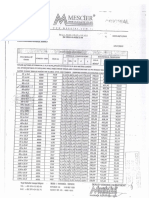

Table 1

The final spool or the closure spool to be installed will be DSP spools, in some cases it will be

the rocker pipes with DSP.

Select two couplings to be installed and place one coupling square onto the end of closure

pipe (with DSP) so that the gasket is in contract around its entire circumference. Push or pull

the coupling uniformly onto closure pipe until the entire coupling is resting on the spigot end. It

may be necessary to gently help the second ring over the chamfered end of the pipes. Repeat

with the second coupling on the other end.

Set the closure pipe (with DSP) in the trench aligned with the adjacent pipes and with equal

clearance on either side.

Keep the closure pipe centred and minimize pipe end contact. Pull the coupling till it touches

the home line of adjacent pipe.

All this have been shown in the drawing below.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 14 / 21

Date: 15/03/2016

Flanged Joints: GRP flanges shall be joined according to the following procedure;

1. Clean the flange face thoroughly and the O-ring groove as well

2. Ensure the sealing gasket / O-ring is clean and undamaged.

3. Position the sealing gasket/ O-ring in the cleaned groove and be secured with small

strips of tape or adhesive.

4. Align flanges to be joined and tightened with required bolts, nuts and washers.

5. Tighten all the bolts by using proper spanners/torque wrench and check the torque

value with Manufacturer.

6. Check all the bolts once again after one hour to ensure the bolts are properly tightened

or to adjust to get the required torque value if necessary.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 15 / 21

Date: 15/03/2016

Other Joining Methods: Mainly there are two kinds of other methods are there to join

two pipes or to join 2 different kind of materials. In this case we have to follow the below

mentioned procedure/steps.

Flexible steel Coupling method (See below picture): When a GRP pipe connecting to

other pipe materials with different outside diameter, the flexible steel coupling joining

method shall be applicable. These couplings consist of a steel mantle with an interior

rubber sealing sleeve.

It is important that to control the bolting torque of the flexible steel coupling. Do not over

tight/torque these coupling bolts and follow only manufactures recommended assembly

instructions, but with the pipe suppliers recommended bolt torque limits.

Mechanical Steel Couplings: Mechanical couplings have been successfully to join pipes

of different materials and diameters, and to adapt to flange outlets. If a mechanical

coupling is used to join GRP to another pipe material then only mechanical coupling with

dual independent bolting system shall be used (see below picture). This allows for the

independent tightening of the GRP pipe side, which typically requires less torque than

recommended by the coupling supplier.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 16 / 21

Date: 15/03/2016

- Joints shall be capable of withstanding the various tests specified for the appropriate class

of pipe. Joints shall withstand, while maintain the specified test pressure ,a deflection of

not less than 1.5% in any direction.

- After completing the pipeline installation the entire system shall be tested according to the

procedure submitted separately as well as pipe list DGT-X-LT-000-801 B.

- Clear the area and do the house keeping properly prior to handover to civil for backfilling.

- A joint inspection shall be made along with the consultant and main contractor Engineer

as per ITP/RFI for final approval and hand over to civil contractor.

10. SEQUENCE OF INSTALLATION

a) Pipe installation shall commence in portion A-B (Ref Fig 4) .Pipes shall be laid in

sequence as shown in fig 4. This installation shall be done without disturbing the

existing lines nearby.

b) Pre-assemble the spool from B to C and A to D (Ref Fig 4) . This is done to save time

during the actual installation process during tie-in.

Fig 4

c) Partial backfilling of portion A to B shall be done by the civil contractor. The joints shall

be exposed for detection of any leaks during operation.

d) Existing pipe shall be emptied of fluid and valves to be isolated shall be locked out.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 17 / 21

Date: 15/03/2016

This shall be done in coordination with O&M.

e) Obtain PTW and LOTO before commencing any cutting or modification works on the

existing pipe. The Supervisor should confirm that the correct valves have been shut as

mentioned in the LOTO sheet.

f)

Upon reception of the PTW, Cut out the existing pipe from the previously marked area

to a length favorable for the installation of new pipe. Two teams shall work

simultaneously for this activity.

g) Pre-assembled spools shall now be placed inside the trench. The connection at point

A & B shall be made via GRP Bell coupling and at point C&D where the connection to

existing pipe occurs, shall be done through Steel Coupling. The data sheet for steel

coupling is attached here with this MOS.

11. SAFETY PRECAUTIONS

a) Isolate the area with proper barrier and warning tape in order to control unauthorized entry to

the working area.

b) Provide common safety equipment at site (fire extinguisher, bucket with sand, fire watch etc.)

in accordance with fire and safety regulations.

c) Prior to start the activity; ensure that all work permit have been obtained from concerned

authorities as per the general site requirements.

d) Ensure that all lifting equipment shall be certified and the lift/drop zone shall be barricaded

with warning tape and sign boards.

e) Daily tool box talk shall be conducted by the supervisor prior to commencement of each day

activity.

f)

Make sure that there shall be adequate air circulation or proper ventilation for the working

area.

g) A dedicated safety officer and supervisor shall be responsible to ensure all safety precautions

and requirements.

h) Ensure proper PPEs for all working groups at all time.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 18 / 21

Date: 15/03/2016

12. LIFTING PLAN

The Lifting Plan describes the List of Equipments and Safety measures deployed for the

installation of GRP underground Pipe identified as 533__ESA103_

As outlined in this method statement, any activity shall commence only after the reception

of a valid work permit.

The concerned Work Supervisor shall coordinate with the Lifting team in arranging all

required tools and tackles for the work. He must ensure that the Crane Operator, Rigger

and Banks man are competent and are holding a valid training certificate. It shall be

confirmed in advance that the crane and all associated vehicles have safe and unimpeded

access and egress to and from site.

Communication between the crane operator and Lifting crew shall be via hand signals.

The following Equipments are purposed for the activity

o

o

Crane - 50 T Capacity, Model No. NK 500 E-V, Manufacturer - KATO

Trailer/ Truck

Once the approval for work is validated, Crane shall be positioned to Stages as shown in

Fig 5.

Fig 5.

The area shall be cordoned off with barrication tape and Proper Cautionary Signage. This

step shall be followed for positioning cranes in different stages based on the installation

Progress.

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Loading Chart

Rev. 0

Page 19 / 21

Date: 15/03/2016

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

Rev. 0

Page 20 / 21

Date: 15/03/2016

DOHA WEST SEWAGE TREATMENT WORKS EXT#5

Doc No: GE-SUEZ-MS-002

METHOD STATEMENT FOR THE INSTALLATION &

TIE-IN OF UG-GRP PIPELINE 533__ESA103_

13. ATTACHMENTS

Isometric Drawings

ITP

Risk Assessment

Particular Technical Specification for Couplings

Crane Catalogue KATO NK-500 EV

Rev. 0

Page 21 / 21

Date: 15/03/2016

Das könnte Ihnen auch gefallen

- MS & RA CombinedDokument49 SeitenMS & RA Combinedanishdev6100% (1)

- Concrete Works Method StatementDokument12 SeitenConcrete Works Method StatementRajarajan RajaNoch keine Bewertungen

- Mos GRPDokument53 SeitenMos GRPslxanto100% (3)

- Method Statement For Installation Anchor BoltsDokument7 SeitenMethod Statement For Installation Anchor BoltsSyed AtherNoch keine Bewertungen

- Method Statement Risk Assessment For Pump Installation 2 - Pipe (Fluid Conveyance) - PumpDokument1 SeiteMethod Statement Risk Assessment For Pump Installation 2 - Pipe (Fluid Conveyance) - PumptunlinooNoch keine Bewertungen

- MOS HDPE Lining General Rev.8 - 1-4-2019 DG PDFDokument13 SeitenMOS HDPE Lining General Rev.8 - 1-4-2019 DG PDFahmadNoch keine Bewertungen

- Excavation and Fill Method Statement SummaryDokument12 SeitenExcavation and Fill Method Statement Summary한상호Noch keine Bewertungen

- Amiantit. Field Installation ProcedureDokument37 SeitenAmiantit. Field Installation ProcedureABAID ULLAHNoch keine Bewertungen

- GRP ProcedureDokument42 SeitenGRP Proceduremansih45775% (4)

- Yanbu Ii Power & Water Project: Method Statement For U/G Piping Installation & Lamination of GRPDokument47 SeitenYanbu Ii Power & Water Project: Method Statement For U/G Piping Installation & Lamination of GRPric leonisoNoch keine Bewertungen

- SA04C2-00-MET-MS-00007 MS Excavation and BackfillingDokument47 SeitenSA04C2-00-MET-MS-00007 MS Excavation and BackfillingABAID ULLAHNoch keine Bewertungen

- PMG-03-010 HDPE Piping MethodologyDokument5 SeitenPMG-03-010 HDPE Piping MethodologyCara DelibogNoch keine Bewertungen

- Methodstatementhq Com GRP Pipe Installation and Lamination Method Statement HTML PDFDokument22 SeitenMethodstatementhq Com GRP Pipe Installation and Lamination Method Statement HTML PDFHaithem ChairiNoch keine Bewertungen

- Lanco Infratech Limited: Proposed Methodology of Construction 1. Collection of DrawingsDokument9 SeitenLanco Infratech Limited: Proposed Methodology of Construction 1. Collection of Drawingslinesh3Noch keine Bewertungen

- KAK-AYT-REC-CMS-0002 Installation of Duct Bank Rev.A01Dokument10 SeitenKAK-AYT-REC-CMS-0002 Installation of Duct Bank Rev.A01rickie7809Noch keine Bewertungen

- YT-PF-Z-16-00202 Rev B Method Statement of GRPDokument47 SeitenYT-PF-Z-16-00202 Rev B Method Statement of GRPsethu1091100% (9)

- Qcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyDokument18 SeitenQcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyRotsapNayrbNoch keine Bewertungen

- Method Statement For GRP Flange Assembly WorkDokument17 SeitenMethod Statement For GRP Flange Assembly WorkAhmed ImranNoch keine Bewertungen

- MIP17-MS-2012 Method Statement For Fabrication and Installation of PipingDokument23 SeitenMIP17-MS-2012 Method Statement For Fabrication and Installation of PipingAmeerHamzaWarraichNoch keine Bewertungen

- INSTALLING PIPESDokument17 SeitenINSTALLING PIPESAhmed Imran100% (2)

- Method of Statement For GRP WorkDokument17 SeitenMethod of Statement For GRP WorkAhmed IbrahimNoch keine Bewertungen

- 1.method Statement - INSTALLATION OF GRP WATER TANKSDokument11 Seiten1.method Statement - INSTALLATION OF GRP WATER TANKSsarmad spectrumNoch keine Bewertungen

- MS For HDPE Pipes Laying ActivityDokument7 SeitenMS For HDPE Pipes Laying ActivityJust Do LoveNoch keine Bewertungen

- 250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchDokument22 Seiten250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchAbdullah AbdullahNoch keine Bewertungen

- Method Statement Form - HDPE PN10,16 PipeDokument22 SeitenMethod Statement Form - HDPE PN10,16 PipeSmith SuwanNoch keine Bewertungen

- Epoxy Coating Method StatementDokument23 SeitenEpoxy Coating Method StatementbukhoriNoch keine Bewertungen

- Method Statement of Lowerin inDokument9 SeitenMethod Statement of Lowerin inahmed08839494Noch keine Bewertungen

- GRP Bonding ProcedureDokument19 SeitenGRP Bonding Proceduremahi1437100% (1)

- 1.sanitary Wastewater MOSDokument13 Seiten1.sanitary Wastewater MOSarshad iqbal0% (1)

- O252-PI-SP-0126 - C04 - Specification For PaintingDokument26 SeitenO252-PI-SP-0126 - C04 - Specification For PaintingBestun AhmedNoch keine Bewertungen

- Method of Statement For HDPE Pipe InstallationDokument2 SeitenMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- Method Statement For InstallationDokument5 SeitenMethod Statement For Installationsamsul maarifNoch keine Bewertungen

- PPR Method StatementDokument53 SeitenPPR Method StatementDiaa Gobran100% (1)

- Road Crossing SpecificationDokument12 SeitenRoad Crossing SpecificationPetrokens Family100% (1)

- MOS-RO Pressure Vessel InstallationDokument16 SeitenMOS-RO Pressure Vessel InstallationShams TabrezNoch keine Bewertungen

- 030-QCP For UG GRP PIPING PDFDokument12 Seiten030-QCP For UG GRP PIPING PDFKöksal Patan100% (1)

- Section 20 Horizontal Directional Drilling (HDD) /hdpe Pipe: 20.01 Scope: A. GeneralDokument6 SeitenSection 20 Horizontal Directional Drilling (HDD) /hdpe Pipe: 20.01 Scope: A. GeneralRon CylNoch keine Bewertungen

- Piping Work Execution Plan: Singa Gas Development ProjectDokument15 SeitenPiping Work Execution Plan: Singa Gas Development ProjectNajeeb A.M100% (1)

- Surface Preaparation and Painting SpecificiationDokument21 SeitenSurface Preaparation and Painting Specificiationvishnu300022Noch keine Bewertungen

- Method Statement For Leakage Testing of Gravity Sewer LineDokument3 SeitenMethod Statement For Leakage Testing of Gravity Sewer LineGerlie DimayugaNoch keine Bewertungen

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionDokument32 SeitenEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇Noch keine Bewertungen

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDokument14 SeitenPPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqNoch keine Bewertungen

- Re-instatement of Cofferdam ProcedureDokument16 SeitenRe-instatement of Cofferdam ProcedureBhargav BbvsNoch keine Bewertungen

- MS For GRP Pipe WorksDokument37 SeitenMS For GRP Pipe WorksWilliam C. PasamonteNoch keine Bewertungen

- MS For Deflection Test-Rev.03Dokument9 SeitenMS For Deflection Test-Rev.03anishdev6Noch keine Bewertungen

- Storm Drain Flushing Method StatementDokument12 SeitenStorm Drain Flushing Method Statementarshad iqbalNoch keine Bewertungen

- UPVC Drainage Pipes & Fittings - ACDokument101 SeitenUPVC Drainage Pipes & Fittings - ACsushant_moreyNoch keine Bewertungen

- PI - Template - 06A Water ITPDokument8 SeitenPI - Template - 06A Water ITPPageduesca RouelNoch keine Bewertungen

- Method of Statement For Excavation, Trenching, Backfilling & Compaction WorkDokument9 SeitenMethod of Statement For Excavation, Trenching, Backfilling & Compaction WorkAhmed Ibrahim100% (1)

- METHOD STATEMENT FOR System Commissinig and Testing - Rev 0Dokument5 SeitenMETHOD STATEMENT FOR System Commissinig and Testing - Rev 0Osama MZNoch keine Bewertungen

- 106 20170705 Method Statement For ExcavationDokument17 Seiten106 20170705 Method Statement For ExcavationEmad RakatNoch keine Bewertungen

- Asphalt Concrete PavingDokument16 SeitenAsphalt Concrete Pavingprobook450_ehsanNoch keine Bewertungen

- Method Statement - Painting - R01Dokument40 SeitenMethod Statement - Painting - R01Rawoofuddin Chand100% (1)

- M02 Polyethylene Coating Rev 2 NWCDokument30 SeitenM02 Polyethylene Coating Rev 2 NWCAlam MD SazidNoch keine Bewertungen

- 029-QCP For Roads & Paving PDFDokument22 Seiten029-QCP For Roads & Paving PDFKöksal PatanNoch keine Bewertungen

- Lean Concrete MOSDokument9 SeitenLean Concrete MOSebrahimlinda25619Noch keine Bewertungen

- Concrete Repair Method for TSE LineDokument14 SeitenConcrete Repair Method for TSE LineBleep NewsNoch keine Bewertungen

- Msra-For Block WorksDokument13 SeitenMsra-For Block WorksSyed AliNoch keine Bewertungen

- Bitumen Painting MOSDokument10 SeitenBitumen Painting MOSebrahimlinda25619Noch keine Bewertungen

- Design & Construction of the Contract Package ConceptVon EverandDesign & Construction of the Contract Package ConceptNoch keine Bewertungen

- ഡ്രാക്കുള ബ്രോം സ്റ്റോക്കർDokument146 Seitenഡ്രാക്കുള ബ്രോം സ്റ്റോക്കർanishdev6100% (1)

- Quality-I Is Safety-Ll - The Integration of Two Management Systems - Sasho Andonov (CRC, 2017)Dokument205 SeitenQuality-I Is Safety-Ll - The Integration of Two Management Systems - Sasho Andonov (CRC, 2017)Tita Eric100% (3)

- Gfe Doc028 Sub 003Dokument43 SeitenGfe Doc028 Sub 003anishdev6Noch keine Bewertungen

- Mobile Platform ModelDokument1 SeiteMobile Platform Modelanishdev6Noch keine Bewertungen

- Replacement of Flowmeter - Risk AssessmentDokument3 SeitenReplacement of Flowmeter - Risk Assessmentanishdev650% (4)

- Risk Assessment 589 Penstock RepairDokument4 SeitenRisk Assessment 589 Penstock Repairanishdev6100% (4)

- ഓവർക്കോട്ട് നിക്കൊളായ് ഗൊഗൊയ്Dokument32 Seitenഓവർക്കോട്ട് നിക്കൊളായ് ഗൊഗൊയ്anishdev6Noch keine Bewertungen

- Inspection of Defective Penstock at Doha West Sewage Treatment WorksDokument19 SeitenInspection of Defective Penstock at Doha West Sewage Treatment Worksanishdev6Noch keine Bewertungen

- Layflat OvalHoseDokument8 SeitenLayflat OvalHoseanishdev6Noch keine Bewertungen

- Flow Losses in Flexible Hose.Dokument186 SeitenFlow Losses in Flexible Hose.Anonymous K3FaYFlNoch keine Bewertungen

- Hose Reel ModelDokument1 SeiteHose Reel Modelanishdev6Noch keine Bewertungen

- AeratorDokument1 SeiteAeratoranishdev6Noch keine Bewertungen

- Hose Support r1Dokument1 SeiteHose Support r1anishdev6Noch keine Bewertungen

- OP410 PipingDokument1 SeiteOP410 Pipinganishdev6Noch keine Bewertungen

- Dewatering Skip R01Dokument1 SeiteDewatering Skip R01anishdev6Noch keine Bewertungen

- Bridge For Floating Platform-ModelDokument1 SeiteBridge For Floating Platform-Modelanishdev6Noch keine Bewertungen

- Reference Material Submittal - Part 6 PDFDokument21 SeitenReference Material Submittal - Part 6 PDFanishdev6Noch keine Bewertungen

- Reference Material Submittal - Part 4 PDFDokument21 SeitenReference Material Submittal - Part 4 PDFanishdev6100% (1)

- Soft Foot-What It Is and How To Minimize It - VibrAlignDokument4 SeitenSoft Foot-What It Is and How To Minimize It - VibrAlignanishdev6Noch keine Bewertungen

- Stiffness Report GRP PIPEDokument19 SeitenStiffness Report GRP PIPEanishdev6Noch keine Bewertungen

- Jafco Profile PDFDokument21 SeitenJafco Profile PDFanishdev6Noch keine Bewertungen

- BS L 117-1975 (2011)Dokument8 SeitenBS L 117-1975 (2011)anishdev6Noch keine Bewertungen

- Bip 0071-2014Dokument130 SeitenBip 0071-2014anishdev6Noch keine Bewertungen

- AeratorDokument1 SeiteAeratoranishdev6Noch keine Bewertungen

- Recovery Plan - Pipe Support FabricationDokument1 SeiteRecovery Plan - Pipe Support Fabricationanishdev6Noch keine Bewertungen

- Reference Material Submittal - Part 7 PDFDokument21 SeitenReference Material Submittal - Part 7 PDFanishdev6Noch keine Bewertungen

- Reference Material Submittal - Part 3 PDFDokument21 SeitenReference Material Submittal - Part 3 PDFanishdev6Noch keine Bewertungen

- Reference Material Submittal - Part 1 PDFDokument21 SeitenReference Material Submittal - Part 1 PDFanishdev6Noch keine Bewertungen

- Reference Material Submittal - Part 8Dokument6 SeitenReference Material Submittal - Part 8anishdev6Noch keine Bewertungen

- Reference Material Submittal - Part 5 PDFDokument21 SeitenReference Material Submittal - Part 5 PDFanishdev6Noch keine Bewertungen

- Business Procedure: Lifting OperationsDokument17 SeitenBusiness Procedure: Lifting OperationsPradeepkumarNoch keine Bewertungen

- Modified Structural Design PDFDokument373 SeitenModified Structural Design PDFDINESHNoch keine Bewertungen

- Opito Oco DiagramDokument21 SeitenOpito Oco DiagramwinhlaingooNoch keine Bewertungen

- Manitowoc Crane Group: 2159610000 (Sheet 2 of 2)Dokument73 SeitenManitowoc Crane Group: 2159610000 (Sheet 2 of 2)Luis Arturo Arenales MaytaNoch keine Bewertungen

- Fabrication SequenceDokument3 SeitenFabrication Sequencenaeimeslami100% (2)

- Rigging Types and ConceptsDokument24 SeitenRigging Types and ConceptsBoom DizzleNoch keine Bewertungen

- Association of Singapore Marine Industries - Signalmen & Riggers CourseDokument2 SeitenAssociation of Singapore Marine Industries - Signalmen & Riggers Coursealan angNoch keine Bewertungen

- Procedure For Making Tandem Crane Lifts in The USADokument4 SeitenProcedure For Making Tandem Crane Lifts in The USAparamarthasom1974100% (1)

- Rci BS 7262Dokument3 SeitenRci BS 7262Rizwan AhmedNoch keine Bewertungen

- TM 5 3825 270 10 Water Distributor Emm WDDokument484 SeitenTM 5 3825 270 10 Water Distributor Emm WDcascade1100% (1)

- Access Cage User Guide Issue 1Dokument11 SeitenAccess Cage User Guide Issue 1Franki Hari MNoch keine Bewertungen

- Timothy LAUDokument43 SeitenTimothy LAUEric S Y KwokNoch keine Bewertungen

- Introduction To Metal Buildings PDFDokument114 SeitenIntroduction To Metal Buildings PDFRonald KahoraNoch keine Bewertungen

- Grove RT600EDokument20 SeitenGrove RT600Ejohuquin50% (2)

- LEEA Oil & Gas Webinar Presentation - 280422Dokument27 SeitenLEEA Oil & Gas Webinar Presentation - 280422Mohammed Ahmed NasherNoch keine Bewertungen

- Navisworks 2011 Tip - Crane Boom AnimationDokument7 SeitenNavisworks 2011 Tip - Crane Boom AnimationmindwriterNoch keine Bewertungen

- DNV-OSS-308 Verification of Lifting Appliances For The Oil and Gass IndustryDokument46 SeitenDNV-OSS-308 Verification of Lifting Appliances For The Oil and Gass IndustryKukuh Statham100% (1)

- HLFT Cargoes GuidlinesDokument76 SeitenHLFT Cargoes GuidlinesСтепан БандераNoch keine Bewertungen

- Vanshikadogra A1904016046 ExperimentfileDokument162 SeitenVanshikadogra A1904016046 ExperimentfileVanshika Dogra100% (1)

- Technical Form 11 - Facilities & Equipment (Rev.1)Dokument44 SeitenTechnical Form 11 - Facilities & Equipment (Rev.1)HoanNoch keine Bewertungen

- Safe Work Method Statement (York Street EC) 2023.06.23Dokument8 SeitenSafe Work Method Statement (York Street EC) 2023.06.23manuel010478Noch keine Bewertungen

- Luffing Mechanism 4th LectureDokument3 SeitenLuffing Mechanism 4th LectureMataifa emmanuelNoch keine Bewertungen

- 10T Tadano Load ChartsDokument12 Seiten10T Tadano Load ChartsBqdcc6100% (2)

- Analysis& Optimizationof Jib Crane Under Influenceof Various Slewing Angles&load Position by Limit State MethodDokument9 SeitenAnalysis& Optimizationof Jib Crane Under Influenceof Various Slewing Angles&load Position by Limit State MethodEvodius RweyemamuNoch keine Bewertungen

- Well ServicingHR ManualDokument149 SeitenWell ServicingHR ManualMohammed teggar100% (3)

- DS350G Boom Control Service AC 120Dokument76 SeitenDS350G Boom Control Service AC 120wal_mzaNoch keine Bewertungen

- Introduction To Industrial Building (Autosaved) Final GIRLS 2Dokument106 SeitenIntroduction To Industrial Building (Autosaved) Final GIRLS 2Annu100% (1)

- Erection of Col - and Beam, StairDokument3 SeitenErection of Col - and Beam, StairChandru100% (1)

- Lifting and RiggingDokument33 SeitenLifting and RiggingLakshmanan amirthamNoch keine Bewertungen

- Concrete Construction Article PDF - Concrete Pumping PDFDokument3 SeitenConcrete Construction Article PDF - Concrete Pumping PDFMuhammed RafeekNoch keine Bewertungen