Beruflich Dokumente

Kultur Dokumente

BP OOG Securing

Hochgeladen von

enigma102Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BP OOG Securing

Hochgeladen von

enigma102Copyright:

Verfügbare Formate

Safety Security and Environment Management (SSE)

Group SSE Cargo Division

BEST PRACTICES

Original Version : 02/15/2011

Update :

OUT OF GAUGE CONTAINERS: CARGO SECURING

CMA CGM IS CURRENTLY EXPERIENCING SERIOUS DAMAGES PERTAINING FROM IMPROPER SECURING OF

RACK CONTAINERS.

CARGO UNITS ON FLAT

OVERVIEW

Lashing a cargo unit is intended to prevent it from moving longitudinally or laterally and to stop it tipping.

Lashing refers to the use of strapping, chains, steel wire, ropes and other securing materials which are fixed, on one hand, to the

package and, on the other hand, to the container.

TYPES OF LASHING

o

o

o

o

o

Top Over Lashing: Increase friction only.

Cross Lashing: Prevents sliding and tipping but needs securing points on the cargo unit.

Loop Lashing: Prevents transverse sliding and tipping but to be used by pair.

Spring Lashing: Prevents longitudinal sliding and tipping.

Round turn lashing: Ropes or belts wound around a piece of cargo. Not recommended as

the cargo can move freely in the loop.

BEST PRACTICES

The important factors that determine the effectiveness of the lashings are the quality of

the materials and the fixing points as well as the directions in which the lashings work.

o

The weight of the cargo unit does not exceed the container Max Payload and the

container floor load limit (see BP card Container weight limits).

Gravity center: As close to the centre of the container, to an height not exceeding the limit

specified by Shipping Lines instructions (CMA CGM SSE department do recommend not

to exceed the height of the container end walls).

Shipper provides the Shipping Agent with accurate description of cargo dimensions and

extent of oversize (For example, an overlength cargo can exceed the distance between

quay crane portal beams ).

Using dunnage, top over lashing you increase friction and you avoid steel to steel contact.

Check container lashing points MSL (7/8 # 49 kN # pull strength 5000 kg or 1 # 65kN).

Shipper/Packer assess the securing arrangements according the IMO Code of Safe

Practice for Cargo Stowage and Securing (CSS Code). See below BP card.

Ships officer, Surveyor (the NCB for the USA) or Terminal Operator to inspect the

container and the securing arrangement prior loading. The shipment is rejected if:

o

o

o

o

Container capabilities are exceeded.

Lengthwise, transverse or securing against tipping or sliding are insufficient or

inadequate.

For under deck stow, it overhangs too near the container corners (at least 30 cm from

outer end of the flat needed for cell guide clearance).

Corrective action cannot be performed on site

Cable wire eyes:

o U bolts on the free end, 4 clips (3 clips achieve only 75% of cable MSL), spaced with

6 rope diameter apart.

o Clips are tightened to a sufficient torque If free end of the wire cable is crushed to half

the thickness of the wire.

MORE INFORMATION

CMA CGM intranet Mira links:

Best Practices Cards : Cargo Securing Assessment Container Weight Limits

Cargo Stowage and Securing: NE P&I Safe Transport of Containers by sea: ICS-WSC

Web:

European Guidelines on Cargo Securing for Road Transport

Container Handbook

Industry Guidance for Shippers: Safe Transport of Containers by Sea

Safety Security and Environment Management (SSE)

Group SSE Cargo Division

BEST PRACTICES

Original Version : 02/15/2011

OUT OF GAUGE CONTAINERS: CARGO SECURING

DONts X

DOs V

Poor lengthwise securing

with wooden wedges

Lengthwise securing with

wooden bracing,

transverse securing with

loop lashing

Carterpillars are partly

outside the container

Axles have been raised

and the excavator stands

on wooden sleepers.

Inadequate lateral

securing

Lateral securing with

wooden wedges

supported on container

stanchions

The container is full,

wooden wedges are not

strength enough

Lengthwise securing with

wooden bracing, cross

lashing, top over lashing

and loop lashing through

forklift pockets

No roof bows, tyres not

lashed together and to

the container

Open Top: Roof bows in

place as much as possible

and tyres lashed together

and to the container

No lateral and no

longitudinal securing,

straps only increase

pressure onto containers

floorboard

The sailing boat is

secured in all the

directions

Wire cables are loose, no

transverse securing

Crosslashing with chains

Handling with slings and

elephant hooks/top lifting

lugs

Handling with Overheigh

frame

Update :

Das könnte Ihnen auch gefallen

- BP OOG Securing - 0Dokument2 SeitenBP OOG Securing - 0Kien Trung NguyenNoch keine Bewertungen

- Risk Watch Vol 08 2 PDFDokument4 SeitenRisk Watch Vol 08 2 PDFkahl983Noch keine Bewertungen

- Tow LinesDokument11 SeitenTow Linesbill baileyNoch keine Bewertungen

- Chapter 3 - Deck Handling EquipmentDokument24 SeitenChapter 3 - Deck Handling EquipmentKatie PearceNoch keine Bewertungen

- Steel Cargo BookletDokument13 SeitenSteel Cargo BookletВалентин И'в100% (1)

- Rules To Follow When Lifting and Moving Loads by CraneDokument13 SeitenRules To Follow When Lifting and Moving Loads by Cranehk331984Noch keine Bewertungen

- Deck CargoesDokument35 SeitenDeck CargoesInnocentvishwaNoch keine Bewertungen

- Unit6 DerrickDokument20 SeitenUnit6 DerrickPratham PandeyNoch keine Bewertungen

- Deck CargoDokument29 SeitenDeck CargoKaede xNoch keine Bewertungen

- CLO3Dokument9 SeitenCLO3saifNoch keine Bewertungen

- January 15 2013Dokument8 SeitenJanuary 15 2013enigma102Noch keine Bewertungen

- Crane and Wire InspectionsDokument2 SeitenCrane and Wire InspectionsnanduNoch keine Bewertungen

- The Basics of Cargo Lashing and Securing On ShipsDokument20 SeitenThe Basics of Cargo Lashing and Securing On ShipsShania Rae FukasanNoch keine Bewertungen

- AssignmentDokument10 SeitenAssignmentedroselloNoch keine Bewertungen

- Hapag-LLoyd Flatracks Lashing Guide Nov 2015Dokument3 SeitenHapag-LLoyd Flatracks Lashing Guide Nov 2015Allen Alex LalisNoch keine Bewertungen

- CARGO OPERATIONS Part10Dokument21 SeitenCARGO OPERATIONS Part10AliNoch keine Bewertungen

- Timber Deck CargoesDokument6 SeitenTimber Deck CargoesGauravRaiNoch keine Bewertungen

- Mooring and AnchoringDokument93 SeitenMooring and Anchoringbehzadbagheri100% (5)

- Safe Lashing / Securing of LoadsDokument38 SeitenSafe Lashing / Securing of LoadsinternettoNoch keine Bewertungen

- Emergency Towing ArrangementDokument9 SeitenEmergency Towing ArrangementManishNoch keine Bewertungen

- SPM (Single Point Mooring) or SBM OperationsDokument9 SeitenSPM (Single Point Mooring) or SBM OperationsGiorgi Kandelaki100% (2)

- WK 6 Anchors and Moors - LecturerDokument21 SeitenWK 6 Anchors and Moors - LecturerPushkar Lamba100% (1)

- MSF Safety Flash 13 09Dokument2 SeitenMSF Safety Flash 13 09Eric BergerNoch keine Bewertungen

- Practical Deck Skills Topic 1 - Mooring Lines SWL WLL BS-1Dokument48 SeitenPractical Deck Skills Topic 1 - Mooring Lines SWL WLL BS-1yxone acedo100% (1)

- Vicroads Guide To Restraining Concrete Panels & BeamsDokument18 SeitenVicroads Guide To Restraining Concrete Panels & BeamsStuart EdwardsNoch keine Bewertungen

- Lashing and Securing Deck CargoesDokument15 SeitenLashing and Securing Deck CargoesBay Bunker0% (1)

- AMastersGuidetoContainerSecuring2ndEdition 3Dokument50 SeitenAMastersGuidetoContainerSecuring2ndEdition 3tenedero100% (1)

- L4-Platform Installation (Compatibility Mode)Dokument37 SeitenL4-Platform Installation (Compatibility Mode)Laxmi Kant PrasadNoch keine Bewertungen

- Anchor Handling GuideDokument32 SeitenAnchor Handling GuideTg Tarro100% (3)

- 2.1.4.5 How To Maintenance of Cargo GearDokument26 Seiten2.1.4.5 How To Maintenance of Cargo Gear4pv6gkwvc9Noch keine Bewertungen

- Cargo Handling & Stability - I: Captain Nazim ErsenDokument52 SeitenCargo Handling & Stability - I: Captain Nazim ErsenberNoch keine Bewertungen

- Conventional General Cargo Handling Including Cargo GearDokument38 SeitenConventional General Cargo Handling Including Cargo GearDELA CRUZ MARK JOSHUA100% (1)

- Effective Mooring2222Dokument37 SeitenEffective Mooring2222Red SkiNoch keine Bewertungen

- Project Cargo Checklist Proof 8Dokument8 SeitenProject Cargo Checklist Proof 8sugiyantoNoch keine Bewertungen

- Anchor Handling EquipmentDokument33 SeitenAnchor Handling EquipmentJayvee Bongon Galos89% (9)

- Anchoring Incident Free Campaign GuidelinesDokument5 SeitenAnchoring Incident Free Campaign Guidelinesdeepakcool4ubuddyNoch keine Bewertungen

- Anchoring SystemDokument29 SeitenAnchoring Systemintan nNoch keine Bewertungen

- Mooring TopicsDokument3 SeitenMooring Topicsjoeven64Noch keine Bewertungen

- Stowage of Breakbulk CargoDokument4 SeitenStowage of Breakbulk Cargoericdeclercq100% (1)

- Dunnage WoodDokument108 SeitenDunnage WoodVitorloss100% (1)

- Safety Precautions While Attending To The 'Anchoring Station'Dokument12 SeitenSafety Precautions While Attending To The 'Anchoring Station'Dank100% (1)

- Structural Damage - HTMLDokument3 SeitenStructural Damage - HTMLstamatisNoch keine Bewertungen

- A Masters Guide To Container SecuringDokument38 SeitenA Masters Guide To Container SecuringTVP_contechNoch keine Bewertungen

- Container SecuringDokument38 SeitenContainer SecuringThaw Zin Tun50% (2)

- Hatch FromDokument2 SeitenHatch Fromtubi74tubi74Noch keine Bewertungen

- Hatch Cover Types and InspectionDokument21 SeitenHatch Cover Types and Inspectionafsal999100% (9)

- Cargo Lashing Pre-Sea - IRDokument67 SeitenCargo Lashing Pre-Sea - IRAnonymous hF1hhmInm3100% (2)

- Timber Deck CargoesDokument6 SeitenTimber Deck Cargoescptmehmetkaptan100% (2)

- Lashing Containers On DeckDokument10 SeitenLashing Containers On DeckReda HmrNoch keine Bewertungen

- Container Lashing WebDokument16 SeitenContainer Lashing WebSined SinedNoch keine Bewertungen

- Answers To CES Test About Hatch Cover Maintenance On Bulk CarrierDokument47 SeitenAnswers To CES Test About Hatch Cover Maintenance On Bulk CarrierMyo Minn Tun100% (2)

- Neil RobertsonDokument3 SeitenNeil Robertsonbogdanel_nbaNoch keine Bewertungen

- Belt ConveyorDokument38 SeitenBelt Conveyorhidai100% (2)

- SOP Lifting and RiggingDokument3 SeitenSOP Lifting and RiggingGoliBharggavNoch keine Bewertungen

- Operation Maintenance Manual PDFDokument28 SeitenOperation Maintenance Manual PDFbulentbulutNoch keine Bewertungen

- BSM CL Timber - 0Dokument14 SeitenBSM CL Timber - 0ShivaramHariharanNoch keine Bewertungen

- The Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsVon EverandThe Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsNoch keine Bewertungen

- Understanding Your Boats Systems and Choices.Von EverandUnderstanding Your Boats Systems and Choices.Bewertung: 3 von 5 Sternen3/5 (1)

- January 15 2013Dokument8 SeitenJanuary 15 2013enigma102Noch keine Bewertungen

- Survey and Examination of Ships' Lifting AppliancesDokument24 SeitenSurvey and Examination of Ships' Lifting Applianceshpss77100% (1)

- Issue11 MNZ Safety Bulletin June 2007Dokument2 SeitenIssue11 MNZ Safety Bulletin June 2007enigma102Noch keine Bewertungen

- Survey and Examination of Ships' Lifting AppliancesDokument24 SeitenSurvey and Examination of Ships' Lifting Applianceshpss77100% (1)

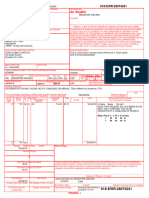

- Awb UsDokument2 SeitenAwb UsAgungAchmadNoch keine Bewertungen

- Shell Tank CleaningDokument63 SeitenShell Tank CleaningNegru P. Plantatie100% (4)

- Cosmetics Industry: Frequently Asked QuestionsDokument4 SeitenCosmetics Industry: Frequently Asked QuestionsShanel WisdomNoch keine Bewertungen

- How To Ship Your Item To Vestiaire Collective ?Dokument3 SeitenHow To Ship Your Item To Vestiaire Collective ?Ngoc KimNoch keine Bewertungen

- McGINNIS RelativeImportanceCost 1990Dokument9 SeitenMcGINNIS RelativeImportanceCost 1990taxohat466Noch keine Bewertungen

- Import and Export VocabularyDokument2 SeitenImport and Export VocabularyCarlos Alberto Rojas0% (1)

- IAPH-WPSP Port Economic Impact Barometer: 9 April 2020Dokument6 SeitenIAPH-WPSP Port Economic Impact Barometer: 9 April 2020Sacheel OrtizNoch keine Bewertungen

- Curriculum Vitae: January 1, 2020Dokument6 SeitenCurriculum Vitae: January 1, 2020Green Sustain EnergyNoch keine Bewertungen

- CDCS Specimen PaperDokument39 SeitenCDCS Specimen Papersreeks45671% (7)

- Original: Straight Bill of Lading - Short Form - Original - Not NegotiableDokument5 SeitenOriginal: Straight Bill of Lading - Short Form - Original - Not NegotiableLe Thi Anh HangNoch keine Bewertungen

- McFadden Lighting - 2014 CatalogDokument174 SeitenMcFadden Lighting - 2014 CatalogmcfaddenlightingNoch keine Bewertungen

- Inter-Orient Maritime Vs NLRCDokument5 SeitenInter-Orient Maritime Vs NLRCPaulineNoch keine Bewertungen

- Home Office and Branch AccountingDokument3 SeitenHome Office and Branch AccountingRamainne RonquilloNoch keine Bewertungen

- Blank COVER SHEETDokument7 SeitenBlank COVER SHEETpermada 15Noch keine Bewertungen

- DMS2400-1 Halal Supply Chain Management System - Part 1 - Transportation - General Requirements - PC - Malaysia Standard PDFDokument44 SeitenDMS2400-1 Halal Supply Chain Management System - Part 1 - Transportation - General Requirements - PC - Malaysia Standard PDFFaridatus Sa'idah100% (1)

- Flow Chart of Import CycleDokument6 SeitenFlow Chart of Import CycleAyyanar100% (1)

- Healthcare Supply Chain PlaybookDokument40 SeitenHealthcare Supply Chain PlaybookKen MoughaluNoch keine Bewertungen

- Annual Surveys/intermediate Surveys/docking Surveys Survey ChecklistDokument13 SeitenAnnual Surveys/intermediate Surveys/docking Surveys Survey Checklistthomaskurian777100% (1)

- S.M.Asghar (PVT) Limited Introduction For CMEC ComtransDokument152 SeitenS.M.Asghar (PVT) Limited Introduction For CMEC ComtransSajidNoch keine Bewertungen

- FBC BrochureDokument25 SeitenFBC BrochurePhilip KennyNoch keine Bewertungen

- BKI 2009 Vol 2 Section 1Dokument8 SeitenBKI 2009 Vol 2 Section 1Nida I. FarihahNoch keine Bewertungen

- Bill of LadingDokument2 SeitenBill of LadingHari TamaNoch keine Bewertungen

- National Exam Sample For Customs BrokingDokument18 SeitenNational Exam Sample For Customs BrokingDarren Guo100% (1)

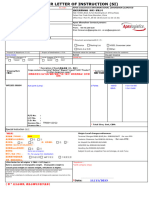

- Booking Form-Apex SZXDokument1 SeiteBooking Form-Apex SZXnganhokwanNoch keine Bewertungen

- Rules and List of Correspondents 2017/2018Dokument245 SeitenRules and List of Correspondents 2017/2018PKNoch keine Bewertungen

- Eurasia International TQMDokument11 SeitenEurasia International TQMJunaid Iqbal100% (1)

- From (Abhay Raj Singh Chauhan (Abhayraj - Nliu@gmail - Com) ) - ID (856) - ITLDokument15 SeitenFrom (Abhay Raj Singh Chauhan (Abhayraj - Nliu@gmail - Com) ) - ID (856) - ITLMukesh TomarNoch keine Bewertungen

- Complete Cargo Loss ControlDokument82 SeitenComplete Cargo Loss Controlmoe_htwe_1Noch keine Bewertungen

- CH 4 PDFDokument109 SeitenCH 4 PDFRefisa Jiru100% (2)

- 160000MT White Sugar Cane Tender On Edition 2Dokument31 Seiten160000MT White Sugar Cane Tender On Edition 2KoMoLoKo100% (1)