Beruflich Dokumente

Kultur Dokumente

Supervision Check List

Hochgeladen von

getCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Supervision Check List

Hochgeladen von

getCopyright:

Verfügbare Formate

Supervision and quality control check list

______________________________________

INTRODUCITON

This checklist for site supervisors is issued in order to ensure a uniform

system of supervision of building construction projects constructed in

the region of those projects budgeted by the government.

As a result to ensure the quality of construction, this checklist used as

guidelines for the supervisors and shows level of responsibilities,

liabilities and limitations of the supervisor are briefly mentioned in the

steps to the general terms.

Details of construction may specify in the drawings, technical

specifications and in the general and special conditions of the contract.

The duty of the site Engineers/Supervisors is to ensure that the

construction works are executed in accordance with the contract

requirement.

Therefore, in the application of this checklist the details specified in the

contract document always precede before the application and use of it.

There are also tables and forms in this checklist that help as records of

the incidences affecting the work and as references. In addition the

standard technical specification is used as reference on the preparation

of this checklist and shall always have precedence over the checklist.

Oromia Regional State Government BWUD

1

_______________________________________________________________________________________________________

____________________________________________________

OWUDB

Supervision and quality control check list

1. PREPARATIONS AND SITE INVESTIGATION

Check::1.1

The site visually if underground utilities cross it.

1.2

The site on maps showing the location of underground structures

and utilities to avoid breaking them during construction.

1.3

The site plan and layout of buildings and sewer system especially

concerning levels and soil condition. If changes are necessary

submit a written report to the designer.

1.4

The area to be cleared off and take measurements.

1.5

The trees and bushes within the foundation to be cut and rooted

up as given in the standard technical specification.

1.6

Permission is obtained from local authorities to cut down trees

outside the foundation areas.

1.7

Boarder lines are agreed with local municipality and corner

stones placed.

1.8

The connection points for water and electricity are agreed upon

with WSA and EEPCO local authorities.

1.9

All necessary temporary drains are constructed to keep the site

free of water.

2. 2. SETTING OUT

Check: 2.1

The setting out is done correctly with proper measuring tape and

accurate leveling instrument.

2.2

All measurements to confirm the accuracy and correct locations

of working areas are properly stated out.

2

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

2.3

The elevation reference point in accordance with the survey map

and confirm

2.4

All bottom of trenches and floor levels are according to the

elevations shown on the drawings.

3.

EXCAVATION & EARTHWORK

Check: 3.1

Check all topsoil is excavated separately.

3.2

Decide the place to pile up the suitable excavated material and

check it is 2 meters outside the building perimeter.

3.3

Decide the place for the cart away that is not necessary for back

filling or terracing.

3.4

For sites where blasting is proposed, the explosives are used the

quantities and manner recommended by the manufacturers.

Check a written consent obtained on each occasion the

contractor wished to use explosives.

3.5

All excavations are carried out to the lines, levels, widths and

depths shown on the drawings.

3.6

Any discrepancies in levels, dispositions etc. Are reported to the

engineer prior to proceeding with the works.

3.7

All necessary temporary drains and culverts and protections are

constructed to keep the site free of water.

3.8

Slopes to embankments, cuttings, shoulders, ditches etc. Are

trimmed to the dimensions and inclinations shown on drawings.

3.9

Cut for roads are carried out until a level of suitable material is

allowed.

3.10 Excavations are suitably trimmed and leveled before any

concrete or masonry work is placed.

3

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

3.11 In locations where the soil is subject to softening during

excavation of a bottom layer of soil is removed immediately

before the placing of concrete, in accordance with the standard

technical specification.

4.

FOUNDATION TRENCH AND PIT EXCAVATION

Check: 4.1

The foundation drawings to correspond with the conditions on the

site. If not prepare a written report and submit to the designer

immediately.

4.2

The foundation depth, width, line and levels to correspond to the

drawings.

4.3

The excavation or foundation is executed 25cm wider on each

side than the thickness of the foundation wall as given in the

standard technical specification.

4.4

The trench and pits to be clean from grass, bushes and pieces of

wood.

4.5

The trench and pits to be kept free of water by pumping or other

means

4.6

The foundation engineer has accepted the excavated foundation

depths by filling form No. 005 inspection certificate.

4.7

In the event of over excavation, without approval the area to be

filled with selected excavation or borrowed material or class 5

concrete in accordance with the standard technical specification.

4.8

The faces of excavation are retained with sheeting, timbering

strutting and shoring to protect workmen and prevent damage

where necessary.

5. FOUNDATION IN STONE MASONRY

Check: 5.1 The trench to be clean from grass, bushes and pieces of wood

4

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

5.2 The stone is of the type given on specifications

5.3 The stone to be hard, sound, free from cracks and decay (and not)

weathered.

5.4 The stone is freshly quarried from an approved quarry.

5.5 The stone not to be round surfaced.

5.6 The stone masonry execution is with specified mortar and with

well-filled joints.

5.7 The stone masonry during execution is kept free from solid and

other kind of dirt.

5.8 The length of stone does not exceed three times its height

5.9 The mix of lean concrete to correspond the specification

5.10The mix proportion of mortar is correct.

6. BACK FILLING

Check: 6.1 All internal back filling is done with approved material if possible

with material excavated on the site.

6.2 All external backfilling around foundation walls and behind

retaining wall shall be done with approved selected materials, if

possible with material excavated on the site which is capable of

being compacted and form a stable filling.

6.3 All organic materials, such as pieces of wood, roots, bushes and

black cotton soil are removed from all backfill material.

6.4 All ground trenches and places where backfilling shall be executed

are clean from grass, bushes and pieces of wood.

6.5 Where pipes and electrical cables are in connection with the

backfilling, the work shall be executed very carefully, so they do

not break or get damaged.

5

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

6.6 All backfilling to be in layers and compacted to 95% of maximum

dry density in accordance with the standard technical

specification.

6.7 Each layer to be well rammed and consolidated with the addition

of water as necessary to achieve the required compaction.

6.8 The maximum layer of fill for one time compaction does not

exceed 15cm the specified thickness in the standard technical

specification depending on the method of compaction.

6.9 Depression or voids that are created during trimming of slopes to

embankments, cutting shoulders, ditches etc., are filled with

suitable material and to approved compaction.

6.10Any material which after repeated compaction does not fulfill the

requirements is removed and replaced.

7.

DISPOSAL OF EXCAVATED MATERIAL

Check: Surplus excavated material is removed from the site to the dumping

ground as specified in contract agreement.

8. HARD CORE

Check: 8.1 Stone for hard core is sound and approved equality

8.2 All stones in the hard core are of approximately equal and

recommended size.

8.3 All hard core is well rammed and consolidated with the top surface

blinded with crushed aggregate of 20mm.

Thickness in

accordance with the standard technical specification.

8.4 The thickness of the hard core satisfies the specification or design.

8.5 The placing of stones to result in minimum voids.

6

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

9. CONCRETE

Check: 9.1 All ingredients cement, aggregates and water are of the type and

quality specified.

9.2 Cement is fresh, not older than six months and is delivered to the

site in the manufacturers original sealed bags.

9.3 Cement is stored in a dry and well-ventilated store, on a wooden

floor raised minimum 20cm. above the ground.

9.4 Cement is stocked separately.

9.5 The cement has markings showing the type and dates of

consignment pinned to it and check it is used in the order of its

arrival.

9.6 Cement more than six months old after production is tested to

satisfy the specified requirements.

9.7 Sand or fine aggregate to be clean river or pits sand of approved

quality and consist of hard, dense, durable uncoated rock

fragments.

9.8 Sand to be clear of impurities like dust, mica and organic matter.

Check course aggregates: 9.9 Rejected samples of aggregates are removed from the site within

24 hours.

9.10Course aggregate to be crushed basaltic stone or gravel of

approved quality

9.11Course aggregate to be hard, dense, durable, non-porous and

uncoated rock fragments.

7

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

9.12Coarse aggregate to be free from impurities like clay, soft thin

elongated or laminated pieces to be free from alkali and organic

matter.

9.13Gradation of (coarse aggregate) to comply with the standard

technical specification.

9.14Quality is approved at the quarry before it is delivered to the site.

9.15 Are stored on clear hard surface to prevent contamination by soil

etc.

9.16 Different grades are stocked independently.

Check Water: 9.17

Used for mixing concrete is clean and free from injurious

amounts of soil, acids, alkalis, and organic materials.

9.18Is not taken from sea or tidal rivers to be used for structural

concrete. If possible water shall be piped or otherwise stored in

an enclosed container free from contamination.

9.19 If there are any doubts about the water a sample shall be taken

for testing.

9.20If the temperature of the water exceeds 60c it is first mixed with

the aggregate before the cement is added.

9.21The concrete is mixed to a uniform color and consistency prior to

placing.

9.22 Hand mixing is not allowed, but if unavoidable it shall be used

only for class II concrete and shall under no circumstance be

allowed for concrete of class C-20 and above.

9.23Concrete is mixed in an approved mechanical batch mixer

machine; the mixer is thoroughly cleaned from burdened dried

concrete and other kind of dirt before use.

8

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

9.24Mixer, which has been cut of use for more than 20 minutes, is

thoroughly washed before any fresh concrete is mixed as

specified in the standard technical specification.

9.25The mixer drum is tight to avoid loss of mortar. The valves must

not leak mixing water.

9.26The specified mixing time is carefully adhere to but in no case

shall the mixing discontinue for less than 2 minutes after adding

water as specified in the standard technical specifications.

9.27The batch capacity. The contractor must not be allowed to exceed

the rated capacity of the mixer.

9.28 The materials enter the drum rapidly.

9.29

The whole of the mixed batch is removed before materials for

fresh batch enter the mixer.

9.30 Mixed concrete is not modified by the addition of extra water and

cement, in order to facilitate handling of any other purpose.

9.31 Before any casting starts at the site, test cubes of side dimension

15x15x15 or cylinders of diameter 15cm and length 30cm of

wood or steel are made ready.

9.32All reinforcement and formwork are properly placed prior to as

concreting and the mix approved and also check inspection

certificate No. 002 is filled and approved by the designer.

9.33For any one structure samples are made at the same time from

the same batch and the date clearly marked on each cube.

9.34Test cubes are made when directed but not less than one set of

nine cubes for each 100m3 of concrete placed, or if the rate of

placing is less than 100m3 then each 10 days or every floor for

multistory structures in accordance with the standard technical

specifications.

9.35Three cubes of each set are tested at 3 and 7 or 7 and 14 days

and the third at 28/45 days for OPC/PPC all in accordance with the

code of practice.

9

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

9.36Approved design mix is used

9.37Before any casting starts the consistency of fresh concrete must

be measured using the slump test, from the same batch for test

cubes.

9.38Concrete is so transported as rapidly as practicable and placed

such that contamination, segregation or loss of constituent

materials does not occur.

9.39All placing of concrete starts from one end and continue in the

same direction without break.

9.40Concrete is deposited as near as practicable and no concrete is

dropped from a height exceeding 2 meters as specified on the

standard technical specification.

9.41When chutting is used the inclination of the chutes shall be such

as to allow the concrete to flow without the use of water in excess

of the specified volume for mix and without segregation or loss of

the ingredients. Details of any proposed chutting plant must be

approved before the plant is delivered.

9.42The vibration is carefully done, and continues until a dense

homogeneous mass is produced and surface is fairly smooth.

9.43Concrete is not over vibrated so that the consistency of the

concrete is maintained and separation of materials is not caused.

9.44If construction joints are necessary they are approved by the

designer.

9.45When concrete casting continues on a construction joint, the joint

is clean from foreign matter.

9.46When concrete casting continues on a construction joint, the

surface of the joint is roughened and aggregate is exposed

without being damaged.

9.47The roughened surface of the construction joint is wetted with thin

layer of mortar prior to concreting.

10

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

9.48After casting is completed and for 7 days thereafter, that the

concrete is depth damp (cured) to minimize lose of moisture from

the concrete.

9.49Whenever testing of a material is required fill the appropriate

requisition form and for the evaluation of test result fill form No.

_____ and get the approval of consultant or designer when the

result is submitted.

9.50Inspection prior to concreting: Check The rigidity of the scaffolding and shuttering

The leak-tightness of joints between formwork elements

Conformity of the dimensions of the formwork with the

(drawings)

The cleanliness of the formwork.

The surface condition of the reinforcement

The position and size of reinforcement

The rigidity of the reinforcement securing systems, and the

quality of the joints between bars.

Cover to reinforcement is correct.

Class of concrete, mix design and water cement ratio.

Pre cast Elements: Check

9.51Pre-cast concrete is a cast under sheds and remain in the molds

for one days and further 7 days after removal from the molds.

Then removed from the sheds and stocked in the open for at

least 7 days to season.

9.52Random load testing is made on the pre-cast units and the

damaged ones immediately replaced.

9.53Pre-cast units are boosted and placed in proper position in such a

way as to avoid overstressing or no damaging the units or

causing damage to previously erected structure.

11

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

9.54If

any doubt about the quality of, aggregate, cement,

reinforcement, and water arises samples are sent for testing.

10. PRE-STRESSING CONCRETE

Check: 10.1

All pre-stressing components are stored in clean dry conditions.

10.2

All pre-stressing components are clean and free from loose rust

at the time of fixing in position and subsequent concreting.

All pre-stressing tendons are not welded within the length to be

tensioned.

All pre-stressing tendons (cables) are not twisted and individual

wires or strands are identifiable at each member.

10.3

10.4

10.5

All ducts and tendons are respectively sealed and protected

until the tendon is threaded through and the stressing

operations are commenced.

10.6

All anchor cones; blocks and plates are positioned and

maintained during concreting such that the center line of the

duct passes axially through the anchorage assembly.

10.7

All bearing surface of the anchorages are clean prior to

concreting and tensioning.

10.8

The tendons immediately and during stressing do not exceed

the strength specified.

10.9

Stressing is from both ends unless required or agreed by the

engineer.

10.10 The tendons are anchored only if the pre-stressing is applied to

the satisfaction of the engineer.

10.11 The jack pressure is released in such a way as to avoid shock to

the anchorage or tendons.

12

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

10.12 If the pull-in of the tendons at completion of anchoring is

greater than that agreed by the engineer, the lead shall be

released slowly and tensioning carried out afresh.

10.13 Sufficient cubes are taken and specified transfer strength is

attained.

10.14 The tendons are not cropped or cut prior to 3 days after

grouting.

10.15 Full records of all tensioning operations including the measured

extensions, pressure gauge of land all readings and the amount

of pull-in at each anchorage, are kept.

10.16 All dusts are thoroughly cleaned by compressed are or method

specified prior to grouting.

10.17 All anchorage is sealed before grouting.

10.18 The ducts are completely filled with grout.

10.19 The filled ducts are protected to the satisfaction of the engineer

that they are not subjected to shock or vibration for one day.

10.20 Full records of grouting including the date each ducts grouted is

kept.

10.21 The grout mixer produces a grout of colloidal and uniform

consistency.

10.22 The grout is mixed for a minimum of two minutes unless

otherwise specified.

10.23 No admixtures like chloride or nitrates are used. But another

admixtures may be used a written permission must be

submitted from the engineer and check it is applied strictly with

the manufactures instructions.

10.24 The grout consists only of ordinary port land cement and water

unless otherwise specified.

13

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

10.25 Pre-stressed members are lifted of supported only at the points

specified and handled and placed without impact.

10.26 Beams are prevented from moving laterally during the placing

of the in situ concrete.

10.27 The engineer informed in advance of the date of

commencement of manufacture and the dates when tensioning

of tendons, casting of members and transfer of stress will be

undertaken for the first time for each type of beam.

10.28 All Pre-stressed concrete construction comply the standard

technical specification.

11. FORM WORK

Check: 11.1 Formwork is so constructed that it can be stripped from the

hardened concrete easily without hammering or without such

shock or vibration in order to protect the concrete or reduce labor

cost.

11.2 The bracing of the formwork. The formwork must be strain

enough to carry the load until concrete is strong enough to carry

itself and burdened sufficiently.

11.3 The inside surface of form works shall, except for permanent form

works, or unless otherwise agreed by the engineer, are coated

with a release agent.

11.4 Release agents do not come into contract with the reinforcement

and anchorages, and should not be visible on the finished works.

14

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

11.5 Wooden form works for unexposed concrete surface, are

executed of sawed boards with sharp edges and of the same

thickness.

11.6 Wooden formworks for exposed concrete surface are generally of

tongued and grooved boards of the same thickness and free from

knots, holes, cracks and splits.

11.7 Formwork lumber shall be kept under shed and in varying

thickness and width and shall be constantly accreted and under

weight to prevent it from decay.

11.8 Before any concreting starts, the formwork has the right

dimensions and is level and straight.

11.9 Before any concreting starts, all irons are thoroughly cleaned out

and free from boles and dirt.

11.10 The top level of the formwork is at the same level as the top of

the finished concrete.

11.11 All formwork is removed without any damage to the concrete

during the striking.

11.12 After removal of the form work remedial treatment to surface of

the broadened concrete is carried out immediately without

delay and period of removal should be in accordance with the

structural technical specification.

11.13 Where intended to re-use formwork it is thoroughly cleaned and

made good to the satisfaction of the engineer.

11.14 Stripping of formwork not to be done until concrete is set i.e.,

should ring under a hammer blow. In no circumstances shall

formwork be struck until the concrete attains cube strength of

at least twice the stress to which it may be (supported) at the

time of striking.

11.15 All formwork construction and quality comply the standard

technical specification.

12.

STEEL REINFORCEMENT

15

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

Check: 12.1

Steel reinforcement is stored in clean condition. It should be

reasonably free from loose rust and other impurities such as

grease oil, or tar and other kind of dirt.

12.2

All reinforcement bars are of the specified quality and in

accordance with the standard technical specification.

12.3

Given in the design in cases where certificates for ultimate

tensile strength yield stress, elongation and cold bend tests are

not issued by the manufacture.

12.4

The dimension, length and shape of the reinforcement bars are

according to the drawings and specifications.

12.5

Bending of reinforcement bars is done with adequate bending

tools but heat is strictly not allowed for bending of reinforcement

bars.

12.6

All bars with cracks or splits at the bend are not used for

construction.

12.7

All mild steels have their ends booked, and the bending radius

meets the specification or drawings.

12.8

The reinforcement bars are placed in position according to the

drawings, and firmly bound together with pliable mild steel

wire, diameter 1.0/1.6mm in accordance with the standard

technical specification.

12.9

Before casting of concrete starts, that pre-cast concrete blocks

or spacers of metal chairs are prepared and all reinforcement

bars are placed on them.

12.10

These blocks or spacers do not turn over when concrete is

caste.

12.11

The thickness of concrete cover is according

requirements of the drawings and specifications.

to

the

16

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

12.12

And approve the placing of the reinforcement and formwork

condition before any concrete is caste.

12.13

The reinforcement in structures is not welded unless permitted

by the designer.

12.14

All reinforcement quality and work comply with the standard

technical specification.

13.

MORTAR

Check: 13.1

All mortar is if possible mixed in an approved mechanical batch

mixer. If not possible it could be mixed by hand until its color

and consistency are uniform

13.2

Lime for mortar in freshly burnt limestone. Lime shall be

delivered to the site in large lumps, slaked, run to putty and

mature for not less than two weeks before use.

13.3

If hydraulic lime is used, it is stored in the same manner as

described for cement.

13.4

Cement used in mortar is Portland cement and have quality as

described for concrete works.

13.5

Sand for mortar is of quality as described for concrete works.

13.6

Water is of quality described for concrete works.

13.7

Cement mortar consists of cement and sand as specified. If not

given in the specification, check that cement mortar consists of

one part cement to three parts of sand (1:3) measured by

volume.

13.8

Compo mortar consists of cement, lime and sand as specified.

If not specified, check that the compo mortar is composed of

one part cements two parts of lime and nine parts of sand

(1:2:9) measured by volume.

17

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

13.9

14.

Cement mortar is used within 30 minutes of the duration of

cement.

STONE MASONRY WALL

Check: 14.1

14.2

The stone is freshly quarried from an approved quarry.

The stone is of type given in specification.

14.3

The stone is hard, sound, free from crack and decay and not

weathered.

14.4

The stone masonry execution is with specified mortar and with

well finished joints.

14.5

All mortar for stone masonry bedding and jointing is 20mm

thick.

14.6

Stone masonry during execution is kept free from solid and

other kind of dirt.

14.7

Stonewalling is carried up with no portion more than 1000mm

above adjacent wall at any one time.

14.8

The wall is in plumb within 3m.

14.9

Sample panel of wall not less than 1m 2 in area including joint

pointing as specified is prepared and approved.

14.10 The type size and pattern of lying is as detailed on drawing.

14.11 All stone masonry walling comply with the standard technical

specification drawing.

15.

HOLLOW CONCRETE BLOCK WALL

Check: -

18

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

15.1

The hollow concrete blocks are free from laminations, cracks and

other defects that would impair the proper setting, strength or

permanence of the construction.

15.2

The hollow concrete blocks are well-compacted, properly cured

and uniform color and texture.

15.3

The hollow concrete blocks manufactured on the site have the

quality of cement and aggregate as described for concrete

works.

15.4

All blocks are manufactured in and approved special hollow

block machine and under shed.

15.5

Before any manufacturing in big scale starts on the site, test

samples are made, cured and sent for testing and test results

are approved by the designer.

15.6

For curing of hollow blocks, that they are kept moist, at least

for /seven/ (7) days after casting.

15.7

That the blocks are properly dried under shade for at least 14

days before they are used for construction.

15.8

Damaged or blocks with defects in the walls are replaced with

good ones at the expenses of the contractor.

15.9

Hollow blocks and the walls are kept free from soil and other

kind of dirt during execution.

15.10 All joints vertical and horizontal are well filled with the specified

mortar.

15.11

Walling is carried up with no portion more than 1000mm above

adjacent wall at any one time.

15.12

Partition walls are well bonded to elevations walls as

specified/shown in the drawings.

15.13

That the joints and the walls are in plum within 3m.

19

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

15.14 If the wall is designated as load bearing by the designer are

special care is taken for the execution of the work.

15.15

A minimum of 6 blocks per 1000 pcs. For site manufactured

blocks are tested.

15.16 The thickness of the joints does not exceed 15mm.

15.17 The comp mortar is used only above ground level.

15.18

The drawings carefully before any wall construction if any

reinforcement or expansion joints are prescribed.

15.19 The minimum compressive strength class A, Class B & Class C

hollow concrete blocks is as follows according to the standard

technical specification.

Class

Average of 6 Blocks

Individual

Blocks

38kg/cm2

32kg/cm2

/cm

Class A

42kg/cm2

Class B

35kg/cm2

Class C

20kg/cm2

18kg

15.20 All hollow concrete block walling comply with the standard

technical specification.

16.

WALLS WITH BRICKS

Check: 16.1

Bricks are not dumped on site but stocked to regular pattern and

are unloaded.

16.2

Bricks to be used for different situations are stocked separately

on a clean place.

20

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

16.3

Bricks are sacked in water for a minimum period of one day

before use.

16.4

Sample panels of not less than 1m 2 for each type of brick work

including joint pointing for painted surface are prepared.

16.5

All brick works are laid in good English bond even and true to

line plumb within 3m, level and all joints accurately kept.

16.6

All points vertical and horizontal are well filled with specified

mortar.

16.7

The thick nesses of the joints do not exceed 10mm.

16.8

All bricks of the same dimensions are only used in the same

wall.

16.9

Brick samples are taken at random from the load approved and

also manufactures test certificate submitted.

16.10 All brick walling

specification.

17.

comply

with

the

standard

technical

WOODEN WALLS

Check: 17.1

The quality and dimensions

specifications and drawings.

of

wood

are

according

to

17.2

All wood for wall are well seasoned, free from major knots,

worms, splits and bends.

17.3

All wood for construction are stored free from the ground and

well protected against rain.

17.4

All wood is specified are treated with anti termite liquid.

17.5

Dimension, placing and number of nails is according to drawings.

Unless indicated on the drawings no wood structure shall be

joined.

21

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

17.6

The wall is plumb and level.

18. PLASTER AND POINTING

Check: 18.1 The cement plaster and comp plaster quality mixture, thickness

and type of surface are According to the specification and

drawing.

18.2 That cement plaster is used where water effect is expected such

as in toilets, laundries and external walls while comp mortar is

used in all cases unless otherwise specified.

18.3 Before any plaster is applied, the wall is thoroughly cleaned from

dirt and dust.

18.4

All plaster is mixed in a mechanical mixer of approved type if

possible.

18.5

The wall, depending on the material is kept wet for some time

before any plaster is applied. Its not enough to sprinkle water

just before plastering.

18.6 All Pointing if prescribed is done with cement mortar.

18.7 All pointing is plumb and level.

18.8

All plastering and pointing comply with the standard technical

specification.

19.

STRUCTURAL STEEL WORK

Check: -

22

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

19.1 The shape and size of structural steel members comply with the

requirements of the specification and the manufactures

standards.

19.2 Size location, elevation and plumbing of anchor bolts.

19.3 Condition and capacity of welding equipment.

19.4 Conformity of electrodes to specifications and correct usage.

19.5

Production and assembly of steel is carried out in accordance

with the detail drawings and specifications.

19.6 Steel before and after fabrication is straight and free from twist

or other damages.

19.7

Cutting is done by shearing, cropping, sawing or machine flame

cutting.

19.8

Cutting by hand operated flame is approved.

19.9

Sheared or cropped edges are dressed to a neat machine work

and are prepared for welding finish.

19.10 Welded sections are inspected and approved prior to priming.

19.11 The max gap for butt welded section is less than 3mm.

19.12 Each weld is continuous, sound without interruption and free of

creators.

19.13 Slag is taken away immediately after welding and the weld

cleared with metal brush.

19.14 All ends of rectangular, square and circular sections (RHS, CHS)

are sealed by welding to prevent ingress of moisture.

19.15 The steel structure is accurately bolted to plates, channels or

angle cleats during erection.

19.16

Direct bolting to sides of steel hollow sections is not carried on.

23

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

19.17

Holes for fixing electrical fittings, partitions, etc are

correctly positioned.

19.18

All structural steel is protected from chemical solutions.

19.19

All structural steel ready to erect is prevented from water or

dirt accumulated against any of the surfaces.

19.20

All steel which will have concrete cast against them are

clean and free from loose rust at the time of concreting.

19.21

All structural steel work comply with the standard technical

specification

20.

PAVING AND TILING WORKS

Check: 20.1 Before any paving starts, the mass concrete is completely free

from standing water.

20.2 Cement tiles conform to the standards.

20.3 In the mass concrete surface immediately before the bedding is

laid, a slum of cement and water is brushed, unless specified.

20.4 The bedding is of cement mortar, one part cement to four parts

sand (1:4) and the slump is 2-5 cm and over.

20.5 The bedding thickness is 2 3 cm.

20.6 The tiles are gently knocked down into the bedding so the mortar

will be forced up in the joints approximately 5mm.

20.7 When the bedding is hard enough usually after one day the joints

which shall be 2 4 mm wide are filled with cement mortar.

20.8 Expansion joints are executed as indicated on drawings.

20.9 The complete floor under construction is protected for the first 14

days and kept wet and is protected against damage.

24

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

21.

WALL TILES

Check: 21.1 Wall tiles are soaked in clean water before laying and taken out

just before use.

21.2 Tiles are bedded with straight joints in cement and sand (1:3) and

grouted in white cement.

21.3 The work when completed is cleaned properly before approval.

21.4 Only tiles free from defects are used for the construction.

22.

PVC TILES

Check: 22.1 PVC tiles are laid on floor screeds with approved glue and in

accordance with manufacturers instruction.

22.2 Only tiles free from defects are used for the construction.

22.3

Damaged tiles are replaced with good ones at the contractors

expense.

23.

ROOFING AND CLADDING

Check: 23.1 Asbestos cement sheets are free from visible defects.

23.2 The surface of asbestos cement sheet is of uniform texture and

smooth on one side.

23.3

The edges of asbestos cement sheets are square, straight and

clean.

25

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

23.4

Asbestos cement sheet unless otherwise specified is 6mm thick

when used for roofing.

23.5

Asbestos cement accessories match the pitch of the sheets.

23.6

Galvanized plain and corrugated EGA sheets comply with the

manufacturers specification.

23.7

Steel hook bolts and nuts are zinc coated, the size and use of

which shall be as per manufacturers instruction.

23.8

Fixing of roofing and flashing is made fully water tight and

performed to the standard of best workmanship.

23.9

Chiseler diamond edges and cover bead nails made of mild

steel round wires as used to fix galvanized steel sheet roofing

and flashing to timber members.

23.10 Steel hook bolts and nuts are used to fix galvanized steel

sheets and asbestos roofing to steel and wooden truss

members and purlins.

23.11 Fixing holes are drilled in crown of corrugation of roofing sheets.

23.12 Holes are 5mm larger in diameter than bolts or screws.

23.13 Holes are 40mm far from edges of sheet.

23.14 Sheets are laid with laps not less than 150mm.

23.15 Side laps of sheets are minimum one and half corrugations.

23.16 Upper laps of sheets are constructed away from prevailing

wind.

23.17 No person other than workmen in roofing has access to roof

area.

23.18 All roofing work

specification.

complies

with

the

standard

technical

26

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

24.

GUTTERS AND DOWN PIPES

Check: 24.1 Gutters and down pipes are formed with the specified gauge

galvanized mild steel flat sheet from suitable lengths and to

shapes

shown on the drawings.

24.2 Gutter hangers and down pipe supports are 2.25mm anti-rust

painted flat sheet spaced at 1 meter center maximum unless

otherwise specified.

24.3 Joints of gutter are lapped 15cm and welded.

24.4 Joints of gutter after welding treated with three coats of zinc

paint.

25.

CARPENTRY AND JOINERY

Check: 25.1

Timber for carpentry and joinery is as specified and of best

quality.

25.2

Timber is reasonably straight grained and obtained from an

approved source.

25.3

And inspect the timber as it arrives, any timber not approved is

removed forthwith.

25.4

25.5

Timber is open stacked for as long as possible before use.

Timber and assembled wood work are protected from rain &

sum.

27

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

25.6

Timber and assembled wood work are stored in such a way as

to prevent attack by termites, insects or decayed fungi.

25.7

Timber ready for use is free from live borer, beetle or other

insect attack.

25.8

All measures to eradicate insect attach of timber are approved.

25.9

Timber is seasoned to moisture content of not more than 20%

for carpentry and 12% for joinery.

25.10 All timber surface exposed by cutting are treated with three

coats of approved preservations.

25.11 All pressure-impregnated timber is treated with preservative

chemicals at a pressure of not less than 10 atmospheres and in

accordance with the chemical manufacturers instruction.

25.12 Fixed joinery is completely protected from damage until the

completion of the construction.

25.13 Profile of sections is not modified from those shown on drawings

without approval.

25.14 Right type of door is fixed in the right place and that the doors

swing in accordance to the drawings.

25.15 Doorframes and window frames are fixed straight and in plumb.

25.16 Hinges, locks, latch, and handles are of approved type and

properly fixed.

25.17 Window panels are of the right thickness and properly fixed.

25.18 All carpentry and joinery to comply with the standard technical

specification.

26.

CEILING

Check: 28

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

26.1 Material and dimensions are according to the specifications and

the drawings.

26.2

Before any mounting, painting of parts in connection with the

ceiling such as steel guides and walls is completed.

26.3 The ceiling is cleaned and well fixed when the work is completed.

27.

PAINTING

27.1

The kind of paints is according to the specifications and

designers instructions.

27.2

The painting

instructions.

is

done

according

to

the

manufacturers

27.3

The paint is not diluted unless specified by the manufacturer.

27.4

All surfaces to be painted are clean from dust and dirt.

27.5

All surfaces to be painted are absolutely dry and free from

defects before painting.

27.6

All brushes and tins used for painting are clean and free from

old paint.

27.7

27.8

28.

The room is closed until the paint dries.

All electrical appliances iron and brass works are removed

before painting and properly re fixed after painting.

GLAZING

Check: 28.1 Frames are fixed straight and in plumb

28.2 The type and thickness of glass is according to the specifications

and drawings.

28.3 The application and properness of putty.

29

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

29.

WATER WELL

Check: 29.1 The water well is dug according to the specifications and

drawings, if possible dug during the dry season.

29.2 If septic tanks, soak away pits and dry latrines are situated

nearby and inform the designer to change the position of the

wall.

29.3 The water is tested and approved after the digging is completed.

29.4 The masonry work is not started before the test result is issued

and approved.

30.

WATER SUPPLY LINES

Check: 30.1 The dimensions and types, tubes, valves and water tower in

according to the specifications and drawings.

30.2 All valves, unless otherwise specified is buried in the ground to a

minimum depth of 30cm.

30.3 All valves are placed according to the drawings.

30.4

Inspect and approve the supply lines before any back filling

starts.

31. PLUMBING AND SANITARY INSTALLATIONS

Check: 31.1

Dimensions and types of pipes, tubes valves and sanitary ware

is according to the specification and drawings.

31.2

All pipes and tubes to be installed in the floor are placed in

position.

30

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

31.3

All joints firmly fixed before mass concrete is cast.

31.4

Pipes and tubes are placed in the hard-core with minimum 10cm

covering layer sand or in channels of floors as indicated on the

drawings.

31.5

All sanitary ware is properly fixed in the correct position.

31.6

All connection between sanitary ware and sewer system is done

with the prescribed siphon.

31.7

All exposed pipes and tubes are well cleaned and painted as

specified.

31.8

32.

All sanitary work complies

specification/drawings.

with

the

standard

technical

SEWER SYSTEM

Check: 32.1

32.2

Dimensions and types of pipes and inspection pits is according

to the specification and the drawings.

The excavation measurements of the sewer lines are according

to the drawings.

32.3

The excavation is done in straight lines on the manholes.

32.4

All trenches before pipes are laid.

32.5

Unless otherwise specified, the pipes are laid on sand bed with a

minimum thickness of 10cm and in an absolutely straight line

with and even slope of minimum 1:100 and covering soil layer is

minimum 50cm.

32.6

Level of overflow pipes between different chambers and inlet

and outlet pipes are according to the drawings.

32.7

All plastering in and out is with cement plaster with thickness

and mixture according to specifications and drawings.

31

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

32.8

All water proofing is done according to specifications and

drawings.

32.9

The joining of concrete to pies is always done with cement

mortar, the joint completely filled all around.

32.10 Joining of asbestos cement pipes is done according to the

manufacturers instruction.

32.11 Inspection pit is according to the drawing before backfilling.

32.12

All pipes connected to the inspection pit come approximately

on the same level and check channel formed in concrete at the

bottom of the pit.

32.13

Backfill soil is of good quality; free from stones and it is not top

soil.

32.14

Backfilling is in layers of minimum 20cm, if vibrating or roller

machine is used the thickness of the layer can be 40cm unless

otherwise specified.

32.15

Each layer of backfill is well rammed and consolidated with the

addition of water if necessary.

32.16

The correct position of the water and sewer systems and

prepare a sketch on the site plan to send to the designer for

preparing drawings showing their correct positions as built on

site.

32.17

Measure the correct length of all trenches, of all tubes and

pipes.

33.

SEPTIC TANK AND SOAK AWAY PIT

Check: 33.1

Dimension and type of septic tank and soak away pit is

according to the specifications and drawings.

32

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

33.2

The position of septic tank and soak away pit if situated nearby

water wells, and inform the designer for the change of the

positions.

33.3

Level of overflow pipes between different chambers and inlet

and outlet pipes are according to the drawings.

33.4

All plastering in and out, it with cement plaster with thickness

and mixture according to specifications and drawings.

33.5

All water proofing is done according to specifications and

drawings.

34.

ELECTRICAL INSTALLATIONS

Check: 34.1

EEPCO or the designated professional approves the electrical

installation.

34.2

Materials to be used for the installation strictly follow the

specifications and the drawings.

34.3

The electrical sub contractor has a valid certificate issued by

EEPCO before he starts his work and his foremen are competent.

34.4

The conduits are free from defects and cover the wires all the

ways.

34.5

All switches and outlets are properly fixed according to the

drawings.

34.6

The connections of wire are always done in junction boxes.

34.7

All external cables are placed with a minimum 10cm depth in

concrete cement pipes and 40cm depth in the ground, unless

otherwise specified.

34.8

The excavation is in a straight line between the inspection pits.

34.9

The inspection pits are constructed every 30m unless otherwise

specified.

33

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

34.10 All trenches should be checked before pipes are laid.

34.11 The pipes are laid on a minimum 10cm thick sand bed unless

otherwise specified.

34.12 The joining of cement pipes is done with cement mortar, the

joint completely filled around.

34.13

The joining of cement pipes is done according to the

manufacturers instructions.

34.14

The inspection pits, pipes and joints are executed before

backfilling.

34.15

The backfill soil is of good quality, free form stones and it is not

top

soil.

34.16

The backfilling is in layers of minimum 80cm if vibrating or

roller machine is used the thickness of the layer can be 40cm

unless otherwise specified.

34.17

Each layer of backfill is well rammed and consolidated with the

addition of water if necessary.

34.18

All underground cable joining are done in special water-tight

junction box approved by EEPCO or designated professional.

34.19

All junction boxes used are placed in the inspection pits.

34.20

Measure the correct length of all trenches and cables.

34.21

The correct position of external cables, pits and prepare a

sketch on the site plan to send to the designer for preparing

drawings showing their correct positions as built on site.

34.22

All electrical installation complies with the standard technical

specification.

35.

RETAINING WALLS

34

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

Check: 35.1

The trench to be free from loose soil, roots and pieces of wood

before construction.

35.2

The depth and width of trench to correspond with the drawing.

35.3

All stones are of good and approved quality.

35.4

All stones and the wall are kept free from soil and other kind of

dirt during execution.

35.5

No borrow pits are to be opened in the vicinity.

35.6

If expansion joints are executed as on the drawings.

35.7

The mix proportion of mortar.

35.8

All retaining wall construction complies with the standard

technical specification.

36.

SITE WORK

Check: 36.1 The clearing of buildings is up to 2 meters from elevation walls on

all sides, and check this limit is approved by the designer:

36.2 The clearing for roads, footpaths and parking areas is up to 1

meter from their boundaries and check this limit is approved by

the designer.

36.3 All roots are taken out within the building area, under roads

footpaths and parking lots transported away from the site.

36.4 The place for down trees and check they are within the building

site

36.5 All topsoil is excavated separately.

35

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

36.6 And decide the place to pile up the excavated top soil and check

it is 2 meters outside the building perimeter.

36.7 And decide the place for the cart away, which is not necessary for

backfilling or terracing.

36.8 All backfilling and terracing is done in layers not exceeding 20cm

and if vibrating or roller machine is used the thickness must be

40cm.

36.9

Each layer of backfilling terracing is well rammed and

consolidated.

36.10 Backfilling and terracing is not with top soil.

36.11 All site work complies with the standard technical specification.

37.

ROADS AND FOOT PATHS

Check: 37.1 Excavation for road footpaths is executed to bottom of hard-core.

37.2 Backfilling for roads and footpaths is done with non-expansive

selected material.

37.3 All backfilling is done in layers not exceeding 20cm and if

vibrating or roller machine is used the thickness must be 40cm.

37.4 Each layer of backfilling is well rammed and consolidated with

addition of water if necessary.

37.5

Before backfilling starts the ground is free from top soil, grass,

bushes, roots and pieces of wood.

37.6

Stone for hard-core of approved quality.

37.7

All stones in the hard-core are of approximately equal size.

37.8

The hardcore is well rammed, consolidated and the top

tightened with crushed stones or gravel.

36

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

37.9

The thickness of hard-core is not less than specified.

37.10 The hardcore as well as the top surface is executed with a

minimum slope of 1:100 towards the sides.

37.11 The top surface is executed with material on the specification or

drawings.

38.

DRAIN CHANNELS AND CULVERTS

Check: 38.1 Drain channels are according to the measurements on the

drawings:

38.2 Drain channels to have a minimum slope of 1:200, unless

otherwise specified.

38.3 Stone channels to be on a bed hard core or well compacted

gravel with joints and pointing in cement mortar (1:3).

38.4

Channels of half concrete pipes are on a well-compacted layer of

fine aggregate with a thickness not less than 10cm.

38.5

Half concrete pipes are laid in and joined with cement mortar

(1:3).

38.6

Stone channels and culverts are constructed according to the

drawings and specifications.

38.7

All pipes are laid so that each one is in contact with the bed

throughout the length of its barrel.

39.

FENCING AND GATE

Check: 39.1 The type of fence and gate are according to the specifications

and drawings.

37

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

39.2 The foundations of fence and gate are according to the

specifications and drawings.

40.

PREPARATION OF PAYMENT CERTIFICATE

40.1 Payment certificate should be prepared on official formats.

40.2 Payment certificates should be prepared in sufficient copies as

needed.

40.3 Payment certificates should be signed by: i. The supervisor,

ii. Consultant, if there is contract provision for such

supervision

iii. The contractor,

iv. The investor/client

40.4 The supervisor shall check payment against: 1.

2.

3.

4.

5.

6.

7.

8.

9.

Arithmetic error

Contract prices

Contract quantities

Contract time

Actual measurement sheets

Variation orders

supplementary agreements

Validity of performance bond

Progress reports

41. INFORMATION ON CONSTRUCTION PROCEDURES

41.1 Check a site book is kept for any construction work and the

following information is included:

Dates on which excavations, concreting, striping of formworks,

backfilling, site work have taken place.

Acceptance of materials and components

Result of test and measurements

Type of cement and aggregate

38

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

Inspection and measurement reports of the positioning of

reinforcement

Important instruction received

Description of any incidents

Construction Material properties

Hollow concrete blocks

Classification

Hollow concrete blocks shall be classified in to the following three

classes

1. Class A and B

are loaded bearing units and are suitable for

External walls pointed, rendered and plastered

The inner leaf of cavity walls or stone masonry

Internal walls or part ions.

2.

walls

Class C

none load bearing units suitable for none load bearing

and portions

Note: - six full size samples shall be taken from a lot of 4000 blocks or

fraction

there of for the compression test.

3. Dimensions.

The nominal dimensions of hollow blocks are indicated

below

Breadth

b (mm)

Height h

(mm)

Length L

(mm)

Face shell

d (mm)

100

200

400

20

Max. unit

weight

(kg/m3)

1200

150

200

400

25

1200

200

200

400

30

1200

39

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

250

200

400

35

1200

300

200

400

40

1200

Minimum compressive strength

The minimum compressive strength of HCB according to ESCD

Class

A

B

C

Average of 6 units

Mpa

Mpa

4.2

42

3.5

35

2.0

20

Individual unit

Mpa

Mpa

3.8

38

3.2

32

1.8

18

Concrete

Concrete is a composite material consisting essentially of a binding medium

with in which are embedded particles of a relatively inert filler materials.

In cement concrete the binder is cement and the filler material is aggregate

of graded size from sand to pieces of stone of varying diameter and shape.

Property of concrete

Property of fresh concrete

As soon as water is brought in contact with other ingredient of concrete,

freshly mixed concrete gradually under goes changes until it becomes hard.

In its plastic the most important properties are.

Workability

Consistency

Segregation

40

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

Bleeding

Workability

Fresh mixed concrete should be easy to be transported, placed. Consolidated

and finished without any segregation. The workability of concrete is affected

by water content, size of aggregate shape of aggregate grading of aggregate

etc.

Consistency

Consistency is closely related to workability. It is a term which describes the

ease with which fresh concrete flows. It is used to indicate degree of

wetness.

Measurement of workability

Among various methods of determining the workability of concrete the most

common method is slump test. It is performed by measuring the subsidence

of a pile of concrete formed in a mould in the shape of a frustum of a cone

with base diameter 20cm and top diameter 10cm and the height is 30cm. A

tamping rod of steel 16mm diameter and 0.60m long is used to compact the

concrete in the mould. The slump which is the subsidence of the concrete

cone after the mould is lifted up and carefully observed gives the following

three results

True slump

Note: -

shear slump

collapsed slump

Concrete with shear or collapse slump is not recommendable

41

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

The recommendable slumps for various works are indicated below

No

Type of construction

Slump in mm

Max

min

50

25

Heavy mass construction

Pavement

50

25

Un reinforced footing casinos and

75

25

substructure walls

75

25

Bridge deck

100

50

Reinforced foundation wall and footing

125

75

Reinforced beams, slabs and walls

125

75

Columns

Properties of hardened concrete

In the it's

are

1)

2)

3)

4)

5)

6)

hardened state the various properties which need consideration

Strength

Permeability

Durability

Elasticity

Shrinkage

Creep

Strength of concrete is the most important property as far structural design is

concerned. Indirectly it gives the idea of most of the other properties such as

water tightness durability, wear resistance etc.

Strength of concrete is measured either in compression strength or tensile

strength. The usual method of compressive strength determination employees

either cubes or cylinder specimen (height equal twice its diameter)

Note: - cylindrical compressive strength is 80% of cube strength

Tensile strength of concrete has low tensile strength, which ranges from 8% to

12 % of its compressive strength. An average value of 10% is generally

accepted.

42

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

Classes of concrete

Concrete is graded in terms of its characteristic compressive cube strength

attained at the age of 28 days in Mpa. For example C25 means characteristics

cube compressive strength attained at the age 28 days (25Mpa).

The permissible grades for concrete for the two classes of concrete work are

given below.

Class

I

II

Class I

registered

C5 C15

C5

C15

Permissible grades

C20 C25 C30 C40 C50 C60

C20

Concrete works carried out under the direction of supervisors

by the Ministry as associate engineer or above.

Class II Concrete works carried out under the direction of supervisors

registered

by the ministry as engineering aid

43

_______________________________________________________________________________________________________

_

OWUDB

Supervision and quality control check list

______________________________________

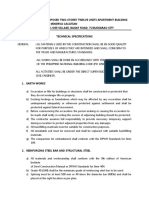

Table: - Standard mixes for ordinary structural concrete per 50kg bag of cement

(OPC. ordinary port land cement)

Concret

e

grade

C5

C 15

C 20

C 25

C 30

Nominal max. size of

aggregate(mm)

workability

limit of slump that

may be expected

(mm)

Total aggregate (kg)

Fine aggregate (c/c)

Vol.

finished

concrete(m3)

Total aggregate (kg)

Fine aggregate (c/c)

Vol.

finished

concrete(m3)

Total aggregate (kg)

Fine aggregate (c/c)

Vol. finished concrete

(m3)

Total aggregate (kg)

Fine aggregate (c/c)

Vol. finished concrete

(m3)

Total aggregate (kg)

Fine aggregate (c/c)

Vol. finished concrete

(m3)

40

20

14

10

Medium

30 to 60

High

60 to 120

Medium

20 to 50

High

50 to 100

Medium

10 to 30

High

30 to 60

Medium

10 to 25

High

25 to 50

640

30 - 45

0.312

550

30 - 45

0.275

540

35 - 50

0.277

480

36 - 50

0.252

370

30- 45

0.20

330

30- 45

0.183

320

35- 50

0.178

280

35- 50

0.16

305

30- 35

0.165

270

30- 40

0.155

280

30- 40

0.156

250

35- 45

0.143

255

35- 45

0.146

220

40- 50

0.13

240

40- 50

0.137

200

45- 55

0.121

265

30- 35

0.147

240

30- 40

0.137

240

30- 40

0.137

215

35- 45

0.127

220

35- 45

0.13

195

40- 50

0.118

210

40- 50

0.124

175

45- 44

0.11

235

30- 35

0.134

215

30- 40

0.127

210

30- 40

0.124

190

35- 45

0.115

195

35- 45

0.115

170

40- 50

0.106

180

40- 50

0.109

150

45- 55

0.097

44

___________________________________________________________________________________________________________________________________________________________

OWUDB

Das könnte Ihnen auch gefallen

- Check ListDokument43 SeitenCheck ListgetNoch keine Bewertungen

- Supervision Check ListDokument44 SeitenSupervision Check Listget100% (1)

- Timesaving MomentRedistribution IADokument23 SeitenTimesaving MomentRedistribution IAYel DGNoch keine Bewertungen

- Timesaving MomentRedistribution IADokument23 SeitenTimesaving MomentRedistribution IAYel DGNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- BRC Mesh A142 BRC Mesh A142: Foundation LayoutDokument1 SeiteBRC Mesh A142 BRC Mesh A142: Foundation LayoutMwesigwa DaniNoch keine Bewertungen

- Block USA - CatalogoDokument12 SeitenBlock USA - CatalogoSebastián Olmos BohórquezNoch keine Bewertungen

- SXRL Data SheetDokument5 SeitenSXRL Data SheetARYANoch keine Bewertungen

- Boq 1ST DraftDokument41 SeitenBoq 1ST DraftOdeniyi JeremiahNoch keine Bewertungen

- Precast ConcreteDokument69 SeitenPrecast Concretecapriciouskash70% (10)

- Hilti North American Product Technical Guide - Volume 1 - Edition 18Dokument204 SeitenHilti North American Product Technical Guide - Volume 1 - Edition 18brianchen06100% (1)

- 042000fl SandellDokument46 Seiten042000fl SandellabobeedoNoch keine Bewertungen

- MASONRY TESTING GUIDEDokument19 SeitenMASONRY TESTING GUIDEDona Mae BayoranNoch keine Bewertungen

- Technical SpecificationsDokument4 SeitenTechnical SpecificationsCrisantie Bande LampasNoch keine Bewertungen

- Bill No. 5 - Cluster B, D & FDokument204 SeitenBill No. 5 - Cluster B, D & FmimrusfanNoch keine Bewertungen

- Canal LiningDokument10 SeitenCanal Liningpune11Noch keine Bewertungen

- 233a2 Pil CC Systems BrochureDokument32 Seiten233a2 Pil CC Systems BrochurebhusanNoch keine Bewertungen

- Inside The Mason's Toolbox: Tools of The TradeDokument19 SeitenInside The Mason's Toolbox: Tools of The TradeTAHER AMMARNoch keine Bewertungen

- Baraya Hospital Calculation NoteDokument117 SeitenBaraya Hospital Calculation NoteMahMoudAbdEl-KaderNoch keine Bewertungen

- Sl. No. Description Unit Qty.: Cement Consumption CoefficientDokument19 SeitenSl. No. Description Unit Qty.: Cement Consumption CoefficientDeepak ChandolaNoch keine Bewertungen

- SASO 186 GS 1421: Hollow Blocks From Burnt Clay For WallsDokument8 SeitenSASO 186 GS 1421: Hollow Blocks From Burnt Clay For WallsomerNoch keine Bewertungen

- Detailed Cost EstimateDokument69 SeitenDetailed Cost EstimateJames PiñolNoch keine Bewertungen

- BS5628 Part 2, 2000, Reinforced and Prestressed MasonryDokument66 SeitenBS5628 Part 2, 2000, Reinforced and Prestressed MasonryDawit Solomon100% (4)

- RF Buildings Sor 2009-10-CivilDokument93 SeitenRF Buildings Sor 2009-10-CivilseshukvsNoch keine Bewertungen

- Load Assumptions: Ground Floor LevelDokument4 SeitenLoad Assumptions: Ground Floor Levelkiritoo kirigayaaNoch keine Bewertungen

- Material RequirementDokument37 SeitenMaterial RequirementHarish ApNoch keine Bewertungen

- A Cavity Wall Anchoring Solution To Maintain Air Barrier IntegrityDokument4 SeitenA Cavity Wall Anchoring Solution To Maintain Air Barrier IntegrityRubal ShawNoch keine Bewertungen

- China Harbour Engineering Co.L.L.C. Concrete Blinding Works Check ListDokument1 SeiteChina Harbour Engineering Co.L.L.C. Concrete Blinding Works Check ListYash SharmaNoch keine Bewertungen

- General FormulaDokument26 SeitenGeneral FormulaHabtamu HaileNoch keine Bewertungen

- Low Cost Housing Report 3 GateDokument71 SeitenLow Cost Housing Report 3 GateS.K. Recruiting100% (1)

- Laying Concrete Hollow Blocks For StructureDokument84 SeitenLaying Concrete Hollow Blocks For StructureRobinson Concordia100% (1)