Beruflich Dokumente

Kultur Dokumente

Torsion in Structural Design

Hochgeladen von

jakeer7Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Torsion in Structural Design

Hochgeladen von

jakeer7Copyright:

Verfügbare Formate

Torsion in Structural Design

1. Introduction

1.1. Problems in Torsion

The role of torsion in structural design is subtle, and

complex. Some torsional phenomena include

(a) Twist of beams under loads not passing through the

shear center

(b) Torsion of shafts

(c) Torsional buckling of columns

(d) Lateral torsional buckling of beams

Two main types of situation involve consideration of

torsion in design

(1) Member's main function is the transmission of a

primary torque, or a primary torque combined with

bending or axial load (Cases (a) and (b) above.)

(2) Members in which torsion is a secondary

undesirable side effect tending to cause excessive

deformation or premature failure. (Cases (c) and

(d) above.)

Torsion in Structural Design - Notes

11/30/01

1.2. Development of Torsional analysis- A few key

contributors

1853 - French engineer Adhemar Jean Barre de

Saint-Venant presented the classical torsion theory

to the French Academy of Science

1899 - A. Michell and L. Prandtl presented results

on flexural-torsional buckling

1905 - S. P. Timoshenko presented a paper on the

effects of warping torsion in I beams

1909 - C. Bach noted the existence of warping

stresses not predicted by classical torsion theory

when the shear center and centroid do not coincide.

1929 - H. Wagner began to develop a general

theory of flexural torsional buckling

V. Z. Vlasov (1906-1958) developed the theory of

general bending and twisting of thin walled beams

1944 - von Karman and Christensen developed a

theory for closed sections (approximate theory)

1954 - Benscoter developed a more accurate

theory for closed sections.

Numerous other contributors, these are just a few

highlights.

Torsion in Structural Design - Notes

11/30/01

2. Uniform Torsion of Prismatic Sections

Consider a prismatic shaft under constant twisting moment

along its length.

Classical theory due to St Venant. Assume

Cross-sections do not distort in plane during twisting, so

every point in the section rotates (in plane) through

angle ( x ) about the center of twist.

Out of plane warping is not constrained

Out of plane warping does not vary along the bar

The resulting displacement field is

u=

d

( y , z )

dx

d

dx

d

w = y( x ) = yx

dx

v = z( x ) = zx

Torsion in Structural Design - Notes

11/30/01

In plane displacements v and w are seen from the figure

below

Torsion in Structural Design - Notes

11/30/01

Out of plane distortion (warping) of the section is assumed

to vary with the rate of twist

d( x )

=constant ( x) = x

dx

and to be a function of the position (y,z) on the crosssection only. Several models may be constructed

Warping function model.

Conjugate Harmonic function model

St Venant's stress function model

Torsion in Structural Design - Notes

11/30/01

Warping Function Model

Substituting the displ. fields into the diff. eq. of equilibrium

from elasticity, we obtain

2 2

+ 2 = 2 = 0

2

y

z

(Laplace's equation)

with b.c.

= zany yanz

n

where n is the normal direction to the boundary, and

( any , anz ) are the components of the unit normal vector n on

the boundary.

It can be shown that the St Venant torsional stiffness of

the section is given by

J = y 2 + z 2 + y

A

z dA

y

z

and that the angle of twist is related to the torque by

T=

JG

d

or T = JG

L

dx

a result that reduces to the usual polar moment of inertia

when the section becomes circular, and the warping

function vanishes.

Problem: The eqn. is hard to solve with the b.c given.

Torsion in Structural Design - Notes

11/30/01

St Venant's Stress Function Model

Assume that the non-zero stresses xy , xz are related to a

stress function ( y , z ) by

xy =

xz =

The function ( y , z ) automatically satisfies equilibrium. In

order for the resulting displacements to be compatible (i.e.

satisfy continuity) the d.e.

2 2

d

+

=

2

G

= 2G

y 2 y 2

dx

be satisfied, where G=the shear modulus.

The boundary conditions for this model are

( x, y ) = constant on

where is the boundary of the section. In many cases, it is

convenient to simply take =0 on the boundary.

Given the stress function, it can be shown that

J = ( y , z )dydz

A

over the section.

Torsion in Structural Design - Notes

11/30/01

This d.e. is somewhat easier to solve because of the

simpler b.c. We are particularly interested in rectangular

sections. Consider such a section, of dimension 2 x 2,

as shown.

It can be shown (using a Levy type solution) that, for this

section

32G2 1

cosh(nz / 2) ny

( n 1) / 2

=

(

1

)

1

cos

3

3

n =1, 3, 5,... n

cosh(n / 2) 2

The corresponding stresses are

16G2 1

cosh(nz / 2) ny

( n 1) / 2

xz =

(

1

)

1

sin

2

2

n =1,3,5,... n

cosh(

/

2

)

2

16G2 1

sinh( nz / 2) ny

( n 1) / 2

xy =

(

1

)

cos

2

2

n =1,3,5,... n

cosh(

/

2

)

2

Torsion in Structural Design - Notes

11/30/01

is shown below for two sections

Assume overall dimensions b=2, t=2. Assume that b>t.

In general, it is useful to write

max = ktG

d

dx

J = k1t 3b

Then, since max T , we may write

max =

T

k2t 2b

9

Torsion in Structural Design - Notes

11/30/01

Values of the coefficients are tabulated below for different

aspect ratios

Table 1 Coefficients for Torsion of a Rectangular

Section

b/t

1.0

1.2

1.5

2.0

2.5

3

4

5

10

k

0.675

0.759

0.848

0.930

0.968

0.985

0.997

0.999

1.000

1.000

k1

0.1406

0.166

0.196

0.229

0.249

0.263

0.281

0.291

0.312

0.333

k2

0.208

0.219

0.231

0.246

0.258

0.267

0.282

0.291

0.312

0.333

It is seen that for the thin section, the response away from

the ends is almost independent of y. Hence, a simplified

model takes the form

d 2

= 2G subject to ( ) = 0

dz 2

10

Torsion in Structural Design - Notes

11/30/01

1.2

1

0.8

k

k1

k2

0.6

0.4

0.2

0

1 1.2 1.5 2 2.5 3

10

This leads to the simple solution

z2

( z ) = G 1 2 with resulting shear stress

2

xy = 2G( z / )

Hence, at z=t/2,

max = Gt = Gt

d

dx

Integrating this approximate function over the area,

1

J = bt 3

3

11

Torsion in Structural Design - Notes

11/30/01

consistent with the limit of the 2-D solution as the width to

thickness ratio approaches . The shear stresses in a

narrow rectangular beam are as shown below

Thin-walled open section beams

Some thin walled open sections: angles, channels, W and

S sections, T sections, etc.

Key result 1. The section torsional stiffness J is

approximately equal to the sum of the J's for the

constituent thin walled plates. Thus,

1 n

3

J = bi ti

3 i =1

Key result 2. The maximum shear stress is estimated as

max =

Ttmax i

J

except that larger stresses may occur at the corners .

Key result 3. The shear flow around the section, caused

by St Venant torsion, is as shown below.

12

Torsion in Structural Design - Notes

11/30/01

That is, the stresses vary linearly through the thickness on

any of the constituent plates, achieving a maximum on

each edge.

13

Torsion in Structural Design - Notes

11/30/01

3. Shear Stresses due to bending - thin walled open

sections

Provides important background needed for analysis of

torsion

Three items are needed

shear stresses and shear flow concept

shear center

sectorial moments

These items can be obtained from a generalization of the

analysis studied in undergraduate Mechanics of Materials.

We summarize the results of the analysis below.

Normal Stresses and Resultants

From generalized analysis of beams,

xx =

I yy M z I yz M y

I yy I zz I yz

where

14

I zz M y I yz M z

I yy I zz I yz

Torsion in Structural Design - Notes

I yy = z 2 dA

A

11/30/01

I zz = y 2 dA = the moments of inertia.

A

I yz = yz dA = product of inertia

A

From equilibrium of the slice of the section cut above,

q = t =

I yyQz ( s ) I yzQ y ( s )

I yy I zz I yz

Vy +

where

15

I zzQ y ( s ) I yzQz ( s )

I yy I zz I yz

Vz

Torsion in Structural Design - Notes

Qy =

11/30/01

zdA = ztds ,

A*( s )

Qz =

ydA = ytds

A*( s )

q is the shear flow on the section. If the shear resultants

act through the shear center, there is no twist.

Summing moments about the centroid, it can be shown

that the coordinates of the shear center are

e y = 2

ez = 2

I zz I y I yz I z

I yy I zz I yz

I yy I z I yz I y

I yy I zz I yz

In the above,

S

I y

1

= Q y ( s ) rds = Q y ( s )d( s )

20

0

I z

1

= Qz ( s ) rds = Qz ( s )d( s )

20

0

are the sectorial products of inertia of the section, and

r ( s )ds = 2d( s ) define the sectorial area (the area shaded

in the figure above.)

r(s) is the perpendicular distance from the origin to the

force q ds needed in calculating moments.

16

Torsion in Structural Design - Notes

11/30/01

4. Bending and torsion of open sections

For combined bending and torsion, a number of additional

sectorial area properties are needed for the section.

Let point A undergo

displacements v, w, and rotation .

A different point s , located at

coordinates (y,z) displaces by

v S = v ( z a z )

ws = w + ( y a y )

This can be resolved into a

normal, and a tangential

displacement component. The

tangential component of

displacement is

=v

dy

dz

+ w + r

ds

ds

The shear strain in the tangential plane is given by

xs =

u

+

0

s x

(Wagner's assumption)

From which the out of plane displacement is approximately

u = y(s)

dv

dw

d

z( s)

2( s ) + u0 ( x )

dx

dx

dx

In the above eqn.

17

Torsion in Structural Design - Notes

11/30/01

2( s ) = rds = 2 d( s )

is the sectorial area at point s. The resulting normal stress

is then

d 2w

d 2 du0

u

d 2v

= E ( y 2 z 2 2 2 +

)

xx = E

dx

dx

dx

x

dx

Integrating the normal stress over the area leads to the

axial and bending resultants.

These may be written as

d 2

du0

ES 2

N x = EA

dx

dx

d 2w

d 2

d 2v

M y = EI yz 2 EI yy 2 + 2 EI y 2

dx

dx

dx

d 2v

d 2w

d 2

M z = EI zz 2 EI yz 2 + 2 EI z 2

dx

dx

dx

In the above, the first sectorial moment

S = 2( s )dA

A

has been used. The sectorial products of inertia I y , I z

were defined in connection with the shear center.

Solving for the displacements,

18

Torsion in Structural Design - Notes

11/30/01

du0 N x S d 2

=

+

dx AE A dx 2

M z I yy M y I yz

I z I yy I y I yz d 2

d 2v

=

+2

2

2

dx 2

E ( I yy I zz I yz )

I yy I zz I yz dx 2

M y I zz M z I yz

I y I zz I z I yz d 2

d 2w

=

2 +2

2

dx 2

E ( I yy I zz I yz )

I yy I zz I yz dx 2

The coefficients multiplying " are the distances from A to

the shear center, so if point A is taken at the shear center,

these terms disappear, and the equations for v and w

reduce to

M z I yy M y I yz

d 2v

=

2

dx 2

E ( I yy I zz I yz )

M y I zz M z I yz

d 2w

=

2

dx 2

E ( I yy I zz I yz )

The equation for u0 " can be written in alternative form as

du0 N x

d 2

=

+ 20 2

dx AE

dx

where 0 = the sectorial area between the outside edge of

the section and the sectorial centroid, a point for which S

vanishes.If the s origin were taken at a sectorial centroid,

instead of at an outside edge, then this term would

disappear.

19

Torsion in Structural Design - Notes

11/30/01

Shear Stresses and Resultants

For a section under bending and twisting, the total shear

stress at any point is

xs = ( xs ) SV +

q

t

where

( xs ) SV = St Venant torsion stresses

q

= shear stresses caused by shear flow on the

t

section.

Integrating the twisting moments caused by the shearing

stresses,

T = GJ

d

+ T

dx

where T is the torque caused by constrained warping

induced shear flow. It is sometimes convenient to express

this in terms of applied torque per unit length t ( x ) . Here,

d 2 dT

dT

= GJ 2

t( x) =

dx

dx

dx

If the free edge is taken as the origin of the s coordinate,

the shear flow is given by

s

q( s ) = xx dA

dx

0

20

Torsion in Structural Design - Notes

11/30/01

Hence,

I Q I yzQ y

I zzQ y I yzQz Q

q( s ) = yy z

V

+

Vz V

y

2

2

I I I

C

I yy I zz I yz

yz

yy zz

where

W = 2 xx ( 0 )dA = the bimoment

A

V =

d

d

W = 2 xx ( 0 )dA

dx

dx A

s

Q = 2( 0 )dA =the first sectorial moment

0

C = 4( 0 ) 2 dA =the warping constant

A

Integrating q over the section, and recognizing that the

bending related shear flow vanishes if the load passes

through the shear center (which we may always impose)

we obtain, after some manipulation

d 3

T = ECw 3

dx

from which the equation for twist of a thin-walled section

d 4

d 2

ECw 4 GJ 2 = t ( x )

dx

dx

is obtained.

Example Consider an I beam, simply supported at each

end, free to warp at the ends, loaded by a twisting moment

in the middle.

21

Torsion in Structural Design - Notes

11/30/01

The conditions at the left and right end are similar to those

at the end of a simply supported beam in bending. Hence

(0) = 0

( L) = 0

" (0) = 0

" ( L) = 0

Rather than use the fourth order differential equation which

has discontinuous load at midspan, use the third order

differential equations

EC' ' 'GJ' = T / 2

0 x L/2

EC' ' 'GJ' = T / 2

L/2 < x l

The homogeneous eqn.

EC' ' 'GJ' = 0

has the solution

22

Torsion in Structural Design - Notes

11/30/01

h ( x ) = C0 + C1 sinh(x ) + C2 cosh(x )

GJ

.

Since the r.h.s. of the nonEC

homogeneous equations are constant, and the lowest

order derivative of in the o.d.e. is one, assume a

particular solution

where =

p = x

Substituting into the o.d.e.'s,

GJ = T / 2 = T / 2GJ 0 x L / 2

GJ = T / 2 = T / 2GJ L / 2 < x L

Hence, the general solution is given by

= C0 + C1 sinh(x ) + C2 cosh(x ) + Tx / 2GJ

0 x L/2

= C0 + C1 sinh(x ) + C2 cosh(x ) Tx / 2GJ

L/2 < x L

The two solutions must be identical at midspan, and by

symmetry, ' ( L / 2) = 0 .

Consider the left half of the beam first. For this portion of

the beam, the b.c. at the origin are

(0) = 0 C0 + C2 = 0

" (0) = 0 2C2 = 0

23

Torsion in Structural Design - Notes

11/30/01

Hence, C0 = C2 = 0 , and the solution reduces to

= C1 sinh(x ) + Tx / 2GJ

Then, the symmetry condition at midspan

' ( L / 2) = 0 = C1 cosh(L / 2) + T / 2GJ

yields C1 =

1

T

.

2GJ cosh(L / 2)

Hence, for the left half of the beam,

T

sinh(x )

2 JG

cosh(L / 2)

For the right hand side of the beam, we may place the

origin at the right end, running to the left.

Then, it can be shown that the resulting solution (after

converting to the original coordinate system) is

T

sinh( ( L x ))

(

L

x

)

2 JG

cosh(L / 2)

Next, consider the relative magnitudes of the two

components of torsion over the span. We have, for the left

half of the span,

TSV = GJ' =

T

cosh(x )

1

2 cosh(L / 2)

24

Torsion in Structural Design - Notes

TW = EC' ' ' =

11/30/01

T cosh(x )

2 cosh(L / 2)

For a typical W section, the values range from roughly

.04 for a heavy column section to less than .01 for some

very slender beams.

Contributions of the warping torsion are shown below for a

20' long beam.

When combined bending and twist of a beam occurs, it is

necessary to include all three components of shear flow

Shear Flow due to bending

St Venant Torsion

Warping Torsion

to evaluate the total shear stresses.

25

Torsion in Structural Design - Notes

11/30/01

The shear flow from bending is calculated in the usual way,

as are the St Venant torsion shear stresses. The shear

flow from torsion may be calculated as

q =

Q

V

C

However, it is more direct to calculate the shear flow from

the fact that

d 2

d 3

W = EC 2 V = EC 3

dx

dx

d 3

So, q = EQ 3 provides the easiest calculation, given .

dx

How do we calculate Q ? By definition,

s

Q = 2( 0 )dA

0

26

Torsion in Structural Design - Notes

11/30/01

S

, where S = 2dA was defined

A

A

earlier. In these integrals, is a continuous function of

position on the section, starting from 0 at the sectorial

origin.

In the integral, 0 =

In general, calculating these integrals is messy, but we

may often use a simpler approach.

27

Torsion in Structural Design - Notes

11/30/01

Example: Suppose the above problem involves a W

section with properties shown.

Since the beam is doubly symmetrical, the shear center

coincides with the centroid. Taking this point as the origin

of sectorial areas, and as the sectorial center, the sectorial

areas (taken positive when rotated counterclockwise) are

as shown below.

The negative and positive

contributions cancel, so

S = 0 0 = 0 . Integrating the

sectorial areas over the flanges,

(from the outside edges), the Q

functions are as shown.

Within the web, the + and - areas

from the flanges cancel, so the

warping torsion induced shear flow

vanishes.

28

Torsion in Structural Design - Notes

11/30/01

Then,

d 3 TQ cosh(x )

q = EQ 3 =

dx

2C cosh(L / 2)

In the above,

3

C =

h 2b f t f

qmax ( x )

24

3 T cosh(x )

=

4 h b f cosh(L / 2)

The same result can be achieved in a much more intuitive

manner. The sketch below illustrates the procedure

The lateral translation v introduced into the flange by the

rotation causes a bending moment unless ' is constant.

29

Torsion in Structural Design - Notes

11/30/01

M = EI f v ' '

V = EI f v' ' '

h

' ' '

2

3

bf t f h

=E

' ' '

12 2

= EI f

This shear produces a torque

2

3

b

t

h

h

T f(1) = V = E f f ' ' '

2

12 2

A similar torque develops on the bottom flange, so

3

T = Tf

(1)

+ Tf

(2)

bf t f h 2

= E

' ' '

24

But the warping torsion is given as

3

bf t f h 2

T = EC' ' ' C =

24

in agreement with the previous result.

Within the top flange, bending introduces a shear flow

30

Torsion in Structural Design - Notes

11/30/01

VQ f

q =

If

From the above sketch,

tf

Qf =

2

b f 2

2

y

2

bf t f

If =

12

So

b f 3t f

t f b f

h ' ' '

E

24

2 2

q =

3

bf t f

2

y

12

h tf

=E

2 2

b f

2

y ' ' '

31

Torsion in Structural Design - Notes

11/30/01

For the beam analyzed previously,

' ' ' =

T

cosh(x )

2 EC cosh(L / 2)

so

h tf

q =

2 2

h tf

=

2 2

b f 2

T cosh(x )

2

y

2

2C cosh(L / 2)

b f 2

24 T cosh(x )

2

y 3 2

2

b f t f h 2 cosh(L / 2)

b f 2

3T cosh(x )

2

= y 3

2

b f h cosh(L / 2)

The peak value of warping shear flow occurs at the middle

of the flange (y=0) at the midspan of the beam (x=L/2),

where

q =

3 T

4 bf h

The third part of the sketch on p. TO.30 re-establishes

compatibility by rotating the flanges, and the web about an

angle about their respective centroids. This introduces

the St Venant torsion, as well as a secondary warping

torsion caused by the plate bending of the individual flange

and web plates. We usually ignore the secondary warping

except for certain torsionally weak sections.

32

Torsion in Structural Design - Notes

11/30/01

Secondary Warping:

For certain sections, the only resistance to warping is the

secondary warping resistance. Several such sections are

shown below

The secondary warping torsional resistance can often be

computed for such sections using an analogy to the

approach used for the flange above. Consider a plate,

rotated about its base through an angle which varies with

x. At y,

v ' ' ' ( y ) = y' ' '

t 3dy

dVs ( y ) = EI s ( y )' ' ' = E

y' ' '

12

t 3dy 2

dTs ( y ) = dVs ( y ) y = E

y ' ' '

12

Integrating over the height of the plate,

33

Torsion in Structural Design - Notes

hp

11/30/01

t 3h p

t3 y2

' ' '

Ts = E

dy ' ' ' = E

12

36

0

t 3h p

Cs =

36

All of the cases shown above can be constructed by

variations of the above. For example, a plate of height h

rotated about its centroid is equivalent to two plates of h/2

rotated about their respective bases. Hence,

t 3 ( h / 2 ) 3 t 3h 3

=

Cs = 2

36

144

Likewise, the T section has warping stiffness

3

t1 b3 t2 h 3

Cs =

+

144 36

and the cruciform shown has warping stiffness

t 3h 3 t 3h 3

=

Cs = 2

144 72

(You should calculate the corresponding warping stiffness

for an angle with unequal legs.)

If the plates are thin, the warping stiffness may be

relatively small. This can have an important effect, as we'll

see.

34

Torsion in Structural Design - Notes

11/30/01

Design Approximations for Torsion

Analysis using the differential equation for torsion is

complicated, even for simple loads, so various

approximations have been introduced.

Idea: In warping torsion, the flanges act like beams

bending laterally.

A (conservative) approximate analysis might be

1. convert the torque into couples acting on the flanges by

dividing by the beam height.

2. Apply the "equivalent" lateral loads as forces on the

flanges.

3. Analyze the flanges as beams under these loads.

35

Torsion in Structural Design - Notes

11/30/01

Example:

For the beam analyzed before, the torque converts into

two lateral loads

P = T /h

applied at the top and bottom flanges.

The resulting shear is half of this, on each end

V = T / 2h

The shear flow is thus

b f 2

2

3 y T

2

q VQ f / I f =

3

h bf

36

Torsion in Structural Design - Notes

11/30/01

The max. shear flow at y=0 is

qmax =

3T

4h b f

which clearly is an upper bound to the actual shear flow.

This approach is often overly conservative, because

The normal stresses caused by the bimoment are most

important quantitatively, and may be as large as the

bending stresses for a beam in combined bending and

torsion

The flange shear flow predicted by the bending analogy

will over-estimate the actual warping torsion shear flow

over much of the beam. Since, in the same way that

x

dM

V=

M ( x ) = M (0) + V ( )d

dx

0

We also have

x

dW

V =

W ( x ) = W (0) + V ( )d

dx

0

37

Torsion in Structural Design - Notes

11/30/01

For example, by the beam analogy,

The beam analogy yields

M f

T L

T L bf / 2

=

from which xx =

2h 2

2h 2 I f

However, the actual shear is

Vf =

T cosh(x )

2h cosh(L / 2)

Hence, the integrated lateral flange moment is

M f

T

=

2h

L/2

cosh(x )

T L T L

dx =

<

cosh(L / 2)

2h 2 2 h 2

where is a reduction factor, dependent upon

L

The end conditions

The specifics of the applied torque

S & J give values of for some common load cases.

38

Torsion in Structural Design - Notes

11/30/01

Are the stresses caused by torsion large enough to be a

problem? Let's see.

Example: A W18x71 beam spanning 24 ft. is loaded with a

concentrated load of 20 kips at midspan. The load acts 2''

away from the Z axis. The beam is fixed at both ends.

(Variation on S&J example.)

For the beam, the properties are

3

bf t f h 2

C =

24

(7.635" )3 (.810" )(18.47".81" ) 2

=

= 4,685 in 6

24

bt 3 1

J =

= [2(7.635" )(.810" )3 + (18.47 1.62)(.495" )3 ]

3 3

= 3.39 in 4

E / G = 2(1 + ) = 2(1 + 0.3) = 2.6

39

Torsion in Structural Design - Notes

11/30/01

JG

3.39

0.01668

=

=

EC

( 4,685)2.6

in.

For the fixed-fixed case, we can show that

T

[x sinh(x )

2 JG

(1 cosh(L / 2) )

+

(1 cosh(x ))

sinh(L / 2)

so

(1 cosh(L / 2) )

T

' =

1

cosh(

x

)

sinh(

x

)

2 JG

sinh(L / 2)

(1 cosh(L / 2) )

T

" =

sinh(

x

)

cosh(

x

)

2 JG

sinh(L / 2)

(a) Saint-Venant Torsion

SV = Gt f '

Tt

[1 cosh(x )

2J

+ (1 cosh(L / 2)) sinh(x ) / sinh(L / 2)]

Here, sinh(L / 2) = 5.477 , 1 cosh(L / 2) = 4.567 , so

40

Torsion in Structural Design - Notes

SV =

11/30/01

( 40" k )(0.81" )

[1 cosh(.01668 x ) + 0.8338 sinh(.01668 x )]

4

2(3.39 in )

For the fixed-fixed case, the Saint-Venant torsion is zero at

both support and centerline, and is maximum at L / 4 ,

where

SV 1 = 2.141 ksi

(b) Warping Torsion Shear: For the W section, following

the above reasoning,

2

max

b h

= E f ' ' '

16

From the solution,

(1 cosh(L / 2) )

T2

' ' ' =

cosh(

x

)

sinh(

x

)

2 JG

sinh(L / 2)

so

2

bf h T

1 cosh(L / 2)

max =

cosh(

x

)

sinh(

x

)

32C

sinh(L / 2)

= 0.2556[ cosh(.01668 x ) + 0.8338 sinh(.01668 x )]

max reaches its max. amplitude at the end, and at the

centerline, where the warping restraint is greatest. There

(0) = ( L / 2) = 0.2556

41

Torsion in Structural Design - Notes

11/30/01

It is smallest at the quarter points where warping restraint

is least.

(c) Lateral bending stresses introduced by warping torsion

The bending stress caused by warping is given by

xx

d 2

= E 2

dx

From the above analysis, the largest magnitude stress

occurs at the flange tips, where = b f h / 4 . Thus,

bh

xx = f E"

4

b h E T

= f

[ sinh(x ) (1 cosh(L / 2) ) cosh(x ) / sinh(L / 2]

4 G 2J

at the flange tips

Substituting the numerical values leads to

42

Torsion in Structural Design - Notes

11/30/01

(7.635" )(17.66" )

(0.01668 / in.)( 40 " k )

( 2.6)

4

2(3.39 in 4 )

[ sinh(.01668 x ) + 0.8338 cosh(.01668 x )]

= 8.625[ sinh(.01668 x ) + 0.8338 cosh(.01668 x )]

xx =

The maximum values of xx occur at the ends, and at

midspan, where xx = 7.192 ksi (compressive on one side

of the flange, tensile on the other.

The maximum normal stress on one edge of the flange is

shown over a half beam length. Maximum warping

restraint exists at the support, and at midspan.

(d) Bending analogy For this case

43

Torsion in Structural Design - Notes

11/30/01

h = 17.66" , T = 40" k Pf =

40

= 2.265 kips

17.66

For a fixed-fixed beam, max moments are

M=

Pf L ( 2.265 kips)( 288" )

=

= 81.54" k

8

8

2

t f bf

(0.81" )(7.635" ) 2

Then, if S fl =

=

= 7.8696 in 3

6

6

xx equiv . =

81.54" k

= 10.361 ksi

3

7.8696 in

As noted above, this is overly conservative.

From table 8.6.2, the interpolated value is

= (0.8)(0.68) + (0.2)(0.76) = 0.696

Then,

xx 0.696(10.361 ksi) = 7.211 ksi

which is pretty close to the maximum value obtained from

the closed form solution.

Observations:

44

Torsion in Structural Design - Notes

11/30/01

The Saint-Venant torsion shear stresses are somewhat

larger than the warping torsion shear stresses, but both

are relatively small.

The warping normal stresses may be significant.

(e) To see how significant, let's compute the bending

stresses

M=

PL ( 20 kips)( 288" )

=

= 720" k

8

8

S x = 127 in 3

xx bending = 720" k / 127 in 3 = 5.67 ksi

In this case, the warping normal stresses are larger than

the bending stresses!

45

Torsion in Structural Design - Notes

11/30/01

5. Other Approaches:

Calculating may be simplified by tabulated solutions for

certain idealized boundary conditions, or a matrix stiffness

equation

T1

a2

a1

W

a3

1 JG a2

=

T

2 a1 a2

a

W

a4

2

2

a1

a2

a1

a2

a2 1

a4 1 '

a2 2

a3 2 '

where

= 2 L sinh(L) 2 cosh(L) + 2

a1 = 2 sinh(L)

a 2 = [cosh(L) 1]

a 3 = L cosh(L) sinh(L)

may be useful.

a 4 = sinh(L) L

This stiffness matrix may be used to replace the 2x2

torsional stiffness submatrix

T1 JG 1 1 1

=

1 1

T

L

2

2

commonly used in the beam (or frame) equations, and

incorporates the end conditions commonly encountered.

46

Torsion in Structural Design - Notes

11/30/01

This approach has the advantage that it can produce

reasonable torsional stiffnesses for applications involving

torsional moments caused by eccentrically connected

beams (See S&J, section 8.7)

The associated solution

( x ) = f1 ( x )1 + f 2 ( x )1 '+ f 3 ( x )2 + f 4 ( x )2 '

can then be used to obtain all derivatives of needed to

calculate the shear flow, where

f1 = [a1(L x) a2 (1 + cosh(x)) + a1 sinh(x) / ]/

f2 = [ a2 x + a3(1 cosh(x)) + (a1L a2 )sinh(x) / ]/

f3 = [a1( x sinh(x) / ) a2 (1 cosh(x))] /

f4 = [a4 (1 cosh(x) a2 ( x sinh(x) / ]/

are the "shape functions" for the problem. Distributed

torques can also be accomodated.

47

Torsion in Structural Design - Notes

11/30/01

S&J suggest that the best approach for determining the

applied torque is one that establishes compatibility

between the twisting rotation of the beam supporting a

torque producing member, and the end bending rotation

of the attached element. They note that

Applying the shear at the face of the web

underestimates the torsion

Applying the shear at the centerline of the connection

overestimates the torsion

Applying the shear so as to achieve rotational continuity

with the end of the beam framing in tends to be about

right.

48

Torsion in Structural Design - Notes

11/30/01

6. LRFD for Torsional Moments

Assumption: Torsion stresses add to bending stresses, but

lateral torsional instability is prevented.

i.e. lateral restraint exists, but laterally restraining

members may induce self-limiting torsion before restraint

becomes effective.

Other problems exist as well, for which torsional rotation

may not be self limited.

AISC Philosophy: (consistent with ASD)

Assume the limit state occurs when yielding is reached.

Elastic analysis is applicable.

Compute factored stresses using wD , wL , etc, e.g.

wu = 1.2 w D + 1.6 w L ,

Once the factored design moment and factored design

lateral flange moments are known, the stresses are

superpositioned with the limit state. Formally,

M bz

Sz

M

b Fy

S

or, in terms of the equivalent lateral flange moment

M bz

Sz

2M f

b Fy

Sy

In the above, b = 0.9 =resistance factor.

49

Torsion in Structural Design - Notes

11/30/01

Since is a section property that influences the M

term, through the factor, or through the d.e. solution,

iterative solution is necessary.

Guess a value of in the

right approximate range.

Use the corresponding value of L , to determine the

value of M to be used with the design bending

moment.

Use the bounds to estimate a section size.

Use the section size to update the estimated value of

., etc.

Example: An A36 beam with torsionally simply supported

ends must carry two 20 kip loads acting at an eccentricity

of 6" (5 Kips DL, 15 Kips LL) (Variation on S&J example)

Pu = 1.2(5 kips) + 1.6(15 kips) = 30 kips

Guess wbeam = 150 plf wu = 1.2(150) = 180 plf

Bending moments:

50

Torsion in Structural Design - Notes

11/30/01

Torsion:

Tu = (6" )(30 kips) = 180" k.

Using beam analogy

Pf = Tu / h = 180" k / h

M f = Pf L / 3 = (180" k )(144" ) / h

= 25,920 in 2 k / h

The reduction factor depends upon L. Guess = 0.015 ,

(for a majority of W sections, .01 < < .02 ) Thus,

L = .015( 432" ) = 6.48 0.36

51

Torsion in Structural Design - Notes

11/30/01

The value for the torques in the middle of the beam

aren't exactly known, but the estimates tend to be

somewhat conservative.

Guessing a 14" beam, the reduced flange moment is

M f = 0.36( 25,920 in 2 - k ) / 14" = 667" k

For a midsized W14,

S y / S z 2.6 , taking both flanges

into account, so

4670" k 667" k 2

+

0.9(36 ksi)

Sy

S y / 2.6

S y 251 in 3

Try W14x159. For this section, S y / S z = 2.64 , so the guess

is o.k. for now. Also, for this section

1

=

EC

= 68.2 (p. 1-148 of AISC-LRFD)

GJ

so L = 432" / 68.2 = 6.33

This implies a revised = 0.37

Now,

52

Torsion in Structural Design - Notes

11/30/01

M f = 0.37( 25,920) / 13.79" = 695" k

So

Sy

4,670 " k (695" k )( 2)

+

= 257 in 3

32.4 ksi 32.4 / 2.64

The W14x159 is not quite big enough, since S y = 254 in 3 .

(actually, it's probably o.k., in view of the approximations in

calculating , but without a more precise calculation, we

can't be sure.)

Try a W14x176 Revise the moment upward to

4,720"k to account for the extra dead load.

From the tables,

= 1 / 62.9 L = 432 / 62.9 = 6.86

Sy =

S y / S z = 2.63

Revised = 0.35

h = 13.91"

M f = .35( 25,920) / 13.91 = 652" k

4720 652 2

+

= 29 ksi < 32.4 ksi

281 281 / 2.63

o.k. A W14x176 is more than adequate here

53

Torsion in Structural Design - Notes

11/30/01

7. Presence of Axial Loads (Torsional Instability)

In presence of axial loads, or under certain lateral load

conditions, instability can occur. In this case, formulation

in the displaced state is necessary.

The relevant displacements are v, w and . So, the first

equation (for u0 ) is not changed.

Formulation is complicated, (as is the result) so, we'll just

present the resulting equations for v, w and .

The complete equations are nonlinear. A linear version

which omits the non-linear terms is presented here.

d 4v

d 2v

d 2w

E ( I yy I zz I yz ) 4 I yy N x 2 + I yz N x 2

dx

dx

dx

d 2

+ [ I yy M ly + I yz M lz N x ( ez I yy + e y I yz )] 2

dx

d

+ ( I yyVz + I yzV y ) = q y I y qz I yz

dx

2

54

Torsion in Structural Design - Notes

11/30/01

d 2v

d 2w

d 4w

E ( I yy I zz I yz ) 4 I zz N x 2 + I yz N x 2

dx

dx

dx

d 2

+ [ I zz M lz I yz M ly + N x ( e y I zz + ez I yz )] 2

dx

d

( I zzV y I yzVz ) = qz I zz q y I yz

dx

d 4

IE

H d 2

EC 4 GJ + N x + C z M lz + C y M ly +

W 2

dx

A

C

dx

2

d 2v

d 2w

dv

dw

+ ( M ly ez N x ) 2 ( M lz e y N x ) 2 + Vz V y

dx

dx

dx

dx

d

H

C zV y + C yVz + V = t ( x )

C dx

In these equations, a number of additional quantities are to

be defined.

M ly , M lz = Moments caused by transverse loads only

I E = I yy + I zz + ( e y + ez ) A = polar moment of inertia about

shear center

2

Three new geometrical quantities are

55

Torsion in Structural Design - Notes

11/30/01

H y = z ( y 2 + z 2 )dA

A

H z = y ( y 2 + z 2 )dA

A

H = 2( 0 )( y 2 + z 2 )dA

A

From these,

Cy =

Cz =

I zz H y I yz H z

I yy I zz I yz

2 ez

I yy H z I yz H y

2e y

2

I yy I zz I yz

The equations are three simultaneous equations in three

unknowns. Although the geometrical properties are

constant, the load coefficients M ly , M lz ,V y ,Vz ,W ,V all vary

with x.

The d.e. coefficients are variable.

Often, the d.e.s can be simplified, by taking advantage of

special properties of different classes of problems.

We will want to do this in practice, since the original set of

equations is unwieldy.

56

Torsion in Structural Design - Notes

11/30/01

First, assume that the y-z coordinates are principal

coordinate axes. Then I yz = 0 , and the eqns reduce to

d

d 2

d 2v

d 4v

EI zz 4 N x 2 + ( M ly N x ez ) 2 + Vz y

= qy

dx

dx

dx

dx

d 4w

d 2w

d 2

d

EI yy 4 N x 2 + ( M lz + N x e y ) 2 V y

= qz

dx

dx

dx

dx

d 4

IE

H d 2

EC 4 GJ + N x + C z M lz + C y M ly +

W 2

dx

A

C

dx

dw

dv

d 2w

d 2v

+ ( M ly ez N x ) 2 ( M lz e y N x ) 2 + Vz

Vy

dx

dx

dx

dx

d

H

C zV y + C yVz + V = t ( x )

C dx

If, in addition, the transverse loads q y , qz are zero, and the

transverse moments are constant, then the shears V y ,Vz

are also zero, and the additional simplification

d 4v

d 2v

d 2

EI zz 4 N x 2 + ( M ly N x ez ) 2 = 0

dx

dx

dx

d 2

d 2w

d 4w

EI yy 4 N x 2 + ( M lz + N x e y ) 2 = 0

dx

dx

dx

57

Torsion in Structural Design - Notes

11/30/01

d 4

IE

d 2 H d d

EC 4 GJ + N x + C z M lz + C y M ly 2

W

dx

A

dx

C

dx

dx

d 2v

d 2w

+ ( M ly ez N x ) 2 ( M lz e y N x ) 2 = t ( x )

dx

dx

is possible.

Now, assuming that the bar is subjected only to an axial

compressive load through the centroid, the moments due

to transverse loads are zero, the applied torque vanishes,

and if the loading is applied so that the bimoment is zero,

the equations become

d 4v

d 2v

d 2

EI zz 4 + N x 2 + N x ez 2 = 0

dx

dx

dx

d 4w

d 2w

d 2

EI yy 4 + N x 2 N x e y 2 = 0

dx

dx

dx

2

d 4

IE

d 2v

d 2w

d

EC 4 GJ N x 2 + ez N x 2 e y N x 2 = 0

dx

A

dx

dx

dx

These equations represent a generalization of the elastic

column buckling problem. (Note sign change in N x

because of compression.)

Assume a pinned end column for which the appropriate

boundary conditions are

v=0

w=0

=0

v" = 0 w" = 0 " = 0

58

Torsion in Structural Design - Notes

11/30/01

Then a solution of the form

v = v0 sin( x / L)

w = w0 sin( x / L)

= 0 sin( x / L)

where v0 , w0 , 0 are the values of v, w, at midspan, will

satisfy the resulting equations provided

2

( EI zz 2 N x )v0 N x ez 0 = 0

L

2

( EI yy 2 N x ) w0 + N x e y 0 = 0

L

2

I

ez N x v0 + e y N x w0 + EC 2 + GJ E N x 0 = 0

L

A

or, in matrix form

2

0

EI

N

N

e

x

x z

zz L2

v0 0

w0 = 0

0

EI yy 2 N x

N xey

L

IE

0 0

N xey

EC 2 + GJ N x

N x ez

L

A

Non-trivial solutions exist iff the determinant of coefficients

is zero. Rather than solve for the general case, let's

consider two special cases.

59

Torsion in Structural Design - Notes

11/30/01

(a) The section is doubly symmetric. Then e y = ez = 0 , and

the equations reduce to

EI zz

2

Nx

L2

2

EI yy 2 N x

L

v 0 0

w0 = 0

0

2

IE

0 0

EC 2 + GJ N x

L

A

The corresponding determinantal equation

2

2

2

I

EI zz 2 N x EI yy 2 N x EC 2 + GJ E N x = 0

A

L

L

L

is already factored, and has the three solutions

2

N x = EI zz 2 = PE zz (buckling about z axis)

L

2

N x = EI yy 2 = PE yy (buckling about y axis)

L

2

A

N x = EC 2 + GJ = PT (Torsional, or twist buckling)

IE

L

rd

The 3 solution corresponds to a new mode of buckling,

shown below, for a cruciform section.

60

Torsion in Structural Design - Notes

11/30/01

Dividing by A and noting that I E = I p for a doubly

symmetrical section yields the critical stress

xx cr

2

1

= EC 2 + GJ

Ip

L

If this critical stress is less than the minor axis Euler

stress, then torsional buckling will preceed Euler buckling

of the section, and must be accounted for in design.

61

Torsion in Structural Design - Notes

11/30/01

Example: Consider an equal leg cruciform section with

h=6",t=1/4".

Section properties:

I yy

th( h 2 + t 2 ) (6" )(.25" )[( 6" ) 2 + (.25" ) 2 ]

= I zz =

=

= 4.508 in 4

12

12

I p = I yy + I zz = 9.016 in 4

A = 2th t 2 = 2(6" )(.25" ) (.25" ) 2 = 2.938 in 2 ry = rz = 1.239"

t 3h 3 (.25" ) 3 (6" )3

=

= 0.04688 in 6

C =

72

72

( h / 2)t 3 2ht 3 2(6" )(.25" ) 3

J =4

=

=

= 0.0625 in 4

3

3

3

For Euler buckling, both axes have the same I, so

( Euler )

xx cr

2 E

2 (30,000)

454,530

2

=

=

=

(

1

.

239

"

)

( L / r)2

L2

L2

For torsional buckling,

62

Torsion in Structural Design - Notes

( Torsion )

xx cr

11/30/01

1

2

= ( EC 2 + GJ )

Ip

L

1

2

=

[(30,000)(0.04688) 2 + (11,540)(0.0625)]

9.016

L

1,540

= 2 + 80

L

(The GJ term dominates the torsional buckling equation

unless the column is very short.)

)

( Euler )

Torsion controls if (xxTorsion

<

, so

xx cr

cr

1540

454,530

+

80

<

L < 75.2"

L2

L2

In a symmetrical section, torsional buckling tends to

control only for short columns.

The thinner the walls of the column, relative to the plate

widths (Thin plates) the more likely it is that torsional

buckling will control. (Increasing the wall thickness to

3/8" in the above calculations decreases the length

column for which torsion controls to 50".)

It may be feasible to ignore the warping torsion term in

the above in the practical range of interest.

For the torsion buckling, it is appropriate to replace E

with E /(1 2 ) consistent with dominant plate action.

(b) The section is singly symmetrical. If the z axis is an

axis of symmetry, then e y = 0 , and

63

Torsion in Structural Design - Notes

2

EI zz L2 N x

N x ez

0

2

EI yy 2 N x

L

0

11/30/01

v 0 0

w0 = 0

0

2

IE

0 0

EC 2 + GJ N x

L

A

N x ez

From which, the determinantal equation is

2

2

2

I

2 2

EI yy 2 N x EI zz 2 N x EC 2 + GJ E N x N x ez = 0

L

L

L

A

Before solving this problem, it is useful to substitute the

relations

2

2

2

IE

PE zz = EI zz 2

PE yy = EI yy 2

PT = EC 2 + GJ

L

L

A

L

Then, the determinantal eqn. takes the form

(P

I

2 2

N x E (PE zz N x )(PT N x ) N x ez = 0

A

This is an important case, as T beams, one section

commonly used for compression elements (e.g. truss

members) is singly symmetrical.

E yy

The leading factor is just Euler column buckling in the

plane of symmetry.

The other factor leads to a coupled flexural-torsional

buckling mode. The formal solution is

64

Torsion in Structural Design - Notes

( PE zz

Nx =

11/30/01

Aez

PE zz PT

+ PT ) ( PE zz + PT ) 41

IE

Aez

21

I

E

Typically, this critical load will be smaller than either the

twist buckling load, or the flexural buckling mode.

65

Torsion in Structural Design - Notes

11/30/01

Dividing the equation by the area permits the relationship

to be written in terms of the critical stresses for the

individual buckling modes.

(

(E)

xx cr

(xxFTcr ) =

(T )

xx cr

Aez ( E ) (T )

xx cr xx cr

) ( + ) 41

I

E

Aez

21

IE

(E)

xx cr

(T ) 2

xx cr

where

E

xx cr

2

=E

( L / ry ) 2

(T )

xx cr

E 2

J

= C 2 +

I E L 2(1 + )

One can use the latter equation to define an equivalent

radius of gyration for torsional buckling. Equating

2 E

E 2

J

=

+

C

( L / rE ) 2 I E L2 2(1 + )

yields the resulting equivalent r

rE =

1

JL2

C + 2

2 (1 + )

IE

66

Torsion in Structural Design - Notes

11/30/01

Example: Consider a WT12x27.5:

A = 8.10 in 2

I yy = 117 in 4

I zz = 14.5 in 4

rz = 3.8"

ry = 1.34"

ez = 3.248"

J = 0.588 in 4

C = 2.764 in 6

I E = 117 in 4 + 14.5 in 4 + (8.1 in 2 )(3.248" )2 = 217 in 4

2

2

531,700

E

2

xx cr = E

=

=

30

,

000

(

1

.

34

"

)

( L / ry ) 2

L2

L2

2 0.588

E 2

J 30,000

= C 2 +

=

2.764 2 +

I E L 2(1 + )

L

217

2. 6

(T )

xx cr

3,771

+ 31.26

2

L

Substituting into the critical stress eqn yields

535,500

535,500

1,289,300 3,771

2

31

.

3

)

(

31

.

3

)

31

.

3

+

2

L2

L2

L2

L

=

1.213

(

(xxFTcr )

This result is shown below in two plots.

First plot shows the interaction of the critical stresses

over a large theoretical range

Second plot shows the interaction of the critical stresses

over a practical range

67

Torsion in Structural Design - Notes

11/30/01

Flexural-Torsional interaction significantly reduces the

buckling load for this column, extending well into the

elastic range!

68

Torsion in Structural Design - Notes

11/30/01

7. References

Bleich, F. (1952), Buckling Strength of Metal Structures,

McGraw Hill Book Co., New York, N.Y.

Boresi, A. P., Schmidt, R. J., and Sidebottom, O. M.,

(1993) Advanced Mechanics of Materials, 5th Edition,

John Wiley and Sons, Ch. 6 and 8.

Chang, F. K., and Johnston, B. G., (1953), "Torsion of

Plate Girders," Transactions, ASCE, 118, 337-396.

Chen, M.-T., and Jolissaint, D. E. Jr., (1983), "Pure and

Warping Torsion Analysis of Rigid Frames," Journal of

Structural Engineering, ASCE, 109, 8, 1999-2003.

Chu, K-H., and Johnson, R. B., (1974), "Torsion in Beams

with Open Sections," Journal of the Structural Division,

ASCE, 100, ST7, 1397-1419.

Chu, K-H., and Longinow, A., (1967), "Torsion in Sections

with Open and Closed Parts," Journal of the Structural

Division, ASCE, 93, ST6, 213-227.

Dean, D. L., (1994), "Torsion of Regular Multicellular

Members," Journal of Structural Engineering, 120, 12,

3675-3678

Driver, R. G., and Kennedy, D. J. L., (1989), "Combined

Flexure and Torsion of I-shaped Steel Beams," Canadian

Journal of Civil Engineering, 16, 124-139.

69

Torsion in Structural Design - Notes

11/30/01

El Darwish, I. A., and Johnston, B. G., (1965), "Torsion of

Structural Shapes," Journal of the Structural Division,

ASCE, 91, ST1, 203-227, Errata: 92, ST1, 471.

Evick, D. R., and Heins, C. P. Jr., (1972), "Torsion of

Nonprismatic Beams of Open Section," Journal of the

Structural Division, ASCE, 98, ST12, 2769-2784.

Felton, L. P., and Dobbs, M. W., (1967), "Optimum Design

of Tubes for Bending and Torsion," Journal of the

Structural Division, ASCE, 93, ST4, 185-200.

Goldberg, J. E., (1953), "Torsion of I-Type and H-Type

Beams," Transactions, ASCE, 118, 771-793.

Goodier, J. N., and Barton, M. V., (1944), "The Effects of

Web Deformation on the Torsion of I Beams," Journal of

Applied Mechanics, ASME, p A-35.

Heins, C. P. Jr., (1975) Bending and Torsional Design in

Structural Members, Lexington Books, Lexington, MA.

Heins, C. P., Jr., and Kuo, J. T. C., (1972), "Torsional

Properties of Composite-Girders," Engineering Journal,

AISC, 9, 2, 79-85.

Heins, C. P. Jr., and Potocko, R. A., (1979), "Torsional

Stiffening of I-Girder Webs," Journal of the Structural

Division, ASCE, 105, ST8, 1689-1698.

70

Torsion in Structural Design - Notes

11/30/01

Hotchkiss, J. G., (1966), "Torsion of Rolled Steel Sections

in Building Structures," Engineering Journal , AISC, 3, 1,

19-45.

Johnston, B. G., (1982), "Design of W Shapes for

Combined Bending and Torsion," Engineering Journal,

AISC, 19, 2, 65-85.

Kubo, G. G., Johnston, B. G., and Eney, W. J., (1956),

"Nonuniform Torsion of Plate Girders," Transactions,

ASCE, 121, 759-785.

Lin, P. H., (1977), "Simplified Design for Torsional Loading

of Rolled Steel Members," Engineering Journal, AISC, 14,

3, 97-107.

Lin, P. H., Discussion of "Design of W-Shapes for

Combined Bending and Torsion," by B. G. Johnston,

Engineering Journal, AISC, 20, 2, 82-87.

Lue, T. and Ellifritt, D. S., (1993), "The Warping Constant

for the W-Section with a Channel Cap," Engineering

Journal, AISC, 30, 1, 31-33.

McGuire, W., (1968) Steel Structures, Prentice Hall,

Englewood Cliffs N.J., pp. 346-400.

Murray, N. W., (1984), Introduction to the Theory of Thinwalled Structures, Oxford Univ. Press, Oxford, Ch. 2 and

3.

71

Torsion in Structural Design - Notes

11/30/01

Oden, J. T., (1967), Mechanics of Elastic Structures,

McGraw Hill, N.Y., Ch. 3, 5 and 7.

Pi, Y. L., and Trahair, N. S., (1995a) "Inelastic Torsion of

Steel I-Beams, Journal of Structural Engineering, ASCE,

121, 4, 609-620.

Pi, Y. L., and Trahair, N. S., (1995b), "Plastic Collapse

Analysis of Torsion," Journal of Structural Engineering,

ASCE, 121, 10, 1389-1395.

Pi, Y. L., and Trahair, N. S., (1994a), "Inelastic Bending

and Torsion of Steel I-Beams," Journal of Structural

Engineering, ASCE, 120, 12, 3397-3417.

Pi, Y. L., and Trahair N. S., (1994b), "Nonlinear Inelastic

Analysis of Steel Beam-Columns I: Theory," Journal of

Structural Engineering, 120, 7, 2041-2061.

Pi, Y. L., and Trahair N. S., (1994c), "Nonlinear Inelastic

Analysis of Steel Beam-Columns II: Applications," Journal

of Structural Engineering, 120, 7, 2062-2085.

Salmon, C. G., and Johnson, J. E., (1996) Steel

Structures, Design and Behavior, Harper and Row, New

York.

Shermer, C. L., (1980), "Torsional Strength and Stiffness

of Steel Structures," Engineering Journal, AISC, 17, 2, 3337.

72

Torsion in Structural Design - Notes

11/30/01

Siev, A. (1966), "Torsion in Closed Sections," Engineering

Journal, AISC, 3, 1, 46-54.

Timoshenko, S., (1941), Strength of Materials, Part II, 2d

ed., New York, Van Nostrand Co. Inc., Ch. 6.

Vacharajittiphan, P., and Trahair, N. S., (1974), "Warping

and Distortion at I-Section Joints," Journal of the Structural

Division, ASCE, 100, ST3, 547-564.

Vlasov, V. Z., (1961) Thin Walled Elastic Beams, Israel

Program for Scientific Translations, Jerusalem.

73

Das könnte Ihnen auch gefallen

- Advanced Steel StructuresDokument1 SeiteAdvanced Steel StructuresRohan KulkarniNoch keine Bewertungen

- On The Evaluation of Critical Lateral Torsional Buckling Loads of Monosymmetric Beam ColumnsDokument8 SeitenOn The Evaluation of Critical Lateral Torsional Buckling Loads of Monosymmetric Beam ColumnsPauloAndresSepulvedaNoch keine Bewertungen

- Chapter 1 Introduction To Steel DesignDokument33 SeitenChapter 1 Introduction To Steel DesignRami Demachki100% (1)

- 21a ShearFlow ShearCenterDokument48 Seiten21a ShearFlow ShearCenterJames BlockeNoch keine Bewertungen

- A New Approach For Design of Steel Beam-Columns Our A.Dokument32 SeitenA New Approach For Design of Steel Beam-Columns Our A.mbrown4382Noch keine Bewertungen

- Ansys Analysis-Trolley Beam 3T1Dokument13 SeitenAnsys Analysis-Trolley Beam 3T1Ye Wint ThuNoch keine Bewertungen

- Eccentric LoadDokument6 SeitenEccentric LoadAtish Kumar100% (3)

- Classification of Cross SectionDokument19 SeitenClassification of Cross SectionAmirul Asyraf Bin Mohd BekeriNoch keine Bewertungen

- Stability of ColumnsDokument45 SeitenStability of ColumnsjemnesNoch keine Bewertungen

- Critical Axial Load For Torsional and Flexural Torsional Buckling ModesDokument5 SeitenCritical Axial Load For Torsional and Flexural Torsional Buckling ModesBobaru MariusNoch keine Bewertungen

- 416 - Steel Members Design PDFDokument195 Seiten416 - Steel Members Design PDFdinoNoch keine Bewertungen

- Design For Torsion For Steel StructureDokument32 SeitenDesign For Torsion For Steel StructurePrantik Adhar Samanta100% (1)

- Torsion of Laminated Composite BeamsDokument28 SeitenTorsion of Laminated Composite BeamsFlmkaneNoch keine Bewertungen

- Formula Sheet 3-Steel DesignDokument7 SeitenFormula Sheet 3-Steel DesignAddrien DanielNoch keine Bewertungen

- Deflections - Conjugate BeamDokument13 SeitenDeflections - Conjugate BeamAfia S HameedNoch keine Bewertungen

- Beam DeflectionDokument16 SeitenBeam DeflectionPrashant MavaleNoch keine Bewertungen

- Lecture 10: Flexibility Method for Temperature, Prestrain, and Support DisplacementDokument32 SeitenLecture 10: Flexibility Method for Temperature, Prestrain, and Support DisplacementSarah SullivanNoch keine Bewertungen

- Beam ColumnsDokument21 SeitenBeam ColumnsSherif Mohamed Ibrahim100% (1)

- AAA - Stability - Lecture - SummaryDokument146 SeitenAAA - Stability - Lecture - SummaryIvan EstradaNoch keine Bewertungen

- Design of Compression MembersDokument56 SeitenDesign of Compression Memberstshepo hlakudiNoch keine Bewertungen

- CAD/CAM/CAE analysis of notched beam bucklingDokument3 SeitenCAD/CAM/CAE analysis of notched beam bucklingGiri DharanNoch keine Bewertungen

- Plate Buckling NotesDokument0 SeitenPlate Buckling NotesSharyn PolleyNoch keine Bewertungen

- Shear CenterDokument12 SeitenShear CenterGuru MaheshNoch keine Bewertungen

- Minimum Potential EnergyDokument9 SeitenMinimum Potential EnergyBright MuzaNoch keine Bewertungen

- Chapter 1 StressDokument39 SeitenChapter 1 StressMaipenrai MemeeNoch keine Bewertungen

- 3 - Compression Member PDFDokument43 Seiten3 - Compression Member PDFYetty Oktavianita100% (2)

- Lecture 3 Bec304Dokument35 SeitenLecture 3 Bec304Mohd Nizam ShakimonNoch keine Bewertungen

- Connection DesignDokument33 SeitenConnection Designjesus curielNoch keine Bewertungen

- Modelling and Analysis of Jacket PlatformDokument11 SeitenModelling and Analysis of Jacket PlatformDr R Panneer SelvamNoch keine Bewertungen

- Chapter 7 BoltDokument38 SeitenChapter 7 BoltRamesh P KoiralaNoch keine Bewertungen

- Chapter18 Beam Subjected To Torsion & Bending IIDokument29 SeitenChapter18 Beam Subjected To Torsion & Bending IIVincent TengNoch keine Bewertungen

- Elastic Lateral Torsional BucklingDokument3 SeitenElastic Lateral Torsional BucklingRuchit ParmarNoch keine Bewertungen

- Wind Load On The RoofDokument14 SeitenWind Load On The RoofHussein HasenNoch keine Bewertungen

- Design For Buckling Columns and PlatesDokument20 SeitenDesign For Buckling Columns and Platesdarebusi1100% (1)

- Theory of Elasticity Supplementary Notes: J. N. ReddyDokument52 SeitenTheory of Elasticity Supplementary Notes: J. N. ReddykkhemmoNoch keine Bewertungen

- Plane Sections Remain Plane. Y: CompressionDokument5 SeitenPlane Sections Remain Plane. Y: CompressionakanyilmazNoch keine Bewertungen

- Lec9 Strength Design Methoddoubly Reinforced Beams 160214192041 PDFDokument8 SeitenLec9 Strength Design Methoddoubly Reinforced Beams 160214192041 PDFဒုကၡ သစၥာNoch keine Bewertungen

- Chapter 4 - Axial LoadingDokument33 SeitenChapter 4 - Axial LoadingMaipenrai Memee100% (1)

- Structural Stability and DesignDokument192 SeitenStructural Stability and DesignSwarna RkNoch keine Bewertungen

- Shear CenterDokument8 SeitenShear CenterArun BattuNoch keine Bewertungen

- Selected Homework Problem Answers: Unified Design of Steel Structures, 3rd EditionDokument20 SeitenSelected Homework Problem Answers: Unified Design of Steel Structures, 3rd EditionJames CE0% (1)

- Time Period Calculation in ETABS As Per IS 1893 Part 1Dokument2 SeitenTime Period Calculation in ETABS As Per IS 1893 Part 1NAYAN RANPURA100% (1)

- 01-15-14 Concrete Damaged Plasticity ModelDokument13 Seiten01-15-14 Concrete Damaged Plasticity ModelatchzytNoch keine Bewertungen

- Bending Stresses in BeamDokument29 SeitenBending Stresses in BeamilhammkaNoch keine Bewertungen

- Thick Plate On Elastic FoundationDokument21 SeitenThick Plate On Elastic FoundationHasanain Almusawi100% (1)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsVon EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNoch keine Bewertungen

- DX E X A X P: Axial LoadsDokument5 SeitenDX E X A X P: Axial LoadsvijshahNoch keine Bewertungen

- Understanding Stresses in BeamsDokument15 SeitenUnderstanding Stresses in BeamsdonjazonNoch keine Bewertungen

- Plane Stress TransformDokument24 SeitenPlane Stress Transformsandrock92Noch keine Bewertungen

- Mec Sol 15Dokument30 SeitenMec Sol 15Vinícius GonçalvesNoch keine Bewertungen

- Shear stresses and shear centre analysisDokument9 SeitenShear stresses and shear centre analysisNithesh ShamNoch keine Bewertungen

- Handouts D8 1Dokument8 SeitenHandouts D8 1ozzy22Noch keine Bewertungen

- Formula Table Solid MechanicsDokument26 SeitenFormula Table Solid MechanicsmechfunNoch keine Bewertungen

- Solid Mechanics FormulasDokument26 SeitenSolid Mechanics FormulasLindi NewmanNoch keine Bewertungen

- Shear Centre of Thin-Walled Open SectionsDokument3 SeitenShear Centre of Thin-Walled Open SectionsAdil GhazanfarNoch keine Bewertungen

- Week 7 Truss DesignDokument39 SeitenWeek 7 Truss DesignFoo He XuanNoch keine Bewertungen

- Bending, Torsion, and StressDokument18 SeitenBending, Torsion, and StressnasirfahimNoch keine Bewertungen

- MD 2Dokument33 SeitenMD 2Wilfredo Nieves OsoriaNoch keine Bewertungen

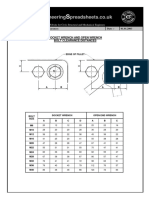

- Beam Theory Basics and Bending StressDokument12 SeitenBeam Theory Basics and Bending Stressabouelrich188Noch keine Bewertungen

- Seismic Analysis of Multistoried BuildingDokument8 SeitenSeismic Analysis of Multistoried Buildingjakeer7Noch keine Bewertungen

- American steel grades A36, A572, A588, A709, A913, A992 propertiesDokument1 SeiteAmerican steel grades A36, A572, A588, A709, A913, A992 propertiesRaymondLeungNoch keine Bewertungen

- Seismic Design Load Distribution in Steel FrameDokument8 SeitenSeismic Design Load Distribution in Steel Framejakeer7Noch keine Bewertungen

- Response Spectrum Analysis For Regular Multistory Structure in Seismic Zone IIIDokument6 SeitenResponse Spectrum Analysis For Regular Multistory Structure in Seismic Zone IIIjakeer7Noch keine Bewertungen

- Foundations For Industrial Machines and Earthquake Effects-InfoDokument17 SeitenFoundations For Industrial Machines and Earthquake Effects-Infojakeer7Noch keine Bewertungen

- Structural Forces in Beams and Frames (38chDokument42 SeitenStructural Forces in Beams and Frames (38chjakeer7Noch keine Bewertungen

- Dynamic Analysis of Machine Foundation-INFODokument8 SeitenDynamic Analysis of Machine Foundation-INFOjakeer7Noch keine Bewertungen

- American steel grades A36, A572, A588, A709, A913, A992 propertiesDokument1 SeiteAmerican steel grades A36, A572, A588, A709, A913, A992 propertiesRaymondLeungNoch keine Bewertungen

- Day 29 Dynamic Analysis Using Response Spectrum MethodDokument9 SeitenDay 29 Dynamic Analysis Using Response Spectrum Methodjakeer7Noch keine Bewertungen

- Aci 351 3R PDFDokument26 SeitenAci 351 3R PDFLakshmi PrabhaNoch keine Bewertungen

- A Comparative Analysis On Absolute and SRSSDokument4 SeitenA Comparative Analysis On Absolute and SRSSjakeer7Noch keine Bewertungen

- American steel grades A36, A572, A588, A709, A913, A992 propertiesDokument1 SeiteAmerican steel grades A36, A572, A588, A709, A913, A992 propertiesRaymondLeungNoch keine Bewertungen

- Process Industry Practices Civil: PIP CVC01015 Civil Design CriteriaDokument17 SeitenProcess Industry Practices Civil: PIP CVC01015 Civil Design Criteriajakeer7Noch keine Bewertungen

- Aci 351 3R PDFDokument26 SeitenAci 351 3R PDFLakshmi PrabhaNoch keine Bewertungen

- PIP STE03350 Vertical Vessel Foundation Design Guide 12-2008 (Last Upd) PDFDokument33 SeitenPIP STE03350 Vertical Vessel Foundation Design Guide 12-2008 (Last Upd) PDFbute79100% (3)

- Offshore Structural Analysis MethodsDokument10 SeitenOffshore Structural Analysis Methodsjakeer7Noch keine Bewertungen

- Machine TypesDokument25 SeitenMachine TypesAnonymous xcFcOgMiNoch keine Bewertungen

- Plastic vs Elastic Section Modulus: Zp and Ze ExplainedDokument1 SeitePlastic vs Elastic Section Modulus: Zp and Ze Explainedjakeer7Noch keine Bewertungen

- Analysis and Design of Vertical Vessel FoundationDokument46 SeitenAnalysis and Design of Vertical Vessel Foundationjakeer7Noch keine Bewertungen

- Analysis of Structural Member Systems - Jerome J. Connor PDFDokument617 SeitenAnalysis of Structural Member Systems - Jerome J. Connor PDFDiego Leonel Suárez Vásquez100% (1)

- Offshore Structural Analysis MethodsDokument10 SeitenOffshore Structural Analysis Methodsjakeer7Noch keine Bewertungen

- Ngineering Preadsheets - Co.uk: Analysis of Equal Span Continuous Beams With Uniformly Distributed LoadsDokument1 SeiteNgineering Preadsheets - Co.uk: Analysis of Equal Span Continuous Beams With Uniformly Distributed Loadsjakeer7Noch keine Bewertungen

- Typical Mat Foundation Design ProcedureDokument7 SeitenTypical Mat Foundation Design Procedurejakeer7Noch keine Bewertungen

- Bolt Load Capacity Tables for EngineersDokument1 SeiteBolt Load Capacity Tables for Engineersjakeer7Noch keine Bewertungen

- Bolt Clearances 01.01.03Dokument1 SeiteBolt Clearances 01.01.03jakeer7Noch keine Bewertungen

- Mat Foundation 2Dokument355 SeitenMat Foundation 2Wondwosen BelayNoch keine Bewertungen

- Bolt Capacity Diagrams To BS5950 01.01.03 PDFDokument1 SeiteBolt Capacity Diagrams To BS5950 01.01.03 PDFjakeer7Noch keine Bewertungen

- Mat Foundation 2Dokument355 SeitenMat Foundation 2Wondwosen BelayNoch keine Bewertungen

- YÖKDİL HAP KELİME SORULARI WWW - Sinavkampi.com - TRDokument14 SeitenYÖKDİL HAP KELİME SORULARI WWW - Sinavkampi.com - TRDemet KöseoğluNoch keine Bewertungen

- STPPT1 Life Processes Interactions and AdaptationsDokument24 SeitenSTPPT1 Life Processes Interactions and AdaptationsIVAN GLENN NAGALNoch keine Bewertungen

- Sartorius YDP20-0CE PrinterDokument116 SeitenSartorius YDP20-0CE Printerblockhead135399Noch keine Bewertungen

- SankarDokument8 SeitenSankarkarteek143Noch keine Bewertungen

- 15 Pawn FormationsDokument11 Seiten15 Pawn FormationsCMCNoch keine Bewertungen

- S4 Aceiteka 2017 AccountsDokument7 SeitenS4 Aceiteka 2017 AccountsEremu ThomasNoch keine Bewertungen

- Financial Accounting Essentials You Always Wanted To Know: 4th EditionDokument21 SeitenFinancial Accounting Essentials You Always Wanted To Know: 4th EditionVibrant Publishers100% (2)

- 00 EAN Abstract 2016 BookDokument956 Seiten00 EAN Abstract 2016 BookAlexandra MardareNoch keine Bewertungen

- Pronunciation + Listening Practice - Ep. 4 PDFDokument3 SeitenPronunciation + Listening Practice - Ep. 4 PDFHoang Nguyen MinhNoch keine Bewertungen

- Ic 78Dokument143 SeitenIc 78Carlos AzañedoNoch keine Bewertungen

- Eve Ross - 10.3a - Note - Images in Concave MirrorsDokument8 SeitenEve Ross - 10.3a - Note - Images in Concave MirrorsEve RossNoch keine Bewertungen

- Government Procurement Reform Act under RA 9184Dokument50 SeitenGovernment Procurement Reform Act under RA 9184Maricel Anober100% (1)

- Chassis Cab: Super DutyDokument17 SeitenChassis Cab: Super DutyJoeNoch keine Bewertungen

- C-Pro Giga: Programmable ControllersDokument46 SeitenC-Pro Giga: Programmable ControllersHeli wilsonNoch keine Bewertungen

- VAT Return - 9.1 - May-2023 - Sumiya TradeDokument63 SeitenVAT Return - 9.1 - May-2023 - Sumiya TradeMD shohelNoch keine Bewertungen

- Sampling and Data CollectionDokument11 SeitenSampling and Data CollectionFil Luayon40% (5)

- Beta12CX Med Vented Cabinet High SPL Mid/High MonitorDokument10 SeitenBeta12CX Med Vented Cabinet High SPL Mid/High MonitorMarius GligorNoch keine Bewertungen

- Semiconductor KIA1117BS/BF/BPI00 KIA1117BS/BF/BPI50: Technical DataDokument6 SeitenSemiconductor KIA1117BS/BF/BPI00 KIA1117BS/BF/BPI50: Technical DataRadu PaulNoch keine Bewertungen

- Subject + Was/were/v II + Object/ComplementDokument6 SeitenSubject + Was/were/v II + Object/ComplementRini TiaraNoch keine Bewertungen

- Application of Electro PneumaticsDokument2 SeitenApplication of Electro PneumaticsMaribel C. MagbanuaNoch keine Bewertungen

- Micropropagation and Microbes DocumentDokument20 SeitenMicropropagation and Microbes DocumentRavneet KaurNoch keine Bewertungen

- Series: Instruction ManualDokument10 SeitenSeries: Instruction Manualjbernal89Noch keine Bewertungen

- Ultrasonic Flow Meter UltraFlow 2500 Data SheetDokument4 SeitenUltrasonic Flow Meter UltraFlow 2500 Data SheetSaman Raza KhanNoch keine Bewertungen

- Timss & Pisa Models: Khalidah AhmadDokument51 SeitenTimss & Pisa Models: Khalidah AhmadMirahmad FadzlyNoch keine Bewertungen

- Photopia User's GuideDokument307 SeitenPhotopia User's GuideJesus VNoch keine Bewertungen

- Data Teknis Gedung Eksisting 3 - As Build - Pemohon - Jika Tidak Ada Kita Yang BuatDokument29 SeitenData Teknis Gedung Eksisting 3 - As Build - Pemohon - Jika Tidak Ada Kita Yang Buatagusta galileoNoch keine Bewertungen

- CPR Covid-19Dokument29 SeitenCPR Covid-19Triana TingNoch keine Bewertungen

- Digging For DinosDokument7 SeitenDigging For Dinosapi-645698424Noch keine Bewertungen

- Golar Viking Case Study NSFMWDokument7 SeitenGolar Viking Case Study NSFMWMatteo ConciNoch keine Bewertungen

- Nihon Kohden Cns 6201 Administrator S Guide PDFDokument171 SeitenNihon Kohden Cns 6201 Administrator S Guide PDFjhon edison rojas villadaNoch keine Bewertungen