Beruflich Dokumente

Kultur Dokumente

Oxy Fuel Torches PDF

Hochgeladen von

borgiamatriceOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Oxy Fuel Torches PDF

Hochgeladen von

borgiamatriceCopyright:

Verfügbare Formate

Oper ating

Oxy/Fuel Torches

CAUTION: THE FOLLOWING INSTRUCTIONS ARE INTENDED AS GENERAL GUIDELINES FOR SETTING UP AND USING AN OXYGEN/FUEL TORCH. DUE TO DIFFERENCES IN TORCHES, SOME INFORMATION MAY NOT BE ACCURATE FOR A PARTICULAR APPLICATION. THOROUGHLY READ ALL SAFETY INFORMATION AND

INSTRUCTIONS PROVIDED BY THE MANUFACTURER. CONTENTI WILL NOT BE HELD RESPONSIBLE FOR DAMAGE RESULTING FROM USE OF THIS INFORMATION.

Setting Up The Torch

FUEL REGULATOR

OXYGEN REGULATOR

1. Secure both Oxygen and Fuel Tanks to a wall, post, or in a tank

Torch Tip

Tank Pressure Gauge

Tank

Tank Pressure Gauge

Tank

caddy, in the upright position.

Oxygen Tank Valve

Working Pressure Gauge

Working

Oxygen

Torch Valve

Working Pressure Gauge

Working

2. With the valve opening pointed away from you, open the Oxygen

Tank Valve and quickly close it. This will expell any dust particles

from the valve opening. Do the same with the Fuel Tank.

Fuel Tank Valve

Fuel Torch Valve

3. Attach the Oxygen Regulator to the tank, tightening the nut with a

Regulator Pressure Screw

wrench. Do not overtighten the nut as this may damage the tting.

Torch Body

Regulator Pressure Screw

4. Attach the Fuel Regulator to the fuel tank by turning the nut

counter-clockwise. The fuel regulator nut has a left-hand thread, to

Oxygen Hose

Hose Set

Fuel Hose

prevent it from being installed on oxygen tanks by mistake. Secure

Oxygen Tank

Fuel Tank

the nut with a wrench, without overtightening.

5. Attach one end of your Hose Set to the Oxygen and Fuel Regulators and the other end to your Torch Body. The Red colored hose is used for fuel and has

left-hand threaded connectors. The Green hose (sometimes, Blue colored) has standard connectors with right-hand thread.

6. Position the torch and hoses so that they do not become tangled or damaged. Maintain a safe distance between your work area and the tanks.

Turning On The Torch

1. Make sure both Regulator Pressure Screws are backed-out and loose and both Torch Valves are closed.

2. Begin by opening the Oxygen Tank Valve slowly, to prevent shock to the regulator. Once the pressure shown on the Tank Pressure Gauge is stabilized, open

the tank valve as far as possible.

3. Open the Fuel Tank Valve slowly and allow pressure to stabilize. Then, open the valve 1/4 turn if using acetylene or as far as possible if using propane.

4. Using a leak detection liquid, or soapy water, check all connections for leaks. If any leaks are found, DISCONTINUE USE and contact the supplier/manufacturer.

5. Purge the hose lines by opening the Torch Valves (one at a time) for several seconds. This will prevent any cross-contamination of gasses. Close the valves.

6. Install a Torch Tip (if one is not already installed).

7. Slowly turn the Oxygen Regulator Pressure Screw inwards until the desired pressure is indicated on the Working Pressure Gauge (see manufacturers

documentation for recommended pressure settings). Do the same with the Fuel Regulator.

8. Open the Fuel Torch Valve a very small amount and light with a spark lighter. Once the ame is lit, open the fuel valve more and open the Oxygen Torch

Valve until the desired ame composition is acheived.

Shutting Off The Torch

1.

2.

3.

4.

Close the Oxygen Tank Valve rst, then the Fuel Tank Valve. If done in the opposite order, the torch may pop and possibly clog the torch tip.

Close both the Oxygen and Fuel Tank Valves completely.

Open the Torch Valves, one at a time, to bleed the hoses. The pressure shown on both Pressure Gauges should drop to zero. Close the torch valves.

Turn both Regulator Pressure Screws counter-clockwise until they are loose.

The Contenti Company, Providence, RI 02903 USA | contenti.com

Das könnte Ihnen auch gefallen

- Ring Sizing ChartDokument1 SeiteRing Sizing ChartborgiamatriceNoch keine Bewertungen

- Types of Metalsmithing Hammers GuideDokument1 SeiteTypes of Metalsmithing Hammers Guideborgiamatrice100% (1)

- Tank/Cylinder Sizes: CGA 520 CGA 540 CGA 540Dokument1 SeiteTank/Cylinder Sizes: CGA 520 CGA 540 CGA 540borgiamatriceNoch keine Bewertungen

- IndustrIial ElectrochemistryDokument562 SeitenIndustrIial ElectrochemistryborgiamatriceNoch keine Bewertungen

- Us 4557759Dokument6 SeitenUs 4557759borgiamatriceNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Scrap Gold Refining Free ReportDokument5 SeitenScrap Gold Refining Free ReportborgiamatriceNoch keine Bewertungen

- Platinum and Palladium Separation MethodDokument1 SeitePlatinum and Palladium Separation Methods_noeeNoch keine Bewertungen

- Refining of Precious Metal Powder Spent Catalyst WasteDokument20 SeitenRefining of Precious Metal Powder Spent Catalyst WasteborgiamatriceNoch keine Bewertungen

- Precious Metals Buyers GuideDokument44 SeitenPrecious Metals Buyers GuideGuillaume PriolNoch keine Bewertungen

- 16 Common Uses of SilverDokument6 Seiten16 Common Uses of SilverborgiamatriceNoch keine Bewertungen

- Chemistry of Precious MetalsDokument316 SeitenChemistry of Precious Metalsborgiamatrice100% (1)

- Mineral Dissolution/precipitation: A A A A KDokument13 SeitenMineral Dissolution/precipitation: A A A A KborgiamatriceNoch keine Bewertungen

- Solubility Rules PDFDokument1 SeiteSolubility Rules PDFsoumendra ghoraiNoch keine Bewertungen

- Us 4319922Dokument7 SeitenUs 4319922borgiamatriceNoch keine Bewertungen

- Novolyte High Performance SolventsDokument11 SeitenNovolyte High Performance SolventsborgiamatriceNoch keine Bewertungen

- Us 4131454Dokument11 SeitenUs 4131454borgiamatriceNoch keine Bewertungen

- Smop Ex Recommendations For UseDokument1 SeiteSmop Ex Recommendations For UseborgiamatriceNoch keine Bewertungen

- Extraction and Refining of Platinum MetalsDokument8 SeitenExtraction and Refining of Platinum MetalsPrie TeaNoch keine Bewertungen

- Fact Sheet: Seneca, South CarolinaDokument1 SeiteFact Sheet: Seneca, South CarolinaborgiamatriceNoch keine Bewertungen

- R7210306-Metallurgy and Material ScienceDokument4 SeitenR7210306-Metallurgy and Material ScienceborgiamatriceNoch keine Bewertungen

- Smopex BrochureDokument9 SeitenSmopex BrochureborgiamatriceNoch keine Bewertungen

- R7210306-Metallurgy and Material ScienceDokument4 SeitenR7210306-Metallurgy and Material ScienceborgiamatriceNoch keine Bewertungen

- Ceramics in Hydrometallurgical Processes: RefractoriesDokument4 SeitenCeramics in Hydrometallurgical Processes: RefractoriesborgiamatriceNoch keine Bewertungen

- Prest O Lite Furnace LP Gas Melting 0 0900 EDokument1 SeitePrest O Lite Furnace LP Gas Melting 0 0900 EborgiamatriceNoch keine Bewertungen

- NCNDADokument5 SeitenNCNDAlinkinpaqNoch keine Bewertungen

- Precipitation ReactionsDokument3 SeitenPrecipitation ReactionsborgiamatriceNoch keine Bewertungen

- Notice - Ad-2012 Rev 12-13-11-For The WebsiteDokument2 SeitenNotice - Ad-2012 Rev 12-13-11-For The WebsiteborgiamatriceNoch keine Bewertungen

- Ncnda NobleDokument5 SeitenNcnda NobleborgiamatriceNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Magura HS 11/33Dokument16 SeitenMagura HS 11/33Nebojša TepićNoch keine Bewertungen

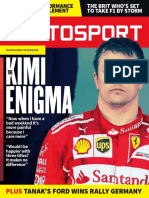

- The Kimi Enigma - Autosport 24th August 2017Dokument16 SeitenThe Kimi Enigma - Autosport 24th August 2017Anonymous AyGXao100% (2)

- Tanaka Fumon - Samurai Fighting Arts PDFDokument236 SeitenTanaka Fumon - Samurai Fighting Arts PDFLokEswaran I100% (3)

- Motion 8 This House Would Ban BoxingDokument4 SeitenMotion 8 This House Would Ban BoxingSanti Sri HartiniNoch keine Bewertungen

- JIU JITSU The Effective Japanese Mode of Self Defense Illustrated by Snapshots of K Koyama Amp A Minami 1916Dokument102 SeitenJIU JITSU The Effective Japanese Mode of Self Defense Illustrated by Snapshots of K Koyama Amp A Minami 1916Mark Zlomislic100% (1)

- Muscular SystemDokument8 SeitenMuscular SystemCHRISTIANNE DENISE EBREONoch keine Bewertungen

- FINAL TEST 1bacDokument3 SeitenFINAL TEST 1bacMARIA JESUS DUQUENoch keine Bewertungen

- CRHW Exercise 1 S. 2017Dokument3 SeitenCRHW Exercise 1 S. 2017Dherick RaleighNoch keine Bewertungen

- CCC2018 - A Year in The LifeDokument36 SeitenCCC2018 - A Year in The LifeCastleknock Community CollegeNoch keine Bewertungen

- OriginalDokument92 SeitenOriginalSayed GodaNoch keine Bewertungen

- Silman, Jeremy - Alekhine's Defense Four Pawns AttackDokument3 SeitenSilman, Jeremy - Alekhine's Defense Four Pawns AttackAjedrez ChessNoch keine Bewertungen

- The Branding of Club Atletico de Madrid Local or GlobalDokument71 SeitenThe Branding of Club Atletico de Madrid Local or Globalheda kaleniaNoch keine Bewertungen

- Dinosaur Arm TrainingDokument34 SeitenDinosaur Arm TrainingMarkk211100% (4)

- Leisure Interest AssessmentDokument13 SeitenLeisure Interest Assessmentapi-279621534Noch keine Bewertungen

- Fundamental of NursingDokument1 SeiteFundamental of Nursingioana_ciobincanNoch keine Bewertungen

- Racecar Engineering 2005 04 PDFDokument100 SeitenRacecar Engineering 2005 04 PDFfreddyonnimiNoch keine Bewertungen

- Programming and Periodization NotesDokument2 SeitenProgramming and Periodization NotesBhavesh HotwaniNoch keine Bewertungen

- Physical Education XiDokument59 SeitenPhysical Education XiAkshitNoch keine Bewertungen

- 58thnssc CircularDokument10 Seiten58thnssc CircularDarshanSundareshNoch keine Bewertungen

- PracticeMock Bazooka September 2018 EditionDokument61 SeitenPracticeMock Bazooka September 2018 EditionCheenaNoch keine Bewertungen

- Car - October 2017Dokument164 SeitenCar - October 2017roberto999999999Noch keine Bewertungen

- Omha - HC Player Evaluation Selection - Dev Series PDFDokument92 SeitenOmha - HC Player Evaluation Selection - Dev Series PDFLucas Tenorio Souza SilvaNoch keine Bewertungen

- PE 3 Individual Dual SportsDokument55 SeitenPE 3 Individual Dual SportsGinalyn BisongaNoch keine Bewertungen

- Honolulu Star-Advertiser's 2019 All-State Football TeamDokument1 SeiteHonolulu Star-Advertiser's 2019 All-State Football TeamHonolulu Star-Advertiser100% (1)

- AABC 2010 Rules and Regulations Handbook)Dokument47 SeitenAABC 2010 Rules and Regulations Handbook)adam5080Noch keine Bewertungen

- 2014 Umarex USA AIRGUN CatalogDokument75 Seiten2014 Umarex USA AIRGUN CatalogGene GattiNoch keine Bewertungen

- Ballroom Dancing For Beginners - Part 2 by Kevin BuellDokument82 SeitenBallroom Dancing For Beginners - Part 2 by Kevin BuellAnonymous w8clYQgdDE100% (1)

- History and Rules of BadmintonDokument16 SeitenHistory and Rules of BadmintonJess RancapNoch keine Bewertungen

- Project Cosco KirthiDokument64 SeitenProject Cosco KirthiAnonymous ar6Upyf8Noch keine Bewertungen

- Woman workout-plan-PPLS-extra-GlutesDokument9 SeitenWoman workout-plan-PPLS-extra-Glutesbomcon123456Noch keine Bewertungen