Beruflich Dokumente

Kultur Dokumente

595

Hochgeladen von

druwid6Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

595

Hochgeladen von

druwid6Copyright:

Verfügbare Formate

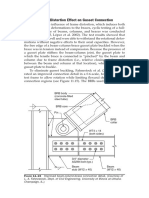

main girder rib was 55 C.

The temperature of external and internal surface in rib was almost equal with

a largest difference of 8 C. On the other hand, for

practical situation, the top surface and lateral surface

had a temperature difference of 42 C with the centre

of main girder rib. The temperature of external and

internal surface in rib was almost equal with a largest

difference of 3 C. The practical temperature difference

was smaller to the theoretical one. Generally, theoretical and practical inside-outside temperature difference

between external and internal surface is following the

same rule.

The external and internal surface of main girder

rib had little temperature difference and the practical

temperature difference was smaller than the theoretical one. Two main reasons bring this consequence. The

first one, a relatively low value of heat transfer coefficient was taken in practical analysis to external and

internal surface of main girder rib. The second one,

the heat transfer coefficient of external surface was

almost equal to that of internal surface.

6

CONCLUSIONS

1) There are three obvious stages in the variation

process, heating period, cooling period and stable period. When the construction situation and

mix proportion of concrete is constant, the larger

the thickness of concrete structure is, the higher

the temperature peak value will be and the later

the peak value will come. At the same time,

inside-outside temperature difference in one section is proportional to the thickness of concrete

structure, too.

2) When the outside environment and mix proportion of concrete is constant, inside-outside temperature difference in one section is proportional

to the heat transfer coefficient of surface. The

inside-outside temperature difference of main

girder rib has already reached to reaches 40 C,

so a drastic measure should be taken to prevent

cracks brought by early hydration heat.

3) Under the early hydration heat temperature field,

cracks are easy to appear in concrete main girder

of cable-stayed bridge. More attention should be

pay to this effect than the temperature gradient

effect by sunlight.

4) Contrasting field test with calculation of early

temperature field of concrete main girder, the

result is consistent to each other. It was proved that

the calculative result is high reliability. This result

could be used to the analysis of early hydration

heat temperature field of concrete bridge and it

can provide a reference for development of study

on early anti-cracking of concrete structures of

similar bridges.

REFERENCES

China Merchants Chongqing Communications Research and

Design Institute Co., LTD. 2010. The research on methods

to prevent cracks in critical segment in huge span cablestayed bridge. [R], Chongqing.

Wang Tiemeng. 1997. Controlling of cracks in engineering structures. [M], Beijing: China architecture &building

press.

Zhu Bofang. 1999. Temperature stress and controlling of temperature in mass concrete. [M], Beijing: China Electric

Power Press.

Peng Lihai. 2005. Temperature controlling and crack prevention of mass concrete. [M], Zhengzhou: The Yellow River

water conservancy press.

Chen Qibiao, Wang Hong, Li Qi, 2010(06). Test and analysis

of early temperature and stress to concrete of cable tower.

[J]. Technology of Highway and Transport.

Wang Peng, Liu Xiaohui, Chen Qibiao, Li Qi. 2009(05).

Investigation for Influences of Hydration Heat on Early

Cracking of Concrete Main Tower of Cable Stayed Bridge.

[J], Technology of Highway and Transport.

Wang Peng, Wang Fumin, Li Qi, Chen Qibiao. 2010(02).

Effect of Cooling on Early-age Cracking in Concrete

Tower of Cable-stayed Bridge. [J], Special Structures.

Li Xing. 2009. The Research on Temperature Field and

Temperature Effect of -TYPE Girder P.C. Cablestayed Bridge [D], Changsha University of Science &

Technology.

576

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Micro - Systemic Bacteriology Questions PDFDokument79 SeitenMicro - Systemic Bacteriology Questions PDFShashipriya AgressNoch keine Bewertungen

- Antifraud PlaybookDokument60 SeitenAntifraud PlaybookDani UsmarNoch keine Bewertungen

- Book Speos 2023 R2 Users GuideDokument843 SeitenBook Speos 2023 R2 Users GuideCarlos RodriguesNoch keine Bewertungen

- Aggressivity of The Environment: Main Exposure ClassesDokument2 SeitenAggressivity of The Environment: Main Exposure Classesdruwid6Noch keine Bewertungen

- Design of Welded Steel Structures 51Dokument1 SeiteDesign of Welded Steel Structures 51druwid6Noch keine Bewertungen

- Design of Welded Steel Structures 81Dokument1 SeiteDesign of Welded Steel Structures 81druwid6Noch keine Bewertungen

- 11.5.3 Frame Distortion Effect On Gusset ConnectionDokument1 Seite11.5.3 Frame Distortion Effect On Gusset Connectiondruwid6Noch keine Bewertungen

- Chapter Eleven: A B C D E FDokument1 SeiteChapter Eleven: A B C D E Fdruwid6Noch keine Bewertungen

- The Abc'S of Autolisp by George Omura: Managing Large Acad - LSP FilesDokument1 SeiteThe Abc'S of Autolisp by George Omura: Managing Large Acad - LSP Filesdruwid6Noch keine Bewertungen

- Simplified Calculation Method For Integral of Mean Square Value of Various Nonstationary Random ResponsesDokument1 SeiteSimplified Calculation Method For Integral of Mean Square Value of Various Nonstationary Random Responsesdruwid6Noch keine Bewertungen

- Sketching A Complete View Containing Circles and ArcsDokument1 SeiteSketching A Complete View Containing Circles and Arcsdruwid6Noch keine Bewertungen

- Problem 6.2: 06 - Bruneau - Ch06 - P273-308.indd 305 6/13/11 3:13:56 PMDokument1 SeiteProblem 6.2: 06 - Bruneau - Ch06 - P273-308.indd 305 6/13/11 3:13:56 PMdruwid6Noch keine Bewertungen

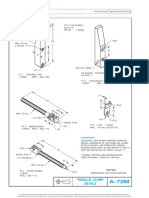

- Interpreting Engineering Drawings: Parallel Clamp DetailsDokument1 SeiteInterpreting Engineering Drawings: Parallel Clamp Detailsdruwid6Noch keine Bewertungen

- Fibres: Named After The Swiss Jacob Bernoulli (1654-1705), From A Famous Family of Mathematicians and PhysicistsDokument1 SeiteFibres: Named After The Swiss Jacob Bernoulli (1654-1705), From A Famous Family of Mathematicians and Physicistsdruwid6Noch keine Bewertungen

- Interpreting Engineering Drawings Common Types of CamsDokument1 SeiteInterpreting Engineering Drawings Common Types of Camsdruwid6Noch keine Bewertungen

- Chapter Six Applications of Plastic Analysis: 6.6 Displacement Compatibility of Nonductile SystemsDokument1 SeiteChapter Six Applications of Plastic Analysis: 6.6 Displacement Compatibility of Nonductile Systemsdruwid6Noch keine Bewertungen

- -ε diagram with a distinct yield region.: Engineering Mechanics. Volume 2: Stresses, Deformations, DisplacementsDokument1 Seite-ε diagram with a distinct yield region.: Engineering Mechanics. Volume 2: Stresses, Deformations, Displacementsdruwid6Noch keine Bewertungen

- Wide-Flange Beam: Plate:: Beams, Girders, and ColumnsDokument1 SeiteWide-Flange Beam: Plate:: Beams, Girders, and Columnsdruwid6Noch keine Bewertungen

- Land Clearing and ControlsDokument1 SeiteLand Clearing and Controlsdruwid6Noch keine Bewertungen

- Figure 1.1 Partial Factors and Their Significance in Eurocode 1 (European Standard, 2000)Dokument1 SeiteFigure 1.1 Partial Factors and Their Significance in Eurocode 1 (European Standard, 2000)druwid6Noch keine Bewertungen

- -ε diagram for glass.: Engineering Mechanics. Volume 2: Stresses, Deformations, DisplacementsDokument1 Seite-ε diagram for glass.: Engineering Mechanics. Volume 2: Stresses, Deformations, Displacementsdruwid6Noch keine Bewertungen

- Ground Improvement Techniques and Lining Systems 119: WaterproofingDokument1 SeiteGround Improvement Techniques and Lining Systems 119: Waterproofingdruwid6Noch keine Bewertungen

- 80 PDFDokument1 Seite80 PDFdruwid6Noch keine Bewertungen

- 12.4.5 Functions Called: Tdofssmodalfun.m, Tdofssmodal1fun.m, Tdofssmodal2fun.m, Tdofssmodal3fun.mDokument1 Seite12.4.5 Functions Called: Tdofssmodalfun.m, Tdofssmodal1fun.m, Tdofssmodal2fun.m, Tdofssmodal3fun.mdruwid6Noch keine Bewertungen

- Tunnel 130 PDFDokument1 SeiteTunnel 130 PDFdruwid6Noch keine Bewertungen

- 15.6.4 Damping, Defining Reduced Frequencies and Modal MatricesDokument1 Seite15.6.4 Damping, Defining Reduced Frequencies and Modal Matricesdruwid6Noch keine Bewertungen

- CH 15Dokument58 SeitenCH 15Chala1989Noch keine Bewertungen

- Rs2-Seamanship (Inc Anchoring, Mooring, Berthing, Pilot Ladder)Dokument19 SeitenRs2-Seamanship (Inc Anchoring, Mooring, Berthing, Pilot Ladder)Mdpn. Salvador67% (3)

- Saif Powertec Limited Project "Standard Operating Process" As-Is DocumentDokument7 SeitenSaif Powertec Limited Project "Standard Operating Process" As-Is DocumentAbhishekChowdhuryNoch keine Bewertungen

- Annex To ED Decision 2013-015-RDokument18 SeitenAnnex To ED Decision 2013-015-RBurse LeeNoch keine Bewertungen

- ProspDokument146 SeitenProspRajdeep BharatiNoch keine Bewertungen

- National Employment Policy, 2008Dokument58 SeitenNational Employment Policy, 2008Jeremia Mtobesya0% (1)

- Catalog Tu ZG3.2 Gian 35kV H'MunDokument40 SeitenCatalog Tu ZG3.2 Gian 35kV H'MunHà Văn TiếnNoch keine Bewertungen

- Garments Costing Sheet of LADIES Skinny DenimsDokument1 SeiteGarments Costing Sheet of LADIES Skinny DenimsDebopriya SahaNoch keine Bewertungen

- D. Das and S. Doniach - Existence of A Bose Metal at T 0Dokument15 SeitenD. Das and S. Doniach - Existence of A Bose Metal at T 0ImaxSWNoch keine Bewertungen

- MQXUSBDEVAPIDokument32 SeitenMQXUSBDEVAPIwonderxNoch keine Bewertungen

- Contemp Person Act.1Dokument1 SeiteContemp Person Act.1Luisa Jane De LunaNoch keine Bewertungen

- Advantages Renewable Energy Resources Environmental Sciences EssayDokument3 SeitenAdvantages Renewable Energy Resources Environmental Sciences EssayCemerlang StudiNoch keine Bewertungen

- Ice 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisDokument15 SeitenIce 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisBipin KrishnaNoch keine Bewertungen

- Trading Journal TDA Branded.v3.5 - W - Total - Transaction - Cost - BlankDokument49 SeitenTrading Journal TDA Branded.v3.5 - W - Total - Transaction - Cost - BlankChristyann LojaNoch keine Bewertungen

- Transposable Elements - Annotated - 2020Dokument39 SeitenTransposable Elements - Annotated - 2020Monisha vNoch keine Bewertungen

- Marieb ch3dDokument20 SeitenMarieb ch3dapi-229554503Noch keine Bewertungen

- DevOps Reference CardDokument2 SeitenDevOps Reference CardIntizarchauhanNoch keine Bewertungen

- Helipal Tbs Powercube ManualDokument29 SeitenHelipal Tbs Powercube Manualoualid zouggarNoch keine Bewertungen

- Cheerios Media KitDokument9 SeitenCheerios Media Kitapi-300473748Noch keine Bewertungen

- Rocker ScientificDokument10 SeitenRocker ScientificRody JHNoch keine Bewertungen

- Contigency Plan On Class SuspensionDokument4 SeitenContigency Plan On Class SuspensionAnjaneth Balingit-PerezNoch keine Bewertungen

- Statistical Techniques EE 532Dokument1 SeiteStatistical Techniques EE 532AdnanNoch keine Bewertungen

- Research Methods in Developmental PsychologyDokument9 SeitenResearch Methods in Developmental PsychologyHugoNoch keine Bewertungen

- Exam First Grading 2nd Semester - ReadingDokument3 SeitenExam First Grading 2nd Semester - ReadingArleneRamosNoch keine Bewertungen

- MSC ACFN2 RD4 ClassDokument25 SeitenMSC ACFN2 RD4 Classmengistu jiloNoch keine Bewertungen

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Dokument19 SeitenEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uNoch keine Bewertungen

- GA Power Capsule For SBI Clerk Mains 2024 (Part-2)Dokument82 SeitenGA Power Capsule For SBI Clerk Mains 2024 (Part-2)aa1904bbNoch keine Bewertungen