Beruflich Dokumente

Kultur Dokumente

FAA APPROVED: November 15, 1988

Hochgeladen von

Imam Arif RahmanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FAA APPROVED: November 15, 1988

Hochgeladen von

Imam Arif RahmanCopyright:

Verfügbare Formate

MICHIGAN DEPARTMENT OF TRANSPORTATION

BUREAU OF AERONAUTICS - STANDARD SPECIFICATION

Item L-110

Installation of Airport Underground Electrical Duct

DESCRIPTION

1.1

This item shall consist of underground

electrical ducts installed in accordance with this

specification at the locations and in accordance with

the dimensions, designs, and details shown in the

plans. This item shall include the installation of all

underground electrical ducts or underground

conduits. It shall also include all trenching,

backfilling, removal, and restoration of any paved

areas, manholes, concrete encasement, mandreling

installation of steel drag wires and duct markers,

capping, and the testing of the installation as a

completed duct system ready for installation of

cables, to the satisfaction of the Engineer.

EQUIPMENT AND MATERIALS

2.1

General. All equipment and materials

covered by referenced specifications shall be subject

to acceptance through manufacturers certification

of compliance with the applicable specification

when so requested by the Engineer.

2.2

Bituminous Fiber Duct. Bituminous fiber

duct and fittings shall conform to the requirements

of Fed. Spec. W-C-581 or W-C-575 and shall be one

of the following, as specified in the proposal:

(a)

encasement

(b)

Type I, for concrete

Type II, for direct burial

2.3

Asbestos Cement Duct. Asbestos cement

duct and fittings shall conform to the requirements

of Fed. Spec. W-C-571 and shall be one of the

following, as specified in the proposal:

(a)

encasement

(b)

Type I, for concrete

Type II, for direct burial

2.4

Steel Conduit. Steel conduit and fittings

shall conform to the requirements of Fed. Spec.

FAA APPROVED: November 15, 1988

WW-C-581 and shall be Class 1-Rigid metal steel

unless otherwise specified on the plans. If Class 2Intermediate steel conduit is specified, it shall be

encased in concrete.

2.5

Concrete. Concrete shall conform to Item

P-610, Structural Portland Cement Concrete, using

25 mm maximum size coarse aggregate.

2.6

Plastic Conduit. Plastic conduit and

fittings shall conform to the requirements of Fed.

Spec. W-C-1094 and shall be one of the following,

as specified in the proposal:

(a)

Type I - Suitable for underground

use either directly in the earth or encased in

concrete.

(b)

Type II - Suitable for either above

ground or underground use.

2.7

Poly (Vinyl Chloride) (PVC). PVC

conduit and fittings shall meet the requirements of

ASTM F 512 or UL 651. Any of the types listed in

ASTM F 512 or UL 651 may be used for concrete

encased burial. Either Type DB 60, DB 120,

Schedule 40 or Schedule 80 may be used for direct

burial.

CONSTRUCTION METHODS

3.1

General. The Contractor shall install

underground ducts at the approximate locations

indicated in the airport layout plans. The Engineer

shall indicate specific locations as the work

progresses. Ducts shall be of the size, material, and

type indicated in the plans or specifications. Where

no size is indicated in the plans or specifications, the

duct shall not be less than 3 inches inside diameter.

All duct lines shall be laid so as to grade toward

handholes, manholes, and duct ends for drainage.

Grades shall be at least 3 inches per 100 feet. On

runs where it is not practicable to maintain the grade

all one way, the duct lines shall be graded from the

center in both directions toward manholes,

handholes, or duct ends. Pockets or traps where

L-110, Installation of Airport Underground Electrical Duct

moisture may accumulate shall be avoided.

The Contractor shall mandrel each duct. An ironshod mandrel, not more than 1/4 inch smaller than

the bore of the duct shall be pushed through each

duct by means of jointed conduit rods. The mandrel

shall have a leather or rubber gasket slightly larger

than the duct hole.

All ducts installed shall be provided with a No. 10

gauge galvanized iron or steel drag wire for pulling

the permanent wiring. Sufficient length shall be left

in manholes or handholes to bend the drag wire back

to prevent it from slipping back into the duct.

Where spare ducts are installed, as indicated on the

plans, the open ends shall be plugged with

removable tapered plugs, designed by the duct

manufacturers, or with hardwood plugs conforming

accurately to the shape of the duct and having the

larger end of the plug at least 1/4-inch greater in

diameter than the duct.

All ducts shall be securely fastened in place during

construction and progress of the work and shall be

plugged to prevent seepage of grout, water, or dirt.

Any duct section having a defective joint shall not

be installed.

All ducts, except Class 1-Rigid metal steel conduit

and PVC Type DB 60, DB 120, Schedule 40 and

Schedule 80, installed under runways, taxiways,

aprons, and other paved areas shall be encased in a

concrete envelope.

Where turf is well established and the sod can be

removed, it shall be carefully stripped and properly

stored.

Trenches for ducts may be excavated manually or

with mechanical trenching equipment. Walls of

trenches shall be essentially vertical so that a

minimum of shoulder surface is disturbed. Blades

of road patrols or graders shall not be used to

excavated the trench. The Contractor shall ascertain

the types of soil or rock to be excavated before

bidding. All excavation shall be unclassified.

3.2

Ducts Encased To Concrete. Unless

otherwise shown in the plans, concrete-encased

ducts shall be installed so that the top of the

concrete envelope is not less than 18 inches below

finished grade where installed under runways,

Page 2 of 4

taxiways, aprons, or other paved areas, and not less

than 18 inches below finished grade where installed

in unpaved areas. Ducts under paved areas shall

extend at least 3 feet beyond the edges of the

pavement or 3 feet beyond any underdrains which

may be installed alongside the paved area. Trenches

for concrete-encased ducts shall be opened the

complete length before concrete is laid so that if any

obstructions are encountered, proper provisions can

be made to avoid them. All ducts for concrete

encasements shall be placed on a layer of concrete

not less than 3 inches thick prior to its initial set.

Where two or more ducts are encased in concrete,

the Contractor shall space them not less than 1-1/2

inches apart (measured form outside wall to outside

wall) using spacers applicable to the type of duct.

As the duct laying progresses, concrete not less than

3 inches thick shall be placed around the sides and

top of the duct bank. End bells or couplings shall be

installed flush with the concrete encasement where

required.

When specified, the Contractor shall reinforce the

bottom side and top of encasements with steel

reinforcing mesh or fabric or other approved metal

reinforcement. When directed, the Contractor shall

supply additional supports where the ground is soft

and boggy, where ducts cross under roadways, or

where otherwise shown on the plans. Under such

conditions, the complete duct structure shall be

supported on reinforced concrete footings, piers, or

piles located at approximately 1.5 m intervals.

When clay or soapstone ducts are specified, they

shall be installed with concrete encasement as

described above. Clay conduit shall be of the

single-bore type. Where the self-centering socketjoint type of single clay duct is used, conduit shall

be built up, tier by tier, and separated only by

sufficient mortar or fine aggregate concrete to bed

the ducts evenly and fill all voids between ducts.

Single ducts shall be jointed together and the joints

grouted with portland cement mortar. A suitable

gasket (of rubber or other approved material) shall

first be placed in the receptacle end of the duct,

prior to the joining operation, in order to exclude all

mortar from the duct.

Where the square bore butt-joint type of clay duct,

single or multicell, is used, sections shall be aligned

with at least four steel dowel pins and joints

wrapped with duct tape 6 inches wide and lapped 6

L-110, Installation of Airport Underground Electrical Duct

inches. All joints in a bank of single-bore ducts

shall be staggered, beginning evenly from the

manhole or handhole, by means of short lengths 6,

8, 9, 12, and 15 inches long. Cement mortar shall be

troweled around each and every joint. Voids in the

duct bank, caused by the external shape of the

corners of the conduit, shall also be filled with

mortar. The joining and joints of soapstone duct

shall be done in accordance with the manufacturers

recommendations.

3.3

Ducts Without Concrete Encasement.

Trenches for single-duct lines shall not be less than

6 inches nor more than 12 inches wide, and the

trench for two or more ducts installed at the same

level shall be proportionately wider. Trench

bottoms for ducts without concrete encasement shall

be made to conform accurately to grade so as to

provide uniform support for the duct along its entire

length.

A layer of fine earth material, at least 4 inches thick

(loose measurement) shall be placed in the bottom

of the trench as bedding for the duct. The bedding

material shall consist of soft dirt, sand or other fine

fill, and it shall contain no particles that would be

retained on a 1/4-inch sieve. The bedding material

shall be tamped until firm.

Unless otherwise shown in plans, ducts for direct

burial shall be installed so that the tops of all ducts

are at least 18 inches below the finished grade.

When two or more ducts are installed in the same

trench without concrete encasement, they shall be

spaced not less than 2 inches apart (measured form

outside wall to outside wall) in a horizontal

direction and not less than 6 inches apart in a

vertical direction.

Trenches shall be opened the complete length

before duct is installed so that if any obstructions

are encountered, proper provisions can be made to

avoid them.

3.4

Duct Markers. The location of the ends of

all ducts shall be marked by a concrete slab marker

2 feet square and 4 inches thick extending

approximately 1 inch above the surface. The

markers shall be located above the ends of all ducts

or duct banks, except where ducts terminate in a

handhole, manhole, or building.

Page 3 of 4

The Contractor shall impress the word DUCT on

each marker slab. He or she shall also impress on

the slab the number and size of ducts beneath the

marker. The letters shall be 4 inches high and 3

inches wide with width of stroke 1/2-inch and 1/4inch deep or as large as the available space permits.

3.5

Backfilling. After concrete-encased ducts

have been properly installed and the concrete has

had time to set, the trench shall be backfilled in at

least two layers with excavated material not larger

than 4 inches in diameter and thoroughly tamped

and compacted to at least the density of the

surrounding undisturbed soil. If necessary to obtain

the desired compaction, the backfill material shall

be moistened or aerated as required.

Trenches shall not be excessively wet and shall not

contain pools of water during backfilling operations.

The trench shall be completely backfilled and

tamped level with the adjacent surface; except that,

when sod is to be placed over the trench, the

backfilling shall be stopped at a depth equal to the

thickness of the sod to be used, with proper

allowance for settlement.

Any excess excavated material shall be removed and

disposed of in accordance with instructions issued

by the Engineer.

For ducts without concrete envelope, 8 inches of

sand, soft earth, or other fine fill (loose

measurement) shall be placed around the ducts and

carefully tamped around and over them with hand

tampers. The remaining trench may be filled with

regular run of excavated material and thoroughly

tamped as specified above.

3.6

Restoration. Where sod has been removed,

it shall be replaced as soon as possible after the

backfilling is completed. All areas disturbed by the

trenching, storing of dirt, cable laying, pad

construction, and other work shall be restored to its

original condition. The restoration shall include any

necessary topsoiling, fertilizing, liming, seeding,

sprigging, or mulching. All such work shall be

performed in accordance with the FAA Standard

Turfing Specifications. The Contractor shall be held

responsible for maintaining all disturbed surfaces

and replacements until final acceptance.

L-110, Installation of Airport Underground Electrical Duct

METHOD OF MEASUREMENT

4.1

The quantity of underground duct to be paid

for under this item shall be the number of linear feet

of duct installed, measured in place, completed, and

accepted. Separate measurement shall be made for

the various types and sizes.

Page 4 of 4

WW-C-581

Conduit, Metal, Rigid and

Intermediate; and Coupling,

Elbow; and Nipple,

Electrical Conduit; ZincCoated Steel

OTHER SPECIFICATIONS REQUIRED

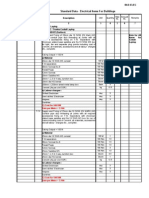

BASIS OF PAYMENT

5.1

Payment will be made at the contract unit

price for each type and size of single-way or multiway duct completed and accepted. This price shall

be full compensation for furnishing all materials and

for all preparation, assembly, and installation of

these materials, and for all labor, equipment, tools,

an incidentals necessary to complete this item.

Payment will be made under the nomenclature and

seven digit item number specified in the plans and

proposal for each type and size of single-way or

multi-way duct completed and accepted.

The first three digits of any item number for work

included under this specification shall be 110, i.e.

110 XXXX.

FEDERAL SPECIFICATIONS REQUIRED

Number

Title

W-C-571

Conduit and Fittings,

Nonmetal, rigid; (AsbestosCement or Fire-Clay

Cement), (for Electrical

Purposes)

W-C-575

Conduit and Fittings;

Nonmetallic, Rigid,

Bituminized Fiber;

Laminated Wall

W-C-581

Conduit and Fittings;

Nonmetallic, Rigid,

(Bituminized Homogeneous

Fiber)

W-C-1094

Conduit and Fittings;

Nonmetallic, Rigid, (Plastic)

UL 651

Schedule 40 and Schedule

80 PVC Conduit

ASTM F 512

Smooth-Wall Poly (Vinyl

Chloride) (PVC) Conduit

and Fittings for

Underground Installation

Das könnte Ihnen auch gefallen

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerVon EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerBewertung: 5 von 5 Sternen5/5 (1)

- Environment, Health & Safety Plan Environment, Health & Safety PlanDokument19 SeitenEnvironment, Health & Safety Plan Environment, Health & Safety PlanParshant SainiNoch keine Bewertungen

- TR - BM Part 5 - Pipes Used in Water, Electricity and Gas NetworksDokument26 SeitenTR - BM Part 5 - Pipes Used in Water, Electricity and Gas Networkskarthik channamsettyNoch keine Bewertungen

- Concrete Encased Duct Bank PDFDokument8 SeitenConcrete Encased Duct Bank PDF101079Noch keine Bewertungen

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Von EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Bewertung: 5 von 5 Sternen5/5 (2)

- Plasticbook PDFDokument33 SeitenPlasticbook PDFrajuksk_pipingNoch keine Bewertungen

- Pipeline InstallationDokument6 SeitenPipeline InstallationSurya Kiran KNoch keine Bewertungen

- HDDDokument6 SeitenHDDRon Cyl100% (1)

- How to Build a Global Model Earthship Operation II: Concrete WorkVon EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNoch keine Bewertungen

- Specification Part 2 Specs - 2 Civil WorksDokument72 SeitenSpecification Part 2 Specs - 2 Civil WorksMaulid100% (1)

- Drainage SanitationDokument16 SeitenDrainage Sanitation2011kumarNoch keine Bewertungen

- Window Design GuideDokument33 SeitenWindow Design GuideSANTI9090Noch keine Bewertungen

- Hangars Supports For Piping EquipmentDokument6 SeitenHangars Supports For Piping EquipmentTONNoch keine Bewertungen

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoDokument4 SeitenGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- Civil Engineering for Underground Rail TransportVon EverandCivil Engineering for Underground Rail TransportJ. T. EdwardsBewertung: 5 von 5 Sternen5/5 (2)

- MOS For Electrical UG Ducts (PVC Pipes) InstallationDokument3 SeitenMOS For Electrical UG Ducts (PVC Pipes) Installationmagdi badran100% (1)

- 33 0401 UTIL Underground Pipe InstallationDokument5 Seiten33 0401 UTIL Underground Pipe InstallationfaissuNoch keine Bewertungen

- Detailed Specifications - EarthworkDokument10 SeitenDetailed Specifications - EarthworkKishan KumarNoch keine Bewertungen

- Sanitary Sewer Design - April03Dokument7 SeitenSanitary Sewer Design - April03TurusanNoch keine Bewertungen

- Duct BankDokument7 SeitenDuct BankAwotiku AbimbolaNoch keine Bewertungen

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringVon EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringBewertung: 4 von 5 Sternen4/5 (5)

- 29.sec.2900 (Pipe Culverts)Dokument4 Seiten29.sec.2900 (Pipe Culverts)Rakesh ParaliyaNoch keine Bewertungen

- Body Care Ingredients To AvoidDokument4 SeitenBody Care Ingredients To AvoidadriagNoch keine Bewertungen

- Concrete Encased Underground Electrical Duct BanksDokument2 SeitenConcrete Encased Underground Electrical Duct BanksVíctor DávilaNoch keine Bewertungen

- Infrastructure Method of ConstructionDokument19 SeitenInfrastructure Method of ConstructionMohamed El-shaarawiNoch keine Bewertungen

- Plumbing Scope of WorksDokument5 SeitenPlumbing Scope of WorksJoven E. VizcaraNoch keine Bewertungen

- Presented By: Laminating Adhesives For Flexible PackagingDokument14 SeitenPresented By: Laminating Adhesives For Flexible PackagingKarim BoudaouchNoch keine Bewertungen

- SECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)Dokument9 SeitenSECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)akvosmNoch keine Bewertungen

- Detailed Specification of PlumbingDokument7 SeitenDetailed Specification of PlumbingNava PavanNoch keine Bewertungen

- Culvert ThicknessDokument23 SeitenCulvert ThicknessNilaAbubakarNoch keine Bewertungen

- Construction Specification Cs-Ut-202, Pipeline Through EmbankmentsDokument3 SeitenConstruction Specification Cs-Ut-202, Pipeline Through EmbankmentsPaola Paternina PadrónNoch keine Bewertungen

- Section - 11 Sewer Pipe Laying and AppurtenancesDokument10 SeitenSection - 11 Sewer Pipe Laying and AppurtenancesImran AzizNoch keine Bewertungen

- Rev DrainDokument6 SeitenRev DrainRaj RahulNoch keine Bewertungen

- Specifications For Highway Drainage - OxfordshireDokument11 SeitenSpecifications For Highway Drainage - OxfordshirexkishanNoch keine Bewertungen

- Construction Specification Mi-182. Plastic (PVC, Pe) PipeDokument3 SeitenConstruction Specification Mi-182. Plastic (PVC, Pe) PipeNaeemSiddiquiNoch keine Bewertungen

- Division 16 - Electrical Section 16115 - Underground Conduits and Distribution Duct BanksDokument3 SeitenDivision 16 - Electrical Section 16115 - Underground Conduits and Distribution Duct BankskooltahaNoch keine Bewertungen

- Instalación de Tuberías EnterradasDokument4 SeitenInstalación de Tuberías EnterradasYana ParravanoNoch keine Bewertungen

- Diaphragm WallDokument4 SeitenDiaphragm Wallリムスィギャン瑞娴Noch keine Bewertungen

- Section-2900 Pipe CulvertsDokument2 SeitenSection-2900 Pipe CulvertsErMelvinDiasNoch keine Bewertungen

- Size Cased (If Contract Documents Specify The Cased Method.)Dokument7 SeitenSize Cased (If Contract Documents Specify The Cased Method.)jmpkumaraNoch keine Bewertungen

- Used Water SES 5 Construction of Tunnels Ancillaries 2012Dokument28 SeitenUsed Water SES 5 Construction of Tunnels Ancillaries 2012Mark BenjieNoch keine Bewertungen

- 16110s01 Conduit and RacewayDokument3 Seiten16110s01 Conduit and RacewayVICTOR JOSE VILORIANoch keine Bewertungen

- Construction and Materials Manual: 5.50.1 Culvert Pipe ListDokument4 SeitenConstruction and Materials Manual: 5.50.1 Culvert Pipe Listt_aligNoch keine Bewertungen

- Section 6 WaterDokument3 SeitenSection 6 WaterBabiker ElrasheedNoch keine Bewertungen

- Appendixc Construction Standards and SpecificationsDokument18 SeitenAppendixc Construction Standards and SpecificationsAzeNoch keine Bewertungen

- ITEM 500 Latest 2004Dokument40 SeitenITEM 500 Latest 2004Michael John EnfestaNoch keine Bewertungen

- Standard Specification For Waste Water - PipelinesDokument26 SeitenStandard Specification For Waste Water - Pipelinespopperoo00Noch keine Bewertungen

- Item 500Dokument19 SeitenItem 500mira01Noch keine Bewertungen

- 4 Highway Lighting: Construction RequirementsDokument21 Seiten4 Highway Lighting: Construction RequirementsMitur PatelNoch keine Bewertungen

- Public Health Specs P1Dokument14 SeitenPublic Health Specs P1Comofco GibraltarNoch keine Bewertungen

- 16127-Underground Ducts and Utility StructuresDokument5 Seiten16127-Underground Ducts and Utility StructuresYousif AbdalhalimNoch keine Bewertungen

- Conduits and FittingsDokument10 SeitenConduits and FittingssultanprinceNoch keine Bewertungen

- ITEM 500-514 Latest 2012 (M) FinalDokument76 SeitenITEM 500-514 Latest 2012 (M) FinalMars TinNoch keine Bewertungen

- Building SPECS 1Dokument5 SeitenBuilding SPECS 1Giselle EspinosaNoch keine Bewertungen

- PROJECTDokument3 SeitenPROJECTErin Trisha Kristel GaspanNoch keine Bewertungen

- Standard Specifications 04Dokument14 SeitenStandard Specifications 04Chokri El WakkelNoch keine Bewertungen

- 3B ManholesDokument5 Seiten3B ManholesRony BaloyiNoch keine Bewertungen

- Section 15250 - Pipe, Duct, and Equipment InsulationDokument7 SeitenSection 15250 - Pipe, Duct, and Equipment InsulationnanajmeeNoch keine Bewertungen

- Storm DrainageDokument8 SeitenStorm DrainageEphrem GizachewNoch keine Bewertungen

- Project TitleDokument7 SeitenProject TitleGerlie Joy CastanosNoch keine Bewertungen

- Code of Practice For Laying of Cast Iron Pipes: Indian StandardDokument15 SeitenCode of Practice For Laying of Cast Iron Pipes: Indian StandardgavallapalliNoch keine Bewertungen

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDokument3 SeitenSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariNoch keine Bewertungen

- 16180Dokument9 Seiten16180uddinnadeemNoch keine Bewertungen

- Building SPECSDokument5 SeitenBuilding SPECSGi SelleNoch keine Bewertungen

- Morth 2900 Pipe CulvertsDokument5 SeitenMorth 2900 Pipe CulvertsRamesh100% (3)

- Dynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationDokument8 SeitenDynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationBala Krishna GallaNoch keine Bewertungen

- Sewage Disposal Works: Their Design and ConstructionVon EverandSewage Disposal Works: Their Design and ConstructionNoch keine Bewertungen

- Derakane Signia™ 411 TDSDokument8 SeitenDerakane Signia™ 411 TDSDidikHariantoNoch keine Bewertungen

- Pages From 70TMSS04R0 Warning Tapes For HV and Telecom (HV)Dokument2 SeitenPages From 70TMSS04R0 Warning Tapes For HV and Telecom (HV)maherNoch keine Bewertungen

- KSH International Continuously Transposed Cables - Conductors (CTC) BrochureDokument4 SeitenKSH International Continuously Transposed Cables - Conductors (CTC) Brochurekshintl100% (3)

- PWD Electrical 2013 14 PDFDokument194 SeitenPWD Electrical 2013 14 PDFMangesh ChavanNoch keine Bewertungen

- LogicroofDokument29 SeitenLogicroofjaswinder singhNoch keine Bewertungen

- Cost Effectiveness of Different Canal Lining Materials: Mr. Amrut Sangale, Dr. S. S. ValunjkarDokument3 SeitenCost Effectiveness of Different Canal Lining Materials: Mr. Amrut Sangale, Dr. S. S. ValunjkarerpublicationNoch keine Bewertungen

- Underground: Drain, Sewer, Surface Water & DuctDokument16 SeitenUnderground: Drain, Sewer, Surface Water & DuctBesmira NurellariNoch keine Bewertungen

- Uc 350Dokument2 SeitenUc 350Luis GuerraNoch keine Bewertungen

- Strength of PlasticsDokument21 SeitenStrength of PlasticsCarinna Saldaña - PierardNoch keine Bewertungen

- C5000 ManualDokument36 SeitenC5000 Manuallinhpic99Noch keine Bewertungen

- Nsf-Ansi-Can 61-2020-20210602150943Dokument163 SeitenNsf-Ansi-Can 61-2020-20210602150943QT Trái Tim Của GióNoch keine Bewertungen

- Revised Standard Data For ElectrificationDokument120 SeitenRevised Standard Data For ElectrificationKishore Ainavilli100% (1)

- Joyforce SDS - PVA Pellet - r2.ENDokument3 SeitenJoyforce SDS - PVA Pellet - r2.ENjituniNoch keine Bewertungen

- Silicone Impression Materials and Latex Gloves. Is Interaction Fact or FallacyDokument4 SeitenSilicone Impression Materials and Latex Gloves. Is Interaction Fact or FallacyBakr Ahmed100% (1)

- Method Statement For Installation of Underground Checmical Waste TanksDokument8 SeitenMethod Statement For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNoch keine Bewertungen

- Conveyor BeltsDokument16 SeitenConveyor BeltsdjsmoniNoch keine Bewertungen

- Kuraray Technical Brochure - EnglishDokument28 SeitenKuraray Technical Brochure - EnglishrbucholzNoch keine Bewertungen

- K Type Thermocouple Extension Cable KXYY (1-50) Pairs X 1.5 MM 300 VDokument1 SeiteK Type Thermocouple Extension Cable KXYY (1-50) Pairs X 1.5 MM 300 VArthurNoch keine Bewertungen

- Proposal Final VersionDokument29 SeitenProposal Final VersioneyobNoch keine Bewertungen

- SDS - DOWSIL™ 813FR Fire Retardant Silicone-MinDokument14 SeitenSDS - DOWSIL™ 813FR Fire Retardant Silicone-MinRajneesh SainiNoch keine Bewertungen

- Boss PVC Pressure Solvent CementDokument8 SeitenBoss PVC Pressure Solvent CementsdrgdfhbfghdNoch keine Bewertungen

- Technical 694 Cable - 1Dokument21 SeitenTechnical 694 Cable - 1santoshcutyNoch keine Bewertungen

- Member/Structure Flr. Level Gride Line Length Width ThicknessDokument92 SeitenMember/Structure Flr. Level Gride Line Length Width ThicknessyzzaNoch keine Bewertungen