Beruflich Dokumente

Kultur Dokumente

K 109

Hochgeladen von

Anonymous MbqTZHLNR9Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

K 109

Hochgeladen von

Anonymous MbqTZHLNR9Copyright:

Verfügbare Formate

DIY KIT 109 STEPPER MOTOR DRIVER

Stepper motors can be used in a wide variety of hobby

applications: searchlights on small boats & cars, video

camera positioning, radio antenna control, controls

operating through waterproof housing, telescope control

where the azimuth, elevation & focus must be varied

independently, moving table positioning.

In these

applications what is required is one or both of a

continuous stepping at varying speeds and a single

stepping, fine control to get the final position.

This kit is a stepper motor driver for 5, 6 & 8 lead

unipolar stepper motors. These are the most common

types today on the surplus market. The older four lead

bipolar stepper motors are not supported by this kit.

Visual indication that a pulse has gone to the stepper

motor is provided by 4 LEDs, one connected to each of

the four coils in the motor. (This may be very useful if

you cannot see the motor and want to be sure that it has

stepped.) The direction of stepping can be changed by a

switch. Three stepping modes are possible.

The kit uses an IC especially designed to drive 6 lead

unipolar stepper motors, the UCN5804B. As will be

shown the 5 and 8 lead steppers can be configured into a

6 lead pattern. Download the data sheet for this IC from

the Allegro website given below. The various features of

this IC are brought out to 5 SPDT switches on the PCB.

This kit was designed using Protel for DOS.

ASSEMBLY

Check the components against the Component listing.

Make sure you identify C1, the 474 monoblok. It looks

just the same as C2 C4 & C6 which are 104 monobloks

with the same pitch. Note there are four links to go on the

board. One of the links goes under an IC socket. Make

sure the flat on the four LEDs corresponds to the bar

shown on the overlay. They all face right. It is generally

best to solder the lowest height components into the board

first. We have included a 6-pin header to make the

connection of the stepper motor to the PCB easier.

Motor Identification.

This is straight forward because the number of wires

coming out of the motor identifies it. Bipolar motors

have 4 leads coming out of them. One winding is on each

stator pole. These motors are not supported by this kit.

They were common in the late 1980s and many kits using

discrete components were built to support them.

Unipolar motors may have 5 leads but generally have 6

or 8 wires. In all the motors we have seen, the wires for

the 6 & 8 types come out in two bundles of 3 or 4 wires

resp. Unipole steppers have two coils per stator pole. In

the 8 lead motors the 2 leads from the 2 coils from both

stators emerge from the motor. In the 6 lead motors the

two coils on each stator pole are joined (opposite sense)

together before they emerge from the motor. In the 5 lead

motors each of the two joined wires are themselves joined

before they leave the motor.

In the 6 wire version a multimeter (set it to 200ohm

resistance range) will show which is the centre lead within

each group of 3 leads. Typically the resistance between

the centre lead to the other two will be about 40 ohms

while the resistance between the outer two leads will be

twice that. Call the outer two leads in each of the two

bunches of wires A & B,

C & D. Solder them into

those positions on the

PCB. The centre lead in

each bunch is the power

lead & goes into the pad

marked +. Note that it

does not matter which

way around the A/B, C/D

leads go onto the pads.

5 wire version. Note that both + pads on the PCB are

connected together. In the 5 wire motor these centre leads

are connected internally.

So to power a 5 lead

stepper just connect the

common centre tap lead

from both phases to one of

the + pads. The A/B, C/D

leads are connected just as

in the 6 lead motors.

8 wire version. In each

bunch of 4 leads find the 2 pairs of wires connected to

each phase of the motor. Take one of each and join them

together. This is now the common lead to connect to the +

pad just as in the 6 lead case. The remaining leads are A

& B and C & D to the PCB..

Now there are 1, possibly

2, complications. First the

common connection must

join the coils in the

opposite sense. This refers

to the way in which they

are wound. This means

that the dot on one coil is

joined to the no-dot end

on the other coil in the

diagram. There is no way to tell the sense of the coils

unless you have the motor winding colour specification

which for surplus motors is generally missing. So you just

have to try it. Now if the wires are colour coded the same

in both bundles this is just a matter of two possibilities to

try. If the wires are not colour coded then there are four

possibilities. You will not damage the motor during this

testing if connections are wrong. The motor will either not

work or oscillate to and fro when the power is connected.

CIRCUIT DESCRIPTION

We have designed the kit so that the stepper motor can be

run continuously at a fast or low stepping rate then, when

it nears the desired position, it can be switched to

DIY KIT 109 STEPPER MOTOR DRIVER

PARTS LIST - K109

Resistors 1/4W, 5%:

180R brown grey brown ......R1 ..................................1

1K brown black red .............R2 R3 ............................2

1M brown black green.........R4 ..................................1

1M potentiometer ................POT ...............................1

1000uF/35V electrolytic capacitor C3.......................1

0.47uF 474 monoblok capacitor C1 ..........................1

0.1uF 104 monoblok capacitor C2 C4 C5 C6 ...........4

UCN5804B .........................IC2.................................1

LM/NE555 nmos.................IC1.................................1

7805 voltage regulator.........IC3.................................1

2 pole terminal block..................................................1

8 pin IC socket............................................................1

16 pin IC socket..........................................................1

SPDT PCB-mounted switch .......................................5

6 pin header ................................................................1

3mm red LED.............................................................4

4 leg tact switch..........................................................1

K109 PCB ..................................................................1

single step mode and manually pulsed into final position.

Another switch controls the direction. A third switch can

turn the IC off and any power to the motor is removed.

Two other switches bring out halfstep and one phase

control modes supported by the IC. A 555 IC is

configured to deliver a continuous stream of pulses to pin

11 of the 5804. The frequency is determined by the values

of the potentiometer and C1. Alternatively, the single step

switch allows individual pulses to be delivered manually

to the 5804 using a tact switch. A switch debounce circuit

is present using R4 & C5. LEDs are included on the

output of the 5804 to show which phases of the motor are

powered.

starting from basics are references 2, 4 and 5 below. You

can see the pattern of coils being turned on/off by looking

at the LEDs as the motor steps.

As the motor is spinning, try varying the supply voltage.

This will make the motor run more roughly or smoothly.

Stepping motors are very sensitive to supply voltage

variations.

If you want the RUN stepping rate to be slower then

replace the 1M potentiometer by a 5M or even 10M pot.

What to do if it does not work

If there are more than 2 LEDs on then there is a short

circuit on the output of the 5804. Check that all the 4 links

are added to the board. Check the 555 IC is in the correct

way.

Ballast or Forcing Resistor

For two reasons a low value (typically 20 to 60 ohm), 5W

or 10W cement resistor is sometimes included in both the

+ lines between the 5804 and the stepper motor.

Lenzs Law. Voltage driving gets into a time constant

problem (L/R) which limits speed & power. If R is

increased then the time constant is reduced. However, for

hobby applications it does not matter if the time constant

is 50msec or 10 msec.

Current Limiting. The resistor helps to limit current to

the motor. This is to help reduce overheating when it is

stopped (not stepping) but the power is still connected to

it to maintain its position.

External Diodes. These are mentioned in the data sheet

on the 5804 as possibly being necessary. However, for the

hobby stepper motors we are discussing here they are not

required.

Data Sheet. Download the data sheet for the UCN5804

from the Allegro website at:

http://www.allegromicro.com/

The Driver. The 5804 stepper driver is one of those

marvellous devices that replaces a handful of discrete

components. The driver will operate motors at up to 35V

and 1.25A. The step input is to pin 11 and direction goes

to pin 14. Pins 9 and 10 control one phase and half step

operation, respectively. Ref. 6 shows how to drive the IC

direct from a computer.

Motor Movement.

To make the motor step, power is applied to each coil in

turn. The 4 windings have to be energised in the right

sequence. Steppers have three different stepping methods:

wave, two phase & half-step. This is because there are

three basic patterns of energising the coils to make them

move. The last two are the most efficient. These patterns

are given in the data sheet on the 5804. No more than 2

coils are on at any one time.

In wave drive (or one phase operation) only one coil is

on at any time. In two phase drive two coils are always

on. In halfstep drive the number of coils energised cycles

between 1 & 2. We will not go into the details here since

they are given every year or so in the hobby electronics

magazines and in text books. Two of the best write-ups

and enter 5804 in the Product Search.

REFERENCES.

1. Control Stepper Motors with your PC, by Marque

Crozman. Silicon Chip, january, 1994, p80.

2. Stepper Motors and how they work, by Peter Phillips.

Electronics Australia, October & November, 1994.

3. A PC-Based Stepper-Motor Controller, by Larry

Antonuk. Popular Electronics, June 1992, p41.

4. Computer Controlled Stepper Motors, by Jim Spence.

ETI, august, 1994, p18.

5. Stepping Motor Driver/Interface, by Mark Stuart.

Everyday Electronics, january, 1992, p34.

6. Linear Motion Table, by John Iovine. Nuts n Volts,

august, 1995, p76.

DIY KIT 109 STEPPER MOTOR DRIVER

Das könnte Ihnen auch gefallen

- Vka Round EngDokument1 SeiteVka Round EngAnonymous MbqTZHLNR9Noch keine Bewertungen

- Amb X 24 3 T SDokument2 SeitenAmb X 24 3 T SAnonymous MbqTZHLNR9Noch keine Bewertungen

- MN6120A1002Dokument8 SeitenMN6120A1002jacinto lopez casteNoch keine Bewertungen

- Belimo Actuator Cross Reference GuideDokument8 SeitenBelimo Actuator Cross Reference GuideAnonymous MbqTZHLNR9Noch keine Bewertungen

- RegelgeraeteDokument626 SeitenRegelgeraeteAnonymous MbqTZHLNR9Noch keine Bewertungen

- Shutter: For Round DuctsDokument1 SeiteShutter: For Round DuctsAnonymous MbqTZHLNR9Noch keine Bewertungen

- K179. Unipolar Steppermotor Driver: Five, Six or Eight Wires. Five-Wire Motors Have The TwoDokument2 SeitenK179. Unipolar Steppermotor Driver: Five, Six or Eight Wires. Five-Wire Motors Have The TwoducchungNoch keine Bewertungen

- Determining Mosfet Driver Need For Motor Drive ApplicationDokument18 SeitenDetermining Mosfet Driver Need For Motor Drive ApplicationfayazkadirNoch keine Bewertungen

- StepperDokument36 SeitenSteppermangyanNoch keine Bewertungen

- K 113Dokument6 SeitenK 113Anonymous MbqTZHLNR9Noch keine Bewertungen

- K179. Unipolar Steppermotor Driver: Five, Six or Eight Wires. Five-Wire Motors Have The TwoDokument2 SeitenK179. Unipolar Steppermotor Driver: Five, Six or Eight Wires. Five-Wire Motors Have The TwoducchungNoch keine Bewertungen

- M4350E K 080414-WebDokument183 SeitenM4350E K 080414-WebAnonymous MbqTZHLNR9Noch keine Bewertungen

- The Solar Panels Are Operating at Optimal Parameters When They Are at The Perfect Right Angle To The SunDokument8 SeitenThe Solar Panels Are Operating at Optimal Parameters When They Are at The Perfect Right Angle To The SunAnonymous MbqTZHLNR9Noch keine Bewertungen

- Catalogo General TeleH ESPDokument156 SeitenCatalogo General TeleH ESPAnonymous MbqTZHLNR9Noch keine Bewertungen

- Ebook Allenbradleybasics1Dokument137 SeitenEbook Allenbradleybasics1Sabir BhatiNoch keine Bewertungen

- Solar TrackerDokument1 SeiteSolar TrackerAnonymous MbqTZHLNR9Noch keine Bewertungen

- MBR2045CT-D 2 PDFDokument8 SeitenMBR2045CT-D 2 PDFtassawarNoch keine Bewertungen

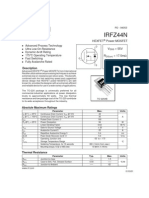

- Irfz 44 NDokument9 SeitenIrfz 44 Nmadhuvariar100% (6)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument17 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768vvvNoch keine Bewertungen

- Example: Item1 Item2 Item3 Item4 Item5 Alice 5 3 4 4 User1 3 1 2 3 3 User2 4 3 4 3 5 User3 3 3 1 5 4 User4 1 5 5 2 1Dokument6 SeitenExample: Item1 Item2 Item3 Item4 Item5 Alice 5 3 4 4 User1 3 1 2 3 3 User2 4 3 4 3 5 User3 3 3 1 5 4 User4 1 5 5 2 1Rajasekhar ReddyNoch keine Bewertungen

- Petrel 2013 Installation GuideDokument86 SeitenPetrel 2013 Installation GuideFebriana Fiona RizkyNoch keine Bewertungen

- Sagiv Nissan CVDokument2 SeitenSagiv Nissan CVSagiv NissanNoch keine Bewertungen

- AVR 3kVA 220VCA DatasheetDokument2 SeitenAVR 3kVA 220VCA DatasheetdulcesinestesiaNoch keine Bewertungen

- Coveo For Sitecore Project Guide Version 2 PDFDokument54 SeitenCoveo For Sitecore Project Guide Version 2 PDFmaldonado.ogNoch keine Bewertungen

- SDI - 128 - Standard Steel Doors and FramesDokument4 SeitenSDI - 128 - Standard Steel Doors and FramesIsang BertingNoch keine Bewertungen

- 574 Danthanh Asm2 Gbd18485Dokument29 Seiten574 Danthanh Asm2 Gbd18485Huynh Ngoc Hai Dang (FGW DN)Noch keine Bewertungen

- B Msgs Server PDFDokument806 SeitenB Msgs Server PDFsabkhNoch keine Bewertungen

- e-StatementBRImo 459501040308532 May2023 20230615 102222Dokument3 Seitene-StatementBRImo 459501040308532 May2023 20230615 102222Donni AdvNoch keine Bewertungen

- 31 SDMS 12Dokument31 Seiten31 SDMS 12Jalizco RuedaNoch keine Bewertungen

- What Is The Difference Between 0.2 and 0.2S Class CTDokument5 SeitenWhat Is The Difference Between 0.2 and 0.2S Class CTshaik abdulaleemNoch keine Bewertungen

- Sppa D3000Dokument20 SeitenSppa D3000Shahab AhmadaniNoch keine Bewertungen

- Professional SummaryDokument3 SeitenProfessional SummaryVijay LS SolutionsNoch keine Bewertungen

- Electronic Bill PaymentDokument2 SeitenElectronic Bill PaymentHeikkiNoch keine Bewertungen

- MongoDB TCO Comparison MongoDB OracleDokument12 SeitenMongoDB TCO Comparison MongoDB Oracleowen liuNoch keine Bewertungen

- Prep4Sure: Real Exam & Prep4Sureexam Is For Well Preparation of It ExamDokument8 SeitenPrep4Sure: Real Exam & Prep4Sureexam Is For Well Preparation of It ExamneeloufershaikNoch keine Bewertungen

- EM 2 Unit 2Dokument16 SeitenEM 2 Unit 2KeerthiSaha100% (1)

- Abbreviation Derivation of AbbreviationDokument37 SeitenAbbreviation Derivation of AbbreviationFawad Ali Sher KhanNoch keine Bewertungen

- Energy Systems TDT HD3 User ManualDokument24 SeitenEnergy Systems TDT HD3 User ManualTrickyDicky2Noch keine Bewertungen

- HI-1573, HI-1574: MIL-STD-1553 3.3V Monolithic Dual TransceiversDokument11 SeitenHI-1573, HI-1574: MIL-STD-1553 3.3V Monolithic Dual TransceiverscetibegizNoch keine Bewertungen

- ITM Mining Sept 2017Dokument8 SeitenITM Mining Sept 2017Mclaren Woro100% (1)

- Authentication GuideDokument60 SeitenAuthentication GuideCon CacNoch keine Bewertungen

- Bharat Sanchar Nigam Limited: Office of The Executive Engineer (Civil) BSNL Civil Division, Imphal - 795001, ManipurDokument47 SeitenBharat Sanchar Nigam Limited: Office of The Executive Engineer (Civil) BSNL Civil Division, Imphal - 795001, Manipurvivekananda sharmaNoch keine Bewertungen

- LAB3.2 - Connecting Windows Host Over iSCSI With MPIODokument13 SeitenLAB3.2 - Connecting Windows Host Over iSCSI With MPIOwendy yohanesNoch keine Bewertungen

- Phy 104 Lab ReportDokument6 SeitenPhy 104 Lab ReportMd. Abdullah ZishanNoch keine Bewertungen

- B06 HydroProfiler-M eDokument2 SeitenB06 HydroProfiler-M eJamjamNoch keine Bewertungen

- Automatic Memory Management (AMM) On 11g & 12cDokument9 SeitenAutomatic Memory Management (AMM) On 11g & 12cejgonzalezpNoch keine Bewertungen

- OneAC1300 UPS Battery For ACE ChemistryDokument75 SeitenOneAC1300 UPS Battery For ACE ChemistryAmanda WardNoch keine Bewertungen

- 04098159Dokument3 Seiten04098159Murali GolveNoch keine Bewertungen