Beruflich Dokumente

Kultur Dokumente

Doors, Windows and Stairs

Hochgeladen von

prashmceOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Doors, Windows and Stairs

Hochgeladen von

prashmceCopyright:

Verfügbare Formate

Building Materials and Construction

6. DOORS, WINDOWS AND STAIRS

Doors and Windows

A door may be defined as a framework of wood, steel, aluminum, glass or a combination of these

materials secured in an opening left in a wall for the purposes of providing access to the users.

The function of a door is to give access to building and to different parts of the building and to

deny the access whenever necessary. Number of doors should be minimum possible. The size of

the door should be of such dimension as will facilitate the movement of the largest object likely

to use the doors.

A window may be defined as an opening made in a wall for the purpose of providing day light,

vision and ventilation. Windows must also provide insulation against heat loss, and in some

cases, against sound. The construction of window is identical to that of door. Window consists of

a window frame and shutter.

Location of doors and windows

1. The number of doors in a room should be kept minimum.

2. Doors should preferably be placed in the corner of the room.

3. If there are two doors in a room, the doors should preferably be located in opposite walls.

4. The size and number of windows should be decided after due consideration to

distribution of light, ventilation and privacy of the occupants.

5. The location of a window should also meet the functional requirements of the room, such

as interior decoration, arrangement of furniture, etc.

6. The windows should be located opposite to each other as far as possible.

7. The windows should be located in the prevalent wind direction.

8. The windows sill should be located about 70 to 80 cm above the floor level of the room.

Size of doors and windows

The size of door depends on the requirement of the room and its size. In general, the size of door

should be such that it would allow the free movement of the large object or tallest person likely

to use the door. The height of the door should not be less than 1.8 m in any case. The width of the

door would be 0.4 to 0.6 times the height of the door.

The following sizes of doors are normally adopted for various types of buildings:

Residential Buildings

Internal doors: 0.9 m X 2.1 m

External doors: 1.0 m X 2.1 m

WC and bathrooms: 0.75 m X 2.1 m

Garages: 2.5 m X 2.25 m

Public Buildings

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 1

Building Materials and Construction

1.2 m X 2.1 m

1.2 m X 2.25 m

The size of windows would be governed by the total area of window space needed. The

following criteria should be kept in mind while designing the windows:

1. Width of window: 1/8 (width of room + height of room)

2. There should be one square metre of window space for every 30 to 40 m3 of inside

content of the room.

3. The area of windows opening should be at least 15% of the floor area of the room.

Technical terms

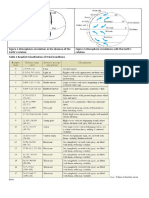

Figs. 1 and 2 show respectively a door and a window. The following are the technical terms

applied to doors and windows:

1. Frame: It is an assembly of horizontal and vertical members, forming an enclosure, to

which the shutters are fixed.

2. Shutters: These are the openable parts of a door or window. It is an assembly of styles,

panels and rails.

3. Head: This is the top or uppermost horizontal part of a frame.

4. Sill: This is the lowermost or bottom horizontal part of a window frame. Sills are

normally not provided in door frames.

5. Horn: These are the horizontal projections of the head and sill of a frame to facilitate the

fixing of the frame on the wall opening. The length of horns is kept about 10 to 15 cm.

6. Style: Style is the vertical outside member of the shutter of a door or window.

7. Top rail: This is the top most horizontal member of a shutter.

8. Lock rail: This is the middle horizontal member of a door shutter, to which locking

arrangement is fixed.

9. Bottom rail: This is the lowermost horizontal member of a shutter.

10. Intermediate or cross-rails: These are additional horizontal rails, fixed between the top

and bottom rails of a shutter. A rail fixed between the top rail and lock rail is called frieze

rail.

11. Panel: This is the area of shutter enclosed between the adjacent rails.

12. Mullion: This is a vertical member of a frame, which is employed to sub-divide a

window or a door vertically.

13. Transom: This is a horizontal member of a frame, which is employed to sub-divide a

window opening horizontally.

14. Hold fasts: These are mild steel flats (section 30mm X 6mm), generally bent into Zshape, to fix or hold the frame to the opening. The horizontal length of hold fast is kept

about 20cm, and is embedded in the masonry.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 2

Building Materials and Construction

15. Jamb: This is the vertical wall face of an opening which supports the frame.

16. Reveal: It is the external jamb of a door or window opening at right angles to the wall

face.

17. Rebate: It is depression or recess made inside the door frame, to receive the door shutter.

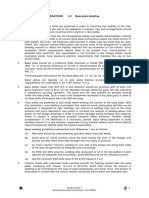

Types of Doors

Various types of doors are in use which may be classified on the basis of arrangement of shutters,

method of constructions, principles of working operations and materials used. Commonly used

doors are briefly explained below:

1. Battened and Ledged Doors: Battens are 100 mm to 150 mm wide and 20 mm thick

wooden boards. Their length is that of door opening. The battens are connected by horizontal

planks, known as ledges of size 100 to 200 mm wide and 30 mm thick. Usually three ledges

are used one at top, one at bottom and the third one at mid-height. This is the simplest form

of door and the cheapest also. Battens are secured by tongued and grooved joint.

2. Battened, Ledged and Braced Doors: If doors are wide apart from using battens and ledges

diagonal members, known as braces, are provided to strengthen the door. Figure shows a

typical battened, ledged and braced door. Sometimes above two types of shutters are

provided within wooden frame work and in those cases they may be called as battened,

ledges and framed doors.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 3

Building Materials and Construction

Fig.: Battened and Ledged Doors

Fig.: Battened, Ledged and Braced Doors

Fig.: Framed and Panelled Doors

3. Framed and Panelled Doors: This type of door consists of vertical members, called styles

and horizontal members called rails. The styles and rails are suitably grooved to receive

panels. The panels may be of wood, A.C. sheet, glasses etc. The panels may be flat or of

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 4

Building Materials and Construction

raised type to get good appearance. These are very commonly used doors. They may be of

single shutter or of double shutter. Figure shows few types of panelled doors. If glass panels

are used they may be called as glazed doors.

4. Flush Doors: The shutters of these doors are made of plywood or block boards. They are of

uniform thickness. These shutters are available with different attractive vineer finishes. The

time consumed in making such doors at site is quite less. These doors are suitable for interior

portion of a building. Nowadays flush doors are commonly used in residential and office

buildings. Figure shows typical flush door.

5. Louvered Doors: Whenever privacy as well as ventilation is required such doors can be

used. Louvers are the glass, wooden or A.C. sheet strips fixed in the frame of shutter such

that they prevent vision but permit free passage of air. The doors may be fully or partially

louvered. Such doors are commonly used for public bathrooms and latrines.

Fig.: Flush Doors

Fig.: Louvered Doors

Fig.: Revolving Doors

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 5

Building Materials and Construction

6. Revolving Doors: It consists of a centrally placed pivot to which four radiating shutters are

attached. The central pivot is supported on ball bearing at the bottom and has a bush bearing

at the top. The shutters may be partly or fully made up of glass. A circular space of entrance

is provided within which shutters rotate. As shutters rotate they give entrance on one side and

exit on other side. These doors are preferred in public buildings like stores, banks, hotels,

theatres where continuous use of doors is necessary. They are very much required in entrance

to air conditioned public buildings. Figure shows a typical revolving door.

Fig.: Plan of Swing Door

Fig.: Plan of Sliding Door

7. Swing Doors: Swing door has its shutter attached to the frame by means of double action

springs. Hence shutter can move both inward and outward. They may be single shuttered or

double shuttered. Such doors are preferred in offices and banks. Since these doors can open

on both sides it is desirable to provide glass panels or peep holes to enable user to see the

persons from other side.

8. Sliding Doors: In this type of doors, shutter slides on the sides. For this purpose runners and

guide rails are provided. Sliding shutters may be one, two or even three. Such doors are used

in banks, offices etc. The arrangement of such shutters in plan is shown in Fig. 8.28.

9. Collapsible Doors: Steel channels 16 to 20 mm wide are used as verticals. They are placed

with 12 to 20 mm gap. Steel flats 16 mm to 20 mm wide and 5 mm thick are hinged to them

as shown in Fig. The rollers are provided at their top as well as at bottom so that shutter can

be pulled or pushed sideways with slight force. There may be single or double shutters.

Usually these doors are used for additional safety. They are commonly used for front doors,

bank locker rooms, and school and college entrance doors.

10. Rolling Shutters: Figure shows a typical rolling shutter door. It consists of a frame, a drum

and a shutter made of thin steel plates. The width of the door may vary from 2 to 3 m. The

shutter moves on steel guides provided on sides and can easily roll up. For this

counterbalancing is made with helical springs on the drum. The shutter can be easily pulled

down. This type of doors is commonly used as additional doors to shops, offices, banks,

factory, and buildings from the point of safety.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 6

Building Materials and Construction

Fig.: Collapsible steel Door

Fig.: Rolling Shutter

Types of windows

Various windows used may be classified on the basis of materials used, types of shutters, types of

openings of shutters and the position of windows.

1.

2.

3.

4.

5.

6.

7.

8.

Fixed windows.

Pivoted windows.

Double hung windows.

Sliding windows.

Casement windows.

Glazed windows.

Louvered windows.

Metal windows.

9. Bay windows.

10. Clere-storey windows.

11. Corner windows.

12. Dormer windows.

13. Gable windows.

14. Lantern windows.

15. Skylights.

1. Fixed windows: In such type of windows the glazed shutter is permanently fixed in the

windows frame. This type of window is provided when light and vision is only needed in the

room. No ventilation is possible through such windows.

2. Pivoted windows: In these windows, the shutters are allowed to rotate about the pivots fixed

to the windows frame. The windows frame has no rebate. The shutter can rotate

horizontally or vertically depending on the position of pivot.

3. Double hung windows: This type of window mainly consists of a frame and two shutters

arranged one above the other, which can move vertically upward or downward by means of

cords passing over pulleys and are connected by corner weights at other ends by open at top

or bottom to the desired extent by pulling the weights suitably. Ventilation can be easily

controlled by these windows.

4. Casement windows: It is an ordinary window, which is commonly used in residential as

well as in public buildings. The shutters of the window open like shutters of the doors. The

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 7

Building Materials and Construction

window has a frame and shutters consist of styles, top rail, bottom rail, intermediate rails,

vertical and horizontal sash bars with glass panels. The panels may be glazed or partly

glazed.

5. Sliding windows: This type of window consists of sliding shutters which move on roller

bearing and can slide either horizontally or vertically. These windows are similar to sliding

doors. Such windows are provided in trains, buses, shops, bank counters etc.

Fixed windows

Double hung windows

Pivoted windows

Wooden casement windows

6. Glazed windows: This type of windows consists of shutters in which panels are fully glazed.

The frame of each shutter has two vertical styles, top rail and bottom rail. The panel space

between the styles and the rails is suitably divided by small wooden members placed

horizontally and vertically to suit the requirements. These bars are known as sash bars or

glazing bars. The sash bars have rebates to receive glass panels. The glass panels are secured

in position either by putty or timber beads and nails. If the window opening is large, the

window frame may have mullions and transome. These are also called as sash windows.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 8

Building Materials and Construction

7. Louvered windows: In this type of window the styles of shutter are grooved to receive the

louvers. The louvers are generally fixed but sometimes, the louvers can be raised and

lowered by means of some operating devices. For economical construction the angle of

inclination of louvers to the vertical styles should be 45 0. The louvers slope downward to the

outside in order to run-off the rainwater. Sometimes venetian shutters are provided in which

louvers are pivoted to the frame at both ends and every louver is connected by a small hinge

to a vertical batten. When the batten is pulled up or down, the gap between the louvers are

opened or closed. These types of windows are commonly used for bathrooms, water closets,

workshops and other places where privacy is main consideration. Sometimes this window is

also known as venetianed window.

Glazed windows

Louvered windows

8. Metal windows: Use of metal windows is becoming very popular these days. They are used

in residential as well as in public buildings. They are strong and cheap also. These windows

are made from metals like mild steel, aluminum, bronze, stainless steel etc. Mild steel being

cheapest of all the metals, hence steel window work out to be most economical. Mild steel

sections are used for fabrication of these windows. They are available in wide range of

standard sizes. The commonly used sections are angle sections, Z-sections, T-sections and

channel sections. These windows are directly fixed in the masonry opening in the wall or it

may be fixed into wooden frame already fitted in the window opening in the wall. Bronze,

aluminum and stainless steel are considered to be the best metals for windows construction.

9. Bay windows: A window projecting outward from the walls of room is known as bay

window. This projection may be triangular, circular, rectangular or polygonal in plan. These

windows provided an increased area of opening for the admission of light and ventilation.

They also provide extra space in the room and improve overall appearance of the building.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 9

Building Materials and Construction

Metal windows

Bay windows

10. Clere-storey windows: These windows are provided near the top of the main roof for the

purpose of light and ventilation. The location of such windows are above the verandah roof,

hence these are termed as clere-storey windows. These windows also improve the appearance

of the building. The window shutter is horizontally pivoted and the window can be opened or

closed by use of two cords, one attached to the top rail and other to the bottom rail of the

shutter. To prevent the entry of rainwater in the room, it is however important that the upper

part of the shutter opens inside and the lower part opens outside.

11. Corner windows: These windows are located in the corner of the room. Corner window has

two faces at right angles. Due to this, it is possible to admit light and air from two directions.

In addition, it also improves the architectural view of the building.

12. Dormer windows: It is the vertical window built in the sloping side of a pitched roof. It

provides proper ventilation and light for enclosed space below the roof. It also improves the

appearance of the building.

13. Gable windows: The window provided at the gable end of a pitched roof is termed as gable

window.

14. Lantern windows: These windows are provided over the flat roofs to ensure more light and

air to the inner of a building. These windows project above the roof level. They admit light

from vertical faces or inclined faces. They have many shapes in plan.

15. Skylights: A skylight is provided on the sloping side of a pitched roof. The window projects

above the top sloping surface. The window being parallel to the sloping surface. The skylight

is provided to admit natural light to the room below of it. The opening for skylight is made

by cutting the common rafters suitably. The framework of skylight supporting the glass

panels consists of trimming pieces, curb frame, bottom rail and top rail. The opening so made

is properly treated by lead flushing to make the roof surrounding of openings waterproof.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 10

Building Materials and Construction

Clere-storey Window

Corner Window

Dormer and Gable Window

Ventilators: These are openings in the walls near the roof for the purpose of light and exit of

foul gases. The shutter of the ventilator is horizontally pivoted and can be opened or closed by

use of two cards, one attached to its top rail and other to the bottom rail. The top edge of the

shutter opens inside and the bottom edge opens outside so as to prevent the entry of rainwater in

the room.

Door with ventilator

Window with ventilator

Window with ventilator

Fixtures and Fastenings

The fixtures and fastenings of doors and windows can be if iron, brass or aluminum. They are

made in different shapes and sizes to suit the requirements of different sizes and types of doors

and windows. The following types of fixtures and fastenings are required for doors, windows and

ventilators:

1. Hinges.

2. Handles.

3. Bolts.

4. Locks.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 11

Building Materials and Construction

Various Fixtures and Fastenings

Stairs

A structure placed between two floors that have a series of steps that allows you to move up or

down freely to different level. Stairs give access from floor to floor. The space/room housing

stairs is called staircase. Stairs consists of a number of steps arranged in a single flight or more

number of flights.

Technical terms

The definitions of some technical terms, which are used in connection with design of stairs, are

given.

Step: It is a portion of a stair which permits ascent and descent. It is comprised of tread and

riser.

Tread: It is the upper horizontal projection of a step in a stair case is called tread. It is also

known as going.

Riser: Vertical portion of a step providing a support to the tread.

Rise: Vertical distance between two consecutive treads.

String: The support to the side of the stair that holds the treads and risers in place.

Waist: The thickness of the structural slab in case of an RCC stair is known as a waist.

Soffit: The bottom surface of a stair slab.

Flight: A series of steps without any platform, break or landing in their direction.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 12

Building Materials and Construction

Landing: It is a horizontal slab provided between two flights. It allows the climber to rest

before climbing again in the same direction or provides a safe place to turn and continue

climbing the stair.

Nosing: The front edge of the tread usually rounded as a safety measure and now often in a

different finish or material so we can define the front edge of the treads making it easier to

see them, climb the stair and they often have a nonslip nosing to reduce accidents.

Baluster: The vertical member of wood or metal supporting the handrail.

Handrail: A continuous rail on top of the balustrade to aid the stair user in climbing and

descending the stair.

Balustrade or barrister: The combined framework of handrail and balusters.

Newel Post: This is the vertical member which is placed at the ends of flights to connect

handrail.

Winders: These are tapering steps which are provided for changing the direction of a stair.

Scotia: It is a moulding provided under the nosing to improve the elevation of the step.

Headroom: It is the minimum clear vertical distance between the tread and ceiling.

Line of nosing: It is an imaginary line touching of each tread and is parallel to the slope of

the stair.

Pitch or slope: It is the angle which the line of nosing of the stair makes with the

horizontal.

Strings or stringers: These are the sloping members which support the steps in a stair.

They run along the slope of the stair.

Location of stairs

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 13

Building Materials and Construction

The stairs should be located so as to provide easy access to the occupants of the building. The

stairs should well-lighted and well-ventilated and must have convenient and spacious

approaches. In case of public buildings, the stair should be located near the main entrance and in

case of residential buildings, the stair should be centrally located so as to have access from all the

rooms without disturbing the privacy of rooms. In case of big buildings, there may be more than

one stair.

Requirements of good stairs

a) Width: The width of stair should be sufficient for two persons to pass on it

simultaneously and for furniture, etc. to be carried up and down the stair. The minimum

width of a stair is taken as about 800 mm. If the width of stair exceeds 1.80 m, it is

desirable to provide a central handrail. Minimum width is 0.9 m in residential buildings

and 1.5 m to 2.5 m in public buildings.

b) Number of Steps in a Flight: Maximum number of steps in a flight should be limited to

12 to 14, while minimum is 3. Suitable landings should be provided to give comfort and

safety to the users of the stair.

c) Rise and tread: Rise and tread provided should be uniform. In residential buildings the

rise must not be more than 230 mm and going of less 230 mm while in public buildings

rise must not be more than 180 mm and a going of not less than 270 mm. The wider the

going, the less should be the riser and greater the rise, the less should be the going.

d) Handrails: Handrails should be provided at a convenient height of a normal person

which is from 800 mm to 900 mm. When a flight consists of more than three steps, a

handrail at least on one side is considered a necessity. The wide stairs should be provided

with handrails on both the sides. Very wide stairs, as required for public buildings, should

be provided with a central handrail.

e) Pitch: The inclination of a stair to the horizontal should be limited to 300 to 450.

f) Headroom: The provision of adequate headroom is a necessity in a good stair. It should

preferably not less than 2 m.

g) Materials and workmanship: The stair should be constructed of sound materials and

good workmanship so as to impart durability and strength to the stair. The stairway

provides a path by which fire can spread from one floor to another and hence the fire

protection of the staircases is extremely important. The materials used for the linings of

walls and ceiling of staircase should be non-combustible and of low flame spread.

Types of stairs

The stairs may be built with wood, concrete masonry or with cast iron. Wooden stairs are not

safe, because of the danger of fire. However, they are used in unimportant buildings to access to

small areas in the upper floors. Cast iron or steel stairs in the spiral forms were used commonly

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 14

Building Materials and Construction

to reduce stair case area. In many residential buildings masonry stairs are also used. Reinforced

concrete stairs are very commonly used in all types of buildings.

Based on the shapes stairs may be classified as:

(a) Straight stairs

(b) Dog legged stairs

(c) Well or open-newel stairs

(d) Geometrical stairs

(e) Spiral stairs

(f) Turning stairs.

Straight Stairs: If the space available for stair case is narrow and long, straight stairs may be

provided. Such stairs are commonly used to give access to porch or as emergency exits to cinema

halls. In this type all steps are in one direction. They may be provided in single flight or in two

flights with landing between the two flights.

Straight stairs

Dog Legged Stairs: It consists of two straight flights with 180 turn between the two. They are

very commonly used to give access from floor to floor. Figure shows the arrangement of steps in

such stairs.

Well or Open-newel Stairs: It differs from dog legged stairs such that in this case there is 0.15

m to 1.0 m gap between the two adjacent flights. Figure shows a typical open newel stair.

Dog legged stairs

Compiled by Dr. Prashanth J. and Dr. Harish N.

Open well (newel) stairs

Page 15

Building Materials and Construction

Geometrical Stairs: This type of stair is similar to the open newel stair except that well formed

between the two adjacent flights is curved. The hand rail provided is continuous.

Geometrical stairs

Spiral or Helical Stairs: These stairs are commonly used as emergency exits. It consists of a

central post supporting a series of steps arranged in the form of a spiral. At the end of steps

continuous hand rail is provided. Such stairs are provided where space available for stairs is very

much limited. Figure shows a typical spiral stair. Cast iron, steel or R.C.C. is used for building

these stairs.

Turning Stairs: Apart from dog legged and open newel type turns, stairs may turn in various

forms. They depend upon the available space for stairs. Quarter turned, half turned with few

steps in between and bifurcated stairs are some of such turned stairs. Figure shows a bifurcated

stair.

Spiral stairs

Bifurcated stairs

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 16

Building Materials and Construction

Fixing of rise and tread

The height of the floor is generally known. The procedure for determining the number of treads

and risers is as follows:

a. The position of first and last risers is determined with regard to the positions of doors,

windows, verandahs etc.

b. A convenient height for the riser is assumed.

c. Number of risers = total height of floor / height of riser.

d. Number of treads in a flight = number of treads 1.

This is due to the fact that the surface of the upper floor forms the tread for the top step.

Example: Let us suppose assume that the height of floor is 3.5 m. Assuming a riser of 140 mm,

No. of risers = 3.5 / 0.14 = 25

No. of treads for stair with single flight = (25 1) = 24

No. of treads for stair with double flight = (25 2) = 23

Depending upon the space available for staircase, the type of stair is selected.

Compiled by Dr. Prashanth J. and Dr. Harish N.

Page 17

Das könnte Ihnen auch gefallen

- CHAPTER-6 Doors and WindowsDokument6 SeitenCHAPTER-6 Doors and WindowsPratik GhimireNoch keine Bewertungen

- Determination of Filed Density of Soil by Core Cutter MethodDokument2 SeitenDetermination of Filed Density of Soil by Core Cutter MethodAkash SahuNoch keine Bewertungen

- Assignment 1Dokument32 SeitenAssignment 1sharifah atiqahNoch keine Bewertungen

- Open Ended - Cantilever TrussDokument13 SeitenOpen Ended - Cantilever TrussIkhwan Z.100% (1)

- FUTURE STRUCTURAL ENGINEER - Where Will We Be in 10 Years - Structural Engineering Art and ApproximationDokument11 SeitenFUTURE STRUCTURAL ENGINEER - Where Will We Be in 10 Years - Structural Engineering Art and Approximationvrb126Noch keine Bewertungen

- PWD Project ReportDokument20 SeitenPWD Project ReportSandeep PatelNoch keine Bewertungen

- AggregateDokument19 SeitenAggregateAMITaXWINoch keine Bewertungen

- Brick Bonds: by Engr. Shahzeb AdilDokument24 SeitenBrick Bonds: by Engr. Shahzeb Adilshahzeb adilNoch keine Bewertungen

- Portal Framesportal FramesDokument28 SeitenPortal Framesportal Frameslolorek2100% (1)

- Split Tensile TestDokument5 SeitenSplit Tensile Testarijitdey6Noch keine Bewertungen

- Prestress Steel TrussDokument6 SeitenPrestress Steel Trusskapinjal_Noch keine Bewertungen

- Chapter 3 Plane TrussDokument15 SeitenChapter 3 Plane TrussKishan PurohitNoch keine Bewertungen

- Abstract UneditedDokument7 SeitenAbstract UneditedRavi Teja SrikaramNoch keine Bewertungen

- Flakiness IndexDokument15 SeitenFlakiness IndexLuqman YusofNoch keine Bewertungen

- Undisturbed Soil SamplingDokument13 SeitenUndisturbed Soil SamplingFazil Bn NazerNoch keine Bewertungen

- Flat Slab - Types of Flat Slab Design and Its AdvantagesDokument7 SeitenFlat Slab - Types of Flat Slab Design and Its AdvantagesnandanaNoch keine Bewertungen

- 14 - FS AHM JRP CMV - EXPANSION - JOINT - TREATMENT - 9 2 2014 Libre PDFDokument15 Seiten14 - FS AHM JRP CMV - EXPANSION - JOINT - TREATMENT - 9 2 2014 Libre PDFMAHAK GUPTANoch keine Bewertungen

- Skid ResistanceDokument5 SeitenSkid ResistanceFiaz GujjarNoch keine Bewertungen

- Approved by AICTIE, New Delhi & Affiliated by BTER, Jodhpur (Raj)Dokument33 SeitenApproved by AICTIE, New Delhi & Affiliated by BTER, Jodhpur (Raj)Jay KothariNoch keine Bewertungen

- Folder BridgeDokument44 SeitenFolder BridgeLuis_DelgadoNoch keine Bewertungen

- Types of Cracks in WallsDokument9 SeitenTypes of Cracks in Wallsswapnil gandhiNoch keine Bewertungen

- Bridge Design 4 - Design of SuperstructuresDokument12 SeitenBridge Design 4 - Design of SuperstructuresgabemzamanNoch keine Bewertungen

- Methodology For Prevention and Repair of Cracks in BuildingDokument7 SeitenMethodology For Prevention and Repair of Cracks in BuildingGRD JournalsNoch keine Bewertungen

- Civil Mini Project DivyaKamathDokument63 SeitenCivil Mini Project DivyaKamathJanaki Vamaraju100% (1)

- Test 1 - Concrete Mix Design DishanDokument20 SeitenTest 1 - Concrete Mix Design DishanYasndra AbeygunewardhaneNoch keine Bewertungen

- GATE 2009 Answer Keys Civil EngineeringDokument1 SeiteGATE 2009 Answer Keys Civil EngineeringAnonymous cQ13WWeNoch keine Bewertungen

- Stabilization of Black Cotton Soil With Marble DustDokument4 SeitenStabilization of Black Cotton Soil With Marble DustIJRASETPublications100% (1)

- Report On LintelDokument13 SeitenReport On LintelTandin Tshewang100% (1)

- PREFABRICATED REINFORCEMENT HANDBOOK Lowres PDFDokument98 SeitenPREFABRICATED REINFORCEMENT HANDBOOK Lowres PDFLuan Truong VanNoch keine Bewertungen

- Repair Procedures Durai MaruthuDokument17 SeitenRepair Procedures Durai MaruthurexdindigulNoch keine Bewertungen

- IS 2185 (Part 3) 1984Dokument18 SeitenIS 2185 (Part 3) 1984Nagaraju ChintaNoch keine Bewertungen

- Chapter 2 Design For ServiceabilityDokument29 SeitenChapter 2 Design For ServiceabilityJoena Linda100% (1)

- Structure of Hydrated Cement PasteDokument11 SeitenStructure of Hydrated Cement PasteAli Ismael100% (1)

- AJEL2013 Notes (202201)Dokument109 SeitenAJEL2013 Notes (202201)JckyNoch keine Bewertungen

- Report Format For DiplomaUGPG&PhDDokument12 SeitenReport Format For DiplomaUGPG&PhDSwapnil ToraskarNoch keine Bewertungen

- Steel Construction - New Development & ChalengesDokument62 SeitenSteel Construction - New Development & ChalengesNIBEDITA DEYNoch keine Bewertungen

- Control Distortion During Design StageDokument5 SeitenControl Distortion During Design StagebalamuruganNoch keine Bewertungen

- Projek Rekabentuk Walkwaybridge 2014 - 15Dokument6 SeitenProjek Rekabentuk Walkwaybridge 2014 - 15HambaliNoch keine Bewertungen

- Failure of Retaining Wall - Case StudyDokument4 SeitenFailure of Retaining Wall - Case StudyRaghavNoch keine Bewertungen

- GroutingDokument15 SeitenGroutingDev Thakkar100% (1)

- Introduction To Steel DesignDokument18 SeitenIntroduction To Steel DesignMuhammad Azuan Tukiar100% (1)

- The Study of MineralsDokument16 SeitenThe Study of MineralsTyler CoffmanNoch keine Bewertungen

- Falling Head Permeability Test Lab ManualDokument3 SeitenFalling Head Permeability Test Lab Manualmm0% (1)

- Chapter 2aDokument30 SeitenChapter 2aSyazwi Hakimi0% (1)

- Site InvestigationDokument7 SeitenSite InvestigationManinder PalNoch keine Bewertungen

- Full Math MicrosoftDokument23 SeitenFull Math MicrosoftajakprotelaNoch keine Bewertungen

- Transportation Engineering LAB MANUALDokument73 SeitenTransportation Engineering LAB MANUALVishwanath B JNoch keine Bewertungen

- Chapter 7 - Destructive and Non Destructive Testing of MaterialDokument33 SeitenChapter 7 - Destructive and Non Destructive Testing of MaterialzainonayraNoch keine Bewertungen

- Concrete CalculationDokument10 SeitenConcrete CalculationKaye Ibañez CastilloNoch keine Bewertungen

- Building Materials and Construction 15CV36: Doors, Windows and VentilatorsDokument22 SeitenBuilding Materials and Construction 15CV36: Doors, Windows and VentilatorsAnonymous Qm0zbNkNoch keine Bewertungen

- Part 1 Module 3.3Dokument4 SeitenPart 1 Module 3.3Sujata SarkarNoch keine Bewertungen

- Door and Window Chapter 5Dokument31 SeitenDoor and Window Chapter 5Devesh KumarNoch keine Bewertungen

- DoorsDokument4 SeitenDoorsapi-115852884Noch keine Bewertungen

- Chapter 8Dokument27 SeitenChapter 8sealedbytheholyspiritforeverNoch keine Bewertungen

- Tag Archives:: Doors and WindowsDokument13 SeitenTag Archives:: Doors and WindowsTichafara NyahundaNoch keine Bewertungen

- Types of Doors Used in Building ConstructionDokument16 SeitenTypes of Doors Used in Building ConstructionpowerpuffNoch keine Bewertungen

- Doors & WondowsDokument11 SeitenDoors & WondowsCh-47JDZNoch keine Bewertungen

- What Is Door and Types of DoorDokument9 SeitenWhat Is Door and Types of Doorjibola harbeebNoch keine Bewertungen

- Chapter 5.4 - Doors and Windows Part 1Dokument17 SeitenChapter 5.4 - Doors and Windows Part 1Hussen MohammedNoch keine Bewertungen

- Ocean Sciences JournalsDokument2 SeitenOcean Sciences JournalsprashmceNoch keine Bewertungen

- Student Quick Guide To GCDokument14 SeitenStudent Quick Guide To GCNurazlina Aziz100% (1)

- Tests On Fine AggregateDokument6 SeitenTests On Fine AggregateprashmceNoch keine Bewertungen

- CBR TestDokument3 SeitenCBR TestprashmceNoch keine Bewertungen

- Durability TestsDokument2 SeitenDurability TestsprashmceNoch keine Bewertungen

- CCS (Leave) RulesDokument53 SeitenCCS (Leave) Rulespoojasikka196380% (5)

- Data Download: Landsat and IrsDokument5 SeitenData Download: Landsat and IrsprashmceNoch keine Bewertungen

- AssignmentDokument1 SeiteAssignmentprashmceNoch keine Bewertungen

- Civil Engineering Material TestingDokument8 SeitenCivil Engineering Material TestingprashmceNoch keine Bewertungen

- Lect 03 00Dokument12 SeitenLect 03 00amr_scorpion_engNoch keine Bewertungen

- HandoutDokument1 SeiteHandoutprashmceNoch keine Bewertungen

- Strain EnergyDokument34 SeitenStrain EnergyprashmceNoch keine Bewertungen

- Coastal EngineeringDokument9 SeitenCoastal EngineeringprashmceNoch keine Bewertungen

- Settling Tank ExamplesDokument8 SeitenSettling Tank ExamplesprashmceNoch keine Bewertungen

- Fig. LayersDokument8 SeitenFig. LayersprashmceNoch keine Bewertungen

- Clay TilesDokument5 SeitenClay Tilesprashmce100% (1)

- Assignment 1Dokument2 SeitenAssignment 1prashmceNoch keine Bewertungen

- Land DisposalDokument5 SeitenLand DisposalprashmceNoch keine Bewertungen

- Remote Sensing and Geographic Information System 15Dokument1 SeiteRemote Sensing and Geographic Information System 15prashmceNoch keine Bewertungen

- Assignment Environmental ScienceDokument2 SeitenAssignment Environmental ScienceprashmceNoch keine Bewertungen

- Image PreprocessingDokument6 SeitenImage PreprocessingprashmceNoch keine Bewertungen

- Assignment RS & GISDokument1 SeiteAssignment RS & GISprashmceNoch keine Bewertungen

- Image EnhancementDokument23 SeitenImage EnhancementprashmceNoch keine Bewertungen

- Radar Basics - Synthetic Aperture RadarDokument2 SeitenRadar Basics - Synthetic Aperture RadarprashmceNoch keine Bewertungen

- Marine PollutionDokument72 SeitenMarine Pollutionprashmce100% (1)

- Strength of MaterialsDokument186 SeitenStrength of MaterialsprashmceNoch keine Bewertungen

- S.No Topics Page No Emranditsinteractionwithatmosphere&Earth MaterialDokument88 SeitenS.No Topics Page No Emranditsinteractionwithatmosphere&Earth MaterialprashmceNoch keine Bewertungen

- Method ConjugateDokument1 SeiteMethod ConjugateprashmceNoch keine Bewertungen

- Som PDFDokument195 SeitenSom PDFSonu Kumar100% (1)

- Marks Distribution: Class Test + Assignments: 10 Minor Test: 10 Mid-Semester Exam: 30 End-Semester Exam: 50Dokument1 SeiteMarks Distribution: Class Test + Assignments: 10 Minor Test: 10 Mid-Semester Exam: 30 End-Semester Exam: 50prashmceNoch keine Bewertungen

- Draft TheoryDokument890 SeitenDraft Theorymehdi jokarNoch keine Bewertungen

- Important PointsDokument4 SeitenImportant PointsRashid MinhasNoch keine Bewertungen

- 62 017 Dowsil 890 SL Si Joint SealantDokument4 Seiten62 017 Dowsil 890 SL Si Joint SealantScott HendersonNoch keine Bewertungen

- SEDC Course SyllabusDokument3 SeitenSEDC Course SyllabusJosh Cirilo SygacoNoch keine Bewertungen

- Plate Girders With Corrugated Steel Webs PDFDokument13 SeitenPlate Girders With Corrugated Steel Webs PDFMarcelo Albe100% (1)

- Uc Booking W.E.F. 01.01.2019 To 30.09.2019 EE (B) - I-WZDokument18 SeitenUc Booking W.E.F. 01.01.2019 To 30.09.2019 EE (B) - I-WZBALAJI ASSOCIATESNoch keine Bewertungen

- LFD Box Culvert Design and Rating: User'S Manual ForDokument150 SeitenLFD Box Culvert Design and Rating: User'S Manual ForMiguel valdivia rosasNoch keine Bewertungen

- Mechanical EngineeringDokument3 SeitenMechanical EngineeringSumit SharmaNoch keine Bewertungen

- BIRCOsir en 03 2017Dokument58 SeitenBIRCOsir en 03 2017raghebomNoch keine Bewertungen

- FD72 Technical Manual 28.10.09Dokument74 SeitenFD72 Technical Manual 28.10.09cavgsi16vNoch keine Bewertungen

- Material ScienceDokument810 SeitenMaterial ScienceNikhil Batham67% (3)

- Tips and Tricks From Joe Flow: Sample Preparation: Shaken or Stirred?Dokument3 SeitenTips and Tricks From Joe Flow: Sample Preparation: Shaken or Stirred?Dan MihailNoch keine Bewertungen

- Assignment01 PPT57Dokument15 SeitenAssignment01 PPT57Usman AhmedNoch keine Bewertungen

- ESTAR HVACRaterChecklistDokument4 SeitenESTAR HVACRaterChecklistMeshal Al-mutairiNoch keine Bewertungen

- 3 - High Temperature CorrosionDokument35 Seiten3 - High Temperature CorrosiondennykvgNoch keine Bewertungen

- Install, Test, Commission and Handover Solar Thermal Hot WaterDokument18 SeitenInstall, Test, Commission and Handover Solar Thermal Hot WaterNoorul Mufas MnNoch keine Bewertungen

- Sheet Metal FabricationDokument28 SeitenSheet Metal Fabricationsamurai7_770% (2)

- Deflection Calculation of Concrete Floors TN292 PDFDokument38 SeitenDeflection Calculation of Concrete Floors TN292 PDFSheik Mohamed LiakathNoch keine Bewertungen

- MacadamDokument14 SeitenMacadamRakesh7770Noch keine Bewertungen

- EDMDokument5 SeitenEDMNibedit NahakNoch keine Bewertungen

- ACI Design Mix ExampleDokument5 SeitenACI Design Mix Examplejay_medrano_1Noch keine Bewertungen

- Detailing Considerations Design Guide 7 - bk745 PDFDokument5 SeitenDetailing Considerations Design Guide 7 - bk745 PDFFunkNoch keine Bewertungen

- Conveyorchains HITACHIDokument173 SeitenConveyorchains HITACHIReno MurdaNoch keine Bewertungen

- REHAU 20UFH InstallationDokument84 SeitenREHAU 20UFH InstallationngrigoreNoch keine Bewertungen

- Deep Rie of Pyrex Glass, Quartz, PZT (Lead Zirconium Titanate) and Sic (Silicon Carbide) Using Thick Nickel MaskDokument47 SeitenDeep Rie of Pyrex Glass, Quartz, PZT (Lead Zirconium Titanate) and Sic (Silicon Carbide) Using Thick Nickel MaskbhawnaNoch keine Bewertungen

- PipeDokument9 SeitenPipeNghiaNoch keine Bewertungen

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDokument1 SeiteSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNoch keine Bewertungen

- RY EAZ7V1 Databook2Dokument50 SeitenRY EAZ7V1 Databook2felicianoNoch keine Bewertungen

- Portal Frame - Airport Hangar PDFDokument12 SeitenPortal Frame - Airport Hangar PDFShinjini BhattacharjeeNoch keine Bewertungen

- EcogenDokument2 SeitenEcogenBelle CervantesNoch keine Bewertungen