Beruflich Dokumente

Kultur Dokumente

Us 5236286

Hochgeladen von

Herlan Setiawan SihombingCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Us 5236286

Hochgeladen von

Herlan Setiawan SihombingCopyright:

Verfügbare Formate

IlllllllllllllllllllllllllllllllllllllllllIllllllllllllllIlllllllllllllllll

US005236286A

Unlted States Patent [19]

[11] Patent Number:

Prough

[45]

[54]

[75]

HIGH PRESSURE FEEDER SPLIT

4,415,296 11/1923 Funk ................................... .. 406/19

4,416,567 11/1983 Elmore et al.

406/105 X

4,430,029

2/1984

Richter et a1. . . . .

. . . .. 406/63

4,516,887

5/1985

Richter et a1. ...................... .. 406/63

Inventor:

James R. Prough, Glens Falls, NY.

Apr. 15, 1992

[22] Filed:

Int.

Cl.5

....................

.. 8656 53/30; B65G

[51]

53/40;

B65G 53/46

US. Cl. ...................................... .. 406/52; 406/63;

406/105; 406/109

[53]

Field of Search ............................ .. 406/52, 62-64,

406/67, 105, 106, 109, 171, 172, 197

[56]

Aug. 17, 1993

OUTFLOW FOR ENHANCED FEEDER

EFFICIENCY

FOREIGN PATENT DOCUMENTS

[731 Assignee: Kamyr, Inc., Glens Falls, NY.

[211 Appl. No.: 868,347

[52]

Date of Patent:

5,236,286

4/1976

4/1977

4,033,811

7/1977

Gloersen ..

4/1978

Funk .......... ..

4,187,043 2/1980

4,338,049 7/1982

4,354,777 10/1982

Fed. Rep. of Germany ...... .. 406/63

1/1961

Sweden ............................. .. 406/109

Primary Examiner-David M. Mitchell

Assistant Examiner-James M. Kannofsky

Attorney, Agent, or Firm-Nixon & Vanderhye

[57]

ABSTRACT

A high pressure transfer device for feeding wood chips

to a digester in the production of paper pulp has en

hanced efficiency. A rotor having ?rst and second sets

with each set, with a screen at the third port of each set

Funk ............................. .. 406/105 X

Funk et al.

.... .. 406/63 X

4,082,368

1/1978

174094

of through extending conduits is mounted for rotation

in a housing having ?rst through fourth ports associated

References Cited

U.S. PATENT DOCUMENTS

3,950,146

4,017,270

2629209

.... .. 406/62 X

406/105

Kindersley .... .,

406/105

Richter et a1.

.... .. 406/63

Richter et al. ...................... .. 406/63

for screening wood chips out of liquid passing through

that third port. The third port of each set is connected

to its own distinct source of suction, so as to enhance

?lling ef?ciency of the rotor.

20 Claims, 4 Drawing Sheets

US. Patent

Aug. 17, 1993

Sheet 1 of 4

5,236,286

mm

mm

NUhk

NT\

mm

PF5,

Tl1l| .o

9

.m

a...

2

...~

....

.t

9mm

u.__

. o_.mp.n_.~ON.m.

hm].

n.a8

mm

\Uhk

US. Patent

Aug. 17, 1993

Sheet 2 of4

5,236,286

US. Patent

Aug. 17, 1993

Sheet 4 of 4

FIG 5

40/

45

28

5,236,286

5,236,286

HIGH PRESSURE FEEDER SPLIT OUTFLOW FOR

ENHANCED FEEDER EFFICIENCY

BACKGROUND AND SUMMARY OF THE

INVENTION

The high pressure feeder, or transfer device, is one of

the most basic and important components of the Kamyr

continuous pulping system. The high pressure feeder is

used to transfer steamed wood chips in a liquid (typi

cally white liquor) at low pressure to the top of the

continuous digester, at high pressure. A typical high

pressure transfer device comprises a rotor having

through extending pockets disposed in ?rst and second

sets spaced along the axis of rotation of the rotor a

housing, a screen, and high and low pressure pumps.

The rotor pockets each have opposite end openings

which function as both inlets and outlets depending

starting to signi?cantly close. Thus the feeder suction is

throttled. Therefore if the feeder is rotated faster, the

time available to ?ll the feeder goes down, and thus the

high pressure transfer device is forced to run at a lower

?lling ef?ciency than desired to get enough ?ow.

In addition to identifying the source of the relatively

low high pressure transfer device ef?ciency, according

to the present invention the problem has been solved by

providing a distinct source of suction for the third

pocket of each set to suck liquid through the screen

means of that third port so as to enhance the filling

ef?ciencies of the pockets at any given speed of rotation

of the rotor. There are two presently contemplated

5 major ways in which the separate suction sources can

be provided. In a ?rst way, ?rst and second elongated

conduits extend from the separate third ports (the third

port associated with each set), and the conduits are

upon the angular position of the rotor, and the pockets

connected to a common low pressure pump. In a second

of one set (typically two) are offset from those of the

other. The housing encloses the rotor and has an exte

embodiment, the distinct elongated conduits are con

nected to separate pumps. When the conduits are con

nected to separate low pressure pumps, it may be neces

rior periphery with ?rst through fourth ports for each

set disposed around the exterior periphery for registry

with the inlets to and outlets from the pockets. The ?rst

and third ports are opposite, and the second and fourth

ports are opposite, and the ?rst and second ports may be

adjacent in the direction of rotation.

In a conventional high pressure feeder screen means

are disposed in the third port of each set for screening

particles above a predetermined size out of the liquid

passing through the third port, and a single low pressure

sary or desirable to provide a mechanism to prevent

water hammer or pump cavitation. This may be pro

vided by utilizing a cross connection having an ori?ce

therein between the elongated conduits, just before the

low pressure pumps.

The invention also contemplates a method of trans

ferring wood chips in liquid through the high pressure

transfer device to boost the flow rate thereof. That

method includes the conventional steps for feeding

wood chips utilizing a high pressure transfer device, but

ports to provide the suction for sucking liquid through

in which suction is supplied separately to the third port

the third port. A high pressure pump is operatively

connected to the second port to provide the ?ow of 35 of each set, so as to enhance the ?lling ef?ciency of the

liquid under high pressure through the second port.

pockets for a given speed of rotation. This may be ac

Normally the ?rst port is on the top, and the third port

complished by connecting the third ports through elon

pump is connected to a single conduit from the third

on the bottom, the ?rst port connected to the chips

chute, and the fourth port connected to the top of the

digester.

While conventional high pressure feeders have func

tioned very well over the decades they have been in use,

there have been relatively few substantive changes to

the high pressure feeder over time. It has been known

that the ?lling ef?ciency of the high pressure feeder is

gated conduits to a single pump, or to separate low

pressure pumps, with a water hammer preventing con

nection therebetween, as described above.

It is the primary object of the present invention to

provide for enhanced ef?ciency of a conventional high

pressure transfer device, particularly for use in a

45 method of boosting the flow rate of a slurry of wood

chips. This and other objects of the invention will be

approximately 50 to 60% on some chip furnishers that is

come clear from an inspection of the detailed descrip

signi?cantly lower than is desired, but to date no signi?

tion of the invention, and from the appended claims.

cant inroads have been made in substantially increasing

that ef?ciency since the source of the lack of ef?ciency

BRIEF DESCRIPTION OF THE DRAWINGS

50

has not been understood.

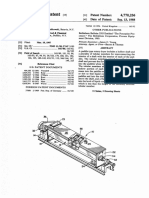

FIG. 1 is a side schematic view illustrating ideal ?ll

To a large extent, the ef?ciency of the high pressure

feeder is dictated by its ability to obtain the chip chute

circulation which carries the chips from the chute into

the pockets of the rotor. The chip chute circulation is

ing of a high pressure feeder pocket;

FIG. 2 is a view like that of FIG. 1 only showing

idea] emptying of the pocket, and illustrating the high

throttled on the suction side of the chip chute circula 55 pressure feeder connected to the top of a continuous

tion pump by the pressure drop across the screen at the

digester;

third port.

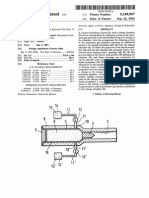

FIG. 3 is a perspective view of a conventional high

According to the present invention, for the ?rst time

pressure feeder;

it is understood why this pressure drop occurs. After

FIG. 4 is an exploded perspective view illustrating

extensive testing, according to the invention it has been 60

certain

parts of the feeder of FIG. 3;

found that as the consecutive pockets open in the differ

ent sets of the rotor, as the chips and liquid are ?owing

into the most open (?rst opened) pocket because it is

connected to the same suction source as the pocket in

FIG. 5 is a schematic side view, partly in cross-sec

tion and partly in elevation, showing a ?rst embodiment

of a mechanism for distinctly separating the suction

the other set that is just opening, there is little pressure 65 sources to the two sets of pockets of the rotor, in accor

dance with the invention; and

to start flow into the second opening pocket. Thus, the

FIG. 6 is a second embodiment of the suction source

second pocket will not really start to effectively ?ll until

separation means according to the invention.

the ?rst pocket has moved to a position where it is

5,236,286

DETAILED DESCRIPTION OF THE

DRAWINGS

shaft 37-connected to a power source for rotating the

rotor 19 and to the rotor itself.

FIGS. 1 and 2 schematically illustrate the operation

of a high pressure transfer device, shown generally by

What has heretofore been described is conventional

for a Kamyr high pressure feed, such as shown in U.S.

Pat. No. 4,187,043. However, according to the inven

. reference numeral 10, according to the present inven

tion. As is conventional, the device 10 is connected to a

improve the ef?ciency of the pocket ?lling operations.

chip chute 11, which is supplied with steamed chips

from a conventional steaming vessel, the chips being

slurried with liquid from line 12. The chute 11 is con

nected up to a ?rst port 13 of a housing 14. The housing

14 also has a second port 15, a third port 16, and a fourth

port 17, disposed at approximately 90 intervals in the

direction of rotation 18 (the direction of rotation is not

particularly important and could either be in the direc

tion 18, or opposite thereto) of a pocketed, tapered,

rotor 19 disposed within the housing 14. The rotor 19

has ?rst and second sets of through extending pockets

(see FIG. 4), and the housing has a port (or port seg

ment) associated with each set.

Connected up to the second port 15 is means for

supplying high pressure liquid, typically the high pres

sure pump 20. As illustrated in FIG. 2, the pump 20

tion various changes are made to the feeder 10 so as to

As illustrated in FIG. 5, means 40 provide a distinct

suction source 44 for the third port of each set of pock

ets 21, 21' so that liquid is sucked through the screen

means 29, when a pocket 21, 21' is rotated into operative

association with the third port 16 of each set, so as to

enhance ?lling ef?ciencies of the pockets 21, 21' at any

given speed of rotation of the rotor 19. In the embodi

ment illustrated in FIG. 5 the means for providing dis

tinct suction sources comprises ?rst and second elon

gated conduits 41, 42, which are separately connected

to the port (or port segment) 16 at one end thereof. For

the speci?c embodiment of FIG. 5, the opposite ends of

the conduits 41, 42 are provided as connectors 44 which

join in a common connection 45 which in turn is con

nected to a single low pressure pump 28 having an

outlet conduit 12 therefrom.

FIG. 6 illustrates a different embodiment 50 of means

provides liquid under high pressure so that when the 25 for providing a distinct suction source for each of the

port 15 is in communication with a pocket 21 within the

ports 16. In the FIG. 6 embodiment, elongated conduits

rotor 19 the chips or like cellulosic ?brous material

within the pocket 21 are flushed out the fourth port 17

into the top circulation line 22 associated with a con

ventional continuous digester 23. The line 22 feeds the

chips in liquid under pressure to the top 24 of the di

gester 23. At the top 24 a conventional solids/liquid

separator is provided, which returns some of the liquid

slurrying the chips in the line 22, via the conduit 25,

51, 52 are connected at the tops thereof to the port 16

just as in the FIG. 5 embodiment, but at the bottoms

thereof are connected to two different low pressure

pumps, 28 and 54. In the embodiment illustrated in FIG.

6, the discharge conduits 55 from the pumps 28, 54

merge in the common conduit 12 which recirculates the

withdrawn liquid to the chip chute 11. In this embodi

ment, there is the possibility that there could be cavita

which is ultimately connected to the inlet to the pump 35 tion of the pump or water hammer if a conduit 51, 52

goes essentially dry during the rotation of the rotor 19

which includes steam condensate and sometimes black

to a position where a pocket 21 or 21' does not commu

liquor, and which may be supplemented from the make

nicate with a pump 28, 54 for a particular length of time.

up line 26. For non-kraft situations, the liquid in lines 22,

In order to avoid that possibility the means 58 are pro

25 could be water, solvent pulping liquid, etc.

vided, which preferably may comprise a cross-conduit

Connected to the third port 16, and providing a suc

59 connected between the elongated conduits 51, 52,

20. The liquid in lines 22, 25 typically is white liquor,

tion thereto, is a line 27 connected to a low pressure

preferably just above the pumps 28, 54, with an ori?ce

pump 28, the pump 28 in turn being connected to the

60 in the conduit 59. In this way, if a pocket 21 is in

line 12 to supply slurrying liquid to the chip chute 11.

communication with the conduit 51, liquid is pumped

Mounted within the housing 14 at the third port 16 of 45 therethrough by the pump 48, but the conduit 52 is

each set is a screen, one of the two screens shown gener

blocked off from communication with a pocket 21

and-if it starts to become dry -enough liquid will

ally by reference numeral 29. As seen in FIG. '1, the

?ow from conduit 51 through the ori?ce 60 to the pump

screens 29 allow liquid to pass into the conduit 27 under

the in?uence of the suction of pump 28, while the chips

54 to prevent cavitation or water hammer.

Utilizing the invention, there always will be a sub

or like cellulosic ?brous material cannot pass through 50

stantial force on the slurried chips tending to pull them

the screen 29 and, therefore, remain in pocket 21 in

into an open pocket 21, 21', even if the pocket has just

rotor 19. In a conventional device 10 a single line 27 and

started to open. Thus the rotor 19 can be rotated at a

single pump 28 are provided, supplying suction to both

higher speed than conventional and still have accept

sets of pockets of the rotor 19.

FIG. 4 illustrates the rotor 19, which is tapered from 55 able ?lling ef?ciency, or if rotated at conventional

a ?rst end 31 thereof to the second end 32. The rotor 31

speed will have a higher ?lling ef?ciency.

includes a plurality of (e.g. four) diametrically through

going pockets 21, 21'. Typically two pockets 21 are

While the invention has been herein shown and de

scribed in what is presently conceived to be the most

disposed in a ?rst set, and two pockets 21' in a second

practical and preferred embodiment, it will be apparent

set, the sets spaced along the axis of rotation, and the 60 to those of ordinary skill in the art that many modi?ca~

tions may be made thereof within the scope of the in

pockets of one set are offset with respect to the pockets

vention, which scope is to be accorded the broadest

of the other.

interpretation of the appended claims so as to encom

As seen in FIG. 3, a plug clearance adjustment mech

pass all equivalent structures and procedures.

anism 33 can be provided for adjusting the tapered rotor

19 within the housing 14, and the housing 14 may be 65 What is claimed is:

1. A high pressure transfer device for transferring a

provided with a plurality of other conventional compo

slurry containing particles, a vast majority of which are

nents such as a bell housing equalization line 34, a white

above a ?rst size, said device comprising:

liquor purge connection 35, a preheat header 36, and a

5,236,286

having diametrically through extending pockets, dis

posed in ?rst and second sets corresponding to said ?rst

and second sets of said ports, with opposite open ends of

said pockets serving as a pocket inlet or outlet depend

ing upon an arcuate position of the rotor, said method

end openings which function as both inlets and

outlets depending upon the angular position of the

rotor and said pockets are provided in at least ?rst

and second sets, with the pockets in each set offset

from the pockets in the at least one other set;

comprising the steps of continuously:

(b) a housing enclosing said rotor, said housing hav

ing an exterior periphery and ?rst through fourth

ports disposed around the exterior periphery

thereof for registry with the inlets to and outlets

from said through going pockets, for each set; for

each set said ?rst port being opposite said third

port, and said second port opposite said fourth

Port;

ing for rotation in the ?rst direction about an axis, and

(a) a pocketed rotor containing a plurality of through

going pockets, said rotor rotatable about a given

axis of rotation and said pockets having opposite

15

(c) means for mounting said rotor in said housing for

rotation with respect to said ports about said given

(a) rotating the rotor in the ?rst direction about its

axis of rotation;,

(b) feeding said chips in liquid to the ?rst port of each

set;

(0) applying suction to the third port of each set;

(d) screening the liquid passing from one of said pock

ets through the third port of its corresponding set

of ports to remove chips of greater size than said

?rst size from the liquid so that the chips remain in

the pocket and do not pass through the third port;

and

axis of rotation, and in a ?rst direction;

(d) screen means disposed in said third port of each

(e) supplying liquid under high pressure to the second

set, for screening particles above said size out of the 20

liquid passing through said third port;

port, so that when said pocket is in communication

with the second and fourth ports of its correspond

(e) means for providing respective distinct suction

ing set of ports the high pressure liquid forces the

chips in the pocket out of the pocket and through

sources to a respective to said third port of each set

to suck liquid through said screen means when one

wherein step (c is practiced by supplying respective

of said pockets is rotated into operative association

with said third port of that set, so as to enhance

the fourth port; and

25

?lling efficiencies of said pockets at any given

speed of rotation of said rotor; and

separate sources of suction to a respective said

third port of each set, so as to enhance the ?lling

efficiency of the pockets for a given speed of rota

tion.

14. A method as recited in claim 13 wherein step (c)

(t) a high pressure pump connected to said second

ports.

is further practiced by connecting the third port of each

2. A device as recited in claim 1 wherein said means

set to respective separate elongated conduits connected

for providing comprises respective elongated conduits

to a common pump.

extending one from each of said third ports, and con

15. A method as recited in claim 13 wherein step (c)

nected to a common pump.

is further practiced by connecting the third port of each

3. A device as recited in claim 2 wherein said pocket

set to respective distinct elongated conduits with there

sets consist of said ?rst andsecond sets.

35 own respective distinct pumps.

4. A device as recited in claim 2 wherein each set

16. A method as recited in claim 15 comprising the

comprises two through extending pockets.

further step of connecting the elongated conduits to

5. A device as recited in claim 4 wherein said pocket

sets consist of said ?rst and second sets.

6. A device as recited in claim 1 wherein said means

gether to prevent water hammer and pump cavitation.

17. A method as recited in claim 16 wherein said

conduit connection step is practiced by providing a

for providing comprises respective elongated conduits

cross conduit with an ori?ce therein between the elon

and respective distinct pumps connected to each of said

gated conduits.

third ports.

7. A device as recited in claim 6 wherein said pocket

sets consist of said ?rst and second sets.

8. A device as recited in claim 6 wherein each set 45

comprises two through extending pockets.

9. A device as recited in claim 8 wherein said pocket

sets consist of said ?rst and second sets.

with the pockets of each set;

means for mounting said rotor in said housing for

rotation with respect to said ports about said given

vent water hammer and pump cavitation.

11. A device as recited in claim 10 wherein said elon

axis of rotation;

gated conduits are parallel, and wherein said connection

comprises an orifice in a cross conduit between said

12. A device as recited in claim 10 further comprising

a common discharge conduit from said distinct pumps,

said common discharge conduit connected to the sec

ond port of all of said at least ?rst and second sets.

13. A method of transferring wood chips in liquid

through a transfer device to boost the flow rate thereof,

a vast majority of said wood chips being greater than, a

?rst size, using said transfer device which has a housing

with ?rst an second sets of ?rst through fourth ports

approximately equally spaced around the circumfer

ets disposed in a ?rst set and four through going

pockets in a second set, and rotatable about an axis;

a housing enclosing said rotor, said housing having an

exterior periphery and ?rst through fourth ports

disposed around the exterior periphery for registry

10. A device as recited in claim 6 further comprising

a connection between said elongated conduits to pre

elongated conduits.

18. A high pressure transfer device comprising

a pocketed rotor containing four through going pock

55

a screen disposed in said third port of each set; and

a ?rst elongated conduit extending from said third

port of said ?rst set, and a second elongated con

duit from said ?rst conduit, extending from said

third port of said second set, said elongated con

duits ultimately being connected to said ?rst ports

of said housing.

19. A device as recited in claim 18 wherein said ?rst

and second elongated conduits are connected to a com

mon pump.

20. A device as recited in claim 18 wherein said ?rst

and second elongated conduits are each connected to

ence thereof, the ?rst and third ports of each set being 65 respective separate pumps, and further comprising a

connection between said elongated conduits to prevent

opposite, and the second and fourth ports of each set

water hammer and cavitation of said pumps.

being opposite, the ports extending in sequence in a ?rst

*

$

$

t

direction of rotation, and a rotor mounted in the hous

Das könnte Ihnen auch gefallen

- Storytown Extra Support Copying Masters Grade 3Dokument176 SeitenStorytown Extra Support Copying Masters Grade 3Bernard Chan0% (1)

- Whelan Associates Inc Vs Jaslow Dental LabDokument2 SeitenWhelan Associates Inc Vs Jaslow Dental Labjuli100% (1)

- Foss & Gaul PDFDokument17 SeitenFoss & Gaul PDFnicolasbelliniNoch keine Bewertungen

- Ducted Prop For STOL PaperDokument8 SeitenDucted Prop For STOL PaperLEADANoch keine Bewertungen

- MKII Hordes Forces Skorne PDFDokument115 SeitenMKII Hordes Forces Skorne PDFleotardnimoy100% (1)

- Astm-D 5748-95 PDFDokument4 SeitenAstm-D 5748-95 PDFcalidadcdokepNoch keine Bewertungen

- United States Patent (19) (11) Patent Number: 5,236,285: Prough (45) Date of Patent: Aug. 17, 1993Dokument9 SeitenUnited States Patent (19) (11) Patent Number: 5,236,285: Prough (45) Date of Patent: Aug. 17, 1993Herlan Setiawan SihombingNoch keine Bewertungen

- 20080012322-Vortex Flow ControlDokument10 Seiten20080012322-Vortex Flow Controlozland9Noch keine Bewertungen

- United States Patent: Attorney-Pastoriza and KellyDokument4 SeitenUnited States Patent: Attorney-Pastoriza and KellyEnrico FermiNoch keine Bewertungen

- Login Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationDokument8 SeitenLogin Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationFilipNoch keine Bewertungen

- TEPZZ 6798 A - T: European Patent ApplicationDokument28 SeitenTEPZZ 6798 A - T: European Patent ApplicationVictor Von DoomNoch keine Bewertungen

- Filed March 20, 1943Dokument8 SeitenFiled March 20, 1943Andrés RamírezNoch keine Bewertungen

- Centrifugal CompressorDokument7 SeitenCentrifugal Compressorrohan112358Noch keine Bewertungen

- Multiple Downcomer Fractional Distillation Tray and ProcessDokument9 SeitenMultiple Downcomer Fractional Distillation Tray and Processziz37Noch keine Bewertungen

- United States Patent: She?ield (10) Patent N0.: (45) Date of PatentDokument8 SeitenUnited States Patent: She?ield (10) Patent N0.: (45) Date of PatentSiva SubramaniyanNoch keine Bewertungen

- United States PatentDokument5 SeitenUnited States PatentPraveen SinghNoch keine Bewertungen

- US3782337Dokument7 SeitenUS3782337Mustafa Umut SaracNoch keine Bewertungen

- United States Patent 119) : Burroughs Et A1Dokument9 SeitenUnited States Patent 119) : Burroughs Et A1asdfasfNoch keine Bewertungen

- Us 3407511Dokument5 SeitenUs 3407511AhmadmartakNoch keine Bewertungen

- Catatan Bab 1 (1.5-1.10)Dokument12 SeitenCatatan Bab 1 (1.5-1.10)Aulia RamadhanNoch keine Bewertungen

- On Isothermal Flow of Viscous Liquids Thorugh Screw PumpsDokument218 SeitenOn Isothermal Flow of Viscous Liquids Thorugh Screw PumpsRicardo BarrosNoch keine Bewertungen

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Dokument5 SeitenJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNoch keine Bewertungen

- EP0335343A2Dokument6 SeitenEP0335343A2gauravjuyal1988Noch keine Bewertungen

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Dokument13 Seiten(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNoch keine Bewertungen

- United States Patent (19) : Hailey (11) Patent Number: 4,618,314 (45) - Date of Patent: Oct. 21, 1986Dokument12 SeitenUnited States Patent (19) : Hailey (11) Patent Number: 4,618,314 (45) - Date of Patent: Oct. 21, 1986KrozeNoch keine Bewertungen

- RFT - Essentials of Pressure Test InterpretationDokument66 SeitenRFT - Essentials of Pressure Test InterpretationRoni Hepson Tambun100% (2)

- Positive Displacement Pump VibrationDokument5 SeitenPositive Displacement Pump Vibrationdeddy asNoch keine Bewertungen

- 1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpDokument7 Seiten1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpRenier SnymanNoch keine Bewertungen

- Pumps and Pumping Stations: 3.2.1 Q-H CurveDokument10 SeitenPumps and Pumping Stations: 3.2.1 Q-H CurveOlanrewaju OlawaleNoch keine Bewertungen

- Flowing Well PerformanceDokument57 SeitenFlowing Well PerformanceTogoumas Djide100% (4)

- Flowing Well PerformanceDokument57 SeitenFlowing Well PerformancemkwendeNoch keine Bewertungen

- Design PatentDokument6 SeitenDesign PatentSuresh JNoch keine Bewertungen

- Patente Columna York - ScheibelDokument6 SeitenPatente Columna York - Scheibeligor1991Noch keine Bewertungen

- Plunger Fall Velocity Model 164495lDokument16 SeitenPlunger Fall Velocity Model 164495lJonathan AvilaNoch keine Bewertungen

- United States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Dokument8 SeitenUnited States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Stanislas AchardNoch keine Bewertungen

- Load AcDokument31 SeitenLoad AcSathiya KumarNoch keine Bewertungen

- May 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecDokument16 SeitenMay 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecluiscremaschiNoch keine Bewertungen

- Us 3690255Dokument5 SeitenUs 3690255wewewewNoch keine Bewertungen

- Jan-1, 1935 - R. G. de La Mater Er Al 1,985,889Dokument8 SeitenJan-1, 1935 - R. G. de La Mater Er Al 1,985,889lfilippiniNoch keine Bewertungen

- Us 3378330Dokument5 SeitenUs 3378330James LindonNoch keine Bewertungen

- BYY "So: June 7, 1966 M, A Brown 3,254,776Dokument7 SeitenBYY "So: June 7, 1966 M, A Brown 3,254,776Yu YangNoch keine Bewertungen

- Ulllted States Patent (10) Patent N0.: US 7,674,380 B2Dokument16 SeitenUlllted States Patent (10) Patent N0.: US 7,674,380 B2mutazsalihNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1Dokument14 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1zbhdzpNoch keine Bewertungen

- Enter Your Search Here: Liquid Ring Pump Lobe PurgeDokument4 SeitenEnter Your Search Here: Liquid Ring Pump Lobe PurgeNARAYANA RAO PUPPALANoch keine Bewertungen

- Hydraulic Bench and Accessories: (Unit Operations Laboratory)Dokument27 SeitenHydraulic Bench and Accessories: (Unit Operations Laboratory)Angeline Paguirigan DionicioNoch keine Bewertungen

- Bubble Cap Tray Assignment: CE 428 Spring 2003Dokument11 SeitenBubble Cap Tray Assignment: CE 428 Spring 2003Thọ NguyễnNoch keine Bewertungen

- Dual Displacement Production System: 1 I I I IDokument4 SeitenDual Displacement Production System: 1 I I I IRichard More LeonNoch keine Bewertungen

- Surge Pressure Prediction For Running LinersDokument13 SeitenSurge Pressure Prediction For Running LinersPegasus Vertex, Inc.100% (1)

- Performance Thermo CompressorsDokument8 SeitenPerformance Thermo CompressorsclintoncNoch keine Bewertungen

- Accelertion Head PDFDokument5 SeitenAccelertion Head PDFEng AlfNoch keine Bewertungen

- US6390148 Valvula de LlenadoDokument8 SeitenUS6390148 Valvula de LlenadoFreddy SalinasNoch keine Bewertungen

- United States PatentDokument7 SeitenUnited States PatentDouglas TondelloNoch keine Bewertungen

- Us 2409624Dokument6 SeitenUs 2409624Giovanni BlancoNoch keine Bewertungen

- Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208Dokument9 SeitenViii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208mohammadreza91Noch keine Bewertungen

- Us 5149907Dokument7 SeitenUs 5149907wewewewNoch keine Bewertungen

- Mod 4 DRLG BasicsDokument26 SeitenMod 4 DRLG BasicsMin Thant MaungNoch keine Bewertungen

- Scientific American Supplement, No. 787, January 31, 1891Von EverandScientific American Supplement, No. 787, January 31, 1891Noch keine Bewertungen

- Scientific American Supplement, No. 481, March 21, 1885Von EverandScientific American Supplement, No. 481, March 21, 1885Noch keine Bewertungen

- Scientific American Supplement, No. 388, June 9, 1883Von EverandScientific American Supplement, No. 388, June 9, 1883Noch keine Bewertungen

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshVon EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNoch keine Bewertungen

- Scientific American Supplement, No. 446, July 19, 1884Von EverandScientific American Supplement, No. 446, July 19, 1884Noch keine Bewertungen

- Vacuum Unit Design For High Metals CrudesDokument10 SeitenVacuum Unit Design For High Metals CrudesHerlan Setiawan SihombingNoch keine Bewertungen

- Buku Panduan Pabrik Kelapa Sawit Skala Kecil Untuk Produksi Bahan Baku ...Dokument47 SeitenBuku Panduan Pabrik Kelapa Sawit Skala Kecil Untuk Produksi Bahan Baku ...daud68100% (2)

- Panteion University, Greece: T.panagiotidis@lboro - Ac.ukDokument18 SeitenPanteion University, Greece: T.panagiotidis@lboro - Ac.ukHerlan Setiawan SihombingNoch keine Bewertungen

- Panteion University, Greece: T.panagiotidis@lboro - Ac.ukDokument18 SeitenPanteion University, Greece: T.panagiotidis@lboro - Ac.ukHerlan Setiawan SihombingNoch keine Bewertungen

- 401 3790 1 PBDokument8 Seiten401 3790 1 PBHerlan Setiawan SihombingNoch keine Bewertungen

- 1 Jurnal Zainuri 1-17Dokument18 Seiten1 Jurnal Zainuri 1-17Eka Tri RahayuNoch keine Bewertungen

- Modifikasi Persamaan Hidrograf Satuan Sintetis Metoda Scs Dimensionless Terhadap Hidrograf Satuan Observasi Das Ciliwung HuluDokument8 SeitenModifikasi Persamaan Hidrograf Satuan Sintetis Metoda Scs Dimensionless Terhadap Hidrograf Satuan Observasi Das Ciliwung HuluHerlan Setiawan SihombingNoch keine Bewertungen

- Digital Testing Test EconomicsDokument17 SeitenDigital Testing Test EconomicsHerlan Setiawan SihombingNoch keine Bewertungen

- Jis G3101-2010 en PDFDokument14 SeitenJis G3101-2010 en PDFabdulloh_99Noch keine Bewertungen

- New Inventions: Bell and The TelephoneDokument4 SeitenNew Inventions: Bell and The TelephoneBrennan ReidNoch keine Bewertungen

- ANSYS Mechanical APDL Programmer's Manual - Release 14 PDFDokument350 SeitenANSYS Mechanical APDL Programmer's Manual - Release 14 PDFprasetyoNoch keine Bewertungen

- English Prep Class-2Dokument35 SeitenEnglish Prep Class-2Ankith SaleemNoch keine Bewertungen

- Subject:Cylinder Head Installation Procedure StandardizedDokument4 SeitenSubject:Cylinder Head Installation Procedure StandardizedEwrys Redondo PerezNoch keine Bewertungen

- GST 101 Lecture 0 Getting To Know FOSS and FOSS4GDokument26 SeitenGST 101 Lecture 0 Getting To Know FOSS and FOSS4GVeronica PetreNoch keine Bewertungen

- E Intraverbal Subtest v.6.0Dokument4 SeitenE Intraverbal Subtest v.6.0Mikaelly RibeiroNoch keine Bewertungen

- Web Development Agreement: - (" Client - DeveloperDokument5 SeitenWeb Development Agreement: - (" Client - Developerkak DilanNoch keine Bewertungen

- Autoscribe Et. Al. v. Merchants Credit Guide CompanyDokument5 SeitenAutoscribe Et. Al. v. Merchants Credit Guide CompanyPriorSmartNoch keine Bewertungen

- Astm D7226 (Viscosidad Dinámica Por Paletas)Dokument4 SeitenAstm D7226 (Viscosidad Dinámica Por Paletas)Santiago Molina Huertas100% (2)

- Vaisala DM70 DatasheetDokument2 SeitenVaisala DM70 Datasheetpetr kubicekNoch keine Bewertungen

- Comparing My Character TraitsDokument1 SeiteComparing My Character TraitsYana StvolovayaNoch keine Bewertungen

- Plexiglas Gs/Plexiglas XT: Product DescriptionDokument8 SeitenPlexiglas Gs/Plexiglas XT: Product DescriptioniarghiroiuNoch keine Bewertungen

- Cluck U Trademark Complaint PDFDokument33 SeitenCluck U Trademark Complaint PDFMark JaffeNoch keine Bewertungen

- OpenSource LicenseDokument11 SeitenOpenSource Licensemohamed Abo-EwishaNoch keine Bewertungen

- Basic Analysis Zh 基本分析Dokument338 SeitenBasic Analysis Zh 基本分析1105195794Noch keine Bewertungen

- Dixon Bayco Dry Bulk 2014 - OptimizedDokument44 SeitenDixon Bayco Dry Bulk 2014 - OptimizedKentNoch keine Bewertungen

- C1364-Standard Speci Cation For Cast StoneDokument3 SeitenC1364-Standard Speci Cation For Cast StoneBrinder DhanoaNoch keine Bewertungen

- Inventors and Inventions. 9 FormDokument12 SeitenInventors and Inventions. 9 Formolga.zvyagintseva85Noch keine Bewertungen

- Percentage of Number Worksheet: Calculate The PercentagesDokument2 SeitenPercentage of Number Worksheet: Calculate The PercentagesMonica ViverosNoch keine Bewertungen

- Full Download Crime and Criminal Justice Concepts and Controversies 1st Edition Mallicoat Test BankDokument6 SeitenFull Download Crime and Criminal Justice Concepts and Controversies 1st Edition Mallicoat Test Bankevelynrockafellowfx100% (37)

- SIMB-A21 Startup ManualDokument6 SeitenSIMB-A21 Startup ManualnguyenhuansNoch keine Bewertungen

- De Bello Gallico PDFDokument342 SeitenDe Bello Gallico PDFLaurzęNoch keine Bewertungen

- PWX 910hf5 (CDC) Guidefor (I5os) enDokument124 SeitenPWX 910hf5 (CDC) Guidefor (I5os) encongkuNoch keine Bewertungen

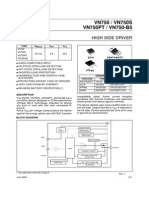

- VN750 / VN750S VN750PT / VN750-B5: High Side DriverDokument31 SeitenVN750 / VN750S VN750PT / VN750-B5: High Side DriverDan EsentherNoch keine Bewertungen

- United States Patent (10) Patent No.: US 8,961,451 B2Dokument37 SeitenUnited States Patent (10) Patent No.: US 8,961,451 B2Widiya Nur FatinahNoch keine Bewertungen