Beruflich Dokumente

Kultur Dokumente

An Experimental Study On Bubble Deck Slab System With Elliptical Balls

Hochgeladen von

rohithOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

An Experimental Study On Bubble Deck Slab System With Elliptical Balls

Hochgeladen von

rohithCopyright:

Verfügbare Formate

Proceeding of NCRIET-2015 & Indian J.Sci.Res.

12(1):021-027, 2015

ISSN: 0976-2876 (Print)

ISSN: 2250-0138 (Online)

AN EXPERIMENTAL STUDY ON BUBBLE DECK SLAB SYSTEM WITH

ELLIPTICAL BALLS

ARATI SHETKARa1 AND NAGESH HANCHEb

a

Engineering Student, Department of Civil Engineering, Affiliated to AICTE Recognized Institution, India

Research Scholar & AP, Department of Civil Engineering, Affiliated to UGC Recognized Institution, India

ABSTRACT

Bubble Deck is a revolutionary method of virtually eliminating concrete from the middle of conventional slab

which does not perform any structural function, thereby dramatically reducing structural dead weight by linking air and

steel directly. Bubble Deck slab uses hollow spherical or elliptical balls made by recycled plastic. A Bubble Deck slab has

a two-dimensional arrangement of voids within the slabs to reduce self-weight. The behaviour of Bubble Deck slabs is

influenced by the ratio of bubble diameter to slab thickness. This new prefabricated construction technology is recently

applied in many industrial projects in the world. This shows the effectiveness and feasibility of the application of Bubble

Deck in the construction. Voids in the middle of a flat slab eliminate 35% of a slabs self-weight removing constraints of

high dead loads and short spans. Combination of recycled plastic bubbles permits 50% longer spans between columns

without any beams. This provides a wide range of cost and construction benefits. Usually the Bubble Deck system

combines the benefits of factory-manufactured elements in controlled conditions along with on-site completion with the

final monolithic concrete, resulting in a completed floor slab. This paper presents a study on the properties and

advantages of Bubble Deck slab system.

KEYWORDS: Bubble Deck Slab System, Filigree Element, Hollow Spherical Balls, Hollow Elliptical Balls, Deck,

etc.

In building constructions, the slab is a very

important structural member to make a space. And

the slab is one of the largest member consuming

concrete. Bubble Deck is the invention of Jorgen

Bruenig in 1990s, who developed the first biaxial

hollow slab (now known as Bubble Deck) in

Denmark. This new prefabricated construction

technology using Bubble Deck slab is recently

applied in many industrial projects in the world.

Bubble Deck slab uses hollow balls made by recycled

plastic and therefore it is an innovatory method of

virtually eliminating the concrete part in the middle

of conventional slab which does not contribute to the

structural performance. This hence reduces

significantly the structural self-weight and also leads

to 30 to 50% lighter slab which reduces the loads on

the columns, walls and foundations, and of course of

the entire building. Bubble Deck uses less concrete

than traditional concrete floor systems; it offers a

more sustainable construction option, contributes less

CO2 to the atmosphere in the manufacturing process

and also meets sustainability goals through the use of

recycled plastic spheres. The spheres could be

recycled even after the building is demolished or

renovated in the future. The dead air space in the

hollow spheres provides insulating value and can be

introduced with foam for additional energy

efficiency. Therefore, the Bubble Deck has many

advantages as compared to traditional concrete slab,

such as: lower total cost, reduced material use,

enhanced

structural

efficiency,

decreased

construction time, and is a green technology. The

reinforcements are placed as two meshes one at the

bottom part and one at the upper part that can be tied

or welded. The distance between the bars are kept

corresponding to the dimensions of the bubbles that

are to be embodied and the quantity of the

reinforcement from the longitudinal and the

transversal ribs of the slab. The two-way concrete

slab system was developed in Denmark and was first

used in Holland. It became an integral part of the

Millennium Tower which was built to celebrate the

new millennium. Now, the Bubble Deck technology

gains much of attention from engineers and

researchers from the world [Amer M 2013].

MATERIALS AND PROPERTIES

The following materials are used in Bubble

Deck slab construction:

Hollow bubbles

The bubbles (Fig.1) are made using high

density polypropylene materials. These are usually

made with nonporous material that does not react

Corresponding author

Organized by Department of E&CE, Bheemanna Khandrre Institute of Technology Bhalki, Bidar, India

SHETKAR AND HANCHE: AN EXPERIMENTAL STUDY ON BUBBLE DECK SLAB SYSTEM WITH

chemically with the concrete or reinforcement bars.

The bubbles have enough strength and stiffness to

support safely the applied loads in the phases before

and during concrete pouring. Bubble diameter varies

between 180mm to 450mm. Depending on this; the

slab depth is 230mm to 600mm. The distance

between bubbles must be greater than 1/9th of bubble

diameter. The nominal diameter of the gaps may be

of: 180, 225, 270, 315 or 360 mm. The bubbles may

be of spherical or ellipsoidal in shape.

are to be used and the quantity of reinforcement from

transverse ribs of the slab.

THE EXPERIMENTAL PROGRAM

In order to investigate the behaviors of

Bubble Deck using traditional spherical balls, the

experimental program were carried out at Laboratory

of Full-Scale Structural Testing.

Bubble Deck Samples

Advanced engineering of the Bubble Deck

system comprises a hollow flat slab, into which

recycled plastic ball void formers are in

incorporated to eliminate concrete that does not

contribute to the structural performance of a slab. The

plastic balls have dimensions and shapes as follows:

hollow elliptical balls with diameter 240mm and

height 180mm as shown in Figure 2. Front View and

Side View.

Fig.1 Hollow spheircal and elliptical

bubbles

Concrete

The concrete used for joint filling in the

Bubble Deck floor system must be above class 20/25.

Usually self-compacting concrete is used, either for

the casting of prefabricated filigree slab, or for the

joint filling on the site. Self compacting concrete can

be poured into forms, flow around congested areas of

reinforcement and into tight sections, allow air to

escape and resist segregation. The nominal maximum

size of the aggregate is the function of thickness of

the slab. The size should be less than15mm. M30

Grade and above should be used.

Front view

Reinforcement bars

The reinforcement of the plates is made of

two meshes, one at the bottom part and one at the

upper part that can be tied or welded. The steel is

fabricated in two forms - the meshed layers for lateral

support and diagonal girders for vertical support of

the bubbles. The distance between the bars are

corresponding to the dimensions of the bubbles that

Side view

Organized by Department of E&CE, Bheemanna Khandrre Institute of Technology Bhalki, Bidar, India

SHETKAR AND HANCHE: AN EXPERIMENTAL STUDY ON BUBBLE DECK SLAB SYSTEM WITH

Figure 2: Shape and Dimension of Plastic Balls

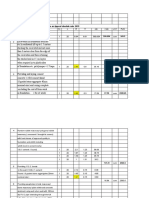

There are total 5 Bubble Deck samples

named as A.BD.2, A.BD.3, A.BD.4, B.BD.2 and

B.BD.3.

sample A.BD4 has been provided the links and other

samples do not have links. Figure 3 demonstrates the

plan view and sections of modified Bubble Deck

using hollow elliptical balls. There have total 18

elliptical balls for 1 Bubble Deck sample. The

reinforcing rebar at the top and bottom layers is 248

and the concrete cover is 25mm. Figure 4 shows the

actual Bubble Deck samples in the laboratory[A.N

Prakash 2011].

All samples have the same dimension of

1900x800x230 mm. The notations A and B denote

for the concrete strength B25 and B35, respectively.

Table 1 depicts the dimension and notation of Bubble

Deck samples. It should be mentioned that only the

Table 1: Dimension and Notation of Bubble Deck Samples

Figure 3: Modified Bubble Deck A.BD.3 v/s B.BD.3

Organized by Department of E&CE, Bheemanna Khandrre Institute of Technology Bhalki, Bidar, India

SHETKAR AND HANCHE: AN EXPERIMENTAL STUDY ON BUBBLE DECK SLAB SYSTEM WITH

Figure 4: Bubble Deck Samples

Experimental procedure

Figure 5 gives the modeling and

actualization of experimental setup. The Bubble Deck

samples are simply supported by two steel beams

1200x200x10x10 along the short span. The applied

force at the center of slabs is produced by the

hydraulic jack with the capacity of maximum loading

1000kN. Initially, the hydraulic jack is adjusted with

the force same as the self weight of the slab. In this

experiment, the applied force is provided from the

Modeling of experimental setup

bottom to the top of the slab, which is opposite to the

direction of gravity. By applying this procedure, it is

easier for us to record the strain and deformation of

concrete and rebar from the top side of the slab. It

should be noted that the strain and deformation of

concrete and rebar are measured by using the wire

strain gauge as shown in Figure 6. Next, the applied

force will be increased step by step until the cracks

are found in the slabs and the failure modes are

appeared.

Actualization of experimental setup

Figure 5: Experimental Setup

Organized by Department of E&CE, Bheemanna Khandrre Institute of Technology Bhalki, Bidar, India

SHETKAR AND HANCHE: AN EXPERIMENTAL STUDY ON BUBBLE DECK SLAB SYSTEM WITH

Figure 6: Wire Strain Gauge

Experimental results

Figure 7 shows the observed crack patterns

at failure for the slab B.BD.2 and B.BD.3. It can be

seen from this figure that failure modes of slabs

B.BD.2 and B.BD.3 are shear and bending modes,

respectively. In details, Table 2 demonstrates the

ultimate loading, maximum deflection at the center

and type of failure of all slabs. It should be noted that

The shear failure of slab B.BD.2

the Bubble Deck using hollow spherical balls A.BD.2

and B.BD.2 has the shear failure modes. On contrary,

the Bubble Deck using modified elliptical balls

A.BD.3, A.BD.4 and B.BD.3 has the bending failure

modes. It can be concluded that with the same

dimension and concrete grade, the Bubble Deck

using modified elliptical balls has greater ultimate

loading compared with using other plastic balls.

The bending failure of slab B.BD.3

Figure 7: The Failure Modes of Bubble Deck

Figure 8 shows the relationship between

ultimate loading P and the maximum deflection at the

center of Bubble Deck. The figure is plotted for two

types of concrete strength, e.g. M35 (type A) and

M25 (type B), and for different types of Bubble

Deck. It can be observed from this figure that the

maximum deflection at the center of slabs is

increased when the applied loading is increased More

details, Table 3 depicts the results of ultimate loading

and center deflection of all types of Bubble Deck. It

can be seen from this table that the loading capacity

of Bubble Deck using concrete grade M35 is higher

from 3% to 8% as compare to that of Bubble Deck

using concrete grade M25. The system shown good

load carrying capacity and shearing capacity. The

loading capacity is increased approximately 6% by

using the links in Bubble Deck, e.g. the links has not

much contribution to the capacity of the slabs.

Figure 8: Load Deflection of Bubble Deck

Organized by Department of E&CE, Bheemanna Khandrre Institute of Technology Bhalki, Bidar, India

SHETKAR AND HANCHE: AN EXPERIMENTAL STUDY ON BUBBLE DECK SLAB SYSTEM WITH

Table 3: Comparison of Ultimate Loading and Center Deflection of Bubble Deck

CONCLUSIONS

1. The Bubble Deck configuration gives much

improved flexural capacity, stiffness and shear

capacity of at least 70% when the same amount of

concrete and the same reinforcement is used as in the

solid slab, realizing 30-50% concrete economy, in

comparison with the solid slab.

2. Advantage of Bubble Deck system is the

significant cost saving, because of the possibility of

obtaining great spans with less support elements.

3. By using the hollow elliptical balls, the better loadbearing capacity in Bubble Deck can be achieved.

4. Concrete usage is reduced as 1 kg of recycled

plastic replaces 100 kg of concrete. This avoids the

cement production and allows reduction in global

CO2 emissions. Hence this technology is

environmentally green and sustainable.

5. Reducing material consumption made it possible to

make the construction time faster, to reduce the

overall costs. Besides that, it has led to reduce dead

weight up to 50%, which allow creating foundation

sizes smaller.

ACKNOWLEDGEMENT

I gratefully acknowledge Prof. Nagesh

Hanche (Guide), Assistant Professor, Department of

Civil Engineering, all staffs of Engineering

Department, friends and parents for their valuable

support and guidance to carry out this study.

REFERENCES

Amer M. Ibrahim, Nazar K. Ali, Wissam D. Salman,

Flexural capacities of reinforced concrete

two-way bubble deck slabs of plastic

spherical voids, Diyala Journal of

Engineering Sciences, ISSN 1999-8716,

Vol. 06, No. 02, June 2013.

A.N Prakash, The revolutionary concept in voided

slabs, Dimensions - A Journal of A N

Prakash CPMC Pvt. Ltd., Issue No.10,

March 2011.

Bubble Deck UK Head Office, Bubble Deck Voided

Flat Slab Solution, Technical Manual and

Documents, Bubble Deck span guide,

January 2009.

By Paul Harding, Managing Director Bubble Deck

C.I. Ltd, Bubble Deck Advanced

Structure Engineering, New construction

technology, Cornerstone 30 Autumn 2004.

Bindea M., Flat slabs with spherical voids. Part I:

Prescriptions for flexural and shear design,

Acta

Technical

Napocensis:

Civil

Engineering & Architecture Vol. 56, No.1,

2013.

Organized by Department of E&CE, Bheemanna Khandrre Institute of Technology Bhalki, Bidar, India

SHETKAR AND HANCHE: AN EXPERIMENTAL STUDY ON BUBBLE DECK SLAB SYSTEM WITH

Bubble Deck floors, Supplementary regulations to

NEN 6720:1995 (VBC 1995), Centre for

Civil Engineering Research and Codes

(CUR) Recommendations 86.

Churakov A.G., Biaxial hollow slab with innovative

types of voids, Construction of Unique

Buildings and Structures, ISSN 23046295.No.6 (21). 2014.

L.V.Hai, V.D. Hung., The experimental analysis of

bubble deck slab using modified elliptical

balls, Hokkaido University.

Nielsen

M., Limit Analysis and Concrete

Plasticicity, Second Edition, CRC Press,

1998.

Gudmand-Hoyer T., Note on the moment capacity

in a Bubble Deck Joint, Rapport BYGDenmark Tekniske Universities R-074,

ISSN 1601- 2917,ISBN 87-7877-136-6,

2003.

Organized by Department of E&CE, Bheemanna Khandrre Institute of Technology Bhalki, Bidar, India

Das könnte Ihnen auch gefallen

- Ce05016 Qa 2Dokument36 SeitenCe05016 Qa 2mote34100% (4)

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Shear Performance Analysis Tapered Beam-Resal PDFDokument11 SeitenShear Performance Analysis Tapered Beam-Resal PDFp rNoch keine Bewertungen

- BS en 13658-2-2005Dokument2 SeitenBS en 13658-2-2005Terry JohnNoch keine Bewertungen

- Bubble Deck TechDokument23 SeitenBubble Deck TechFasi Ur RahmanNoch keine Bewertungen

- Structural Behavior of Bubble Deck SlabDokument6 SeitenStructural Behavior of Bubble Deck SlabrohithNoch keine Bewertungen

- Bubble Deck Slab Seminar by Waseem Raja, Sec CDokument20 SeitenBubble Deck Slab Seminar by Waseem Raja, Sec CWaseem Rj100% (1)

- Structural Behavior of Bubble Deck SlabDokument7 SeitenStructural Behavior of Bubble Deck Slabgulilero_yo100% (1)

- Experimental Studies On Comparison of Conventional Slab and Bubble Deck Slab Based On Strength and EconomyDokument14 SeitenExperimental Studies On Comparison of Conventional Slab and Bubble Deck Slab Based On Strength and EconomyDESH KARTHIKNoch keine Bewertungen

- Experimental Study On Bubbled Beam: Shaikh Nadeem Ashraf Nawazoddin, Prof. Shete G.NDokument6 SeitenExperimental Study On Bubbled Beam: Shaikh Nadeem Ashraf Nawazoddin, Prof. Shete G.NluckyNoch keine Bewertungen

- Comparitive Study of Voided Slab and Conventional Slab Using ANSYS Workbench 14.5Dokument25 SeitenComparitive Study of Voided Slab and Conventional Slab Using ANSYS Workbench 14.5Shinde vishalNoch keine Bewertungen

- Bubble Deck Slab DesignDokument9 SeitenBubble Deck Slab Designnihar100% (1)

- Bubble DeckDokument10 SeitenBubble Deckalaalao2000Noch keine Bewertungen

- F 11600476 C 219Dokument6 SeitenF 11600476 C 219AbdelRahman AyoubiNoch keine Bewertungen

- Bubble Deck AbstractDokument4 SeitenBubble Deck AbstractRajat Maheshwari0% (1)

- Presented By: Akshayapriyadharshini.V Santhoshkumar .K.SDokument24 SeitenPresented By: Akshayapriyadharshini.V Santhoshkumar .K.SSanket MahadikNoch keine Bewertungen

- Bubble Research PDFDokument4 SeitenBubble Research PDFRobin ParmarNoch keine Bewertungen

- Experimental Study On Bubble Deck Beam Using HDPE BallsDokument8 SeitenExperimental Study On Bubble Deck Beam Using HDPE BallsIJRASETPublicationsNoch keine Bewertungen

- An Introduction To Bubble-Voided Concrete Flat Slabs: by Kamron Skaggs University of Cincinnati Class of 2017Dokument6 SeitenAn Introduction To Bubble-Voided Concrete Flat Slabs: by Kamron Skaggs University of Cincinnati Class of 2017garysootetNoch keine Bewertungen

- Bubble Deck SlabDokument4 SeitenBubble Deck SlabbbnNoch keine Bewertungen

- Review On Bubble Deck Slabs Technology and Their ApplicationsDokument6 SeitenReview On Bubble Deck Slabs Technology and Their ApplicationsNoor KhreisatNoch keine Bewertungen

- Voided Biaxial Slabs - State of Art: IOP Conference Series: Earth and Environmental ScienceDokument10 SeitenVoided Biaxial Slabs - State of Art: IOP Conference Series: Earth and Environmental ScienceShinde vishalNoch keine Bewertungen

- Seminar Report FinalDokument34 SeitenSeminar Report FinalSanthosh PrabuNoch keine Bewertungen

- Biaxial Hollow Slab With Innovative Types of Voids: Journal HomepageDokument19 SeitenBiaxial Hollow Slab With Innovative Types of Voids: Journal HomepagerohithNoch keine Bewertungen

- Comparative Study of Bubble Deck Slab With Conventional R.C.C SlabDokument7 SeitenComparative Study of Bubble Deck Slab With Conventional R.C.C SlabIJRASETPublicationsNoch keine Bewertungen

- Review On Bubble Deck With Spherical Hollow BallsDokument10 SeitenReview On Bubble Deck With Spherical Hollow BallsRESHMA RNoch keine Bewertungen

- Building Concrete ShellsDokument9 SeitenBuilding Concrete ShellsMashaNoch keine Bewertungen

- Jain College of EngineeringDokument19 SeitenJain College of Engineeringrohan0% (2)

- Irjet V5i2116 PDFDokument6 SeitenIrjet V5i2116 PDFCharles Kyle CerezoNoch keine Bewertungen

- Application of The Bubble Deck Slab Technology in MalaysiaDokument11 SeitenApplication of The Bubble Deck Slab Technology in MalaysiaGrace HerdiyantiNoch keine Bewertungen

- The Effect of Balls Shapes and Spacing On Structur PDFDokument11 SeitenThe Effect of Balls Shapes and Spacing On Structur PDFHaitham HassanNoch keine Bewertungen

- 1.1general: Structural Engineering Bec, BGKDokument22 Seiten1.1general: Structural Engineering Bec, BGKLata HaNoch keine Bewertungen

- U Boot TechnologyDokument8 SeitenU Boot TechnologyTalmeez KundgolNoch keine Bewertungen

- Voided Slab: % Weight SavingsDokument3 SeitenVoided Slab: % Weight SavingsHemanth GowdaNoch keine Bewertungen

- Instability of Slender Concrete Deep BeamDokument12 SeitenInstability of Slender Concrete Deep BeamFrederick TanNoch keine Bewertungen

- Final Report - Bubble Deck - Hollow Core SlabDokument24 SeitenFinal Report - Bubble Deck - Hollow Core SlabDaphne Tan 丽文Noch keine Bewertungen

- 1.1 Concrete Floor Systems: CivilDokument4 Seiten1.1 Concrete Floor Systems: CivilPrashant SunagarNoch keine Bewertungen

- 55 Falih2020Dokument18 Seiten55 Falih2020eng. douaaNoch keine Bewertungen

- Fin Irjmets1639807704 PDFDokument6 SeitenFin Irjmets1639807704 PDFAkhil RajasekaranNoch keine Bewertungen

- Method For Bubbledeck Concrete Slab With GapsDokument8 SeitenMethod For Bubbledeck Concrete Slab With GapsMaru MruNoch keine Bewertungen

- Siti Quraisyah 2020 J. Phys. ConfDokument7 SeitenSiti Quraisyah 2020 J. Phys. ConfVikas SharmaNoch keine Bewertungen

- 220 226 PDFDokument7 Seiten220 226 PDFengrfarhanAAANoch keine Bewertungen

- A Structural Study On Bubble Deck Slab and Its Properties: Mir Shahed Ali, Dr. S. Amaresh BabuDokument6 SeitenA Structural Study On Bubble Deck Slab and Its Properties: Mir Shahed Ali, Dr. S. Amaresh BabuGrace HerdiyantiNoch keine Bewertungen

- Bubble Deck TechnologyDokument21 SeitenBubble Deck TechnologyPrashant Sunagar100% (2)

- Name: Suchitra Ramasamy Matrix Number: CF160003Dokument4 SeitenName: Suchitra Ramasamy Matrix Number: CF160003ikhmal siddiqNoch keine Bewertungen

- Analytical and Experimental Investigation On Voided Slab: NtroductionDokument8 SeitenAnalytical and Experimental Investigation On Voided Slab: NtroductionShinde vishalNoch keine Bewertungen

- Filler Slab AdvantageDokument8 SeitenFiller Slab AdvantageSuranjana Chaudhuri100% (1)

- U-Boot Technology in Construction 2019Dokument16 SeitenU-Boot Technology in Construction 2019Snehalatha P100% (1)

- Voided SlabDokument34 SeitenVoided SlabSuresh Chandra Mangena100% (1)

- 192 Experimental Study On Voided Biaxial Slab and Its ApplicationDokument5 Seiten192 Experimental Study On Voided Biaxial Slab and Its Applicationbogdan.kukosNoch keine Bewertungen

- Comparative Studies of Conventional Slab and Bubble Deck Slab Based On Stiffness and EconomyDokument4 SeitenComparative Studies of Conventional Slab and Bubble Deck Slab Based On Stiffness and EconomyNoor KhreisatNoch keine Bewertungen

- Experimental and Numerical Investigation On Structural Behaviour of Bubble Deck Slab With Conventional SlabDokument4 SeitenExperimental and Numerical Investigation On Structural Behaviour of Bubble Deck Slab With Conventional SlabEditor IJTSRDNoch keine Bewertungen

- Shear Capacity of Self-Compacting ConcreteDokument10 SeitenShear Capacity of Self-Compacting ConcreteHuda JawadNoch keine Bewertungen

- Bubble DeckDokument16 SeitenBubble Deckdeepuvarghese100% (1)

- U BootDokument23 SeitenU Bootakshayvadje16Noch keine Bewertungen

- Comparative Study About AAC Block With Porotherm BrickDokument8 SeitenComparative Study About AAC Block With Porotherm BrickIJRASETPublicationsNoch keine Bewertungen

- U Boot ReportDokument5 SeitenU Boot ReportTalmeez KundgolNoch keine Bewertungen

- Structural Analysis of Concrete Spherical Shells: MEKJAVIC, I (Vana)Dokument2 SeitenStructural Analysis of Concrete Spherical Shells: MEKJAVIC, I (Vana)Iver LopezNoch keine Bewertungen

- Bubble DeckDokument2 SeitenBubble Deckvigneshwarimahamuni100% (1)

- Department of Civil Engineering Presented BY M.Bhargavi 176B5A0109Dokument16 SeitenDepartment of Civil Engineering Presented BY M.Bhargavi 176B5A0109Manchi BhargaviNoch keine Bewertungen

- Voided SlabDokument35 SeitenVoided SlabPallepatiShirishRaoNoch keine Bewertungen

- Paper On Design Voded SlabDokument9 SeitenPaper On Design Voded SlabAnonymous b9fkTYfEoRNoch keine Bewertungen

- Elastic, Plastic and Yield Design of Reinforced StructuresVon EverandElastic, Plastic and Yield Design of Reinforced StructuresNoch keine Bewertungen

- 04 Acknowledgement PDFDokument3 Seiten04 Acknowledgement PDFrohithNoch keine Bewertungen

- 12 - Chapter 4 PDFDokument33 Seiten12 - Chapter 4 PDFrohithNoch keine Bewertungen

- 691 Calculated Anchor Bolt PullDokument1 Seite691 Calculated Anchor Bolt PullbayuNoch keine Bewertungen

- Dr. A. Shajahan,: CknoledgementDokument3 SeitenDr. A. Shajahan,: CknoledgementrohithNoch keine Bewertungen

- Tensgrity StructuresDokument21 SeitenTensgrity StructuresrohithNoch keine Bewertungen

- AmmerDokument3 SeitenAmmerrohithNoch keine Bewertungen

- Fdot Design Standards: 292 1 Standard Precast Concrete Box CulvertsDokument14 SeitenFdot Design Standards: 292 1 Standard Precast Concrete Box CulvertsnelsonsainzNoch keine Bewertungen

- AcknoledgementDokument1 SeiteAcknoledgementrohithNoch keine Bewertungen

- 14 01 06 PDFDokument6 Seiten14 01 06 PDFrohithNoch keine Bewertungen

- StairsDokument21 SeitenStairstomnubiNoch keine Bewertungen

- BIS Specification Structura Circular ISI 116 PDFDokument9 SeitenBIS Specification Structura Circular ISI 116 PDFrohithNoch keine Bewertungen

- Athiji AjjiDokument3 SeitenAthiji AjjirohithNoch keine Bewertungen

- EventDokument3 SeitenEventrohithNoch keine Bewertungen

- Visvesvaraya Technological University Jnanasangama Belagavi - 590 018Dokument2 SeitenVisvesvaraya Technological University Jnanasangama Belagavi - 590 018rohithNoch keine Bewertungen

- Irjet V3i10147 PDFDokument5 SeitenIrjet V3i10147 PDFrohithNoch keine Bewertungen

- Bubbledeck - : Advanced Structure EngineeringDokument2 SeitenBubbledeck - : Advanced Structure EngineeringRus JouanaNoch keine Bewertungen

- B Dint Design GuideDokument5 SeitenB Dint Design Guidechernl2004Noch keine Bewertungen

- SlabEstimatorV100 3Dokument44 SeitenSlabEstimatorV100 3rohithNoch keine Bewertungen

- BubbleDeck Design Guide v1.2Dokument18 SeitenBubbleDeck Design Guide v1.2trozza28100% (2)

- BubbleDeck Design Guide v1.2Dokument18 SeitenBubbleDeck Design Guide v1.2trozza28100% (2)

- Structural Behavior of Bubbledeck Slabs and Their Application To Lightweight Bridge DecksDokument42 SeitenStructural Behavior of Bubbledeck Slabs and Their Application To Lightweight Bridge Deckscewaleed2590Noch keine Bewertungen

- Bubbledeck - : Advanced Structure EngineeringDokument2 SeitenBubbledeck - : Advanced Structure EngineeringRus JouanaNoch keine Bewertungen

- Bubble Deck TechnologyDokument21 SeitenBubble Deck TechnologyrohithNoch keine Bewertungen

- Structural Behavior of Bubbledeck Slabs and Their Application To Lightweight Bridge DecksDokument42 SeitenStructural Behavior of Bubbledeck Slabs and Their Application To Lightweight Bridge Deckscewaleed2590Noch keine Bewertungen

- Bubble Deck TechnologyDokument21 SeitenBubble Deck TechnologyrohithNoch keine Bewertungen

- BubbleDeck Design Guide v1.2Dokument18 SeitenBubbleDeck Design Guide v1.2trozza28100% (2)

- Biaxial Hollow Slab With Innovative Types of Voids: Journal HomepageDokument19 SeitenBiaxial Hollow Slab With Innovative Types of Voids: Journal HomepagerohithNoch keine Bewertungen

- Crude Oil Tank ConstructionDokument3 SeitenCrude Oil Tank ConstructionEpiphany ChijiokeNoch keine Bewertungen

- Detailed Quty. For R/R Wall Estimate As HPPWD Shedule Rate 2019Dokument6 SeitenDetailed Quty. For R/R Wall Estimate As HPPWD Shedule Rate 2019rahulNoch keine Bewertungen

- Soil ReportDokument59 SeitenSoil ReportHarshitha N SNoch keine Bewertungen

- Aqc Steel Structure Paint Area ASAD WORKINGDokument3 SeitenAqc Steel Structure Paint Area ASAD WORKINGMUHAMMAD WARIS SQNoch keine Bewertungen

- Civil Engineering: Year ofDokument4 SeitenCivil Engineering: Year ofdipinnediyaparambathNoch keine Bewertungen

- Trip Ura UsefulDokument58 SeitenTrip Ura UsefuldhineshNoch keine Bewertungen

- Detailed Design Consultancy Services For Sahnewal - Pilkhani Section of Eastern Dedicated Freight Corridor (Package - 301) Bridge Inventory ReportDokument4 SeitenDetailed Design Consultancy Services For Sahnewal - Pilkhani Section of Eastern Dedicated Freight Corridor (Package - 301) Bridge Inventory Reportkaushik960Noch keine Bewertungen

- Proposal PresentationDokument22 SeitenProposal Presentationtofik abaduraNoch keine Bewertungen

- G Tech Coupler - Proposal - 2018Dokument49 SeitenG Tech Coupler - Proposal - 2018sunaryoNoch keine Bewertungen

- Circular Slabs - PpsDokument19 SeitenCircular Slabs - PpssrivaruniNoch keine Bewertungen

- RTHD - 5 - SASEC Road Connectivity ProjectDokument3 SeitenRTHD - 5 - SASEC Road Connectivity ProjectsorowareNoch keine Bewertungen

- Solid Wall HDPE Pipe: NRCS NEH 636 Chap. 52 Buried Pipeline Design CalculationsDokument13 SeitenSolid Wall HDPE Pipe: NRCS NEH 636 Chap. 52 Buried Pipeline Design CalculationsBalaji HariNoch keine Bewertungen

- FLOW METER DEMONSTATION ReportDokument15 SeitenFLOW METER DEMONSTATION ReportAbenezer TasewNoch keine Bewertungen

- Siphonic Roof DrainsDokument16 SeitenSiphonic Roof DrainsTu Burin DtNoch keine Bewertungen

- Backfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersDokument1 SeiteBackfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersRVNLPKG6B VBL-GTLMNoch keine Bewertungen

- GLSR Design 11 06 04 1 - PDF - Wall - Classical MechanicsDokument22 SeitenGLSR Design 11 06 04 1 - PDF - Wall - Classical MechanicsWhaosidqNoch keine Bewertungen

- ECCECCS PublicationsDokument2 SeitenECCECCS PublicationsDaniel JamesNoch keine Bewertungen

- Rock Bolt Capacity CalculationDokument2 SeitenRock Bolt Capacity CalculationROHIT PADHARIA100% (1)

- Ceo QuizDokument1 SeiteCeo QuizJohn Lesther PabiloniaNoch keine Bewertungen

- Soil 2 Chapter1Dokument21 SeitenSoil 2 Chapter1AbduNoch keine Bewertungen

- INFRA Water QMS MIS Report - SEP 2020Dokument57 SeitenINFRA Water QMS MIS Report - SEP 2020Kumar AbhishekNoch keine Bewertungen

- Ce 8Dokument6 SeitenCe 8Sambriddhi ShresthaNoch keine Bewertungen

- ADAPT ABI BrochureDokument1 SeiteADAPT ABI BrochureHarrys PurnamaNoch keine Bewertungen

- LePage Epoxy Steel, 25-mL Canadian TireDokument5 SeitenLePage Epoxy Steel, 25-mL Canadian Tireming_zhu10Noch keine Bewertungen

- Ak26230233 PDFDokument4 SeitenAk26230233 PDFRahil QureshiNoch keine Bewertungen

- DTC E Brochure 2015 16Dokument29 SeitenDTC E Brochure 2015 16Kirat SinghNoch keine Bewertungen

- Life Cycle Cost - (Vivek Abhyankar)Dokument20 SeitenLife Cycle Cost - (Vivek Abhyankar)Vivek G. Abhyankar100% (1)