Beruflich Dokumente

Kultur Dokumente

Advanced Technologies of Preventive Maintenance For

Hochgeladen von

Jessica SandersCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Advanced Technologies of Preventive Maintenance For

Hochgeladen von

Jessica SandersCopyright:

Verfügbare Formate

Hitachi Review Vol. 51 (2002), No.

137

Advanced Technologies of Preventive Maintenance for

Thermal Power Plants

OVERVIEW: Although thermal power generating facilities are aging, flexible

operation in response to changes in the demand for electrical power is

required. To extend the life and manage the maintenance of those facilities,

advanced preventive maintenance technology is important. For that reason,

Hitachi has been grappling with nondestructive inspection, life assessment

technology, rationalization technology for scheduled inspections of the

boilers, steam turbines, gas turbines and other machinery used in thermal

power generation to strengthen preventive maintenance and increase the

efficiency of maintenance. Recently, we have been developing products and

services for advanced support for maintenance and preservation through

the use of IT (information technology) and network technology, going beyond

what has previously been available.

Kiyoshi Shimomura, Dr. Eng.

Hideaki Ishitoku

Shigeo Sakurai, Dr. Eng.

Fumiyuki Hirose

INTRODUCTION

IN recent years, startup and shutdown operations have

become frequent in aging thermal power generation

facilities, and preventive maintenance technology has

steadily been increasing in importance from the

viewpoints of extending the scheduled inspection

interval and strengthening the independent management

of facilities. Furthermore, concerning preservation of

the global environment as well, there is also a strong

demand for the reduction of CO2 emissions through

improved generation efficiency and fuel conversion

in existing facilities.

Under such circumstances, Hitachi is going beyond

the application of new technology that has been

developed for new power plants to old facilities, and

has taken up the challenge of developing our own

preventive maintenance technology.

Together with these advanced technologies and

products, Hitachi is making use of IT, which has

developed rapidly in recent years, to provide global

services that contribute to life-cycle cost minimization

for power generation facilities (see Fig. 1).

Power companies

Head

office

Administration

Fig. 1Preventive

Maintenance

Solutions for

Thermal Power

Plants Provided by

Hitachi.

Hitachi is making

full use of IT to

provide the newest

preventive

maintenance systems

and services for

thermal power

plants.

Central load

dispatching office

Power demand adjustment

Thermal power

plants

Thermal power

plants

Power

generation

Power

generation

Plant monitoring service

CALS technology

answering service

Internet

Large-demand

customers

HITACHI

Ordinary

households

Answer Center

Information to customers

(subscribers) via the Internet

Remote Monitoring Center

Boiler

Turbine

Generator

Controller

CALS: continuous acquisition

and life-cycle support

Advanced Technologies of Preventive Maintenance for Thermal Power Plants

Here, we describe the latest technology for the

preventive maintenance of thermal power plants.

APPLICATION OF IT TO PREVENTIVE

MAINTENANCE OF THERMAL POWER

PLANTS

Hitachi is proceeding to add intelligence in a wide

range of fields by making use of IT and the proprietary

knowledge we have accumulated in various industrial

areas with the objective of being the customers Best

Solutions Partner by offering new solutions.

In the field of preventive maintenance for thermal

power plants, too, we have taken up the challenge of

using IT and network technology to provide services

for the support of advanced maintenance and

preservation that go beyond what has been available

to the customer in the past.

With the increasingly severe demands on the

operation of aging thermal power plants, typified by

extension of the period for scheduled inspections and

DSS (daily start-up and shut-down) operations, there

is increasing need to know the quantitative state of the

facilities, such as by monitoring operation at times of

transition and knowing the deterioration state of

equipment, in addition to the regular monitoring of

operation. There is also a demand for the provision of

performance evaluation technology for life-cycle cost

minimization, as well as the provision of operation

methods that use such technology to optimize

efficiency and the provision of operation data

management services. To meet that demand, Hitachi

is developing services which make use of IT, such as

plant monitoring services and engineering services.

As example of an engineering service, a means of

Customer (contract holder)

Hitachi Group Answer Center

Internet

Rapid reply to technical questions

Provision of the latest operations and

maintenance technology

Provision of information on improvements

Fig. 2Mechanism for Providing Technical Information via the

Internet.

Technical questions from customers can be answered quickly

and the latest information can be provided over the Internet.

138

providing information over the Internet is illustrated

in Fig. 2. In that service, subscribing customers can

get speedy answers to technical questions via the

Internet by directly accessing the Answer Center Web

Site set up by the Thermal Power Preventive

Maintenance Department, a process that previously

required waiting for written responses. It is also

possible to access information on the latest operation

and maintenance technology and improvements in real

time. This service can be provided to overseas

customers as well as to domestic power companies.

PREVENTIVE MAINTENANCE

TECHNOLOGY FOR THERMAL POWER

PLANTS

In an environment of deregulation, there has been

little progress in the construction of new thermal power

generation. Furthermore, load conditions have recently

become severe, including operation according to

varying load (middle load operation), etc., and there

is an accelerating trend of material damage. To cope

with that problem, Hitachi is promoting the

development and application of preventive maintenance

technology for boilers, steam turbines, gas turbines,

and other core technologies of thermal power plants,

as described in the following sections.

Preventive Maintenance Technology for Boilers

Application of the latest development technology

The conventional techniques for nondestructive

inspection of boiler materials and parts include PT

(liquid penetrant testing), MT (magnetic particle

testing), and UT (ultrasonic testing), among others.

These types of inspection, however, have problems

such as:

(1) difficulty of inspecting narrow gapped areas,

(2) requiring a large amount of associated work, and

(3) difficulty of lifetime diagnosis or can predict

quantitative damage progress.

To cope with these problems, Hitachi has been

developing various kinds of scheduled inspection

rationalization technology to achieve lower-cost,

timely inspection by reducing the preparation work

and to achieve fast, highly accurate inspection by

employing advanced inspection equipment without

direct contact. The main diagnostic points and

diagnosis technology are shown in Fig. 3. These

rationalized technologies are already being applied in

actual plants.

Of these technologies, ELFOSS UT (electronic

focus sector scan ultrasonic testing), which can

Hitachi Review Vol. 51 (2002), No. 5

Main pipes, headers and drums

ELFOSS UT

Non-contact electromagnetic

acoustic crack detector

Main

pipes

Attemperator

Cooler inspection

equipment

Drum

Insulated pipes

Equipment for inspection

of insulation from above

Fig. 3Main

Diagnostic Points

and Diagnosis

Technology.

Hitachi has

developed inspection

equipment that is

capable of nondestructive,

quantitative

evaluation of all of

the pressure

containment parts of

the boiler.

Suspended heat exchange tubes

Waterwall

tubes Heat exchange

tubes

Burner

Internal tube UT inspection equipment

Steam oxidation scale thickness detector

Local erosion thickness detector

Sling tube inspection equipment

EMAT crack detector

Clinker removal by water jet method*

Fuel

pipe

evaluate internal defects in the welds of main pipes, is

described below:

ELFOSS UT can evaluate defects contained in

welds and in narrow nozzle stubs by electronic

focusing and sector scanning techniques. A major

feature of this device is that the scanning range of the

UT probe is smaller than that used in the conventional

UT method, so the defect size and location can be

determined accurately.

The results of ELFOSS UT inspection of a plate

(100-mm thick) butt weld that contains an artificial

defect are shown in Fig. 4. The defect detected by the

nondestructive method matches well with the defect

as confirmed by cross-section examination. With such

an excellent defect detection capability, this equipment

is being applied to precise inspection of important

areas, such as the welds of main pipes.

Scheduled inspection rationalization technology

The various types of nondestructive inspection

equipment shown in Fig. 3 are all capable of

quantitative evaluation of defects, and can also be

called rationalized technologies with respect to

shortening inspection time for schedule inspections.

In addition to such higher performance of the

inspection equipment itself, rationalization technology

such as for shortening the preparation time for

inspection is also desired.

For example, in the furnace of coal-fired boilers,

fused ash adheres to places such as the bends in the

heat exchange pipes that are suspended from the top

of the furnace. Such ash may grow to form hard

clinkers. Because it is very dangerous if those clinkers

fall inside the furnace, they should be removed before

EMAT: electromagnetic acoustic transducer

*: Preparation for inspection

Measurement of an

internal defect in a

butt welded plate

(100-mm thick)

100 mm

Water-wall tubes

Water wall corrosion fatigue

inspection equipment

Corrosion fatigue detector

Elephant skin depth detector

Local erosion thickness detector

Water wall backside UT

equipment

Clinker removal by water

jet method*

Cooler

Header

Horizontal heat exchange tubes

Internal UT tube inspection equipment

New internal UT tube inspection equipment

Support equipment for visual

inspection of deep coil levels

Ash erosion inspection equipment

Horizontal heat transfer tube inspection robot

Acoustic ash removal equipment

139

Crack

Confirmation of

detection accuracy

by comparison

with cross-section

examination

Macroscopic photo

of cross section

Result of cross-section examination

UT result

Fig. 4ELFOSS UT Performance.

The results of inspecting a sample butt weld that contains an

internal defect show that the defect size and location can be

detected accurately.

installing the scaffolding and performing the inspection

and repair work at the time of scheduled inspections.

The removal of the clinkers in this way requires much

time and labor.

For that reason, we turned attention to WJ (water

jet) technology, and developed a special nozzle that

produces several times the force of the conventional

nozzle. Using this nozzle reduces the time required

for clinker removal significantly, and the time from

the shutdown of a plant to the beginning of inspection

and repair can be greatly reduced.

Preventive Maintenance Technology for Steam

Turbines

Lifetime diagnosis of steam turbines

For high-temperature components of aging steam

turbines, accurate preventive maintenance and

Advanced Technologies of Preventive Maintenance for Thermal Power Plants

Corrosion

Steam

AE analyzer

AE emission

With the continuing relaxation of regulation, there

is an even stronger demand for improvement in the

operating efficiency of facilities as well as the lowering

of maintenance costs. For those reasons, we are

endeavoring to raise the efficiency of work involved

in the scheduled inspection of turbines and to develop

various types of technology for increasing efficiency

and conserving energy. The technology for

rationalizing scheduled inspection work not only

improves that work directly, but also includes

technologies, such as facility diagnosis technology, that

minimizes that work and asset management

technology that in turn increases the efficiency of

managing the scheduled inspection data.

(1) Rationalization technology for scheduled

inspections

To shorten the scheduled inspection process, we

have developed tapered sleeve type bolting equipment

for the bucket coupling and oil flushing reduction

equipment. The tapered sleeve type bolting equipment

allows smooth bolt extraction, so the bolt loosening

time can be reduced to half a day per coupling.

Previously, five to seven days were required to flush

the oil for cleaning the bearings and bearing box after

completing the assembly of the turbine and generator.

The oil flushing reduction equipment, however,

achieved results that fully satisfy the specified bearing

oil cleanness requirement in only three days, as well

as reducing the test operation time.

Result of frequency analysis

Frequency

Voltage

Amplitude

Time

Time

Development of scheduled inspection technology for

improving in efficiency

AE sensor

Voltage

Amplitude

No leak

AE waveform

Leak

extension of machine life is becoming established.

On the other hand, for low-temperature

components, of which low-pressure turbines are a

typical example, damage related to corrosion has been

appearing in recent years. In most of those cases,

corrosion fatigue cracking or SCC (stress corrosion

cracking) is seen in the severely corrosive phase

transition zone environment. To deal with these

problems, we are establishing highly accurate lifetime

evaluation technology derived from an understanding

of actual operation in service. That technology is based

on analysis of the vibratory response in grouped blades

in the low pressure stage and accumulating data on

the occurrence and growth of corrosion pitting in the

actual environment. As a result, we are trying to

maintain the reliability of low-temperature parts in a

corrosive environment by recommending the overhaul

of low-pressure turbines that have been in service for

20 years or more by removal of the bucket.

140

Frequency

Fig. 5Mechanism for Detecting Steam Leaks in Stop Valves

and AE Waveform for a Leak.

An example application of AE to stop valves and other static

parts.

(2) Facility diagnosis technology

For facility diagnosis, we developed leak diagnosis

technology that makes use of AE (acoustic emission).

Up to now, AE diagnosis has been applied to

abnormality detection in rotating parts such as turbines

and pumps. Now we have developed technology for

applying this method to steam leaks in stop valves as

well. An application example is shown in Fig. 5.

(3) Asset management technology

As an asset management technology, we have

developed a scheduled inspection record and history

management application system. Rapid and paperless

recording of data from the time of measurement to

data management is made possible by using a network

to connect the inspection site and the persons

responsible for data approval and management. This

inspection recording application is linked to a history

management system, and serves to provide data for

the history management of assets. In this way, the

various types of information from the inspections is

databased for each asset so that the deterioration trend

of each asset can be known. Furthermore, data mining

is done easily by time series of the maintenance data

for each asset or by phenomenon. A sample window

Hitachi Review Vol. 51 (2002), No. 5

141

History menu window

Details (case record)

Corrosion was seen in the 1993

scheduled inspection; continuous

monitoring is being done.

from the turbine history management application is

shown in Fig. 6.

Introducing the various types of rationalization

equipment that have been developed can shorten the

standard process for a 600-MW turbine to about five

days and a 10 to 15% saving in energy can be expected.

Preventive Maintenance Technology for Gas

Turbines

The load conditions are very severe for gas turbines,

which use high-temperature combustion gases as the

working fluid. For that reason, differently from steam

turbines, the hot gas path components that are placed

in the path of the combustion gases have a relatively

short operating time and are repaired repeatedly during

the course of use.

Maintenance costs for repair, reconditioning and

part updating are a large proportion of the cost of

generating electricity, so the advancement of

preventive maintenance technology is important in

terms of economy as well as reliability.

Lifetime management and repair of hot gas path

components

The life of hot gas path components is shortened

by creep, abrasion, oxidation and other such damage

that is related to operating time and by damage that

occurs as the result of repeated startups and shutdowns,

such as low-cycle fatigue.

Accordingly, lifetime management employs the

equivalent operating time method, which takes into

account the effects of the number of startups,

Fig. 6 Screen Images from the

Turbine History Management

Application.

Detailed information on each asset

is easily grasped.

shutdowns and sudden changes in load, etc. as well as

the actual operating time. When the equivalent

operating time reaches the specified lifetime, that

component is considered to have reached the end of

its operating life.

Concerning the hot gas path components, if the

inspection result exceeds the judgement criteria, the

component is repaired. See Table 1 for a description

of the repairs.

Of those, the latest repair technology that is

currently being used in actual plants is described below.

Gas turbine bucket recoating repair

Gas turbine buckets are subjected to severe

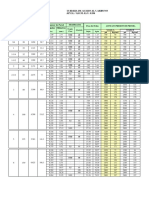

TABLE 1. Hot Gas Path Component Repairs

Examples of the latest gas turbine repair technologies are

described in this table.

Component

Description of Repair

Static blade of turbine

Welding repair of cracks (build-up)

Brazing and diffusion bonding

Creep deformation repair

Recoating

Turbine bucket

Tip welding build-up

Recoating

Combustion liner

Welding repair of cracked parts

Replacement of spring seals, collars, etc.

Recoating

Transition piece

Welding repair of cracks and abrasion

Creep deformation repair

Recoating

Advanced Technologies of Preventive Maintenance for Thermal Power Plants

conditions of centrifugal force and high thermal stress

load in the high-temperature and high-pressure

combustion gases. For that reason, Ni-based superalloys are used and an oxidation resistance coating is

applied to the bucket surface to protect the base

material. With long-term use of the buckets, the coating

suffers damage by deterioration, so it is necessary to

strip the old coating and recoat the buckets before the

base material is damaged. Measures are also taken

against erosion of the bucket tips by high-temperature

oxidation. Hot tearing from welding heat flux usually

occurs in Ni-based super-alloys with high Ti or Al

content, so it is a difficult material to weld. In recent

years, however, low-current welding methods have

been developed, so repair by build-up welding has

become practical for the low-stress bucket tips.

Gas turbine nozzle blade diffusion brazing repair

Gas turbine nozzle blades suffer thermal fatigue

cracking due the thermal stress caused by start-up and

shut-down. Those cracks must be repaired by welding

during the course of nozzle blade use. There is a

tendency for multiple thermal stress cracks to appear

over a wide area of the nozzle blades, so repairing them

takes a great deal of time and effort. Furthermore,

deformation of the nozzle blades occurs in proportion

to the amount of heat applied during the welding.

Diffusion brazing repair avoids that problem by using

a brazing filler metal that has about the same

composition as the base metal, but with a low melting

point metal added. This method involves cleaning the

surfaces of the cracks, flowing the filler metal into the

cracks and then diffusing the filler metal into the blade

metal with a heat treatment. This method reduces labor

for the repair and prevents deformation of the blades.

By using both welding repair and diffusion brazing

repair, we are reducing labor and extending the life of

nozzle blades.

CONCLUSIONS

We have described the development situation for

IT application technology and the latest technology

relevant to boilers, steam turbines, gas turbines in the

field of preventive maintenance for thermal power

plants, as well as how Hitachi is solving problems

related to this technology.

Hitachi will continue to propose IT services,

142

including Internet application technology, and core

technology services.

REFERENCES

(1) S. Sakurai et al., Gas Turbine Preventive Maintenance

Technology for Reliable Maintenance and Extended Life,

Hitachi Hyoron 79, pp. 271-274 (Mar. 1997) in Japanese.

(2) Preventive Maintenance and Lifetime Diagnosis Technology

for Thermal Power Plants/Preventive Maintenance at Hitachi,

Thermal and Nuclear Power Generation, No. 530, Vol. 51, pp.

1583-1587, 1599-1602 (2000) in Japanese.

ABOUT THE AUTHORS

Kiyoshi Shimomura

Joined Hitachi, Ltd. in 1980, and now works at the

Thermal and Hydroelectric Power Technology

Headquarters, the Thermal and Hydroelectric Power

Business Department of the Power and Industrial

Systems. He is currently working on the promotion of

preventive maintenance for thermal power plants. Dr.

Shimomura is a member of the Japan Society of

Mechanical Engineers (JSME) and Gas Turbine

Society of Japan, and can be reached by e-mail at

kiyoshi_shimomura@pis.hitachi.co.jp.

Hideaki Ishitoku

Joined Babcock-Hitachi K.K. in 1981, and now works

at the Project Integration Department of the Thermal

Power Technology Headquarters at Kure Business

Office. He is currently working on projects related to

preventive maintenance. Mr. Ishitoku is a member of

the Thermal and Nuclear Power Engineering Society,

and can be reached by e-mail at

isitoku@kure.bhk.co.jp.

Shigeo Sakurai

Joined Hitachi, Ltd. in 1977, and now works at the

Hitachi Production Headquarters, the Thermal and

Hydroelectric Power Business Department of the

Power and Industrial Systems. He is currently

engaged in the development of preventive

maintenance technology for steam turbines and gas

turbines. Dr. Sakurai is a member of the JSME, the

Society of Materials Science, Japan, and the Japan

Institute of Metals, and can be reached by e-mail at

shigeo_sakurai@pis.hitachi.co.jp.

Fumiyuki Hirose

Joined Hitachi, Ltd. in 1973, and now works at the

Hitachi Production Headquarters, the Thermal and

Hydroelectric Power Business Department of the

Power and Industrial Systems. He is currently

working on preventive maintenance for thermal

power plants. Mr. Hirose can be reached by e-mail at

fumiyuki_hirose@pis.hitachi.co.jp.

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Cummins D1703 Engine Parts Catalog PDFDokument72 SeitenCummins D1703 Engine Parts Catalog PDFxxxxxxxxxxxxxxxxxxx100% (2)

- CAESAR II Expansion JointsDokument26 SeitenCAESAR II Expansion Jointskamal_md100% (4)

- Manufacturing Processes Ch.4 (10 and 11) CastingDokument143 SeitenManufacturing Processes Ch.4 (10 and 11) Castingashoku24007Noch keine Bewertungen

- Advantages of High Speed Balancing - ToshibaDokument3 SeitenAdvantages of High Speed Balancing - ToshibaJessica SandersNoch keine Bewertungen

- PNSMV025Dokument36 SeitenPNSMV025Philippe Alexandre100% (1)

- 9 Storage TanksDokument10 Seiten9 Storage TanksFebriannada Abiyyu100% (1)

- Rotordynamics 2: Problems in Turbo MachineryDokument6 SeitenRotordynamics 2: Problems in Turbo MachineryJessica SandersNoch keine Bewertungen

- Pico Log Self Help GuideDokument34 SeitenPico Log Self Help GuideJessica SandersNoch keine Bewertungen

- Self Archive CrackDokument17 SeitenSelf Archive CrackJessica SandersNoch keine Bewertungen

- Productflyer EAST - 978 3 319 06589 2Dokument1 SeiteProductflyer EAST - 978 3 319 06589 2Jessica SandersNoch keine Bewertungen

- A ContinuumDokument6 SeitenA ContinuumJessica SandersNoch keine Bewertungen

- Detection and Interactive Isolation of Faults in Steam Turbines ToDokument15 SeitenDetection and Interactive Isolation of Faults in Steam Turbines ToJessica SandersNoch keine Bewertungen

- Advances in Motor and Generator Rotor HealthDokument4 SeitenAdvances in Motor and Generator Rotor HealthJessica SandersNoch keine Bewertungen

- Stock Clearance Sale Price List 06 May 2013Dokument1 SeiteStock Clearance Sale Price List 06 May 2013Jessica SandersNoch keine Bewertungen

- Ger 4618Dokument4 SeitenGer 4618Jessica SandersNoch keine Bewertungen

- Enerflow ERHP SU Specs Aug2013Dokument1 SeiteEnerflow ERHP SU Specs Aug2013Jessica SandersNoch keine Bewertungen

- General Information Brochure: Aston Goosey Educational CentreDokument3 SeitenGeneral Information Brochure: Aston Goosey Educational CentreJessica SandersNoch keine Bewertungen

- Aston Manor Primary SchoolDokument2 SeitenAston Manor Primary SchoolJessica SandersNoch keine Bewertungen

- 2015 Rand Show Exhibitor ListDokument6 Seiten2015 Rand Show Exhibitor ListJessica SandersNoch keine Bewertungen

- Dynamic Balancing: Need A High-Speed Balance? No ProblemDokument1 SeiteDynamic Balancing: Need A High-Speed Balance? No ProblemJessica SandersNoch keine Bewertungen

- TBD 1 Brick + Slasto DressingDokument2 SeitenTBD 1 Brick + Slasto DressingJessica SandersNoch keine Bewertungen

- A Premium Interior Ultra Matt Finish With Supreme Stain ResistanceDokument2 SeitenA Premium Interior Ultra Matt Finish With Supreme Stain ResistanceJessica SandersNoch keine Bewertungen

- BLR Hyperion - Kwikot - Clean Heat - Price List WEBDokument4 SeitenBLR Hyperion - Kwikot - Clean Heat - Price List WEBJessica SandersNoch keine Bewertungen

- An Demand ResponseDokument3 SeitenAn Demand ResponseJessica SandersNoch keine Bewertungen

- University of Nottingham School of Mechanical, Materials, Manufacturing Engineering and Management Advanced Dynamics of Machines (H3 C ADM)Dokument3 SeitenUniversity of Nottingham School of Mechanical, Materials, Manufacturing Engineering and Management Advanced Dynamics of Machines (H3 C ADM)Jessica SandersNoch keine Bewertungen

- WEO FactSheet NuclearDokument1 SeiteWEO FactSheet NuclearJessica SandersNoch keine Bewertungen

- 下载Dokument4 Seiten下载Mars JackNoch keine Bewertungen

- Trujillo PDFDokument12 SeitenTrujillo PDFVerdy A. KoehuanNoch keine Bewertungen

- MR810 Torsional Rigidity and Beaming Stiffness Test Procedure 8.14Dokument4 SeitenMR810 Torsional Rigidity and Beaming Stiffness Test Procedure 8.14Maduka SmartNoch keine Bewertungen

- RST 2010 CatalogDokument90 SeitenRST 2010 CatalogGoodBikesNoch keine Bewertungen

- Electric Feed Systems For Liquid Propellant Rocket Engines PDFDokument178 SeitenElectric Feed Systems For Liquid Propellant Rocket Engines PDFandradesosNoch keine Bewertungen

- OSS Hardware SectionDokument72 SeitenOSS Hardware SectionglobalindosparepartsNoch keine Bewertungen

- Chain Wheels ChainconveyorDokument9 SeitenChain Wheels ChainconveyorPedro RBNoch keine Bewertungen

- WascatorDokument87 SeitenWascatorRobinson SmithNoch keine Bewertungen

- Boiling and CondensationDokument13 SeitenBoiling and CondensationPrithvi de VilliersNoch keine Bewertungen

- Chain LatchesDokument2 SeitenChain Latchesdzamir203Noch keine Bewertungen

- IcatDokument122 SeitenIcatViraj ParmarNoch keine Bewertungen

- Den Co Close Control Product GuideDokument40 SeitenDen Co Close Control Product GuideJarwantoNoch keine Bewertungen

- I.S. Code - 456 Recommendation:: 1. For ConcreteDokument4 SeitenI.S. Code - 456 Recommendation:: 1. For ConcreteSonu PanwarNoch keine Bewertungen

- AWQ5522EGEDokument2 SeitenAWQ5522EGEpant.vk8514Noch keine Bewertungen

- Lecture 2 UpdateDokument80 SeitenLecture 2 Updateماجد مدحت سعيدNoch keine Bewertungen

- Experiment 5 - FLUIDSDokument7 SeitenExperiment 5 - FLUIDSJoeNoch keine Bewertungen

- Cuptor Coven - 6emd UslDokument22 SeitenCuptor Coven - 6emd UslPaul MocanuNoch keine Bewertungen

- For Cylinders and Blocks: Compression MachinesDokument4 SeitenFor Cylinders and Blocks: Compression MachineshistoNoch keine Bewertungen

- Parts Manual Yanmar VIO82Dokument187 SeitenParts Manual Yanmar VIO82Stephen Rivett100% (1)

- SchifflerisedDokument17 SeitenSchifflerisedJitendraNoch keine Bewertungen

- TK-RC95 - Rev1 - 1211 SpecsDokument2 SeitenTK-RC95 - Rev1 - 1211 SpecsJames LoewenNoch keine Bewertungen

- AGP PWT - WPM Presentation by AILLC (20th Sep 2022) - EngineeringDokument4 SeitenAGP PWT - WPM Presentation by AILLC (20th Sep 2022) - EngineeringsudsNoch keine Bewertungen

- Tablas Medidas Tubos de Acero API5L - ASTM A53 - A106Dokument6 SeitenTablas Medidas Tubos de Acero API5L - ASTM A53 - A106Reinaldo AndaraNoch keine Bewertungen

- Amit Goswami Quantum Mechanics, Second Edition 2003Dokument577 SeitenAmit Goswami Quantum Mechanics, Second Edition 2003Solange Ev75% (4)

- Tractor: Workshop ManualDokument292 SeitenTractor: Workshop Manualyosy prastiyoNoch keine Bewertungen