Beruflich Dokumente

Kultur Dokumente

ASQ Certified Quality Inspector Body of Kowledge

Hochgeladen von

black bettyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASQ Certified Quality Inspector Body of Kowledge

Hochgeladen von

black bettyCopyright:

Verfügbare Formate

American Society for Quality (ASQ)

Certified Quality Inspector

Body of Knowledge (BOK)

This NEW Quality Inspector Body of Knowledge is effective March 3, 2012.

The topics in this body of knowledge include additional detail in the form of subtext

explanations and the cognitive level at which the questions will be written. This information will

provide useful guidance for both the Exam Development Committee and the candidate preparing

to take the exam. The subtext is not intended to limit the subject matter or be all-inclusive of

what might be covered in an exam. It is meant to clarify the type of content to be included in the

exam. The descriptor in parentheses at the end of each line of subtext refers to the maximum

cognitive level at which the topic will be tested. A complete description of cognitive levels is

provided at the end of this document.

I.

Technical Mathematics

(20 Questions)

A. Basic Shop Math

Solve basic shop math problems using addition, subtraction, multiplication, division

of fractions and decimals, squares and square roots. Use methods such as truncating

and rounding to obtain significant digits for positive and negative numbers. (Apply)

B. Basic Algebra

Solve or simplify first-degree and single-variable equations. (Apply)

C. Basic Geometry

Calculate general parameters such as area, circumference, perimeter, and volume for

basic geometric shapes. Calculate complementary and supplementary angles. (Apply)

D. Basic Trigonometry

Compute angles and lengths using trigonometric functions such as sine, cosine,

tangent, and the Pythagorean Theorem. (Apply)

E. Measurement Systems

Convert units within and between English and metric measurement systems (SI) such

as inch to micro-inch, liter to quart, meter to millimeter, etc. (Apply)

F. Numeric Conversions

Use various numbering methods such as scientific notation, decimals, and fractions,

and convert values between these systems. (Apply)

II.

Metrology

(30 Questions)

A. Common Gauges and Measurement Instruments

1. Variable gauges

Identify and use variable gauges, including micrometers, calipers, dial indicator,

CMM, linear scales, etc. (Apply)

2. Attribute gauges

Identify and use attribute gauges, including thread plug, progressive ring, flush pin,

radius gauge, etc. (Apply)

2012 CQI - Inspector BOK.doc

Page 1 of 7

2011 Draft BOK for Certified Quality Inspector

B.

C.

D.

E.

3. Transfer gauges

Identify and use transfer gauges, including small-hole gauges, spring calipers, etc.

(Apply)

4. Measurement scales

Describe and distinguish between dial, digital, and vernier scales. (Remember)

Special Gauges and Applications

Identify and describe the following basic tools and components. (Remember)

1. Electronic gauging tools: oscilloscopes, multimeters, pyrometers, etc.

2. Automatic gauging components: machine vision, ultrasonic, X-ray, laser, etc.

3. Pneumatic gauging components: air columns, probes, rings, etc.

Gauge Selection, Handling, and Use

1. Gauge selection

Select gauges according to the feature or characteristic to be measured, the

applicable tolerance and the accuracy, and the resolution and capability of the test

instrument. Determine whether the type of measurement should be direct,

differential, or transfer. (Apply)

2. Gauge handling, preservation, and storage

Identify and apply various methods of cleaning, handling, and storing gauges.

(Apply)

3. Gauge correlation

Identify and apply methods for establishing the correlation between measurement

instruments such as gauge-to-gauge or manual-to-automated process. (Apply)

Surface Plate Tools and Techniques

1. Surface plate equipment

Select and use height gauges, V-blocks, indicators, etc., to measure various types

of features. (Apply)

2. Angle measurement instruments

Identify and use protractors, sine bars, angle blocks, etc. (Apply)

Specialized Inspection Equipment

1. Measuring mass

Describe and apply weights, balances and scales. (Apply)

2. Measuring finish

Describe and apply profilometers, fingernail comparators, etc. (Apply)

3. Measuring shape and profile

Describe and apply mechanical comparators, roundness testers, precision spindles,

profile tracers, etc. (Apply)

4. Optical equipment

Describe and apply optical comparators, optical flats, microscopes, etc. (Apply)

5. Digital vision systems

Define and describe the use of digital cameras, in-line optical sensors, and other

digital systems for product inspection. (Remember)

6. Coordinate measuring machine (CMM)

Describe the advantages and disadvantages of the CMM and the basic operation of

the x, y, and z axes. Describe its limitations with regard to locating functional

datums, target points and areas, and hole positions. (Understand)

2011 CQI - Inspector BOK-SjC review.doc

Page 2 of 7

2011 Draft BOK for Certified Quality Inspector

F. Calibration

1. Calibration systems

Describe the principles and purpose of a calibration system, including the

importance of establishing calibration intervals. Identify and use basic tracking and

identification methods such as logs, stickers, identification codes, etc., to control

calibration equipment. (Apply)

2. Calibration standards

Describe the hierarchy of standards, from working standards through international

standards. (Remember)

3. Equipment traceability

Describe the requirements for documenting traceability to standards. (Remember)

4. Gage calibration environment

Describe the effects that environmental conditions, such as temperature, humidity,

vibration and cleanliness of the gauge, etc., can have on calibration. (Apply)

5. Out-of-calibration effects

Describe the effects that out-of-calibration instruments can have on product

acceptance and the actions to take in response to this situation. (Apply)

G. Measurement System Analysis (MSA)

Define and describe the following elements of MSA. (Remember)

1. Bias

2. Stability

3. Accuracy

4. Linearity

5. Repeatability and reproducibility (R&R) studies

III.

Inspection and Test (30 Questions)

A. Blueprints, Drawings, Geometric Dimensioning & Tolerancing (GD&T)

1. Blueprints and engineering drawings

Define and interpret various sections of technical drawings: title block, tolerances,

change or revision blocks, including notes, scale, and size details, etc. (Apply)

2. Terminology and symbols

Define and interpret drawing views and details for product specifications or other

controlling documents. Define and use various terms and symbols from the ASME

Y14.5M Standard. (Analyze)

3. Position and bonus tolerances

Calculate position and bonus tolerances from various drawings. (Analyze)

4. Part alignment and datum structure

Determine part alignment and setup using the datum structure. (Analyze)

B. Sampling

Define and interpret the following terms related to sampling. (Apply)

1. Acceptance quality limit (AQL)

2. Random sampling

3. Lot and sample size

4. Acceptance number

5. Sampling plans

2011 CQI - Inspector BOK-SjC review.doc

Page 3 of 7

2011 Draft BOK for Certified Quality Inspector

C. Inspection Planning and Processes

1. Inspection types

Define and distinguish between inspection types such as incoming material, firstarticle (first-piece), in-process, final, etc. (Apply)

2. Inspection errors

Identify potential inspection errors such as bias, fatigue, flinching, distraction, etc.

(Apply)

3. Product traceability

Identify methods to trace products and materials such as age control, shelf life, and

first-in first-out (FIFO). (Apply)

4. Identification of nonconforming material

Describe various methods of identifying nonconforming material such as tagging,

labeling, and segregating. (Apply)

5. Level of severity

Define and describe levels of severity (critical, major, minor, etc.) and apply them

to product features and defects. (Apply)

6. Disposition of nonconforming material

Describe disposition methods including rework, reprocess, scrap, customer waiver,

etc., as determined by a material review board (MRB) or other authority. (Apply)

D. Testing Methods

Define and use the following methods in various situations. (Apply)

1. Nondestructive testing: X-ray, eddy current, ultrasonic, dye penetrant,

magnetic particle, etc.

2. Destructive testing: tensile, force testing, drop test, etc.

3. Functionality testing: tension, torque, leak testing and compression, etc.

4. Hardness testing: Brinell, Rockwell, durometer, and micro-hardness scales

E. Software for test equipment

Identify and describe basic tools (e.g., safeguarding, functional checks, comparison of

test results, identification of attributes and parameters) used to ensure that the

software for test equipment adequately and correctly performs its intended functions.

(Remember)

IV.

Quality Assurance

(20 Questions)

A. Basic Statistics and Applications

1. Measures of central tendency

Calculate mean, median, and mode. (Apply)

2. Measures of dispersion

Calculate range, standard deviation, and variance. (Apply)

3. Measures of proportion

Calculate percentage and ratio measures for various data sets. (Apply)

4. Graphical displays

Define, interpret, and use scatter diagrams, tally sheets, bar charts, etc., to display

data effectively in various situations. (Apply)

5. Normal distribution

2011 CQI - Inspector BOK-SjC review.doc

Page 4 of 7

2011 Draft BOK for Certified Quality Inspector

Describe various characteristics of a normal distribution: symmetry, bell curve,

central tendency, etc. (Understand)

B. Statistical Process Control (SPC)

1. Common and special cause variation

Explain the difference between these causes of variation. Determine whether a

process is in statistical control by analyzing data patterns (runs, trends, hugging,

etc.), and identify what actions should be taken in response. (Evaluate)

2. Control limits and specification limits

Define, describe, and distinguish between these limits as used in SPC. (Apply)

3. Variables charts

Identify characteristics and uses of X R and X s charts. (Apply)

4. Attributes charts

Identify characteristics and uses of p, np, c, and u charts. (Apply)

5. Process capability analysis

Define and distinguish between Cp, Cpk, Pp, and Ppk studies and identify their

application to various types of data. (Understand)

C. Quality Improvement

1. Terms and concepts

Define basic quality improvement concepts such as defect detection and

prevention, the cost of poor quality, total quality management (TQM), the

importance of customer satisfaction, etc. (Understand)

2. Products and processes

Define and distinguish between products and processes. Describe the

interrelationships of product design, materials used, manufacturing processes, and

final output, and how individual steps in a process can affect the final product or

the system as a whole. (Understand)

D.

Quality Audits

1. Types of audits

Define and describe various types of audits, including internal, external, system,

product, process, etc. (Understand)

2. Audit process

Define and describe various stages of the audit process (planning, performance,

and closure), including audit scope and purpose, resources needed, audit schedule,

opening meeting, interviewing, data gathering, document and record review,

analysis of results, closing meeting, audit documentation and recordkeeping,

verification of corrective actions, etc. (Understand)

3. Audit tools

Define and describe the purpose of checklists, log sheets, sampling plans, record

and document reviews and forward-and backward-tracing. (Understand)

4. Communication tools and techniques

Define and describe the use of graphs, charts, diagrams, and other aids for written

and oral presentations including interview techniques and listening skills.

(Understand)

5. Corrective action requests (CARs)

Describe how CARs from audits can support quality improvement. (Understand)

2011 CQI - Inspector BOK-SjC review.doc

Page 5 of 7

2011 Draft BOK for Certified Quality Inspector

E. Quality Tools and Techniques

Define and use the following quality tools and techniques. (Apply)

1. Pareto charts

2. Cause and effect diagrams

3. Flowcharts

4. Control charts

5. Check sheets

6. Scatter diagrams

7. Histograms

F. Problem-solving Tools and Continuous Improvement Techniques

Describe and use the following tools and techniques in various situations. (Apply)

1. Plan-do-check-act (PDCA) or plan-do-study-act (PDSA) cycles

2. Lean tools for eliminating waste: 5S, error-proofing, value-stream mapping;

and lean concepts: kaizen, flow, pull,

3. Six sigma phases: define, measure, analyze, improve, control (DMAIC)

4. Failure mode and effects analysis (FMEA)

G. Resources

1. Environmental and safety support

Define and use various resources related to personal and environmental safety:

material safety data sheet (MSDS), personal protective equipment (PPE), etc.

(Apply)

2. Reference documents

Identify and use national and international standards (e.g., ISO, ANSI, ASTM, QS)

and customer requirements as authorities that support processes and procedures

used to assure quality products. (Apply)

3. Technical reports

Review, analyze, and interpret technical reports that are used to diagnose problems

and communicate solutions. (Analyze)

4. Employees as resources (Remember)

Describe how employees can be empowered and the value they add to project

teams or quality improvement teams. Describe typical team roles and

responsibilities: facilitator, ground rules, project or team charter, etc. Describe the

four stages of team development: forming, storming, norming, performing.

(Remember)

Note: Approximately 20% of the questions in each test will require calculation.

2011 CQI - Inspector BOK-SjC review.doc

Page 6 of 7

2011 Draft BOK for Certified Quality Inspector

SIX LEVELS OF COGNITION

BASED ON BLOOMS TAXONOMY (REVISED)

In addition to content specifics, the subtext detail also indicates the intended complexity level of

the test questions for that topic. These levels are based on the Revised Levels of Cognition

(from Blooms Taxonomy, 2001) and are presented below in rank order, from least complex to

most complex.

REMEMBER

Be able to remember or recognize terminology, definitions, facts, ideas, materials, patterns,

sequences, methodologies, principles, etc. (Also commonly referred to as recognition, recall, or

rote knowledge.)

UNDERSTAND

Be able to read and understand descriptions, communications, reports, tables, diagrams,

directions, regulations, etc.

APPLY

Be able to apply ideas, procedures, methods, formulas, principles, theories, etc., in job-related

situations.

ANALYZE

Be able to break down information into its constituent parts and recognize the parts relationship

to one another and how they are organized; identify sublevel factors or salient data from a

complex scenario.

EVALUATE

Be able to make judgments regarding the value of proposed ideas, solutions, methodologies, etc.,

by using appropriate criteria or standards to estimate accuracy, effectiveness, economic benefits,

etc.

CREATE

Be able to put parts or elements together in such a way as to show a pattern or structure not

clearly there before; be able to identify which data or information from a complex set is

appropriate to examine further or from which supported conclusions can be drawn.

2011 CQI - Inspector BOK-SjC review.doc

Page 7 of 7

Das könnte Ihnen auch gefallen

- ASQ CQPA Body of KnowledgeDokument6 SeitenASQ CQPA Body of KnowledgeAngel Cortez EspinozaNoch keine Bewertungen

- Quality Engineer Exam Prep - How To Study For Your ASQ CQE CertificationDokument17 SeitenQuality Engineer Exam Prep - How To Study For Your ASQ CQE CertificationJennyNoch keine Bewertungen

- The ASQ Certified Quality Improvement Associate HandbookVon EverandThe ASQ Certified Quality Improvement Associate HandbookNoch keine Bewertungen

- The ASQ CQE Study GuideDokument20 SeitenThe ASQ CQE Study Guideflyinzesky0% (1)

- Asqm Asqc12518Dokument20 SeitenAsqm Asqc12518keldhaiNoch keine Bewertungen

- Manufacturing ISO 9001 A Complete Guide - 2019 EditionVon EverandManufacturing ISO 9001 A Complete Guide - 2019 EditionNoch keine Bewertungen

- CERTIFIED Quality EngineerDokument16 SeitenCERTIFIED Quality Engineeracadjournals. comNoch keine Bewertungen

- Software Validation A Complete Guide - 2020 EditionVon EverandSoftware Validation A Complete Guide - 2020 EditionNoch keine Bewertungen

- Cqa PDFDokument39 SeitenCqa PDFcasmith430% (1)

- Project Quality Management A Complete Guide - 2019 EditionVon EverandProject Quality Management A Complete Guide - 2019 EditionNoch keine Bewertungen

- Cqe Exam Preparation CourseDokument2 SeitenCqe Exam Preparation CourseAhmed M. Hashim0% (1)

- Tables For CQE ExamDokument22 SeitenTables For CQE Examjr2k7osuNoch keine Bewertungen

- The Certified Manager of Quality/Organizational Excellence (CMQ/OE) Mind Map BookVon EverandThe Certified Manager of Quality/Organizational Excellence (CMQ/OE) Mind Map BookBewertung: 5 von 5 Sternen5/5 (2)

- Chapter 6 Quality QuestionsDokument3 SeitenChapter 6 Quality QuestionsnsadnanNoch keine Bewertungen

- Certified Quality Engineer A Complete Guide - 2020 EditionVon EverandCertified Quality Engineer A Complete Guide - 2020 EditionNoch keine Bewertungen

- CSQE Exam Preparation: Douglas HoffmanDokument390 SeitenCSQE Exam Preparation: Douglas HoffmanAnirban DasNoch keine Bewertungen

- CQE Practice ExamDokument35 SeitenCQE Practice ExamgogasinghNoch keine Bewertungen

- Cqe Sample ExamDokument17 SeitenCqe Sample ExamnewdaoNoch keine Bewertungen

- Cqia Sample ExamDokument9 SeitenCqia Sample ExamAhsan SaleemNoch keine Bewertungen

- Quality assurance QA The Ultimate Step-By-Step GuideVon EverandQuality assurance QA The Ultimate Step-By-Step GuideNoch keine Bewertungen

- Cqe Q&aDokument51 SeitenCqe Q&aGaren Chen 凯仁100% (1)

- Integrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodVon EverandIntegrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodNoch keine Bewertungen

- ABCQ Cqe - PDokument13 SeitenABCQ Cqe - PAntonio Melgaço da Silva0% (2)

- What The Heck You Should Know About Quality Engineering?Von EverandWhat The Heck You Should Know About Quality Engineering?Noch keine Bewertungen

- What does "each individual plot pointDokument33 SeitenWhat does "each individual plot pointShirley100% (1)

- Cqe Sample ExamDokument16 SeitenCqe Sample ExamAlireza Radfarma100% (2)

- CertifiedqualityengineerDokument10 SeitenCertifiedqualityengineersriram100% (1)

- Looking For Real Exam Questions For IT Certification Exams!Dokument11 SeitenLooking For Real Exam Questions For IT Certification Exams!Kabala UsmanNoch keine Bewertungen

- CQPA Exam Prep: Top 9 Books for Quality Process Analyst CertificationDokument1 SeiteCQPA Exam Prep: Top 9 Books for Quality Process Analyst CertificationBharathNoch keine Bewertungen

- CQT Sample Exam PDFDokument12 SeitenCQT Sample Exam PDFMMFAWZYNoch keine Bewertungen

- SSGB PDFDokument78 SeitenSSGB PDFBima AntasenaNoch keine Bewertungen

- CQE Fact SheetDokument2 SeitenCQE Fact Sheetippon_osotoNoch keine Bewertungen

- CQEDokument3 SeitenCQEMeetrra Deva Dharsini SelvamNoch keine Bewertungen

- CQE Sample Test #5Dokument32 SeitenCQE Sample Test #5gogasinghNoch keine Bewertungen

- AsqDokument33 SeitenAsqAhmed M. HashimNoch keine Bewertungen

- Quality Council of Indiana Version As of June 26, 2022Dokument24 SeitenQuality Council of Indiana Version As of June 26, 2022Suresh Anand BSNoch keine Bewertungen

- Cui - Practical Exercise 3.1Dokument5 SeitenCui - Practical Exercise 3.1John Ronnie Tare CuiNoch keine Bewertungen

- Six Sigma Black Belt Roadmap-Lynda PDFDokument4 SeitenSix Sigma Black Belt Roadmap-Lynda PDFChino Estoque FragataNoch keine Bewertungen

- Study Guide and How To Crack Exam On Asq Certified Quality Engineer (Cqe)Dokument5 SeitenStudy Guide and How To Crack Exam On Asq Certified Quality Engineer (Cqe)Arun KangeyanNoch keine Bewertungen

- Prep Courses For Certifications, ASQ CQE, CSTE & CSQA & Business Analyst.Dokument7 SeitenPrep Courses For Certifications, ASQ CQE, CSTE & CSQA & Business Analyst.api-376397650% (2)

- Certified Quality Engineer Problem Bank 4Dokument36 SeitenCertified Quality Engineer Problem Bank 4jackanddiane1Noch keine Bewertungen

- Virtual Certified Supplier Quality ProfessionalDokument1 SeiteVirtual Certified Supplier Quality ProfessionalPapaiNoch keine Bewertungen

- PPAP FundamentalsDokument21 SeitenPPAP FundamentalsRajdeep SinghNoch keine Bewertungen

- Certified Quality Auditor (ASQ Sample Exam Paper)Dokument24 SeitenCertified Quality Auditor (ASQ Sample Exam Paper)Farhan Shariff86% (7)

- CQE Sample1Dokument19 SeitenCQE Sample1Mani Rathinam Rajamani50% (2)

- Understanding Iso 9000 Understanding Iso 9000 Quality Management System QDokument24 SeitenUnderstanding Iso 9000 Understanding Iso 9000 Quality Management System QManikandan100% (2)

- CQE Testing SampleDokument17 SeitenCQE Testing Samplemohammad_reza_49Noch keine Bewertungen

- Guide For Final ExamDokument28 SeitenGuide For Final ExamScribdTranslationsNoch keine Bewertungen

- CQEproblem 2Dokument61 SeitenCQEproblem 2Aaibonmagaling Lumipipad Mataas Bangiscrocodile100% (2)

- ASQ 6 Sigma Green BeltDokument12 SeitenASQ 6 Sigma Green BeltSamantha DlimaNoch keine Bewertungen

- ASQ CQE Sample QuestionsDokument3 SeitenASQ CQE Sample QuestionsDickson ChoyNoch keine Bewertungen

- Referance SSBBDokument4 SeitenReferance SSBBJahidul IslamNoch keine Bewertungen

- 7 Measure StatisticsDokument76 Seiten7 Measure StatisticsSrini Vasan100% (2)

- CEH Exam Blueprint v2.0Dokument3 SeitenCEH Exam Blueprint v2.0aqil_shamsiNoch keine Bewertungen

- CEHv9 Instructor GuideDokument112 SeitenCEHv9 Instructor Guideblack bettyNoch keine Bewertungen

- W225002 SaleDokument1 SeiteW225002 Saleblack bettyNoch keine Bewertungen

- W2045002 SalDokument1 SeiteW2045002 Salblack bettyNoch keine Bewertungen

- MindCert CEH Ethical Hacking MindMapDokument1 SeiteMindCert CEH Ethical Hacking MindMapyki01Noch keine Bewertungen

- W2045002 SalDokument1 SeiteW2045002 Salblack bettyNoch keine Bewertungen

- Hacking - CEH Cheat Sheet ExercisesDokument49 SeitenHacking - CEH Cheat Sheet ExercisesTetuan AzlanNoch keine Bewertungen

- Sample ExamDokument38 SeitenSample ExamjayarajanNoch keine Bewertungen

- Certified Ethical Hacking Module 5 MapDokument1 SeiteCertified Ethical Hacking Module 5 MapRismal Ray VaughanNoch keine Bewertungen

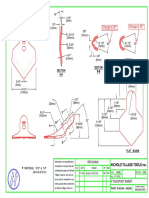

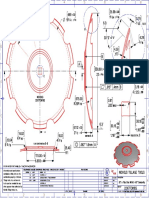

- Seed Disc Assembly SchemeDokument1 SeiteSeed Disc Assembly Schemeblack bettyNoch keine Bewertungen

- W225001 SaleDokument1 SeiteW225001 Saleblack bettyNoch keine Bewertungen

- W 2045002 SaleDokument1 SeiteW 2045002 Saleblack bettyNoch keine Bewertungen

- W164131 WfeDokument1 SeiteW164131 Wfeblack bettyNoch keine Bewertungen

- W2045002 - SAL - Rev 06-08Dokument1 SeiteW2045002 - SAL - Rev 06-08black bettyNoch keine Bewertungen

- 8" Disk Assembly (Nichols PN 08035DYCAB) 540500: Revisions Zone Rev. Description Date ApprovedDokument1 Seite8" Disk Assembly (Nichols PN 08035DYCAB) 540500: Revisions Zone Rev. Description Date Approvedblack bettyNoch keine Bewertungen

- W184001WFDMEDokument1 SeiteW184001WFDMEblack bettyNoch keine Bewertungen

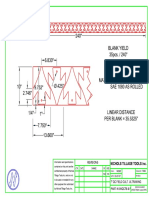

- UWQC7 Blank LayoutDokument1 SeiteUWQC7 Blank Layoutblack bettyNoch keine Bewertungen

- W 174001 WfeDokument1 SeiteW 174001 Wfeblack bettyNoch keine Bewertungen

- MG4A-MG4B - Rev 01 - 2012-11-16Dokument1 SeiteMG4A-MG4B - Rev 01 - 2012-11-16black bettyNoch keine Bewertungen

- Mg4a MG4BDokument1 SeiteMg4a MG4Bblack bettyNoch keine Bewertungen

- 22X14FCN18SDokument1 Seite22X14FCN18Sblack bettyNoch keine Bewertungen

- MG2B - Rev 01 - 2012-11-16Dokument1 SeiteMG2B - Rev 01 - 2012-11-16black bettyNoch keine Bewertungen

- 22X14FCN12RDokument1 Seite22X14FCN12Rblack bettyNoch keine Bewertungen

- G9a G9BDokument1 SeiteG9a G9Bblack bettyNoch keine Bewertungen

- 24X14FC12RDokument1 Seite24X14FC12Rblack bettyNoch keine Bewertungen

- 22X7FC18DSDokument1 Seite22X7FC18DSblack bettyNoch keine Bewertungen

- 24X14FC12SDokument1 Seite24X14FC12Sblack bettyNoch keine Bewertungen

- 22X7FCN18SDokument1 Seite22X7FCN18Sblack bettyNoch keine Bewertungen

- 22X14FC18SDokument1 Seite22X14FC18Sblack bettyNoch keine Bewertungen

- 22X7FC18SDokument1 Seite22X7FC18Sblack bettyNoch keine Bewertungen

- Department of Ece Vjec 1Dokument29 SeitenDepartment of Ece Vjec 1Surangma ParasharNoch keine Bewertungen

- CadLink Flyer 369044 937 Rev 00Dokument2 SeitenCadLink Flyer 369044 937 Rev 00ShanaHNoch keine Bewertungen

- PRE EmtionDokument10 SeitenPRE EmtionYahya JanNoch keine Bewertungen

- 13-07-01 Declaration in Support of Skyhook Motion To CompelDokument217 Seiten13-07-01 Declaration in Support of Skyhook Motion To CompelFlorian MuellerNoch keine Bewertungen

- Dinsmore - Gantt ChartDokument1 SeiteDinsmore - Gantt Chartapi-592162739Noch keine Bewertungen

- Part I-Final Report On Soil InvestigationDokument16 SeitenPart I-Final Report On Soil InvestigationmangjuhaiNoch keine Bewertungen

- Introduction To Succession-1Dokument8 SeitenIntroduction To Succession-1amun dinNoch keine Bewertungen

- Diagnostic Information For Database Replay IssuesDokument10 SeitenDiagnostic Information For Database Replay IssuesjjuniorlopesNoch keine Bewertungen

- MSBI Installation GuideDokument25 SeitenMSBI Installation GuideAmit SharmaNoch keine Bewertungen

- Meanwhile Elsewhere - Lizzie Le Blond.1pdfDokument1 SeiteMeanwhile Elsewhere - Lizzie Le Blond.1pdftheyomangamingNoch keine Bewertungen

- SAP ORC Opportunities PDFDokument1 SeiteSAP ORC Opportunities PDFdevil_3565Noch keine Bewertungen

- Analyze Oil Wear DebrisDokument2 SeitenAnalyze Oil Wear Debristhoma111sNoch keine Bewertungen

- Quezon City Department of The Building OfficialDokument2 SeitenQuezon City Department of The Building OfficialBrightNotes86% (7)

- Overhead Door Closers and Hardware GuideDokument2 SeitenOverhead Door Closers and Hardware GuideAndrea Joyce AngelesNoch keine Bewertungen

- Ju Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperDokument11 SeitenJu Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperBiponjot KaurNoch keine Bewertungen

- Geneva IntrotoBankDebt172Dokument66 SeitenGeneva IntrotoBankDebt172satishlad1288Noch keine Bewertungen

- Model:: Powered by CUMMINSDokument4 SeitenModel:: Powered by CUMMINSСергейNoch keine Bewertungen

- Banas Dairy ETP Training ReportDokument38 SeitenBanas Dairy ETP Training ReportEagle eye0% (2)

- Database Chapter 11 MCQs and True/FalseDokument2 SeitenDatabase Chapter 11 MCQs and True/FalseGauravNoch keine Bewertungen

- WELDING EQUIPMENT CALIBRATION STATUSDokument4 SeitenWELDING EQUIPMENT CALIBRATION STATUSAMIT SHAHNoch keine Bewertungen

- Elaspeed Cold Shrink Splices 2010Dokument3 SeitenElaspeed Cold Shrink Splices 2010moisesramosNoch keine Bewertungen

- Overall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarDokument2 SeitenOverall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarVishak ThebossNoch keine Bewertungen

- Leg Wri FInal ExamDokument15 SeitenLeg Wri FInal ExamGillian CalpitoNoch keine Bewertungen

- Chapter 6: Structured Query Language (SQL) : Customer Custid Custname OccupationDokument16 SeitenChapter 6: Structured Query Language (SQL) : Customer Custid Custname OccupationSarmila MahendranNoch keine Bewertungen

- Arizona Supreme CT Order Dismisses Special ActionDokument3 SeitenArizona Supreme CT Order Dismisses Special Actionpaul weichNoch keine Bewertungen

- Chill - Lease NotesDokument19 SeitenChill - Lease Notesbellinabarrow100% (4)

- 4Q Labor Case DigestsDokument53 Seiten4Q Labor Case DigestsKaren Pascal100% (2)

- Ata 36 PDFDokument149 SeitenAta 36 PDFAyan Acharya100% (2)

- CASE DigeSTDokument2 SeitenCASE DigeSTZepht BadillaNoch keine Bewertungen

- CCS PDFDokument2 SeitenCCS PDFАндрей НадточийNoch keine Bewertungen

- Make It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningVon EverandMake It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningBewertung: 4.5 von 5 Sternen4.5/5 (55)

- The Everything Guide to Study Skills: Strategies, tips, and tools you need to succeed in school!Von EverandThe Everything Guide to Study Skills: Strategies, tips, and tools you need to succeed in school!Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- IELTS Speaking Vocabulary Builder (Band 5-6): Master Phrases and Expressions for the IELTS Speaking ExamVon EverandIELTS Speaking Vocabulary Builder (Band 5-6): Master Phrases and Expressions for the IELTS Speaking ExamBewertung: 5 von 5 Sternen5/5 (1)

- Math Olympiad Contests Preparation For Grades 4-8: Competition Level Math for Middle School Students to Win MathCON, AMC-8, MATHCOUNTS, and Math LeaguesVon EverandMath Olympiad Contests Preparation For Grades 4-8: Competition Level Math for Middle School Students to Win MathCON, AMC-8, MATHCOUNTS, and Math LeaguesNoch keine Bewertungen

- A-level Maths Revision: Cheeky Revision ShortcutsVon EverandA-level Maths Revision: Cheeky Revision ShortcutsBewertung: 3.5 von 5 Sternen3.5/5 (8)

- 700 Driving Theory Test Questions & Answers: Updated Study Guide With Over 700 Official Style Practise Questions For Cars - Based Off the Highway CodeVon Everand700 Driving Theory Test Questions & Answers: Updated Study Guide With Over 700 Official Style Practise Questions For Cars - Based Off the Highway CodeNoch keine Bewertungen

- TEF Canada Expression Écrite : 150 Topics To SucceedVon EverandTEF Canada Expression Écrite : 150 Topics To SucceedBewertung: 4.5 von 5 Sternen4.5/5 (17)

- BCBA Exam Prep A Study Guide to Practice Test Questions With Answers and Master the Board Certified Behavior Analyst ExaminationVon EverandBCBA Exam Prep A Study Guide to Practice Test Questions With Answers and Master the Board Certified Behavior Analyst ExaminationNoch keine Bewertungen

- 71 Ways to Practice English Reading: Tips for ESL/EFL LearnersVon Everand71 Ways to Practice English Reading: Tips for ESL/EFL LearnersBewertung: 5 von 5 Sternen5/5 (2)

- ATI TEAS Study Guide: The Most Comprehensive and Up-to-Date Manual to Ace the Nursing Exam on Your First Try with Key Practice Questions, In-Depth Reviews, and Effective Test-Taking StrategiesVon EverandATI TEAS Study Guide: The Most Comprehensive and Up-to-Date Manual to Ace the Nursing Exam on Your First Try with Key Practice Questions, In-Depth Reviews, and Effective Test-Taking StrategiesNoch keine Bewertungen

- Learning from Lectures: Learning from lectures, listening & notetaking skillsVon EverandLearning from Lectures: Learning from lectures, listening & notetaking skillsBewertung: 5 von 5 Sternen5/5 (6)

- Real Stories: The All-Inclusive Textbook for Developmental Writing and ReadingVon EverandReal Stories: The All-Inclusive Textbook for Developmental Writing and ReadingNoch keine Bewertungen

- PSI National Real Estate License Exam Prep 2020-2021: A Study Guide with 550 Test Questions and Answers Explanations (Includes Practice Tests for Brokers and Salespersons)Von EverandPSI National Real Estate License Exam Prep 2020-2021: A Study Guide with 550 Test Questions and Answers Explanations (Includes Practice Tests for Brokers and Salespersons)Bewertung: 1 von 5 Sternen1/5 (1)

- SIE Exam Prep 2021-2022: SIE Study Guide with 300 Questions and Detailed Answer Explanations for the FINRA Securities Industry Essentials Exam (Includes 4 Full-Length Practice Tests)Von EverandSIE Exam Prep 2021-2022: SIE Study Guide with 300 Questions and Detailed Answer Explanations for the FINRA Securities Industry Essentials Exam (Includes 4 Full-Length Practice Tests)Bewertung: 5 von 5 Sternen5/5 (1)

- The LearnCurious Companion to the Digital SAT: VerbalVon EverandThe LearnCurious Companion to the Digital SAT: VerbalNoch keine Bewertungen