Beruflich Dokumente

Kultur Dokumente

Maxon EC22 50watt

Hochgeladen von

ElectromateOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Maxon EC22 50watt

Hochgeladen von

ElectromateCopyright:

Verfügbare Formate

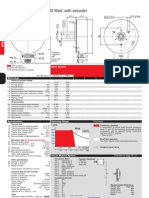

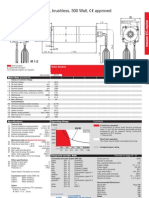

EC 22 Æ22 mm, brushless, 50 Watt

A with hall sensors B sensorless

maxon EC motor

Connector:

MKF 13268-6-0-808

Stocko Elektronik GmbH

M 1:1

Stock program

Standard program Order Number

Special program (on request)

A with Hall sensors 167130 167129

B sensorless 201049 201048

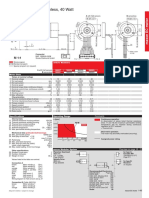

Motor Data

Values at nominal voltage

1 Nominal voltage V 32.0 32.0

2 No load speed rpm 38700 22400

3 No load current mA 327 128

4 Nominal speed rpm 36600 20200

5 Nominal torque (max. continuous torque) mNm 30.6 37.2

6 Nominal current (max. continuous current) A 4.16 2.82

7 Stall torque mNm 692 437

8 Starting current A 88.2 32.1

9 Max. efficiency % 88 88

Characteristics

10 Terminal resistance phase to phase W 0.363 0.997

11 Terminal inductance phase to phase mH 0.0490 0.147

12 Torque constant mNm / A 7.85 13.6

13 Speed constant rpm / V 1220 702

14 Speed / torque gradient rpm / mNm 56.2 51.4

15 Mechanical time constant ms 2.47 2.26

16 Rotor inertia gcm2 4.20 4.20

Specifications Operating Range Comments

Thermal data n [rpm]

17 Thermal resistance housing-ambient 7.0 K / W Continuous operation

18 Thermal resistance winding-housing 1.0 K / W In observation of above listed thermal resistance

19 Thermal time constant winding 5.06 s (lines 17 and 18) the maximum permissible winding

temperature will be reached during continuous

20 Thermal time constant motor 355 s

operation at 25°C ambient.

21 Ambient temperature -20 ... +100°C

= Thermal limit.

22 Max. permissible winding temperature +125°C

Mechanical data (preloaded ball bearings) Short term operation

23 Max. permissible speed1) 50000 rpm The motor may be briefly overloaded (recurring).

24 Axial play at axial load < 5 N 0 mm

>5N max. 0.14 mm

25 Radial play preloaded Assigned power rating

26 Max. axial load (dynamic) 4N

27 Max. force for press fits (static) 60 N

(static, shaft supported) 250 N

28 Max. radial loading, 5 mm from flange 16 N

1) in combination with encoder MR nmax = 37500 rpm

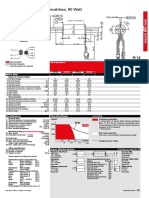

maxon Modular System Overview on page 16 - 21

Other specifications Planetary Gearhead for type A:

29 Number of pole pairs 1 Æ22 mm Encoder MR

30 Number of phases 3 0.5 - 3.4 Nm 128 / 256 / 512 CPT

31 Weight of motor 130 g Page 226 / 227 Page 263

Spindle Drive

Values listed in the table are nominal. Æ22 mm for type B:

Connection A Page 249 / 250 Resolver

brown Motor winding 1 Pin 1 on request

red Motor winding 2 Pin 2

orange Motor winding 3 Pin 3

yellow VHall 4.5 ... 24 VDC Pin 4

green GND Pin 5 Recommended Electronics:

blue Hall sensor 1* Pin 6 DECS 50/5 Page 288

violet Hall sensor 2* Pin 7 DEC 24/3, DEC 50/5 289

grey Hall sensor 3* Pin 8 DECV 50/5 295

*Internal pull-up (7 … 13 kW) on pin 4 DES 50/5 296

Connection B (Cable AWG 24) EPOS 24/1 302

brown Motor winding 1 EPOS2 Module 36/2 302

red Motor winding 2 EPOS 24/5 303

EPOS2 50/5 303

orange Motor winding 3 Sold & Serviced By:

EPOS P 24/5 306

Wiring diagram for Hall sensors see page 27 ELECTROMATE

INDUSTRIAL SALES LIMITED Notes 20

PRECISION TECHNOLOGY & QUALITY

152 Toll Free Phone (877) SERVO98 May 2009 edition / subject to change

Toll Free Fax (877) SERVO99

sales@electromate.com

www.electromate.com

Das könnte Ihnen auch gefallen

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Electrical and Electronic Principles: Volume 2Von EverandElectrical and Electronic Principles: Volume 2Bewertung: 4 von 5 Sternen4/5 (5)

- Boq ElectricalDokument22 SeitenBoq Electricaleng_hosNoch keine Bewertungen

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsVon EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNoch keine Bewertungen

- 1047A Refractive Index Detector: Service HandbookDokument148 Seiten1047A Refractive Index Detector: Service HandbookbowcoastieNoch keine Bewertungen

- Erection Testing and CommissioningDokument30 SeitenErection Testing and CommissioningEngr Muhammad Abu BakrNoch keine Bewertungen

- Analog Circuit Design Volume Three: Design Note CollectionVon EverandAnalog Circuit Design Volume Three: Design Note CollectionBewertung: 3 von 5 Sternen3/5 (2)

- Maintain Your Vibrating Roller MachineDokument96 SeitenMaintain Your Vibrating Roller MachineOggy ToffyNoch keine Bewertungen

- Titan 10k Schematic PDFDokument24 SeitenTitan 10k Schematic PDFTan Hung LuuNoch keine Bewertungen

- Analog Circuit Techniques: With Digital InterfacingVon EverandAnalog Circuit Techniques: With Digital InterfacingNoch keine Bewertungen

- 33KV & PTR (ABB) Relay SettingDokument16 Seiten33KV & PTR (ABB) Relay SettingJayam KondanNoch keine Bewertungen

- Digital Power Electronics and ApplicationsVon EverandDigital Power Electronics and ApplicationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Voltages Induced in Sheaths and Armour of Single Core CablesDokument2 SeitenVoltages Induced in Sheaths and Armour of Single Core CablesHameedNoch keine Bewertungen

- EC 22 22 MM, Brushless, 50 Watt: Part NumbersDokument1 SeiteEC 22 22 MM, Brushless, 50 Watt: Part NumbersfurkanfurkanfurkanNoch keine Bewertungen

- Maxon EC-Powermax30 200wattDokument1 SeiteMaxon EC-Powermax30 200wattElectromateNoch keine Bewertungen

- Maxon EC22 50watt SterilisableDokument1 SeiteMaxon EC22 50watt SterilisableElectromateNoch keine Bewertungen

- Maxon EC90 Flat 90watt With EncoderDokument1 SeiteMaxon EC90 Flat 90watt With EncoderElectromateNoch keine Bewertungen

- Maxon EC6 1.2wattDokument1 SeiteMaxon EC6 1.2wattElectromateNoch keine Bewertungen

- Maxon EC-Max40 70wattDokument1 SeiteMaxon EC-Max40 70wattElectromateNoch keine Bewertungen

- Maxon EC90 Flat 90wattDokument1 SeiteMaxon EC90 Flat 90wattElectromateNoch keine Bewertungen

- Maxon EC-Max16 5wattDokument1 SeiteMaxon EC-Max16 5wattElectromateNoch keine Bewertungen

- EC 20 MOTOR SPECSDokument1 SeiteEC 20 MOTOR SPECSivanlawms6745Noch keine Bewertungen

- Maxon EC20 Flat 5wattDokument1 SeiteMaxon EC20 Flat 5wattElectromateNoch keine Bewertungen

- Maxon EC-Max22 25wattDokument1 SeiteMaxon EC-Max22 25wattElectromateNoch keine Bewertungen

- Motor Maxon 323772Dokument1 SeiteMotor Maxon 323772Henry Daniel VerdugoNoch keine Bewertungen

- 12 156 enDokument1 Seite12 156 enLuka MadridNoch keine Bewertungen

- Maxon EC22 20watt Integrated ElectronicsDokument2 SeitenMaxon EC22 20watt Integrated ElectronicsElectromateNoch keine Bewertungen

- En 21 250Dokument1 SeiteEn 21 250compimagmaticNoch keine Bewertungen

- Maxon EC60 400wattDokument1 SeiteMaxon EC60 400wattElectromateNoch keine Bewertungen

- 12 149 enDokument1 Seite12 149 enLuka MadridNoch keine Bewertungen

- Maxon EC-Max30 40wattDokument1 SeiteMaxon EC-Max30 40wattElectromateNoch keine Bewertungen

- En 21 251Dokument1 SeiteEn 21 251Froylan OchoaNoch keine Bewertungen

- Maxon Ec45 136210Dokument1 SeiteMaxon Ec45 136210compimagmaticNoch keine Bewertungen

- 90mm EC Brushless MotorDokument1 Seite90mm EC Brushless MotorLucas SuplinoNoch keine Bewertungen

- Maxon EC45 Flat 30wattDokument1 SeiteMaxon EC45 Flat 30wattElectromateNoch keine Bewertungen

- Maxon RE30 Graphite Brushes 60wattDokument1 SeiteMaxon RE30 Graphite Brushes 60wattElectromateNoch keine Bewertungen

- Maxon EC20 Flat 3wattDokument1 SeiteMaxon EC20 Flat 3wattElectromateNoch keine Bewertungen

- EC 40 40 MM, Brushless, 170 Watt: Part NumbersDokument1 SeiteEC 40 40 MM, Brushless, 170 Watt: Part NumbersfurkanfurkanfurkanNoch keine Bewertungen

- RE 50 50mm Graphite Brushes 200W MotorDokument1 SeiteRE 50 50mm Graphite Brushes 200W MotorJorge Alejandro Barrutia BorbollaNoch keine Bewertungen

- RE50Dokument1 SeiteRE50Yhony Gamarra VargasNoch keine Bewertungen

- F2140 Eng DatasheetDokument4 SeitenF2140 Eng Datasheettngyew leeNoch keine Bewertungen

- EC 90 Flat: 90 MM, Brushless, 600 WattDokument1 SeiteEC 90 Flat: 90 MM, Brushless, 600 WattDiy DoeNoch keine Bewertungen

- Maxon RE65 Graphite Brushes 250wattDokument1 SeiteMaxon RE65 Graphite Brushes 250wattElectromateNoch keine Bewertungen

- Motor 30 WattDokument1 SeiteMotor 30 WattPRED4T0R85Noch keine Bewertungen

- Maxon Re40 DC Motor 148866 Datasheet PDFDokument1 SeiteMaxon Re40 DC Motor 148866 Datasheet PDFtoony reyesNoch keine Bewertungen

- Motores Maxon 2017Dokument1 SeiteMotores Maxon 2017--Noch keine Bewertungen

- 17 en 170 Lstage DatasheetDokument1 Seite17 en 170 Lstage DatasheetSana SyedNoch keine Bewertungen

- MAXON Brushed Motor A-Max 26, 4.5 WDokument1 SeiteMAXON Brushed Motor A-Max 26, 4.5 WRadu BabauNoch keine Bewertungen

- Maxon Re40Dokument1 SeiteMaxon Re40compimagmaticNoch keine Bewertungen

- Maxon RE25 Precious Metal Brushes 10wattDokument1 SeiteMaxon RE25 Precious Metal Brushes 10wattElectromateNoch keine Bewertungen

- EC 60mm 400W Brushless MotorDokument1 SeiteEC 60mm 400W Brushless MotorZoltán SoósNoch keine Bewertungen

- Maxon RE-Max17 Graphite Brushes 4.5wattDokument2 SeitenMaxon RE-Max17 Graphite Brushes 4.5wattElectromateNoch keine Bewertungen

- Maxon RE40 Graphite Brushes 150wattDokument1 SeiteMaxon RE40 Graphite Brushes 150wattElectromateNoch keine Bewertungen

- 12 171 enDokument1 Seite12 171 enLuka MadridNoch keine Bewertungen

- EC-max 30 ∅30 mm, brushless, 60 Watt motor specsDokument1 SeiteEC-max 30 ∅30 mm, brushless, 60 Watt motor specsfurkanfurkanfurkanNoch keine Bewertungen

- Maxon EC45 4 Pole 300wattDokument1 SeiteMaxon EC45 4 Pole 300wattElectromateNoch keine Bewertungen

- 16 275 enDokument1 Seite16 275 enmawadNoch keine Bewertungen

- Maxon RE50 Graphite Brushes 200wattDokument1 SeiteMaxon RE50 Graphite Brushes 200wattElectromateNoch keine Bewertungen

- Graphite Brushes, 60 Watt Maxon DC MotorDokument1 SeiteGraphite Brushes, 60 Watt Maxon DC MotorRatanieriNoch keine Bewertungen

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesDokument1 SeiteGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateNoch keine Bewertungen

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionDokument1 SeiteIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateNoch keine Bewertungen

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseDokument1 SeiteElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateNoch keine Bewertungen

- Electromate Elated With Win at The 2022 Business Achievement AwardsDokument2 SeitenElectromate Elated With Win at The 2022 Business Achievement AwardsElectromateNoch keine Bewertungen

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaDokument1 SeiteElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateNoch keine Bewertungen

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsDokument1 SeiteNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateNoch keine Bewertungen

- Kollmorgen Debuts EKM Series Servo MotorsDokument1 SeiteKollmorgen Debuts EKM Series Servo MotorsElectromateNoch keine Bewertungen

- Exor X5 Wireless Press ReleaseDokument1 SeiteExor X5 Wireless Press ReleaseElectromateNoch keine Bewertungen

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotDokument2 SeitenMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateNoch keine Bewertungen

- Electromate Recertified As A Great Place To Work' Press ReleaseDokument1 SeiteElectromate Recertified As A Great Place To Work' Press ReleaseElectromateNoch keine Bewertungen

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMDokument2 SeitenAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateNoch keine Bewertungen

- New 100 Amps Peak FlexPro Servo Drives Available From AMCDokument1 SeiteNew 100 Amps Peak FlexPro Servo Drives Available From AMCElectromateNoch keine Bewertungen

- Electromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesDokument2 SeitenElectromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesElectromateNoch keine Bewertungen

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesDokument2 SeitenNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateNoch keine Bewertungen

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesDokument2 SeitenADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateNoch keine Bewertungen

- Meet The World's Most Precise Six-Axis RobotDokument1 SeiteMeet The World's Most Precise Six-Axis RobotElectromateNoch keine Bewertungen

- Electromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardDokument2 SeitenElectromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardElectromateNoch keine Bewertungen

- POSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsDokument1 SeitePOSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsElectromateNoch keine Bewertungen

- New Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseDokument1 SeiteNew Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseElectromateNoch keine Bewertungen

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseDokument2 SeitenElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateNoch keine Bewertungen

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsDokument1 SeiteNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateNoch keine Bewertungen

- Excellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesDokument2 SeitenExcellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesElectromateNoch keine Bewertungen

- New Integrated Spindle Drives Available From JVLDokument1 SeiteNew Integrated Spindle Drives Available From JVLElectromateNoch keine Bewertungen

- Electromate Extends Its Product Portfolio To Include Robots From MecademicDokument1 SeiteElectromate Extends Its Product Portfolio To Include Robots From MecademicElectromateNoch keine Bewertungen

- Electromate Recognized With 2021 AHTD Foundation AwardDokument1 SeiteElectromate Recognized With 2021 AHTD Foundation AwardElectromateNoch keine Bewertungen

- Netzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsDokument1 SeiteNetzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsElectromateNoch keine Bewertungen

- Electromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020Dokument2 SeitenElectromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020ElectromateNoch keine Bewertungen

- Maxon's New IDX Integrated Motor - Power at The Press of A ButtonDokument1 SeiteMaxon's New IDX Integrated Motor - Power at The Press of A ButtonElectromateNoch keine Bewertungen

- Electromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsDokument2 SeitenElectromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsElectromateNoch keine Bewertungen

- ADVANCED Motion Controls Releases The FM060-25-CMDokument1 SeiteADVANCED Motion Controls Releases The FM060-25-CMElectromateNoch keine Bewertungen

- CMOS DC & Transient ResponseDokument40 SeitenCMOS DC & Transient Responsesadia santaNoch keine Bewertungen

- Teorie PROTECTIIDokument177 SeitenTeorie PROTECTIIbdsrlNoch keine Bewertungen

- ATI 390 User Manual Completed Version - 20180410Dokument128 SeitenATI 390 User Manual Completed Version - 20180410williamppNoch keine Bewertungen

- 3-Asynchronous ServomotorsDokument30 Seiten3-Asynchronous ServomotorschochoroyNoch keine Bewertungen

- Basic Electrical SafetyDokument25 SeitenBasic Electrical Safetyperezes100% (1)

- Star Delta StarterDokument11 SeitenStar Delta Starterasus zenfone5Noch keine Bewertungen

- Mobile Rect 110,48 - 100aDokument2 SeitenMobile Rect 110,48 - 100aKatsukiDaitoNoch keine Bewertungen

- Presented By-T.Mahendra Reddy Ankur Sahoo Shubham VarmaDokument30 SeitenPresented By-T.Mahendra Reddy Ankur Sahoo Shubham VarmaShubham VermaNoch keine Bewertungen

- Connection Cable: VDOGH050VAS0005E05STGH050VASDokument3 SeitenConnection Cable: VDOGH050VAS0005E05STGH050VASBishoo ShenoudaNoch keine Bewertungen

- HE IgniterDokument17 SeitenHE IgniterSahil MishraNoch keine Bewertungen

- NRLT Curriculum CrosswalkDokument12 SeitenNRLT Curriculum CrosswalkJulio SibrianNoch keine Bewertungen

- Chapter 1. Electronic Components & SignalsDokument12 SeitenChapter 1. Electronic Components & SignalsPavankumar Gosavi100% (2)

- Symplified Wiring System Book Guide A Profound Guide To Designing, Wiring and Installation (KUNTZ PH.D, ARNOLD)Dokument48 SeitenSymplified Wiring System Book Guide A Profound Guide To Designing, Wiring and Installation (KUNTZ PH.D, ARNOLD)carlosNoch keine Bewertungen

- Schaltplan GP 320 Interlock Panel +ISDokument74 SeitenSchaltplan GP 320 Interlock Panel +ISJose Luis Lopez100% (1)

- Basics of Intrinsically Safe and Non - Intrinsically Safe SystemsDokument8 SeitenBasics of Intrinsically Safe and Non - Intrinsically Safe Systemsnivprash8811Noch keine Bewertungen

- Gamo Wankam Daniel Coltech UBA18P0174: Good Answer 1mark, Wrong Answer - 1marks, No Answer No MarksDokument2 SeitenGamo Wankam Daniel Coltech UBA18P0174: Good Answer 1mark, Wrong Answer - 1marks, No Answer No MarksDanny JrNoch keine Bewertungen

- ABB State of The Art Switchgear PDFDokument7 SeitenABB State of The Art Switchgear PDFrimce77Noch keine Bewertungen

- Experiment 3Dokument10 SeitenExperiment 3Yogeswaran SundarrajNoch keine Bewertungen

- File3 PDFDokument119 SeitenFile3 PDFikkemijnnaam0% (1)

- Sony KV 29ls60e Part2Dokument47 SeitenSony KV 29ls60e Part2Kostas AthanasiadisNoch keine Bewertungen

- An 9742Dokument12 SeitenAn 9742EmersonMagnoMoraesNoch keine Bewertungen

- CH 4Dokument28 SeitenCH 4Nasser AlmofariNoch keine Bewertungen

- DC Motors Modified NewDokument19 SeitenDC Motors Modified NewsatyaNoch keine Bewertungen