Beruflich Dokumente

Kultur Dokumente

Chemset 101 Plus MSDS

Hochgeladen von

jlolhnpOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chemset 101 Plus MSDS

Hochgeladen von

jlolhnpCopyright:

Verfügbare Formate

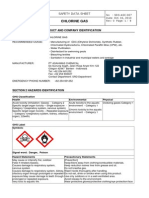

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 1 of 12

Section 1 - CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

PRODUCT NAME

CHEMSET 101 PLUS

SYNONYMS

"Product Code: C101C, C101J, ISKP"

PROPER SHIPPING NAME

POLYESTER RESIN KIT

PRODUCT USE

The use of a quantity of material in an unventilated or confined space may result in increased exposure and

an irritating atmosphere developing. Before starting consider control of exposure by mechanical ventilation.

Used according to manufacturer's directions.

SUPPLIER

Company: Ramset Fasteners Pty Ltd

Address:

296- 298 Maroondah Hwy

Mooroolbark

VIC, 3138

Australia

Telephone: 1300 780 063

Telephone: +613 9727 6229

Emergency Tel:1800 039 008

Section 2 - HAZARDS IDENTIFICATION

STATEMENT OF HAZARDOUS NATURE

HAZARDOUS SUBSTANCE. DANGEROUS GOODS. According to the Criteria of NOHSC, and the ADG

Code.

CHEMWATCH HAZARD RATINGS

Flammability

Toxicity

Body Contact

Reactivity

Chronic

SCALE:

RISK

Risk Codes

R10

R43

R52/53

SAFETY

Safety Codes

S22

Min/Nil=0

Low=1

Moderate=2

High=3

Extreme=4

Risk Phrases

Flammable.

May cause SENSITISATION by skin contact.

Harmful to aquatic organisms, may cause long- term adverse

effects in the aquatic environment.

Safety Phrases

Do not breathe dust.

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

S24

S25

S37

S39

S51

S09

S53

S401

S26

S46

S60

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 2 of 12

Section 2 - HAZARDS IDENTIFICATION

Avoid contact with skin.

Avoid contact with eyes.

Wear suitable gloves.

Wear eye/face protection.

Use only in well ventilated areas.

Keep container in a well ventilated place.

Avoid exposure - obtain special instructions before use.

To clean the floor and all objects contaminated by this material, use water

and detergent.

In case of contact with eyes, rinse with plenty of water and contact Doctor or

Poisons Information Centre.

If swallowed, IMMEDIATELY contact Doctor or Poisons Information Centre. (show

this container or label).

This material and its container must be disposed of as hazardous waste.

Section 3 - COMPOSITION / INFORMATION ON INGREDIENTS

NAME

1- ethylene- 4- methylbenzene [CAS 622- 97- 9]

1- ethylene- 3- methylbenzene [CAS 100- 80- 1]

dibenzoyl peroxide

2- ethylhexylbenzoate

CAS RN

94-36-0

5444-75-7

%

1-10

1-10

1-5

1-5

Section 4 - FIRST AID MEASURES

SWALLOWED

- If swallowed do NOT induce vomiting.

- If vomiting occurs, lean patient forward or place on left side (head-down position, if possible) to

maintain open airway and prevent aspiration.

- Observe the patient carefully.

- Never give liquid to a person showing signs of being sleepy or with reduced awareness; i.e. becoming

unconscious.

- Give water to rinse out mouth, then provide liquid slowly and as much as casualty can comfortably drink.

- Seek medical advice.

EYE

If this product comes in contact with the eyes:

- Wash out immediately with fresh running water.

- Ensure complete irrigation of the eye by keeping eyelids apart and away from eye and moving the eyelids by

occasionally lifting the upper and lower lids.

- Seek medical attention without delay; if pain persists or recurs seek medical attention.

- Removal of contact lenses after an eye injury should only be undertaken by skilled personnel.

SKIN

If skin contact occurs:

- Immediately remove all contaminated clothing, including footwear.

- Flush skin and hair with running water (and soap if available).

- Seek medical attention in event of irritation.

INHALED

- If fumes or combustion products are inhaled remove from contaminated area.

- Lay patient down. Keep warm and rested.

- Prostheses such as false teeth, which may block airway, should be removed, where possible, prior to

initiating first aid procedures.

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 3 of 12

Section 4 - FIRST AID MEASURES

- Apply artificial respiration if not breathing, preferably with a demand valve resuscitator, bag-valve mask

device, or pocket mask as trained. Perform CPR if necessary.

- Transport to hospital, or doctor.

NOTES TO PHYSICIAN

For acute or short term repeated exposures to petroleum distillates or related hydrocarbons:

- Primary threat to life, from pure petroleum distillate ingestion and/or inhalation, is respiratory failure.

- Patients should be quickly evaluated for signs of respiratory distress (e.g. cyanosis, tachypnoea,

intercostal retraction, obtundation) and given oxygen. Patients with inadequate tidal volumes or poor

arterial blood gases (pO2 50 mm Hg) should be intubated.

- Arrhythmias complicate some hydrocarbon ingestion and/or inhalation and electrocardiographic evidence of

myocardial injury has been reported; intravenous lines and cardiac monitors should be established in

obviously symptomatic patients. The lungs excrete inhaled solvents, so that hyperventilation improves

clearance.

- A chest x-ray should be taken immediately after stabilisation of breathing and circulation to document

aspiration and detect the presence of pneumothorax.

- Epinephrine (adrenalin) is not recommended for treatment of bronchospasm because of potential myocardial

sensitisation to catecholamines. Inhaled cardioselective bronchodilators (e.g. Alupent, Salbutamol) are the

preferred agents, with aminophylline a second choice.

- Lavage is indicated in patients who require decontamination; ensure use of cuffed endotracheal tube in

adult patients. [Ellenhorn and Barceloux: Medical Toxicology].

Section 5 - FIRE FIGHTING MEASURES

EXTINGUISHING MEDIA

Do not use a water jet to fight fire.

FIRE FIGHTING

- Alert Fire Brigade and tell them location and nature of hazard.

- May be violently or explosively reactive.

- Wear breathing apparatus plus protective gloves.

- Prevent, by any means available, spillage from entering drains or water course.

- If safe, switch off electrical equipment until vapour fire hazard removed.

- Use water delivered as a fine spray to control fire and cool adjacent area.

- Avoid spraying water onto liquid pools.

- DO NOT approach containers suspected to be hot.

- Cool fire exposed containers with water spray from a protected location.

- If safe to do so, remove containers from path of fire.

When any large container (including road and rail tankers) is involved in a fire,

consider evacuation by 500 metres in all directions.

FIRE/EXPLOSION HAZARD

- Liquid and vapour are flammable.

- Moderate fire hazard when exposed to heat or flame.

- Vapour forms an explosive mixture with air.

- Moderate explosion hazard when exposed to heat or flame.

- Vapour may travel a considerable distance to source of ignition.

- Heating may cause expansion or decomposition leading to violent rupture of containers.

- On combustion, may emit toxic fumes of carbon monoxide (CO).

Combustion products include: carbon monoxide (CO), carbon dioxide (CO2), other pyrolysis products typical of

burning organic material.

FIRE INCOMPATIBILITY

- Avoid contamination with oxidising agents i.e. nitrates, oxidising acids, chlorine bleaches, pool

chlorine etc. as ignition may result.

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 4 of 12

Section 5 - FIRE FIGHTING MEASURES

HAZCHEM

2YE

Section 6 - ACCIDENTAL RELEASE MEASURES

MINOR SPILLS

- Remove all ignition sources.

- Clean up all spills immediately.

- Avoid breathing vapours and contact with skin and eyes.

- Control personal contact by using protective equipment.

- Contain and absorb small quantities with vermiculite or other absorbent material.

- Wipe up.

- Collect residues in a flammable waste container.

MAJOR SPILLS

- Clear area of personnel and move upwind.

- Alert Fire Brigade and tell them location and nature of hazard.

- May be violently or explosively reactive.

- Wear breathing apparatus plus protective gloves.

- Prevent, by any means available, spillage from entering drains or water course.

- Consider evacuation (or protect in place).

- No smoking, naked lights or ignition sources.

- Increase ventilation.

- Stop leak if safe to do so.

- Water spray or fog may be used to disperse /absorb vapour.

- Contain spill with sand, earth or vermiculite.

- Use only spark-free shovels and explosion proof equipment.

- Collect recoverable product into labelled containers for recycling.

- Absorb remaining product with sand, earth or vermiculite.

- Collect solid residues and seal in labelled drums for disposal.

- Wash area and prevent runoff into drains.

- If contamination of drains or waterways occurs, advise emergency services.

Personal Protective Equipment advice is contained in Section 8 of the MSDS.

Section 7 - HANDLING AND STORAGE

PROCEDURE FOR HANDLING

- Containers, even those that have been emptied, may contain explosive vapours.

- Do NOT cut, drill, grind, weld or perform similar operations on or near containers.

- Avoid all personal contact, including inhalation.

- Wear protective clothing when risk of overexposure occurs.

- Use in a well-ventilated area.

- Prevent concentration in hollows and sumps.

- DO NOT enter confined spaces until atmosphere has been checked.

- Avoid smoking, naked lights or ignition sources.

- Avoid generation of static electricity.

- DO NOT use plastic buckets.

- Earth all lines and equipment.

- Use spark-free tools when handling.

- Avoid contact with incompatible materials.

- When handling, DO NOT eat, drink or smoke.

- Keep containers securely sealed when not in use.

- Avoid physical damage to containers.

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 5 of 12

Section 7 - HANDLING AND STORAGE

- Always wash hands with soap and water after handling.

- Work clothes should be laundered separately.

- Use good occupational work practice.

- Observe manufacturer's storing and handling recommendations.

- Atmosphere should be regularly checked against established exposure standards to ensure safe working

conditions.

SUITABLE CONTAINER

- Packing as supplied by manufacturer.

- Plastic containers may only be used if approved for flammable liquid.

- Check that containers are clearly labelled and free from leaks.

- For low viscosity materials (i) : Drums and jerry cans must be of the non-removable head type. (ii) : Where

a can is to be used as an inner package, the can must have a screwed enclosure.

- For materials with a viscosity of at least 2680 cSt. (23 deg. C)

- For manufactured product having a viscosity of at least 250 cSt. (23 deg. C)

- Manufactured product that requires stirring before use and having a viscosity of at least 20 cSt (25 deg. C)

(i) : Removable head packaging;

(ii) : Cans with friction closures and

(iii) : low pressure tubes and cartridges may be used.

- Where combination packages are used, and the inner packages are of glass, there must be sufficient inert

cushioning material in contact with inner and outer packages

- In addition, where inner packagings are glass and contain liquids of packing group I there must be

sufficient inert absorbent to absorb any spillage, unless the outer packaging is a close fitting moulded

plastic box and the substances are not incompatible with the plastic.

STORAGE INCOMPATIBILITY

WARNING:

May decompose violently or explosively on contact with other substances.

- This substance, or one of its components, is one of the relatively few compounds which are described as

"endothermic" i.e. heat is absorbed into the compound, rather than released from it, during its formation.

- The majority of endothermic compounds are thermodynamically unstable and may decompose explosively under

various circumstances of initiation.

- Many but not all endothermic compounds have been involved in decompositions, reactions and explosions and,

in general, compounds with significantly positive values of standard heats of formation, may be considered

suspect on stability grounds.

BRETHERICK L.: Handbook of Reactive Chemical Hazards.

- Avoid reaction with oxidising agents.

Vinyl toluene polymerises explosively unless inhibited with, typically, 10-50 ppm tert-butylcatechol

reacts violently with strong oxidisers, strong acids, peroxides

is incompatible with aluminium chloride, ammonia, aliphatic amines, alkanolamides, caustics, metal salts

uninhibited monomer may block vents and confined spaces by forming a solid polymeric material

STORAGE REQUIREMENTS

- Store in original containers in approved flammable liquid storage area.

- Store away from incompatible materials in a cool, dry, well-ventilated area.

- DO NOT store in pits, depressions, basements or areas where vapours may be trapped.

- No smoking, naked lights, heat or ignition sources.

- Storage areas should be clearly identified, well illuminated, clear of obstruction and accessible only to

trained and authorised personnel - adequate security must be provided so that unauthorised personnel do not

have access.

- Store according to applicable regulations for flammable materials for storage tanks, containers, piping,

buildings, rooms, cabinets, allowable quantities and minimum storage distances.

- Use non-sparking ventilation systems, approved explosion proof equipment and intrinsically safe electrical

systems.

- Have appropriate extinguishing capability in storage area (e.g. portable fire extinguishers - dry chemical,

foam or carbon dioxide) and flammable gas detectors.

- Keep adsorbents for leaks and spills readily available.

- Protect containers against physical damage and check regularly for leaks.

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 6 of 12

Section 7 - HANDLING AND STORAGE

- Observe manufacturer's storing and handling recommendations.

In addition, for tank storages (where appropriate):

- Store in grounded, properly designed and approved vessels and away from incompatible materials.

- For bulk storages, consider use of floating roof or nitrogen blanketed vessels; where venting to atmosphere

is possible, equip storage tank vents with flame arrestors; inspect tank vents during winter conditions for

vapour/ ice build-up.

- Storage tanks should be above ground and diked to hold entire contents.

Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTION

EXPOSURE CONTROLS

Source

___________

Australia Exposure Standards

Material

___________

dibenzoyl peroxide (Benzoyl peroxide)

The following materials had no OELs on our records

2- ethylhexylbenzoate:

EMERGENCY EXPOSURE LIMITS

Material

Revised

dibenzoyl peroxide|2085- 1

1, 500

TWA mg/m

_______

5

CAS:5444- 75- 7

IDLH

MATERIAL DATA

CHEMSET 101 PLUS:

DIBENZOYL PEROXIDE:

For benzoyl peroxide:

The recommendation for the TLV-TWA is based on the absence of subjective symptoms of irritation of the

nose and throat in humans exposed to 5.25 mg/m3. Whether this is sufficiently low to prevent cumulative

effects in man is not known.

CHEMSET 101 PLUS:

as vinyl toluene

IDLH Level: 5000 ppm

The toxicological properties of vinyltoluene are similar to those of styrene and

the TLV- TWA and STEL are analogous. The limits are thought to be protective

against mucous membrane and ocular irritation and should reduce the complaints

of objectionable odour. Given that axonal degeneration found in rats inhaling

vinyltoluene is more significant than in rats inhaling comparable concentrations

of styrene, and that neurological changes are more prominent, the limits are the

subject of review.

Human subjects show ocular and upper respiratory tract irritation at 400 ppm, complain of a strong

objectionable odour at 300 ppm and a strong but tolerable odour at 200 ppm.. At 50 ppm, the odour is

detectable and may become disagreeable, but does not produce irritation of the mucous membranes.

2-ETHYLHEXYLBENZOATE:

No exposure limits set by NOHSC or ACGIH.

PERSONAL PROTECTION

EYE

- Safety glasses with side shields.

- Chemical goggles.

- Contact lenses may pose a special hazard; soft contact lenses may absorb and concentrate irritants. A

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 7 of 12

Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTION

written policy document, describing the wearing of lens or restrictions on use, should be created for each

workplace or task. This should include a review of lens absorption and adsorption for the class of chemicals

in use and an account of injury experience. Medical and first-aid personnel should be trained in their

removal and suitable equipment should be readily available. In the event of chemical exposure, begin eye

irrigation immediately and remove contact lens as soon as practicable. Lens should be removed at the first

signs of eye redness or irritation - lens should be removed in a clean environment only after workers have

washed hands thoroughly. [CDC NIOSH Current Intelligence Bulletin 59], [AS/NZS 1336 or national equivalent].

HANDS/FEET

- Wear chemical protective gloves, eg. PVC.

- Wear safety footwear or safety gumboots, eg. Rubber.

NOTE:

- The material may produce skin sensitisation in predisposed individuals. Care must be taken, when removing

gloves and other protective equipment, to avoid all possible skin contact.

- Contaminated leather items, such as shoes, belts and watch-bands should be removed and destroyed.

OTHER

- Overalls.

- PVC Apron.

- PVC protective suit may be required if exposure severe.

- Eyewash unit.

- Ensure there is ready access to a safety shower.

- Some plastic personal protective equipment (PPE) (e.g. gloves, aprons, overshoes) are not recommended as

they may produce static electricity.

- For large scale or continuous use wear tight-weave non-static clothing (no metallic fasteners, cuffs or

pockets), non sparking safety footwear.

RESPIRATOR

Type A-P Filter of sufficient capacity. (AS/NZS 1716 & 1715, EN 143:2000 & 149:2001, ANSI Z88 or national

equivalent)

The local concentration of material, quantity and conditions of use determine the type of personal protective

equipment required. For further information consult site specific CHEMWATCH data (if available), or your

Occupational Health and Safety Advisor.

ENGINEERING CONTROLS

Engineering controls are used to remove a hazard or place a barrier between the worker and the hazard. Welldesigned engineering controls can be highly effective in protecting workers and will typically be independent

of worker interactions to provide this high level of protection.

The basic types of engineering controls are:

Process controls which involve changing the way a job activity or process is done to reduce the risk.

Enclosure and/or isolation of emission source which keeps a selected hazard "physically" away from the worker

and ventilation that strategically "adds" and "removes" air in the work environment. Ventilation can remove

or dilute an air contaminant if designed properly. The design of a ventilation system must match the

particular process and chemical or contaminant in use.

Employers may need to use multiple types of controls to prevent employee overexposure.

For flammable liquids and flammable gases, local exhaust ventilation or a process enclosure ventilation

system may be required. Ventilation equipment should be explosion-resistant.

Section 9 - PHYSICAL AND CHEMICAL PROPERTIES

APPEARANCE

Off-white paste with an aromatic odour; not miscible with water.

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 8 of 12

Section 9 - PHYSICAL AND CHEMICAL PROPERTIES

PHYSICAL PROPERTIES

Does not mix with water.

Sinks in water.

State

Melting Range (C)

Boiling Range (C)

Flash Point (C)

Decomposition Temp (C)

Autoignition Temp (C)

Upper Explosive Limit (%)

Lower Explosive Limit (%)

Free- flowing Paste

Not Available

>165

53

Not Available

Not Available

5.2

1.1

Volatile Component (%vol)

Not Available

Molecular Weight

Viscosity

Solubility in water (g/L)

pH (1% solution)

pH (as supplied)

Vapour Pressure (kPa)

Specific Gravity (water=1)

Relative Vapour Density

(air=1)

Evaporation Rate

Not Applicable

Not Available

Immiscibl e

Not Available

Not A vailable

Not Available

1.7

Not Available

Not Available

Section 10 - STABILITY AND REACTIVITY

CONDITIONS CONTRIBUTING TO INSTABILITY

- Presence of incompatible materials.

- Product is considered stable.

- Hazardous polymerisation will not occur.

For incompatible materials - refer to Section 7 - Handling and Storage.

Section 11 - TOXICOLOGICAL INFORMATION

POTENTIAL HEALTH EFFECTS

ACUTE HEALTH EFFECTS

SWALLOWED

Accidental ingestion of the material may be damaging to the health of the individual.

EYE

There is some evidence to suggest that this material can cause eye irritation and damage in some persons.

SKIN

There is some evidence to suggest that this material can cause inflammation of the skin on contact in some

persons.

Open cuts, abraded or irritated skin should not be exposed to this material.

Entry into the blood-stream, through, for example, cuts, abrasions or lesions, may produce systemic injury

with harmful effects. Examine the skin prior to the use of the material and ensure that any external damage

is suitably protected.

INHALED

Inhalation of vapours or aerosols (mists, fumes), generated by the material during the course of normal

handling, may be damaging to the health of the individual.

There is some evidence to suggest that the material can cause respiratory irritation in some persons. The

body's response to such irritation can cause further lung damage.

The use of a quantity of material in an unventilated or confined space may result in increased exposure and

an irritating atmosphere developing. Before starting consider control of exposure by mechanical ventilation.

CHRONIC HEALTH EFFECTS

Skin contact with the material is more likely to cause a sensitisation reaction in some persons compared to

the general population.

There has been some concern that this material can cause cancer or mutations but there is not enough data to

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 9 of 12

Section 11 - TOXICOLOGICAL INFORMATION

make an assessment.

Substance accumulation, in the human body, may occur and may cause some concern following repeated or longterm occupational exposure.

There is some evidence that inhaling this product is more likely to cause a sensitisation reaction in some

persons compared to the general population.

Based on experience with animal studies, there is a possibility that exposure to the material may result in

toxic effects to the development of the foetus, at levels which do not cause significant toxic effects to the

mother.

Prolonged or repeated skin contact with benzoyl peroxide may result in allergic skin reactions even at

diluted concentrations. Ingestion results in abdominal pain, low body oxygen and severe depression. Chronic

effects of exposure include allergic reactions characterised by redness, itching, oozing, crusting, and

scaling of the skin and asthmatic wheezing. Although it does not exhibit complete carcinogenic or tumourinitiating activity, it has been associated with certain tumours of like papillomas and squamous cell

carcinomas.

There is inadequate evidence in humans for the carcinogenicity of vinyl toluene. There is evidence suggesting

lack of carcinogenicity of vinyl toluene in experimental animals.

TOXICITY AND IRRITATION

unless otherwise specified data extracted from RTECS - Register of Toxic Effects of Chemical Substances.

2-ETHYLHEXYLBENZOATE:

CHEMSET 101 PLUS:

No significant acute toxicological data identified in literature search.

DIBENZOYL PEROXIDE:

CHEMSET 101 PLUS:

Contact allergies quickly manifest themselves as contact eczema, more rarely as urticaria or Quincke's

oedema. The pathogenesis of contact eczema involves a cell-mediated (T lymphocytes) immune reaction of the

delayed type. Other allergic skin reactions, e.g. contact urticaria, involve antibody-mediated immune

reactions. The significance of the contact allergen is not simply determined by its sensitisation potential:

the distribution of the substance and the opportunities for contact with it are equally important. A weakly

sensitising substance which is widely distributed can be a more important allergen than one with stronger

sensitising potential with which few individuals come into contact. From a clinical point of view, substances

are noteworthy if they produce an allergic test reaction in more than 1% of the persons tested.

DIBENZOYL PEROXIDE:

TOXICITY

IRRITATION

Oral (rat) LD50: 7710 mg/kg

Eye (rabbit): 500 mg/24h - Mild

Inhalation (human) TCLo: 12 mg/m

Skin effects (MAK): very weak

Subcutaneous (Rat) LD: 40 mg/kg (@ 50%)

Intraperitoneal (Mouse) LD50: 440 mg/kg

Intravenous (Rabbit) LD: 16 mg/kg

The material may be irritating to the eye, with prolonged contact causing inflammation. Repeated or

prolonged exposure to irritants may produce conjunctivitis.

The material may cause skin irritation after prolonged or repeated exposure and may produce on contact skin

redness, swelling, the production of vesicles, scaling and thickening of the skin.

Benzoyl peroxide may cause double vision, breathing problems, excess saliva and tear formation, redness of

the skin and changes in motor activity. It did not produce blood or biochemical adverse effects, gene

mutation or evidence of cancer. Repeated oral administration may result in decreased weights of testes and

the newborn.

The substance is classified by IARC as Group 3:

NOT classifiable as to its carcinogenicity to humans.

Evidence of carcinogenicity may be inadequate or limited in animal testing.

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CARCINOGEN

Benzoyl peroxide

International Agency

for Research on Cancer

(IARC) - Agents

Reviewed by the IARC

Monographs

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 10 of 12

Section 11 - TOXICOLOGICAL INFORMATION

Group

Section 12 - ECOLOGICAL INFORMATION

2-ETHYLHEXYLBENZOATE:

DIBENZOYL PEROXIDE:

DO NOT discharge into sewer or waterways.

DIBENZOYL PEROXIDE:

For benzoyl peroxide:

Benzoyl peroxide has a melting point of 104 -106 C, vapor pre ssure of 0.00929 Pa, solubility of 9.1 mg/L in

water at 25 C, and log Pow of 3.43 at 25 C.

Environmental Fate: For indirect photolysis in the atmosphere, the half-life is estimated to be 3 days. The

substance is readily biodegradable and hydrolyses rapidly in water. The main hydrolysis product of benzoyl

peroxide is benzoic acid. The estimated BCF of 92 suggests that the chemical has a low potential for

bioaccumulation. Benzoyl peroxide is most likely to partition to water, where it will remain.

Ecotoxicity: Green algae (Selenastrum capricornutum) EbC50 (72 h): 0.07 mg/L (biomass) and 0.44 mg/L (growth

rate).

Daphnia magna: EC50 (48 h):

0.07 mg/L.

Fish LC50 (96 h): Oryzias latipes 0.24 mg/L.

Microorganism (activated sludge):EC50 (30 min): 35 mg/L

The toxicity observed is assumed to be due to benzoyl peroxide rather than benzoic acid, which shows much

lower toxicity to aquatic organisms. One can assume that effects occur before hydrolysis takes place.

2-ETHYLHEXYLBENZOATE:

Very toxic to aquatic organisms.

Do NOT allow product to come in contact with surface waters or to intertidal areas below the mean high water

mark. Do not contaminate water when cleaning equipment or disposing of equipment wash-waters.

Wastes resulting from use of the product must be disposed of on site or at approved waste sites.

Ecotoxicity

Ingredient

dibenzoyl peroxide

2- ethylhexylbenzoate

Persistence:

Water/Soil

LOW

LOW

Persistence: Air

Bioaccumulation

Mobility

HIGH

No Data

Available

LOW

LOW

MED

MED

Section 13 - DISPOSAL CONSIDERATIONS

- Containers may still present a chemical hazard/ danger when empty.

- Return to supplier for reuse/ recycling if possible.

Otherwise:

- If container can not be cleaned sufficiently well to ensure that residuals do not remain or if the

container cannot be used to store the same product, then puncture containers, to prevent re-use, and bury at

an authorised landfill.

- Where possible retain label warnings and MSDS and observe all notices pertaining to the product.

- Recycle wherever possible.

- Consult manufacturer for recycling options or consult local or regional waste management authority for

disposal if no suitable treatment or disposal facility can be identified.

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 11 of 12

Section 13 - DISPOSAL CONSIDERATIONS

- Dispose of by: burial in a land-fill specifically licenced to accept chemical and / or pharmaceutical

wastes or Incineration in a licenced apparatus (after admixture with suitable combustible material).

- Decontaminate empty containers. Observe all label safeguards until containers are cleaned and destroyed.

Section 14 - TRANSPORTATION INFORMATION

Labels Required: FLAMMABLE LIQUID

HAZCHEM:

2YE (ADG7)

ADG7:

Class or Division:

UN No.:

Special Provision:

Portable Tanks & Bulk

Containers Instruction:

Packagings & IBCs Packing Instruction:

3

3269

236

None

Subsidiary Risk:

Packing Group:

Limited Quantity:

Portable Tanks & Bulk

Containers - Special

Provision:

Packagings & IBCs Special Packing

Provision:

None

III

5L

None

Subsidiary risk:

UN packing group:

None

III

3

3269

A66

ICAO/IATA Subrisk:

Packing Group:

None

III

370

Maximum Qty/Pack:

Passenger and Cargo

Maximum Qty/Pack:

Passenger and Cargo

Limited Quantity

Maximum Qty/Pack:

5 kg

IMDG Subrisk:

Packing Group:

Special provisions:

None

III

236 340

None

P302

Name and Description: POLYESTER RESIN KIT

Land Transport UNDG:

Class or division:

3

UN No.:

3269

Shipping Name:POLYESTER RESIN KIT

Air Transport IATA:

ICAO/IATA Class:

UN/ID Number:

Special provisions:

Cargo Only

Packing Instructions:

Passenger and Cargo

Packing Instructions:

Passenger and Cargo

Limited Quantity

Packing Instructions:

370

Y370

5 kg

1 kg

Shipping name:POLYESTER RESIN KIT

Maritime Transport IMDG:

IMDG Class:

3

UN Number:

3269

EMS Number:

F- E, S- D

Limited Quantities:

5L

Shipping name:POLYESTER RESIN KIT

Section 15 - REGULATORY INFORMATION

POISONS SCHEDULE None

REGULATIONS

continued...

CHEMSET 101 PLUS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 25-Nov-2011

A317LP

CHEMWATCH 4753-61

Version No:4

CD 2011/4 Page 12 of 12

Section 15 - REGULATORY INFORMATION

Regulations for ingredients

dibenzoyl peroxide (CAS: 94-36-0) is found on the following regulatory lists;

"Australia - South Australia Controlled Substances (Poisons) Regulations - Schedule E: Schedule 2 poisons authorised to be sold by holder of a medicine sellers

licence","Australia Dangerous Goods Code (ADG Code) - List of Currently Assigned Organic Peroxides in Packagings","Australia Exposure Standards","Australia

Hazardous Substances","Australia Inventory of Chemical Substances (AICS)","Australia Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP) Appendix E (Part 2)","Australia Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP) - Appendix F (Part 3)","Australia Standard for the Uniform

Scheduling of Medicines and Poisons (SUSMP) - Schedule 2","Australia Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP) - Schedule 4",

"Australia Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP) - Schedule 5","International Agency for Research on Cancer (IARC) - Agents

Reviewed by the IARC Monographs","International Air Transport Association (IATA) Dangerous Goods Regulations","International Air Transport Association (IATA)

Dangerous Goods Regulations - Prohibited List"

2-ethylhexylbenzoate (CAS: 5444-75-7) is found on the following regulatory lists;

"FEMA Generally Recognized as Safe (GRAS) Flavoring Substances 24 - Primary Names and Synonyms"

No data for Chemset 101 Plus (CW: 4753-61)

Section 16 - OTHER INFORMATION

Denmark Advisory list for selfclassification of dangerous substances

Substance

CAS

Suggested codes

2- ethylhexylbenzoate

5444- 75- 7

N; R51/53

Classification of the preparation and its individual components has drawn on official and authoritative

sources as well as independent review by the Chemwatch Classification committee using available literature

references.

A list of reference resources used to assist the committee may be found at:

www.chemwatch.net/references.

The (M)SDS is a Hazard Communication tool and should be used to assist in the Risk Assessment. Many factors

determine whether the reported Hazards are Risks in the workplace or other settings. Risks may be determined

by reference to Exposures Scenarios. Scale of use, frequency of use and current or available engineering

controls must be considered.

This document is copyright. Apart from any fair dealing for the purposes of private study, research, review or

criticism, as permitted under the Copyright Act, no part may be reproduced by any process without written

permission from CHEMWATCH. TEL (+61 3) 9572 4700.

Issue Date: 25-Nov-2011

Print Date: 28-Nov-2011

This is the end of the MSDS.

Das könnte Ihnen auch gefallen

- Chemwatch Australian MSDS 6632-96Dokument15 SeitenChemwatch Australian MSDS 6632-96Vijo JoseNoch keine Bewertungen

- Dunlop Vinyl Adhesive MSDSDokument8 SeitenDunlop Vinyl Adhesive MSDSSN NazihahNoch keine Bewertungen

- Weldcool 20080515Dokument11 SeitenWeldcool 20080515Vijo JoseNoch keine Bewertungen

- Galmet Spraypaint Aerosol SilverDokument11 SeitenGalmet Spraypaint Aerosol SilverBiju_PottayilNoch keine Bewertungen

- Msds WD-40 3-IN-ONE PROFESSIONAL GARAGE DOOR LUBRICANTDokument8 SeitenMsds WD-40 3-IN-ONE PROFESSIONAL GARAGE DOOR LUBRICANTHai HaNoch keine Bewertungen

- Ceramic BlueDokument17 SeitenCeramic BlueDAvid Alvarez CastilloNoch keine Bewertungen

- Isobutylene C4H8 Safety Data Sheet SDS P4614Dokument8 SeitenIsobutylene C4H8 Safety Data Sheet SDS P4614Wayan PartaNoch keine Bewertungen

- Galmet Rustpaint Aerosol All Colours Except Silver - ITW Polymers & FluidsDokument9 SeitenGalmet Rustpaint Aerosol All Colours Except Silver - ITW Polymers & FluidsBiju_PottayilNoch keine Bewertungen

- Denatured Alcohol, BI GHS 2012Dokument15 SeitenDenatured Alcohol, BI GHS 2012Nur Isma NazariahNoch keine Bewertungen

- MSDS-r40-Radiator Flush and CleanDokument5 SeitenMSDS-r40-Radiator Flush and CleanHashim ElhajNoch keine Bewertungen

- Trakmaster Fuel Cells MsdsDokument9 SeitenTrakmaster Fuel Cells MsdsSyerifaizal Hj. Mustapha100% (1)

- Sds Paint Marker Sl.250 PmucDokument5 SeitenSds Paint Marker Sl.250 Pmucfakename4bugmenotNoch keine Bewertungen

- RS Potting Compound Safety Data Sheets PDFDokument25 SeitenRS Potting Compound Safety Data Sheets PDFAchira Chanaka PeirisNoch keine Bewertungen

- Nitric Acid 0 2n (n5) 24-9824 v2 1 1 1 23-Jul-2010 Us-English-local On Apr-29-2013Dokument9 SeitenNitric Acid 0 2n (n5) 24-9824 v2 1 1 1 23-Jul-2010 Us-English-local On Apr-29-2013LucioMerloNoch keine Bewertungen

- Kerosene PDFDokument9 SeitenKerosene PDFishnafathonahNoch keine Bewertungen

- MSDS EverstickDokument7 SeitenMSDS EverstickDil VasconcelosNoch keine Bewertungen

- 07 SDS Cl2Dokument8 Seiten07 SDS Cl2Fadlul Akbar HerfiantoNoch keine Bewertungen

- 4-Amino-3-Hydroxynapthlene-1-Sulphonic AcidDokument8 Seiten4-Amino-3-Hydroxynapthlene-1-Sulphonic AcidIqraNoch keine Bewertungen

- Wattyl Colourthane Thinner Standard 6100-99 MSDS May13Dokument12 SeitenWattyl Colourthane Thinner Standard 6100-99 MSDS May13Dil VasconcelosNoch keine Bewertungen

- Demulsifier MSDSDokument7 SeitenDemulsifier MSDSfructoraNoch keine Bewertungen

- Mercuric Nitrate 0.0141N: Section 1 - Chemical Product and Company IdentificationDokument10 SeitenMercuric Nitrate 0.0141N: Section 1 - Chemical Product and Company IdentificationLucioMerloNoch keine Bewertungen

- Exxsol D95Dokument9 SeitenExxsol D95Elisa Arroyo RodriguezNoch keine Bewertungen

- Material Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDokument11 SeitenMaterial Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDeshanNoch keine Bewertungen

- Safety Data Sheet: Section 1 - Product and Company IdentificationDokument10 SeitenSafety Data Sheet: Section 1 - Product and Company IdentificationAndhie OsloNoch keine Bewertungen

- MSDS Etilen Oksida 2Dokument8 SeitenMSDS Etilen Oksida 2shekureNoch keine Bewertungen

- Ms Ds NaphthaDokument12 SeitenMs Ds NaphthaCatharina Natasa BellaFortunaNoch keine Bewertungen

- Dimethyl Ether SDS E4589Dokument7 SeitenDimethyl Ether SDS E4589Daniil GhilescuNoch keine Bewertungen

- 06 ZMSDS - VCM - ASC R3Dokument8 Seiten06 ZMSDS - VCM - ASC R3HoshiNoch keine Bewertungen

- Nalco Tri Act 1820Dokument13 SeitenNalco Tri Act 1820anon_336536469Noch keine Bewertungen

- Septone Brake Dust Cleaner SDSDokument15 SeitenSeptone Brake Dust Cleaner SDSMarkSomniumNoch keine Bewertungen

- PC 56 Biocide (Old)Dokument13 SeitenPC 56 Biocide (Old)Hyun Jin YooNoch keine Bewertungen

- Methyl Ethyl Ketone MSDSDokument15 SeitenMethyl Ethyl Ketone MSDSArjunNoch keine Bewertungen

- Section 1 - Product and Company Identification: Fl-20 PrimerDokument5 SeitenSection 1 - Product and Company Identification: Fl-20 PrimerDAvid Alvarez CastilloNoch keine Bewertungen

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDokument6 SeitenMaterial Safety Data Sheet: Section 1. Chemical Product and Company Identificationandy hamonanganNoch keine Bewertungen

- Sds Garnet enDokument7 SeitenSds Garnet enBSB Material ControllerNoch keine Bewertungen

- Orth Oxy LeneDokument15 SeitenOrth Oxy LeneChemical.AliNoch keine Bewertungen

- MSDS - Unol7Dokument8 SeitenMSDS - Unol7mhaeducationNoch keine Bewertungen

- Proxitane MSDSDokument6 SeitenProxitane MSDSbeatcookNoch keine Bewertungen

- Exxsol D60Dokument10 SeitenExxsol D60Adi WiraNoch keine Bewertungen

- Dp-40 Dye Penetrant 20091105Dokument14 SeitenDp-40 Dye Penetrant 20091105normansetonNoch keine Bewertungen

- Material Safety Data Sheet: R170 EthaneDokument7 SeitenMaterial Safety Data Sheet: R170 Ethanebleve68Noch keine Bewertungen

- Bio Kleen Diesel Fuel BiocideDokument13 SeitenBio Kleen Diesel Fuel BiocideDavannendran ChandranNoch keine Bewertungen

- Ms Ds BiodieselDokument10 SeitenMs Ds BiodieselOsckar DezNoch keine Bewertungen

- PGPlus MSDSDokument10 SeitenPGPlus MSDSmahmudiNoch keine Bewertungen

- NP-40 Alternative: Material Safety Data SheetDokument8 SeitenNP-40 Alternative: Material Safety Data SheetIkumi MisuNoch keine Bewertungen

- Asphalt SDSDokument12 SeitenAsphalt SDSCarlos MontanoNoch keine Bewertungen

- Engen Dynamic 95 Unleaded Petrol (Ulp)Dokument9 SeitenEngen Dynamic 95 Unleaded Petrol (Ulp)timbrinNoch keine Bewertungen

- MSDSDokument9 SeitenMSDSshishir4870Noch keine Bewertungen

- MSDS - PetrolDokument10 SeitenMSDS - PetrolManeesh MenonNoch keine Bewertungen

- SF6 MSDSDokument7 SeitenSF6 MSDSjaycarpioNoch keine Bewertungen

- Rp7-Aus SDSDokument7 SeitenRp7-Aus SDSRùa ConNoch keine Bewertungen

- Safety Data Sheet: 1. Identification of The Material and Supplier Methoxy PropanolDokument8 SeitenSafety Data Sheet: 1. Identification of The Material and Supplier Methoxy PropanolPamela E. PeñaNoch keine Bewertungen

- Isopar HDokument11 SeitenIsopar Hwaxim26322Noch keine Bewertungen

- Material Safety Data Sheet: Product: Propylene P-4648-G Date: May 1999Dokument10 SeitenMaterial Safety Data Sheet: Product: Propylene P-4648-G Date: May 1999طاهرالياسرNoch keine Bewertungen

- Methanol MSDS PDFDokument10 SeitenMethanol MSDS PDFYan Lean DollisonNoch keine Bewertungen

- SDS GHS 01 EthyleneDokument7 SeitenSDS GHS 01 EthylenededehendarsyahNoch keine Bewertungen

- After a Disaster: Information to Help You and Your Family RecoverVon EverandAfter a Disaster: Information to Help You and Your Family RecoverNoch keine Bewertungen

- PEDIATRIC FIRST AID: How to respond quickly when your child is in dangerVon EverandPEDIATRIC FIRST AID: How to respond quickly when your child is in dangerNoch keine Bewertungen

- Registration of Engineers Stakeholder Consultation PaperDokument26 SeitenRegistration of Engineers Stakeholder Consultation PaperjlolhnpNoch keine Bewertungen

- SAL ReportDokument130 SeitenSAL ReportjlolhnpNoch keine Bewertungen

- Product CatalogDokument66 SeitenProduct CatalogEnkhmend-Od UlziibatNoch keine Bewertungen

- Concrete Construction Article PDF - Repairing Curled SlabsDokument5 SeitenConcrete Construction Article PDF - Repairing Curled SlabsjlolhnpNoch keine Bewertungen

- Revisiting A 90-Year-Old Debate - The Advantages of The Mean DeviationDokument10 SeitenRevisiting A 90-Year-Old Debate - The Advantages of The Mean DeviationAreem AbbasiNoch keine Bewertungen

- Registration of Engineers Stakeholder Consultation PaperDokument26 SeitenRegistration of Engineers Stakeholder Consultation PaperjlolhnpNoch keine Bewertungen

- Color Bond Metallic Data SheetDokument3 SeitenColor Bond Metallic Data SheetjlolhnpNoch keine Bewertungen

- Revisiting A 90-Year-Old Debate - The Advantages of The Mean DeviationDokument10 SeitenRevisiting A 90-Year-Old Debate - The Advantages of The Mean DeviationAreem AbbasiNoch keine Bewertungen

- Starting Your Business Checklist PDFDokument86 SeitenStarting Your Business Checklist PDFengr_dkNoch keine Bewertungen

- Bi-Fold-instructions-v1 Final Aug 2012Dokument1 SeiteBi-Fold-instructions-v1 Final Aug 2012jlolhnpNoch keine Bewertungen

- Joints in Poured Walls - tcm45-342541Dokument3 SeitenJoints in Poured Walls - tcm45-342541Youssef RomanosNoch keine Bewertungen

- Salary and Remuneration Survey 2017Dokument12 SeitenSalary and Remuneration Survey 2017jlolhnpNoch keine Bewertungen

- Kelly Salary Survey 2017Dokument39 SeitenKelly Salary Survey 2017jlolhnpNoch keine Bewertungen

- Slab Design by Wood Armer MethodDokument2 SeitenSlab Design by Wood Armer MethodUmesh Patil75% (4)

- Seismic RC Design Guide SRIADokument76 SeitenSeismic RC Design Guide SRIAjlolhnp100% (1)

- Hyspan Span Guide 28pp Oct12 PDFDokument28 SeitenHyspan Span Guide 28pp Oct12 PDF_Asylum_Noch keine Bewertungen

- Ramset Specifiers Anchoring Resource Book ANZ Chemical Anchoring Anchor StudsDokument59 SeitenRamset Specifiers Anchoring Resource Book ANZ Chemical Anchoring Anchor StudsjlolhnpNoch keine Bewertungen

- Split HangerDokument6 SeitenSplit HangerjlolhnpNoch keine Bewertungen

- 07 TransverseShearDokument34 Seiten07 TransverseShearEssy BasoenondoNoch keine Bewertungen

- Masonry Design GuideDokument62 SeitenMasonry Design GuideFernando Lopez100% (10)

- Steel Reinforcement SRIADokument2 SeitenSteel Reinforcement SRIAjlolhnpNoch keine Bewertungen

- 484 Welding Guidelines For Design EngineersDokument4 Seiten484 Welding Guidelines For Design EngineersPham Song Hong100% (1)

- Mechanical Anchoring TruBoltDokument3 SeitenMechanical Anchoring TruBoltjlolhnpNoch keine Bewertungen

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDokument10 SeitenRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpNoch keine Bewertungen

- Purlin and Girts Design TablesDokument32 SeitenPurlin and Girts Design TablesTimothy BarnesNoch keine Bewertungen

- Triple L GripDokument4 SeitenTriple L GripjlolhnpNoch keine Bewertungen

- Orrcon Steel Purlins GirtsDokument3 SeitenOrrcon Steel Purlins GirtsLandon MitchellNoch keine Bewertungen

- STAAD - Difference Between Surface Element, PlateDokument4 SeitenSTAAD - Difference Between Surface Element, PlatejlolhnpNoch keine Bewertungen

- Design and Implementation of Bioamplifier For Portable ECG DeviceDokument19 SeitenDesign and Implementation of Bioamplifier For Portable ECG Devicej4everNoch keine Bewertungen

- The Consumption of WaterDokument2 SeitenThe Consumption of WaterasungapeNoch keine Bewertungen

- Effect of Educational Environment On Personality and Adjustment of Female Students Studying in Colleges of UttarakhandDokument5 SeitenEffect of Educational Environment On Personality and Adjustment of Female Students Studying in Colleges of UttarakhandESSENCE - International Journal for Environmental Rehabilitation and ConservaionNoch keine Bewertungen

- 4 26 12Dokument9 Seiten4 26 12stevenscreekNoch keine Bewertungen

- Guía Oficial de La Delegación Argentina de Los Juegos Olímpicos Tokio 2020Dokument330 SeitenGuía Oficial de La Delegación Argentina de Los Juegos Olímpicos Tokio 2020Leandro BonavidaNoch keine Bewertungen

- CT VT Basics SonnenbergDokument71 SeitenCT VT Basics SonnenbergAnonymous OCDJg17Z67% (3)

- Master Handover Rev 4-2013Dokument8 SeitenMaster Handover Rev 4-2013MeysamGholizadehNoch keine Bewertungen

- Civil EngineeringDokument13 SeitenCivil EngineeringMahmoud OuryemchiNoch keine Bewertungen

- Prevent Cross Contamination and Mix UpDokument2 SeitenPrevent Cross Contamination and Mix UpPrince Moni100% (1)

- AppendicitisDokument14 SeitenAppendicitispreethijojo2003558288% (8)

- HEM Duplex Cooling MotorDokument4 SeitenHEM Duplex Cooling MotorAbhishek Kumar Pandey1Noch keine Bewertungen

- A Guide To Patient Medication Review: September 2003Dokument33 SeitenA Guide To Patient Medication Review: September 2003Muhamad GunturNoch keine Bewertungen

- Icu2 Vol22 Sepsisincriticalcare 29marchDokument52 SeitenIcu2 Vol22 Sepsisincriticalcare 29marchricardoatejassNoch keine Bewertungen

- DMD 2018 Stem and Non Stem Checklist Effective 2020-2021Dokument8 SeitenDMD 2018 Stem and Non Stem Checklist Effective 2020-2021Elle DyNoch keine Bewertungen

- Carjackked TrainingDokument7 SeitenCarjackked TrainingErios 50Noch keine Bewertungen

- Healthy and Unhealthy FoodDokument16 SeitenHealthy and Unhealthy FoodGeovanny ValladarezNoch keine Bewertungen

- 4 Strength and Durability of Concrete With LC3Dokument41 Seiten4 Strength and Durability of Concrete With LC3Mirza BasitNoch keine Bewertungen

- Northern NVProvider DirectoryDokument82 SeitenNorthern NVProvider DirectoryGuru NandeshwarNoch keine Bewertungen

- Natural Resources NotesDokument5 SeitenNatural Resources NotesRajesh Kumar GuptaNoch keine Bewertungen

- Index: General Notices (1) Apply To All Monographs and Other TextsDokument36 SeitenIndex: General Notices (1) Apply To All Monographs and Other TextsGhenaNoch keine Bewertungen

- Experiment-3: Study of Microstructure and Hardness Profile of Mild Steel Bar During Hot Rolling (Interrupted) 1. AIMDokument5 SeitenExperiment-3: Study of Microstructure and Hardness Profile of Mild Steel Bar During Hot Rolling (Interrupted) 1. AIMSudhakar LavuriNoch keine Bewertungen

- I. Leadership/ Potential and Accomplishments Criteria A. InnovationsDokument5 SeitenI. Leadership/ Potential and Accomplishments Criteria A. InnovationsDEXTER LLOYD CATIAG100% (1)

- Trump ReportDokument237 SeitenTrump ReportAaron Nobel100% (1)

- Easy Exercises For Hip Flexor PainDokument1 SeiteEasy Exercises For Hip Flexor PainJackieNoch keine Bewertungen

- Pneumatic Oscillator Valve - Pneumatic Controls - Impulse Automation LTDDokument3 SeitenPneumatic Oscillator Valve - Pneumatic Controls - Impulse Automation LTDDindin NajmudinNoch keine Bewertungen

- Morgan - Electrostatics 2003 (Institute of Physics Conference Series) - Institute of Physics Publishing (2004)Dokument386 SeitenMorgan - Electrostatics 2003 (Institute of Physics Conference Series) - Institute of Physics Publishing (2004)Tsiory RanaivosonNoch keine Bewertungen

- Report On Laxmi Niwas PalaceDokument72 SeitenReport On Laxmi Niwas PalaceRenu MahayachNoch keine Bewertungen

- College RecipesDokument29 SeitenCollege RecipeskrunziNoch keine Bewertungen

- (AC-S07) Week 07 - Pre-Task - Quiz - Weekly Quiz (PA) - INGLES IV (7573)Dokument5 Seiten(AC-S07) Week 07 - Pre-Task - Quiz - Weekly Quiz (PA) - INGLES IV (7573)Lucero JimenezNoch keine Bewertungen

- Resume PLPDokument2 SeitenResume PLPapi-302180779Noch keine Bewertungen