Beruflich Dokumente

Kultur Dokumente

Swirlax Burner

Hochgeladen von

Safeer AbbasCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Swirlax Burner

Hochgeladen von

Safeer AbbasCopyright:

Verfügbare Formate

Single machines

Swirlax kiln burner

Application, design and operation

The Swirlax burner offers the following advantages :

-

Improved heat economy

Low amount of primary air

Coal conveyance air independent of

air used for flame shaping

Widely adjustable flame shape

Various fuel combinations

Easy change-over between fuels

Use of low-grade coal

Position of Swirlax kiln burner in a production line

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Burner pipe

External coal pipe

Internal coal pipe

Protective pipe

Oil burner

Guide vanes

Axial air

Coal meal

Radial air

Geared motor for travelling movement

Swirlax coal-cum-oil burner

Swirlax burner installed at plant in Greece

Swirlax is a combined fuel burner for

rotary kilns. It can be used for firing

pulverised coal, gas, oil or combinations

of these fuels in any proportion. When

burning two or three fuels a minimum of

10% of any fuel is recommended.

The burner is suspended from a carriage

and designed so that the burner nozzle is

adjustable both vertically and horizontally.

The Swirlax combined fuel burner has

three annular cross-sections with the oil

or gas burner and its protective tube placed

in the centre. The coal is injected axially

through the intermediate annular crosssection.

The burner nozzle cross-section can easily be adjusted by means of eye bolts at

the rear of the burner.

Primary air is divided into two flows,

viz. an inner radial, swirling flow and an

outer, axial flow.

The distribution of primary air into radial and axial air flows is regulated by two

manually-operated dampers, each fitted

with a scale.

The possibility of varying the burner

nozzle settings as well as the ratio between

axial and radial primary air, makes the

flame shape fully adjustable. An increased

radial air volume at high injection rate

results in a short, wide flame, whereas an

increased axial flow gives a long, narrow

flame.

As the adjustment of the flame shape is

completely independent of the coal feed,

the amount of primary air can be kept

down to about 7%.

The primary air fan, however, is designed for 10% primary air and a total

pressure of Pt = 120-130 mbar to allow

for adverse operational conditions.

The air velocity in the burner nozzle can

be regulated in the range of 35 m/sec. to

120 m/sec.

With a coal/conveyance air ratio in the

range of 3.5-8 kg coal meal/M3 air, the

conveyance air plus primary air will account for only about 10% of the combustion air theoretically required.

The above illustration shows a Swirlax

coal-cum-oil burner. In the case of

coallgas or coal/oil/gas firing, the oil

burner is simply replaced by a gas burner

or a combined gas/oil burner.

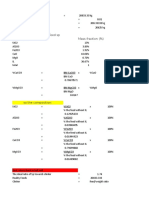

Dimensioning

Fuel consumption

Burner

Type

Trolley

Lt

mm

Kiln burner pipe

Castable

Diameter

Length Diameter

Kg

with insul.

Total

Coal

Kg/h

Oil

Kg/h

1000-3000

550-1700

CO-1

2500

5000

270

390

925

1150

3000-5000

1700-2850

CO-2

2500

6000

300

420

1225

1660

5000-7500

2850-4300

CO-3

2500

6000

330

450

1325

1965

7500-9500

4300-5450

co-4

2500

6000

350

470

1375

2120

9500-11500

5450-6600

co-5

3000

6000

380

500

1550

2605

11500-13500

6600-7750

co-6

3000

6000

430

550

1650

2780

13500-17000

7750-9750

co-7

3000

6000

450

570

1725

2900

17000-22000 9750-12600

co-8

3000

6000

500

620

1900

3050

22000-28000 12600-16050

co-9

3000

6000

520

640

1950

3150

28000-34000 16050-19500

co-10

3000

6000

550

670

2050

3375

Kg

Data in this brochure is intented forpreliminary project planning only. Manufacturer reserves the right to modify equipment details and/or specifications without notice.

DENMARK: F. L.Smidth & Co. A/S.Vigerslev All 77, DK-2500 Valby Copenhagen.

USA: FULLER COMPANY, 2040 Avenue C, Bethlehem, Pennsylvania, 18017-2188.

F. L.SMIDTH & FULLER SUBSIDIARIES: AUSTRALIA: FULLER

F. L.SMIDTH (PACIFIC) PTY. LTD. Level 4,156 Pacific Highway, Greenwich, N.S.W.

2065. BRAZIL : F.L.SMIDTH, COMRCIO E INDSTRIA LTDA. Rua Nebraska,

443, Brooklin Paulista- CEP 04560, Caixa Postal 3506,01051 Sao Paulo- SP.

CANADA: FULLER- F. L.SMIDTH CANADA LIMITED, lO.Thornmount Drive,

Scarborough, Ontario M1B3J4. FULLER -F.L.SMIDTH CANADA LIMITED,3300

Cavendish Boulevard, Montreal, Quebec H4B 2M8. CHILE: FULLER-TRAYLOR,

INC., Independent Sales Office, Ternac SA., FanorVelasso 12, Santiago. FEDERAL

REPUBLIC OF GERMANY: F. L.SMIDTH - FULLER GMBH, Rheinstern Haus,

Emanuel Leutze Strasse 17,4000 Dsseldorf 11. FRANCE: FULLER-F. L.SMIDTH

SA., 2/4 rue Vincent van Gogh, 93364 Neuilly-Plaisance Cdex. ITALY:

F. L.SMIDTH & C. ITALIANA S.r.L.,Via Aterno, 26,1-66020 S. Giovanni Teatino (CH).

JAPAN: FLS Japan Ltd.,Togeki Building, l-l.Tsuldji 4- chome, Chuo-ku,Tokyo 104.

Postal address: Kyobashi P.O. Box 78, Tokyo 104-91. MEXICO: F. L.SMIDTH FULLER MEXICO, SA. DE C.V., Ave. Campos Eliseos 385,Torre B, Primer Piso,

Chapultepec Polanco, 11560 Mexico City, D.F. P.R. CHINA: F. L.Smidth & Co. A/S,

Beijing Representative Office. Scite Tower, Room 1307,22 Jianguo MenWai Dajie,

Beijing 100004. SOUTH KOREA: FULLER INTERNATIONAL, INC., Independent

Sales Office, C.P.O. Box 2016, Hwa-Shin Building, 3rd Floor, 82 1-KA Bongrae-Dong,

Choong-Ku, Seoul. SPAIN: F. L.SMIDTH& CIA ESPAOLA, SA., Carretera de La

Corua, km. 17,8,28230 Las Rozas (Madrid). TURKEY: F. L.Smidth & Co.A/S.,

Liaison Office, c/o Trakmak.Traktre MakineTicaret Ltd. Sirketi, Ismet Ind Cad.,

Mithat Pasa Han. 92-94,80090 Gmssuyu, Istanbul. UNITED KINGDOM:

F. L.SMIDTH- FULLER LTD., 17, Lansdowne Road, Croydon, CR9 2JT.

LICENSEES/JOINT VENTURES: INDIA: Larsen &Toubro Ltd., Cement

Machinery Division, Powai Works, P. 0. Box 8901, Bombay 400072. FULLER - K.C.P.

LTD., Ramakrishna Building, No. 2, Victoria Crescent, Madras 600105. FULLER K.C.P. LTD., 220, Arun Chambers,}. Dadaji Road.Tardeo, Bombay 400 034. FULLER

K.C.P. LTD., 10-E. Annapurna Apartments, 68, Ballygunge Circular Road, Calcutta

700 019. FULLER - K.C.P. LTD., 1009, Tolstoy House, 15 Tolstoy Marg, New Delhi

110001. SOUTH AFRICA: FULLER - F. L.SMIDTH (PTY) LTD., 363 Rivonia

Boulevard, Rivonia, P. 0. Box 1537. Rivonia 2128.

Das könnte Ihnen auch gefallen

- Duoflex BurnerDokument6 SeitenDuoflex Burnersinghite100% (1)

- Duo FlexDokument8 SeitenDuo FlexIsaac Martínez AlcocerNoch keine Bewertungen

- Pillard Low NOxDokument36 SeitenPillard Low NOxadanis01100% (1)

- Duoflex PDFDokument8 SeitenDuoflex PDFTinTunNaingNoch keine Bewertungen

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDokument12 SeitenEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julNoch keine Bewertungen

- Click Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelDokument26 SeitenClick Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelhamedNoch keine Bewertungen

- Mill ProcessDokument6 SeitenMill ProcesskamjulajayNoch keine Bewertungen

- Grate CoolerDokument10 SeitenGrate CoolerAamir HayatNoch keine Bewertungen

- Mombasa: WR 2954 Raw Materials Study and KFUI Improvement PlanDokument22 SeitenMombasa: WR 2954 Raw Materials Study and KFUI Improvement PlanmustafNoch keine Bewertungen

- Advancement in Cement TechnologyDokument12 SeitenAdvancement in Cement Technologyreubenmth100% (1)

- Dalmia Cement (B) Limited: Description Unit ALR DPM Kadapa ValueDokument10 SeitenDalmia Cement (B) Limited: Description Unit ALR DPM Kadapa ValueSenthilkumar PragasamNoch keine Bewertungen

- Typical Anchors Used in Cement PlantsDokument1 SeiteTypical Anchors Used in Cement PlantsEhab Attia SelimNoch keine Bewertungen

- Fuller Kiln DataDokument1 SeiteFuller Kiln DatazementheadNoch keine Bewertungen

- BurnerDokument3 SeitenBurnerRavi sharmaNoch keine Bewertungen

- 2.02.burning Zone CoatingDokument2 Seiten2.02.burning Zone CoatingJCSNoch keine Bewertungen

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDokument7 SeitenUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084Noch keine Bewertungen

- Study of The Grinding Balls Distribution Inside The MillDokument2 SeitenStudy of The Grinding Balls Distribution Inside The Millsempatik721Noch keine Bewertungen

- Impact of Alkali, Sulphur and Chlorine in The KilnDokument3 SeitenImpact of Alkali, Sulphur and Chlorine in The KilnJa Phe Ti100% (1)

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDokument2 SeitenBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyNoch keine Bewertungen

- Novaflam BurnerDokument2 SeitenNovaflam BurnerDaniel ZambranoNoch keine Bewertungen

- Simulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesDokument8 SeitenSimulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesNael100% (1)

- VRM Fan ..Dokument2 SeitenVRM Fan ..harikrushnaNoch keine Bewertungen

- Questionnaire For Pyroprocessing ModificationDokument8 SeitenQuestionnaire For Pyroprocessing ModificationVijay BhanNoch keine Bewertungen

- Tips On Kiln OperationDokument1 SeiteTips On Kiln OperationVipan Kumar DograNoch keine Bewertungen

- (J-1) Burner TypesDokument1 Seite(J-1) Burner Typesgie pradanaNoch keine Bewertungen

- Design of A Rotary Kiln For The ReductionDokument16 SeitenDesign of A Rotary Kiln For The ReductionMadhav Krishna M100% (2)

- V2 Materials Technology 2Dokument526 SeitenV2 Materials Technology 2Liya Nur SholihahNoch keine Bewertungen

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDokument5 SeitenUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditNoch keine Bewertungen

- Process Control of LURM MillDokument6 SeitenProcess Control of LURM Millimam janiNoch keine Bewertungen

- Burner ComparisonDokument2 SeitenBurner ComparisonIrshad HussainNoch keine Bewertungen

- Burner ModellingDokument7 SeitenBurner Modellingkhurram482Noch keine Bewertungen

- Sulphate ModulusDokument2 SeitenSulphate ModulusM. Ali ParvezNoch keine Bewertungen

- Kiln Area Maintenance Checklist - Infinity For Cement EquipmentDokument25 SeitenKiln Area Maintenance Checklist - Infinity For Cement EquipmentAhmed El-ShafeiNoch keine Bewertungen

- Cement Plant VIPDokument51 SeitenCement Plant VIPengr kazamNoch keine Bewertungen

- Heat Balance ComparisionDokument5 SeitenHeat Balance Comparisiongvrr1954Noch keine Bewertungen

- Silo 9 Boulders Investigation ReportDokument20 SeitenSilo 9 Boulders Investigation ReportWaka OngetiNoch keine Bewertungen

- Solid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversityDokument36 SeitenSolid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversitysreeNoch keine Bewertungen

- Operacion 44Dokument44 SeitenOperacion 44Nelly Isabel Narvaez PachecoNoch keine Bewertungen

- Cement Chapter 6Dokument17 SeitenCement Chapter 6shani5573Noch keine Bewertungen

- Fuel Cost ComaparaisionDokument8 SeitenFuel Cost ComaparaisionIrfan AhmedNoch keine Bewertungen

- 1.0 General Plant Information: Existing Cement Mill Process Data SheetDokument6 Seiten1.0 General Plant Information: Existing Cement Mill Process Data SheetBùi Hắc HảiNoch keine Bewertungen

- 042 Drying PDFDokument9 Seiten042 Drying PDFbkchoudhury1993Noch keine Bewertungen

- Clinker Temperature Measurement BoxDokument3 SeitenClinker Temperature Measurement BoxVijay BhanNoch keine Bewertungen

- Mod 7Dokument47 SeitenMod 7mkpq100% (1)

- Dry Feed: Feed Entered SP H2O Content in SP H2O Content in SPDokument20 SeitenDry Feed: Feed Entered SP H2O Content in SP H2O Content in SPIrfan Ahmed100% (1)

- CKC Guidance Manual Jan 10 2008 PDFDokument34 SeitenCKC Guidance Manual Jan 10 2008 PDFamk2009Noch keine Bewertungen

- Main BurnerDokument3 SeitenMain BurnerIrfan Ahmed100% (1)

- Alkali CyclesDokument14 SeitenAlkali CyclesElwathig BakhietNoch keine Bewertungen

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasVon EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNoch keine Bewertungen

- Rotary Kilns: Transport Phenomena and Transport ProcessesVon EverandRotary Kilns: Transport Phenomena and Transport ProcessesBewertung: 4.5 von 5 Sternen4.5/5 (4)

- 185 Ljungstrom Air PreheaterDokument8 Seiten185 Ljungstrom Air Preheatervalor0Noch keine Bewertungen

- Duoflex Burner PDFDokument6 SeitenDuoflex Burner PDFIndra D. Winarko100% (1)

- TPV PDFDokument2 SeitenTPV PDFAntyox StarkNoch keine Bewertungen

- Block 3 Module 1Dokument8 SeitenBlock 3 Module 1Sandra FerrellNoch keine Bewertungen

- Module Unit XDokument3 SeitenModule Unit XKEZIA MAE JALANDONINoch keine Bewertungen

- PILLARD AKTUEL Progressive BurningDokument3 SeitenPILLARD AKTUEL Progressive BurningSteveih100% (1)

- Sunflower: Husks BoilersDokument8 SeitenSunflower: Husks BoilersalfredopinillosNoch keine Bewertungen

- Esl Ie 85 05 120Dokument10 SeitenEsl Ie 85 05 120losmoscasbrNoch keine Bewertungen

- Burner Training BookDokument32 SeitenBurner Training BookNguyễn Thanh Hải100% (3)

- Legal Opinion LetterDokument3 SeitenLegal Opinion LetterLola LaRue100% (7)

- Urban Transportation System EvaluationDokument18 SeitenUrban Transportation System EvaluationMuhammad Faisal Habib JanjuaNoch keine Bewertungen

- Leveling Leveling The Playing The Playing Field For Persons With Field For Persons With Disabilities DisabilitiesDokument63 SeitenLeveling Leveling The Playing The Playing Field For Persons With Field For Persons With Disabilities Disabilitiesversa17Noch keine Bewertungen

- Traction CONTROLDokument18 SeitenTraction CONTROLkiransideasNoch keine Bewertungen

- Illustratedpartsexport TACHOGRAPHSDokument43 SeitenIllustratedpartsexport TACHOGRAPHSgreemax100% (2)

- Terminal 1 and Terminal 3 at Delhi AirportDokument5 SeitenTerminal 1 and Terminal 3 at Delhi AirportAnonymous QdmttSTiNoch keine Bewertungen

- OHS Risk Assessment Form 03 ForDokument32 SeitenOHS Risk Assessment Form 03 ForSohail khanNoch keine Bewertungen

- Choose Brighter,: Make Roads SaferDokument2 SeitenChoose Brighter,: Make Roads Safervivek jayswalNoch keine Bewertungen

- 2017 Asphalt Plant Technician Instruction ManualDokument238 Seiten2017 Asphalt Plant Technician Instruction ManualMeriç DUMANOĞLUNoch keine Bewertungen

- Driver Handbook 2021 2022 PDFDokument77 SeitenDriver Handbook 2021 2022 PDFBob SmithNoch keine Bewertungen

- KZ650 C1 UserManualDokument56 SeitenKZ650 C1 UserManualadhillNoch keine Bewertungen

- That I May Die RoamingDokument276 SeitenThat I May Die RoamingOisinHughes94% (16)

- Change Procedure of Hub BearingsDokument4 SeitenChange Procedure of Hub BearingsRadu DumbravaNoch keine Bewertungen

- Unit 4 Test GMF 2Dokument5 SeitenUnit 4 Test GMF 2Al O'FlahertyNoch keine Bewertungen

- 3x6x5.6 Box CulvertDokument851 Seiten3x6x5.6 Box CulvertRudra Sharma100% (1)

- Visited Places by RizalDokument96 SeitenVisited Places by RizallacbanesdianeNoch keine Bewertungen

- Magic Body ControlDokument27 SeitenMagic Body ControlEdwin Davis100% (1)

- Civil & Environmental Engineering Schematic Design ( 20%) : ChecklistDokument5 SeitenCivil & Environmental Engineering Schematic Design ( 20%) : ChecklistJorgeCancio-BelloNoch keine Bewertungen

- Greenbush Line Weekend ScheduleDokument1 SeiteGreenbush Line Weekend ScheduleNate BoroyanNoch keine Bewertungen

- Form Na Walang Pamagat (Mga Tugon)Dokument1 SeiteForm Na Walang Pamagat (Mga Tugon)Jemark Abarico CenizaNoch keine Bewertungen

- Gravel Paser 02Dokument24 SeitenGravel Paser 02Jesus SanovalNoch keine Bewertungen

- Template Tugas ItineraryDokument12 SeitenTemplate Tugas ItineraryGisela Atalia EarlyNoch keine Bewertungen

- A2 Progress Test 5Dokument4 SeitenA2 Progress Test 5Diana Begeluri100% (1)

- NMH Tuesday - 27 - April - 1915 PDFDokument8 SeitenNMH Tuesday - 27 - April - 1915 PDFFairfax MediaNoch keine Bewertungen

- Te CRPQ PDFDokument38 SeitenTe CRPQ PDFRe DesignNoch keine Bewertungen

- VW Jetta Gear (GLI & SportWagen)Dokument17 SeitenVW Jetta Gear (GLI & SportWagen)Volkswagen of AmericaNoch keine Bewertungen

- Vatika Now (Jul - Dec 2017)Dokument56 SeitenVatika Now (Jul - Dec 2017)vatika_groupNoch keine Bewertungen

- IESNA Illuminance GuideDokument41 SeitenIESNA Illuminance Guide이지언100% (3)

- TractionDokument26 SeitenTractionYogesh GurjarNoch keine Bewertungen

- Transit Oriented Development - A Process Oriented ApproachDokument35 SeitenTransit Oriented Development - A Process Oriented ApproachPriyal NimjeNoch keine Bewertungen