Beruflich Dokumente

Kultur Dokumente

847 T Instructions

Hochgeladen von

Emerson MárquezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

847 T Instructions

Hochgeladen von

Emerson MárquezCopyright:

Verfügbare Formate

Installation Instructions

847T 2 in. Diameter Solid Shaft Incremental Encoders

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

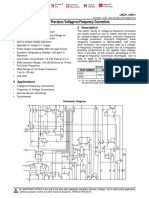

Selection Guide

847

T

a

P Y 1 4

b c d e

- Rf

C 01204

g

h

a

Code

T

2 in. diameter, solid shaft

Code

Mounting Configuration

Standard square flange

Standard servo mount

5 PY mounting*

*P can be ordered only with option Y from table c

c

Code

Shaft Size

6 mm diameter shaft with flat

10 mm diameter shaft with flat

1/4 in. diameter shaft with flat

3/8 in. diameter shaft with flat

Connector/Cable Exit

Radial exit

g

Code

d

Code

M12 connector, 8-pin with mating connector

M12 connector, 8-pin

MS connector, 6-pin with mating connector

MS connector, 6-pin

MS connector, 7-pin with mating connector

MS connector, 7-pin

MS connector, 10-pin with mating connector

MS connector, 10-pin

Cable with 1.5 m (4.92 ft) length

Cable with 5 m (16.4 ft) length

Cable with 10 m (32.8 ft) length

h

Code:

4.55.5V DC

830V DC

Resolution

0000165536

0000165536 pulses/revolution

Accessories

Description

Power Supply

Connector/Cable Type

5/8 in. diameter extended shaft with flat**

**Y can be ordered only with option P from table b

Part Number

High performance flexible coupling 845-FC-*-*

e

Code

Code

Encoder Diameter/Type

Output Configuration

Signal Phasing A-leads-B, Z gated A

4

4.55.5V line driver outputs

4.55.5V open collector outputs

830V line driver outputs

830V open collector outputs

Signal Phasing B-leads-A, Z gated BN

Measuring wheels

845-MW-A-*

Mounting plates

845-MB-*

Servo clamps

845-SC

Pre-wired cables

845-CA-*-*

Mating connectors

845-6P

845-7P

845-7P-RT

845-10P

845-10P-RT

Differential encoder buffer board

845-BB*

M12 cable

889D-F8FB-*

Not available for PY mounting

* See Sensor Catalog for selection.

4.55.5V line driver outputs

4.55.5V open collector outputs

Specifications

830V line driver outputs

Electrical

830V open collector outputs

Code format

Options 5 and B cannot be ordered with option 2 from table d.

Options 6, 7, C and D cannot be ordered with option 1 from table d.

Incremental, 2 channels with zero index

Signal options, clockwise

A-leads-B, 180 marker gated with A, or

rotation viewed from shaft end B-leads-A, 180 marker gated with BN

Mechanical (continued)

Electrical (continued)

Signal phase relation

90 22 channels

MTTFd (EN ISO 13849-1)

330 years

Symmetry

50% 10%

Shaft loading

Zero index channel

Gated 1/2 cycle

Supply current

50 mA

80 N radial, 20 mm (0.79 in.) from front

bearing and 40 N axial provide L10 life

of 3.6 x109 revolutions at 9,000 RPM

and 80 C ambient temperature

Frequency response

4.55.5V line driver output: 820 kHz

830V line driver output: 820 kHz

Open collector: 150 kHz

Shaft diameter [mm (in.)]

Resolution

165536 pulses/revolution

6 (0.24), 10 (0.39), 6.4 (0.25), and

9.2 (0.38) diameter for solid shaft

encoders

7.94 (0.313) for encoder with PY

mounting

Load current

30 mA for all output types

Environmental

Output drivers

4.55.5V line driver - IC HD2

830V line driver - IC HD2

Open collector - 7406

Enclosure type rating

Shaft: IP 65

Housing, connector version with

mating connector installed: IP67

Housing, cable version: IP67

Electrical protection

Reverse polarity and short circuit for all

output types

Temperature

-3080 C (-22...176 F) operating

-40100 C (-4...212 F) storage

Cable outer diameter

0.25 in (6.2 mm)

Relative humidity

90% non-condensing

Cable type

300V, 105 C, 26 AWG, 9-conductor with

overall braided shield, UL AWM type

20327 for use in fixed (non-flexing)

installations; RoHs compliant

Shock

100G/11 ms duration

Vibration

30G/102,000 Hz

EMC

EN 61000-6-2 and EN 61000-6-3

(M12 connector)

Housing material

EN AC-47100 die-cast aluminium

Housing finish

Powder coat paint, color RAL 9005,

Pantone black C (jet black)

Cable bend radius

Minimum 5x outer diameter

Mechanical

Maximum operating speed

9,000 RPM

Angular acceleration

500,000 radians/s

Moment of inertia

15 gcm

Flange material

6061-T6 aluminium

Startup torque at 20 C (68 F)

0.8 Ncm

Shaft material

SAE 303 stainless steel

Operating torque at 20 C (68 F) 0.6 Ncm

Certifications

RoHS compliant

CE Marked for all applicable directives,

UL listed only with cable or M12

connections

Approximate weight [kg (lb)]

0.22 (0.50) square flange mounting

with M12 connector

0.34 (0.75) PY mounting with M12

connector

Output Waveforms

Complementary signals AN, BN, and ZN are supplied only on units with line driver outputs.

Signals and marker option - A leads B (CW rotation)

Signals and marker option - B leads A (CW rotation)

Measuring step

90

90

360

360

A leads B, 180

marker gated with A

Clockwise rotation when facing encoder shaft

Measuring step

B leads A, 180

marker gated with BN

Clockwise rotation when facing encoder shaft

Connector Pins and Signal Availability

Signal Name

MS 6-pin

MS 7-pin

MS 10-pin

M12 8-pin

Cable wire colors

V DC

Red

Common

Black with red band

A output

White

AN output

Black with white band

B output

Blue

BN output

Black with blue band

Z output

Green

ZN output

Black with green band

Zero set input

Yellow

Case

Encoder connectors

845-CA-A-*

H

B

G

D

Recommended mating cable

Cat. No.

845-CA-B-*

G

F

Black

8

4

B

E

845-CA-C-*

889D-F8FB-*

(Attached to encoder)

Dimensions [mm (in.)]

Square Flange Mounting with

Radial M12 Connector

Servo Flange Mounting with

Radial M12 Connector

19.1

(0.75)

Shaft Options

Nominal

1/4 in.

3/8 in.

6 mm

10 mm

Shaft dia. , A

Shaft Options

Nominal

Flat dim., B

6.327/6.312 (0.2491/0.2485) 5.5 (0.22)

9.507/9.492 (0.3743/0.3737) 8.5 (0.33)

6.000/5.988 (0.2362/0.2357) 5.5 (0.22)

9.977/9.962 (0.3928/0.3922) 9 (0.35)

1/4 in.

3/8 in.

6 mm

10 mm

Dia. A

19.1 0.5

(0.750.02)

Flat dim. B

Shaft dia. A

Dia. A

6.327/6.312 (0.2491/0.2485) 5.5 (0.22)

9.507/9.492 (0.3743/0.3737) 8.5 (0.33)

6.000/5.988 (0.2362/0.2357) 5.5 (0.22)

9.977/9.962 (0.3928/0.3922) 9 (0.35)

3.1 (0.12)

3.1

(0.12)

52.4

(2.06)

44.5

(1.75)

35.9

(1.41)

7.6

(0.30)

16.0

(0.63)

4 x dia. 4.0 (0.16) thru

44.5 52.4

(1.75) (2.06)

50.8

(2.00) dia.

44.0

(1.73)

31.70 0.03

(1.248 0.001) dia.

Square Flange Mounting

with RadialCable

35.9

(1.41)

46.1

(1.82)

31.70 0.03

1.248 0.001 dia.

2.5 (0.10)

3X 4-40 UNC 5.6 (0.22)

equally spaced

ia.

MS Connector Options

Type

C

6 pin

63.9 (2.52)

7 pin

63.9 (2.52)

10 pin

69.4 (2.73)

Servo Flange Mounting with

Radial MS Connector

Cable options

1.5 m (4.9 ft)

5 m (16.4 ft)

10 m (32.8 ft)

50.0

1.97

MS Connector Options

Type

C

63.9 (2.52)

6 pin

7 pin

63.9 (2.52)

10 pin

69.4 (2.73)

50.8

(2.00)

9.0 (0.35)

35.9 (1.41)

49.7

(1.96)

18.0

0.71

44.0

(1.73)

Servo Flange Mounting with

Radial Cable

46.1 (1.82)

per part

number

18.0

(0.71)

35.9 (1.41)

(1 38.

.50 1

)d

3X M4x0.7 - 6H

5.6 (0.22)

equally spaced

49.7

1.96

2.5

(0.10)

47.0

(1.85) dia. B

50.8

(2.00) dia.

29.2

(1.15)

42.0 ia.

(1.65) d

9.0

(0.35)

Square Flange Mounting with

Radial M12 Connector

4X 10-32 UNF 5.6 (0.22)

29.2 (1.15)

Cable options

1.5 m (4.9 ft)

5 m (16.4 ft)

10 m (32.8 ft)

per part

number

50.0

(1.97)

Dimensions [mm (in.)] (continued)

0.000

Dia. 7.938 -0.013

0.0000

0.3125 -0.0005

PY Flange Mounting with Radial M12 Connector

24.6

(0.97)

4 x dia. 7.1 (0.28) thru

40.7

(1.60)

90.0

1.5

(0.06)

4.8

(0.19)

12.7

(0.50)

45.0

10

(3.9 1.0

8) d

ia.

63.5

(2.50)

116.6

(4.59) dia.

50.8

(2.00) dia.

44.0

(1.73)

7.3

(0.29)

9.0 (0.35)

PY Flange Mounting with Radial MS Connector

PY Flange Mounting with Radial Cable

40.7

1.60

50.9

2.01

49.7

(1.96)

C

MS Connector Options

Type

C

63.9 (2.52)

6 pin

7 pin

63.9 (2.52)

10 pin

69.4 (2.73)

per part

number

18.0

(0.71)

Cable options

1.5 m (4.9 ft)

5 m (16.4 ft)

10 m (32.8 ft)

50.0

(1.97)

Rockwell Automation maintains current product environmental information on its website at

http//www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page.

www.rockwel lautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Copyright 2014 Rockwell Automation, Inc. All rights reserved.

10001065811 Ver 00 Jul7 2014

847T-IN001A-EN-P

Printed in USA

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Est Can BusDokument32 SeitenEst Can BusRuben EstradaNoch keine Bewertungen

- Intel Server Board SE7210TP1-EDokument145 SeitenIntel Server Board SE7210TP1-Emajmun123456Noch keine Bewertungen

- TECH VibrationDiagnosticGuideDokument2 SeitenTECH VibrationDiagnosticGuidetiagofer84575Noch keine Bewertungen

- CSS-TESDA-Module - 2nd QuarterDokument39 SeitenCSS-TESDA-Module - 2nd QuarterRasec Nayr Cose0% (1)

- University of Engineering and Technology: Power Supply and BreadboardDokument7 SeitenUniversity of Engineering and Technology: Power Supply and BreadboardEtsham Amjad100% (1)

- Content Sheet: Micro-Star Int'L Co.,Ltd Micro-Star Int'L Co.,Ltd Micro-Star Int'L Co.,LtdDokument32 SeitenContent Sheet: Micro-Star Int'L Co.,Ltd Micro-Star Int'L Co.,Ltd Micro-Star Int'L Co.,LtdkasimkaNoch keine Bewertungen

- AK4527Dokument33 SeitenAK4527andresoares2007Noch keine Bewertungen

- Pioneer CKDokument1 SeitePioneer CKrabiulfNoch keine Bewertungen

- Industrial Ethernet Switch GuideDokument22 SeitenIndustrial Ethernet Switch GuideSivertNoch keine Bewertungen

- Emi Question BankDokument4 SeitenEmi Question Bankraviteja62Noch keine Bewertungen

- Ec2305 Transmission Lines and Waveguides L T P C 3 1 0 4Dokument1 SeiteEc2305 Transmission Lines and Waveguides L T P C 3 1 0 4durgadevikarthikeyanNoch keine Bewertungen

- BD643Dokument2 SeitenBD643Mario Juarez de ParadaNoch keine Bewertungen

- OJT Weekly Report Edit For HardboundDokument8 SeitenOJT Weekly Report Edit For HardboundveliantmNoch keine Bewertungen

- Galleon II: 1KVA/1.5KVA/2KVA/3KVADokument2 SeitenGalleon II: 1KVA/1.5KVA/2KVA/3KVAWil LiamNoch keine Bewertungen

- GSLC Week 3 Tour de France PDFDokument5 SeitenGSLC Week 3 Tour de France PDFDerian WijayaNoch keine Bewertungen

- Toshiba PDFDokument22 SeitenToshiba PDFSohail AhmedNoch keine Bewertungen

- SIP Trunking For Dummies PreviewDokument12 SeitenSIP Trunking For Dummies PreviewManish GandhiNoch keine Bewertungen

- Assignment # 2Dokument1 SeiteAssignment # 2Mod454Noch keine Bewertungen

- Manual Cordex 48-3.6KWDokument64 SeitenManual Cordex 48-3.6KWPabloSanabriaNoch keine Bewertungen

- Lm331 Voltaje A FrecuenciaDokument24 SeitenLm331 Voltaje A FrecuenciaLeguel LNoch keine Bewertungen

- TPC817Dokument10 SeitenTPC817Felipe CostaNoch keine Bewertungen

- Memory Test Updated V3 ReducedDokument96 SeitenMemory Test Updated V3 ReducedKruthi SubramanyaNoch keine Bewertungen

- 02 Microwave Experiment Manual - PolarizationDokument2 Seiten02 Microwave Experiment Manual - PolarizationAriel Carlos CaneteNoch keine Bewertungen

- EdSim51 simulator and 8051 instruction set experimentDokument6 SeitenEdSim51 simulator and 8051 instruction set experimentJohn Jacobsen PerezNoch keine Bewertungen

- Vu 4K UHD HDR10 Official Android Oreo 8.0 Smart TV 254cms LED TV Model: VU100OADokument3 SeitenVu 4K UHD HDR10 Official Android Oreo 8.0 Smart TV 254cms LED TV Model: VU100OADinesh KumarNoch keine Bewertungen

- philips+40PFL4409 F8+sm PDFDokument81 Seitenphilips+40PFL4409 F8+sm PDFArthur BaxNoch keine Bewertungen

- Poe NVR Zosi View EnglishDokument46 SeitenPoe NVR Zosi View EnglishdirtinlaNoch keine Bewertungen

- VoiceBlue Manual-V2 1Dokument100 SeitenVoiceBlue Manual-V2 1Havesovgosh_Hh_6638Noch keine Bewertungen

- Bluetooth HM-13 enDokument22 SeitenBluetooth HM-13 enNicolas Prudencio RojasNoch keine Bewertungen

- RF Plan Tables iPASOLINKDokument31 SeitenRF Plan Tables iPASOLINKEr Praveen ThakurNoch keine Bewertungen