Beruflich Dokumente

Kultur Dokumente

11 4 6

Hochgeladen von

arunkmepesOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

11 4 6

Hochgeladen von

arunkmepesCopyright:

Verfügbare Formate

J.

Electrical Systems 11-4 (2015): 420-432

Abdelmonoem

(1,3)

Nayli ,

Regular paper

Sami

Guizani(2,3),

Faouzi Ben

Implantation of the scalar control for the

Ammar(3)

open-end winding induction machine On

FPGA Spartan 3E

JES

Journal of

Electrical

Systems

In this paper, the authors propose the implantation of the scalar control for controlling the

open-end winding induction machine on FPGA. The scalar control is simulated in matlab

Simulink environment using a Xilinx System Generator. This control is implemented in a Xilinx

Spartan 3E FPGA board. It is experimentally verified by the visualization of command signals

for the switches of the inverters.

Keywords: Open-end winding induction machine; Scalar control; Field Programmable Gate Arrays;

Xilinx System Generator.

Article history: Received 9 January 2014, Received in revised form 18 September 2015, Accepted 14 October 2015

1. Introduction

The power segmentation is now a major interest in electrical engineering researches. the

considerable interests are given for multiphase machines [1,2], multi star machines [3,4],

and open-end stator windings induction machines OEWIM [5-8], and the dual open-end

stator windings induction machines [9,10].

The implementation of digital control of electric machines on the Field Programmable

Gate Arrays FPGA occupies a large part of industrial drive systems. Indeed, the "FPGA"

are reconfigurable components. They present the advantage that they can be reconfigured as

many times as needed which allows their quickly reuse with different algorithms. In

addition, they present time very impressive calculation capabilities without forgetting the

flexibility that they offer for the designer since it is alone to design algorithms [11] and to

implement them [12-17].

The authors treat in the paper three parts:

In the first part, the different modules made which allowed to have the scalar control are

presented. The each module is validated in the Matlab-Simulink environment using Xilinx

System Generator.

The second part is presented the digitization validation of the scalar control for an openend winding induction machine using Matlab-simulink with Xinlinx System Generator.

Finally, the composed algorithm of the different modules of the scalar control is

implemented on Spartan 3E FPGA board. The implementation is verified by the

visualization of command signals for the switches of the inverters.

2. Digitization of the scalar control

Before commencing the digitization of the scalar control "V / f law ", the figure 1 shows

the supply of the open-end winding induction machine by two PWM voltage source

inverters based on V/f law.

(1) University of Tunis, ESSTT, Tunisia. Email: n.ayli@hotmail.fr

(2) University of El Manar, IPEIEM, Tunisia. Email: Guizani_sami@yahoo.fr,

(3) University of Carthage, MMA Laboratory, INSAT, Tunisia. Email : Faouzi.Benamar@insat.rnu.tn

Copyright JES 2015 on-line : journal/esrgroups.org/jes

J. Electrical Systems 11-4 (2015): 420-432

Inverter 1

T11

E

2

T11

T12

Inverter 2

T13

T23

T22

T21

E

2

T12

T13

OEWIM

T23

T22

T21

Fig. 1. Open-end winding induction machine supplied by two voltage source inverters.

The figure 2 shows the principle of PWM to supply the open-end winding induction

machine by two 2- level inverters.

triangular Signal

Vref 11 = VMax/2 sin (2 fs t)

Vref 12

T11

T11

T12

T12

Towards Inverter 1

Vref 13

T13

+

T13

Vref 21 = VMax /2 sin (2 fst)

T21

Vref 22

T21

T22

Towards Inverter 2

T22

Vref 23

T23

T23

Fig. 2. Principle of the PWM sine triangle.

The principle of the scalar control V / f law is to vary the speed of the machine while

holding constant the ratio of the voltage about the stator frequency.

In the following, we will interest in the numerical algorithm of the V / f law, for this

we must generate three voltages of variable references in amplitude and frequency during

the acceleration phase which corresponds to the transitional regime.

The three reference signals are compared with a triangular carrier for the command

signals. Then just create the dead time in order to avoid any short circuit between the

different switches.

421

A. Nayli et all: Implantation of the scalar control for the OEWIM On FPGA

The different blocks necessary to obtain the control signals for each entry of the stator

windings, are shown in figure 3.

V11

Module of

the reference

voltages at

the entry 1

Max

Module of

V/f law Teta

V12

V13

Clk t

Clk t

Sig T11

T11

Sig T11c

T11c

Sig T12

T12

T12c

Regitres

Sig T12c

Clk R

T13

T13c

Sig T13

Sig T13c

Triangle

module

FPGA Clock

of Spartan 3E

100MHz

Regitres

Clk ct

Clk R

Clk R

V21

Shifting

module

Clk t

Module of

the reference

voltages at

the entry 2

V22

Regitres

Comparison

module

Dead time

module

Sig T21

T21

Sig T21c

Sig T22

T21c

T22

Sig T22c

T22c

Sig T23

T23

Sig T23c

T23c

V23

Clk t

Fig. 3. Diagram of the scalar control "V / f law".

By the figure 3, the diagram of the digitization of the scalar control "V / f law" groups

the following modules:

- Triangle module

- Generation module of the variation law

- Generation module of the reference voltages

- Comparison module

- Module of the dead time

- Module of the shift 180 .

2.1. Triangle module

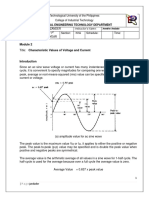

This module generates a triangular carrier of the frequency and fixed amplitude. The

triangular design of a signal is based on the block counter / down counter which counts

from 0 to (N-1) / 2 and count of (N-1) / 2 to 0, is shown in the figure 4.

422

J. Electrical Systems 11-4 (2015): 420-432

Fig. 4. Principle of a digital triangular carrier.

With :

- Tct : the period of the counter and down counter

- Tt : the period of the triangular carrier = chopping period of the inverter

- ft : the frequency of the triangular carrier

- fct : the frequency of the counter and down counter

- n : number of bits of the counter / down counter

- N-1 = 2n -1 : modulo counter / down counter

We will use an operating frequency identical to that used for the simulation in the

Matlab Simulink environment, is a frequency triangular signal ft equal to 3150Hz. This

value will be adjusted to 3258Hz order to have all periods of the operation of the integer

values.

1

Tt =

= 306900ns

(1)

ft

The clock period of the counter can be determined according to the period of the

triangular carrier by the following relationship:

T t = (N 1).T ct

(2)

So we must determine the period counter and down counter as equal:

306900 . 10 -9

= 300ns (3)

1023

1

f ct =

= 3.333MHz

(4)

T ct

We use a RS flip-flop to control the counter / down counter block. The output of this

T ct =

2 10 1

= 5 12 .

2

The block counter fonctions as a down counter to the minimum value which is equal to 0.

The detection of the maximum count value (512) and the minimum value of counting (0)

is provided by the two comparison blocks C1 and C2 of the figure 5. According to the state

of the two comparators, we must give orders (sel) to the multiplexer across the RS flip-flop

to indicate the operating state of the up / down counter.

The module of the triangular signal is mainly constituted by an counter, an RS flip-flop,

a multiplexer and two comparators. In the figure 5, this module is presented in System

Generator.

flip-flop is set to 1 if the counter reaches the maximum amplitude

423

A. Nayli et all: Implantation of the scalar control for the OEWIM On FPGA

We show the operation of the RS flip-flop and block counter / down counter in the

following truth table.

Table 1: Truth table of the RS flip-flop.

S

0

0

1

0

R

1

0

0

0

sel

0

0

1

1

Operation

Counter

Down counter

- If the selection entry sel equals 0 then the multiplexer passes in its output, input

d0 = 1 that forces the input up / down counter to 1, this latter it starts counting to the max

value.

- If the input sel is equal to 1 then the multiplexer passes in its output, input d1 = 0

that forces the input up/ down counter to 0, to get this up/down counter in phase down

counting up to 0.

From the truth table of the RS flip-flop, we can extract the following equation:

Q n = R .S + R .Q n 1

(5)

After the output of the counter, we added a block 'scale' and a block of subtraction that

allows to have a triangle whose amplitude varies between (-1) and 1 to center the triangle

obtained on time axis, thereafter the amplitude of the triangle is regulated by adding a

multiplication block whose the constant is equal to Vmax. The simulation result of the

triangular signal is shown in the figure 5.

Triangular signal

RS flip-flop block

Fig. 5. Carrier triangular block and simulation result.

2.2. Generation module of the variation law and of the angle

For the realization of this module, we desire have the possibility to vary at starting, the

value of the frequency and the acceleration time. In the figure 6, we represent the general

generation module of the variation law of the acceleration time and the angle .

424

J. Electrical Systems 11-4 (2015): 420-432

The design of this module groups the following blocks:

- Generation Block of the variation law of the frequency and of the acceleration time

With the aid of the library "system generator", we carry a slope "f / tacc" with

saturation. To do this we use a 12-bit adder block and a delay block that replaces the ramp

under "Simulink". Then we have a comparator that will block its 4087 counter maximum

value for the saturation which fixes the value of the frequency f. Initially, the output of the

adder is equal to 1, from where the input 'en' of the adder is forced to 1; it starts to

increment up to maximum value 4087. Thereafter for pass the blocking phase, the

comparison block 4087 detects the maximum value and the input 'en' goes to 0.

To fix the value of the desired frequency, we multiplied by a constant K2

1

(K2 =

) which allows us to have a unit amplitude. Then we inserted a

12

2 1

multiplication block to specify the value of the frequency f. For the voltage, we have

multiplied by a constant equal to VMax.

- Generation block of the angle

The angle is always varying between 0 and 2 , then to determine the angle , we

have the following relationship:

(6)

= dt = 2 f dt

: angular speed (rad.s-1)

f : frequency (Hz)

In digital, the integration requires the multiplication of the entries of integrator block by

a sampling period Te, as shown in the equation below:

z

S(z)

(7)

I(z) = T e .

=

z 1

E(z)

His recursion equation is:

s(k) = s(k 1) + T e .e(k)

(8)

VMax

Integration block

1/ t acc

Evolution of the angle

Fig. 6. Generation block of the angle .

425

A. Nayli et all: Implantation of the scalar control for the OEWIM On FPGA

2.3. Generation module of the reference voltages

To obtain the reference voltages (Vs11, Vs12, Vs13), we used the 2/3 transformation from

the two voltages (Vs, Vs).

2.3.1. Generation module of two voltages Vs and Vs

This module generates two sinusoidal signals varying in amplitude and frequency with

the following equations:

Vs=Vmax cos()

(9)

Vs=Vmax sin()

(10)

For this module, we have a block 'SineCosine' having such as entered the angle , the

block generate in outputs of the values of sine and cosine between (-1) and 1. The general

structure of the generation module voltages Vs , Vs under "Generator System" is

represented in the figure 7(a) and the evolution of the two voltages by figure 7 (b).

(a)

(b)

Fig. 7. (a) Generation module of the voltages Vs, Vs; (b) Evolution of the two voltages.

2.3.2. Generation module of the reference voltages

The 2/3 transformation is based on the following mathematical relationship:

Vs11 = [Vs cos() - Vs sin()].

Vs12 = 1 V s .(( cos ) +

2

Vs13 = - (Vs11+ Vs12)

3 sin ) +

(11)

1

V s .(sin +

2

3 cos )

(12)

(13)

With the aid of "System Generator" toolbox, we will implant the mathematical

relationships of the 2/3 transformation. We have a block 'SineCosine' which generate in the

output the values of sin () and cos (). Thereafter, we apply the mathematical relationships

using blocks of multiplication, addition ... the representation of the block is shown by the

figure 8. The clock period Th used for these blocks is equal to the sampling period where

Th = 306900 ns.

426

J. Electrical Systems 11-4 (2015): 420-432

Fig. 8. Generation block of the reference voltages.

2.4. Generation module of control signals of entry 1

Before comparing the voltages of the sinusoidal reference with triangular carrier, it is

essential to synchronize the period of the reference voltages with that of the carrier with

using a register block. Also the registers of the reference voltages and carrier must have the

smallest sampling period which is the carrier Tct = 300e-9ns.

After the synchronization of the different signals, we move to the comparison module, to

generate the control signals with complementary signals, is represented by the figure 9.

Fig. 9. Generation module of the control signals.

427

A. Nayli et all: Implantation of the scalar control for the OEWIM On FPGA

2.5. Module of the dead time

The switches of each arm of the inverter being complementary, but their opening time

and the closing time are not zero. To avoid short circuit when commutation of the switches

we have introduced a dead time module.

The dead time block consists of a block 'Delay' and a port logic 'AND'. This module

insert a dead time at the beginning of each command at the switch close. The principle of

this module is given in the figure 10.

Dead time

Fig. 10. Generated control signals by the dead time module.

2.6 Shift module of 180

To ensure the supply of entry 2 of the machine, we have to introduce a shift of 180 to

the generation module of the reference voltages (VS11, VS12, VS13).

Then to introduce a shift of 180 of the angle , we have shift the T

period , we

2

used it for a subtraction block which calculates the difference between the generated angle

from 0 at 2 for different times and the constant 0.5 to generate new shifting by 180 .

For the subtraction block must keep the same parameters as the addition block and of

integration in the generation module of the angle is shown in the figure 6. For the

transitional regime (t < 0.5s), we have a variable period which results the shifting variable

but proportional at the period with a proportionality coefficient equal to 0.5. Once the three

reference signals shifted by 180 are obtained, we do the same thing for the command

signals of the inverter 2. The figure 11 shows the simulation results of the command signals

of arm 1 of the inverter 2 shifted by 180.

-180

Fig. 11. Command signals shifted of 180

428

J. Electrical Systems 11-4 (2015): 420-432

3. Validation of the scalar control for a open-end winding induction machine

The scalar control controlled the open-end winding induction machine, whose controller

is embedded into Xilinx Spartan-3E FPGA by means of the Xilinx System Generator

Toolbox; the simulation model of scalar control is validated in the Matlab simulink

environment. Design details of the controller developed using Xilinx System generator are

provided in the previous sections.

The following cycle of operation, at t = 0.5s, the system has a starting cycle, from t =

0.5s to t = 1s, the machine in working in no-load conditions. At time t = 1s, a load torque

Tr = 300mN.

Figure 12 shows the pole voltage inverter 1 (Vs11-Vs12), inverter 2 (Vs21-Vs22) and pole

voltage machine U1= (Vs11-Vs12) - (Vs21-Vs22), the currents stator Isa, Isb, speed and the

torque, for load torque Tr = Tn.

Fig. 12. Evolution of voltage, currents of stator, speed, and torque.

The characteristics of the machine used:

- Nominal power P = 45 KW.

- Speed n = 1450 rpm.

- Resistance of stator Rs = 0.15 .

429

A. Nayli et all: Implantation of the scalar control for the OEWIM On FPGA

- Resistance of rotor Rr = 0.046 .

- Inductance of stator Ls = 17.9 mH.

- Inductance of rotor Lr = 18.6 mH.

- Mutual inductance Msr = 17.2 mH.

4. Experimental results of the FPGA implementation of the scalar control

To validate the digitalization of scalar control for the open-end winding induction

machine, we represent the implementation of the command using an evaluation board

Nexys 2 based on FPGA of the family SPARTAN 3E-XC3S1200e-4fg320 of the society

XILINX, figure 13.

Fig. 13. Implementation of the command algorithm on FPGA.

The report "Map" is shown by the table 2 of the VHDL code of the scalar control that

shows the effectiveness of FPGA Spartan3E for this sort of application. This phase allowed

to minimize the resources consumed.

Table 2: The report "Map" of the VHDL code

430

Number of Slice Flip Flops

2,131 out of 17,344

12%

Number of 4 input LUTs

Number of occupied Slices

Number of Slices containing only related logic

Number of Slices containing unrelated logic

Total Number of 4 input LUTs

Number used as logic

Number used as a route-thru

Number used as Shift registers

Number of bonded IOBs

Number of RAMB16s

Number of BUFGMUXs

3,530 out of 17,344

2,041 out of 8,672

2,041 out of 2,041

0 out of 2,041

3,780 out of 17,344

3,327

250

203

13 out of 250

3 out of

28

1 out of

24

20%

23%

100%

0%

21%

5%

10%

4%

J. Electrical Systems 11-4 (2015): 420-432

The experimental results of the different command signals for the arm 1 of inverters 1

and 2 are shown by figures 14, 15 and 16. These results are obtained at the output of the

FPGA Spartan 3E of the board Nexys 2 for the carrier frequency 3258 Hz and dead time

equal to 3s.

T11

T11C

Fig. 14. Command signals of the switches T11 and T11C

T21

T21C

Fig. 15. Command signals of the switches T21 and T21C

T11

T21

Fig. 16. Command signals of the switches T11 and T21.

431

A. Nayli et all: Implantation of the scalar control for the OEWIM On FPGA

5. Conclusion

The preparation of an algorithm allowing for the scalar control of the open-end winding

induction motor is investigated. Indeed, the realized program is validated in the MATLAB

Simulink environment using the Xilinx System Generator.

The simulation model of the open-end winding asynchronous machine supplied by two

voltage sources based on V/f law in the environment of Matlab Simulink using the

Xilinx System Generator is presented.

The program of scalar control is implemented on the Spartan 3E FPGA board while

specifying the different steps. The experimental results of the different command signals for

the each inverter are visualized and verified the dead time between command signals of the

switches.

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

432

G.K.Singh, V. Pant and Y.P. Singh, Voltage source inverter driven multi-phase induction machine,

Computer and Electrical Engineering Elsevier, Vol. 29, pp. 813-834, 2003.

A.S. Abdel-Khalik, A.S. Morsy, S. Ahmed and A.M. Massoud, Effect of stator winding connection on

performance of five-phase induction machines, IEEE Transactions on Industrial Electronics, Vol. 61, pp. 3 19, 2014.

F. Ben Ammar and S. Guizani, The Improvement Avalability of a Double Star Asynchronous Machine

Supplied by redondant voltage source inverters, Journal of electrical system JES, Vol. 4, 2008.

K. Marouani, L. Baghli, D. Hadiouche, A. Kheloui and A. Rezzoug, A New PWM Strategy Based on a 24Sector Vector Space Decomposition for a Six-Phase VSI-Fed Dual Stator Induction Motor, IEEE

Transactions on Industrial Electronics, Vol. 55, pp.1910-1920, May 2008.

V. T. Somasekhar, K. Gopakumar, M. R. Baiju, K. K. Mohapatra and L. Umanand, A Multilevel Inverter

System for an Induction Motor With Open-End Windings, IEEE transactions on industrial electronics

(2005), Vol. 52, pp. 824-836, 2005.

A. Nayli, S. Guizani and F. Ben Ammar, Open-end Winding Induction Machine Supplied by Two Flying

Capacitor Multilevel Inverters. IEEE Conference on Electrical Engineering and Software Applications

ICEESA 2013,Hammamet, Tunisia, March 2013.

S. Guizani, A. Nayli, and F. Ben Ammar, Fault-Tolerant control for Open-end Stator Winding Induction

Machine supplied by two three phase cascaded inverters with one failed inverter, Journal of Electrical

Engineering JEE , Vol. 14, 2014.

J. Kalaiselvi and S. Srinivas, Bearing Currents and Shaft Voltage Reduction in Dual-Inverter-Fed Open-End

Winding Induction Motor With Reduced CMV PWM Methods, IEEE Transactions on Industrial

Electronics, Vol. 62, pp. 144-152, January 2015.

S. Guizani and F. Ben Ammar, the dual open-end winding induction machine fed by quad inverters in

degraded mode, International Journal of Scientific and Engineering Research IJSER, Vol. 4, 2013.

S. Guizani and F. Ben Ammar, Dual open-end stator winding induction machine fed by redundant voltage

source inverters, Turkish Journal of Electrical Engineering & Computer Sciences, 2013, accepted.

M. Cirstea, A. Aounis, M. McCormick, P. Urwin and L. Haydock, Induction Motor Drive system Modelled

in VHDL, IEEE Conference on Proceedings VHDL International Users Forum Fall Workshop 2000,

Orlando, FL, pp. 113-117, October 2000.

F. Ricci and H.L. Luy, An FPGA-Based Rapid Prototyping Plaform for Variable-Speed Drives, IEEE

Conference on Industrial Electronic Society IECON 2002, Vol.2, pp. 1156-1161, November 2002.

O. AKIN and A. Irfan, The use of FPGA in field-oriented control of an induction machine, Turkish Journal

of Electrical Engineering & Computer Sciences, Vol.18, 2010.

B. Badre, K. Mohammed, I. Silviu and L. Ahmed, Low- speed sensorless control of PMSM motor drive

using a nonlinear approach backstepping control: FPGA-based implementation, Journal of Theoretical and

Applied Information Technology, Vol. 36, 2012.

T. Sutikno, N. Idris, A. Jidin, and M. Cirstea, An improved FPGA implementation of direct torque control

for induction machines, IEEE Transactions on Industrial Informatics, Vol.9, pp. 1280-1290, 2013.

M. A. Zare, R. G. Kavasseri and C. Ababei, FPGAbased design and implementation of direct torque for

induction machines, International Conference Reconfigurable Computing and FPGAs (ReConFig) 2014,

Cancun, pp. 1-6, December 2014.

Xilinx Corp, Xilinx System Generator V10.1 Reference Guide for Simulink www.xilinx.com.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Krab 8.0 ENDokument43 SeitenKrab 8.0 ENPablo ZuñigaNoch keine Bewertungen

- Theory PhotoacousticsDokument8 SeitenTheory PhotoacousticsWaskito Aji100% (1)

- Vehicle and Driver Vibration - PPTDokument16 SeitenVehicle and Driver Vibration - PPTAnirban MitraNoch keine Bewertungen

- Low Pass Filter 1st OrderDokument7 SeitenLow Pass Filter 1st OrdervlsijpNoch keine Bewertungen

- Module 2 - VanderzanderDokument6 SeitenModule 2 - Vanderzanderpeter vanderNoch keine Bewertungen

- Epoch LT: User's ManualDokument142 SeitenEpoch LT: User's ManualWalter SuarezNoch keine Bewertungen

- Introduction To Data Communications (And Signal Analysis (DCS Unit-1) )Dokument43 SeitenIntroduction To Data Communications (And Signal Analysis (DCS Unit-1) )Mukesh83% (12)

- DEEPSOIL User Manual v7Dokument169 SeitenDEEPSOIL User Manual v7Narayan RoyNoch keine Bewertungen

- Numerical Simulation of Wave Propagation in Soil MediaDokument6 SeitenNumerical Simulation of Wave Propagation in Soil MediaNarayan RoyNoch keine Bewertungen

- Engineering Practices Laboratory: Lab ManualDokument51 SeitenEngineering Practices Laboratory: Lab ManualKarthikeyan100% (1)

- Alternating Voltages and CurrentsDokument15 SeitenAlternating Voltages and CurrentsDavid AmarteyNoch keine Bewertungen

- TAL BassLine UserManual PDFDokument6 SeitenTAL BassLine UserManual PDFKihira NaokiNoch keine Bewertungen

- ISO 6721 - Part 2Dokument19 SeitenISO 6721 - Part 2Isadora HenriquesNoch keine Bewertungen

- Assignment 1Dokument4 SeitenAssignment 1ngunasenaNoch keine Bewertungen

- Sound Intensity and ResonanceDokument13 SeitenSound Intensity and Resonanceapi-243289431100% (1)

- Lab#7 I&M 078Dokument9 SeitenLab#7 I&M 078Asad saeedNoch keine Bewertungen

- Determination of Effective Hydrophone Sizes From 1 To 50 MHZ According To Iec 62127-3:2022 Using Short Pulse ExcitationDokument4 SeitenDetermination of Effective Hydrophone Sizes From 1 To 50 MHZ According To Iec 62127-3:2022 Using Short Pulse ExcitationwangcosimoNoch keine Bewertungen

- Machine Foundation Irrigation Pump 1762001 559Dokument1 SeiteMachine Foundation Irrigation Pump 1762001 559Riddhima MukherjeeNoch keine Bewertungen

- Omicron ProtectionDokument188 SeitenOmicron ProtectionBoobesh Kumar Sekar100% (4)

- EWP Independent Study Booklet III (Wave Properties)Dokument34 SeitenEWP Independent Study Booklet III (Wave Properties)navNoch keine Bewertungen

- Universal Vibration Meter: Instruction ManualDokument24 SeitenUniversal Vibration Meter: Instruction ManualLong NguyenNoch keine Bewertungen

- Practical Clamping CircuitDokument11 SeitenPractical Clamping Circuitarjuna4306Noch keine Bewertungen

- Steel Chimney Oscillations: A Comparative Study of Their Reported Performance Versus Predictions Using Existing Design TechniquesDokument9 SeitenSteel Chimney Oscillations: A Comparative Study of Their Reported Performance Versus Predictions Using Existing Design TechniqueshikoNoch keine Bewertungen

- Week 3 1 PDFDokument33 SeitenWeek 3 1 PDFosmanriazNoch keine Bewertungen

- CH 12 Physics AnswersDokument21 SeitenCH 12 Physics AnswersSam Likes HamNoch keine Bewertungen

- Forced and Free Vibration ProjectDokument4 SeitenForced and Free Vibration ProjectHarshdeep SinghNoch keine Bewertungen

- Lab3 FisicaDokument5 SeitenLab3 FisicaDavid BravoNoch keine Bewertungen

- 11.10.01 - Minimum Loadings and Load Combinations For Onshore Structural DesignDokument17 Seiten11.10.01 - Minimum Loadings and Load Combinations For Onshore Structural Designawie1982Noch keine Bewertungen

- IJSSBT Vol-2 No. 2 May 14Dokument117 SeitenIJSSBT Vol-2 No. 2 May 14Aditya DoyaleNoch keine Bewertungen

- 3101 Physics Paper With Answer MorningDokument5 Seiten3101 Physics Paper With Answer Morningmonishbro41Noch keine Bewertungen