Beruflich Dokumente

Kultur Dokumente

1 s2.0 S2212827116001232 Main

Hochgeladen von

toroomionOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 s2.0 S2212827116001232 Main

Hochgeladen von

toroomionCopyright:

Verfügbare Formate

Available online at www.sciencedirect.

com

ScienceDirect

Procedia CIRP 40 (2016) 225 229

13th Global Conference on Sustainable Manufacturing - Decoupling Growth from Resource Use

Enterprise resource planning (ERP) in improving operational efficiency:

Case study

Ignatio Madanhirea,*, Charles Mbohwab *

School of Engineering Management, University of Johannesburg, Auckland Park 2006, Johannesburg, 0027, South Africa

OR

Mechanical Engineering Department, University of Zimbabwe, Mount Pleasant, Harare, 00263, Zimbabwe

b

School of Engineering Management, University of Johannesburg, Auckland Park 2006, Johannesburg, 0027, South Africa

* Corresponding author. . Tel.: +263-721-453-451; fax: +263-04-621-420 E-mail address: imadanhire@eng.uz.ac.zw

Abstract

The research is an investigation into prospects of improving operational efficiency in a manufacturing system through enterprise resource

planning (ERP). This was done on a South African company which is into linen manufacturing and making uniforms for the hospitality

industry. This was achieved by improving effective communication among departments to meet delivery dates. ERP framework was designed

to reduce work in progress on the shop floor and inventory. Integration of firms activities, intra organizational communication and wider

collaboration were some of the pillar considered in the process to achieve a reduction in working capital. Wastage in the form of material or

energy, inventory, defects or wasted capacity, was eliminated for effectiveness. Reduction of product cycle times was done through minimizing

set-up and delays, coordinating machine maintenance with production operations and optimizing space in order to better utilize workers,

equipment and workstations.

2016 Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license

2016 The Authors. Published by Elsevier B.V.

(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Peer-review under responsibility of the International Scientific Committee of the 13th Global Conference on Sustainable Manufacturing.

Peer-review under responsibility of the International Scientific Committee of the 13th Global Conference on Sustainable Manufacturing

Keywords: ERP; operational efficiency; wastage reduction; resource effectiveness

1. Introduction

Todays dynamic business is becoming increasingly

complex with functional units requiring more and more inter

departmental data flow for decision making, timely and

efficient procurement of parts, management of inventory,

accounting, human resources and distribution of goods. In this

regard, efficient information systems would improve

competitiveness through cost reduction and better logistics [1].

There has been also been emphasis of a greater interaction

between the customers and suppliers, in order to achieve

production of goods and services that conform to customer

specifications [2,3]. Enterprise Resource Planning (ERP) is the

strategic tool which synchronizes, integrates, and streamlines

data and processes of the organization into one single system

to gain a competitive edge in the uncertain business

environment.

In developing countries, there is tendency for departments

to work independently resulting in various sections competing

rather than working together. This has compromised the

operational efficiency of a greater number of manufacturing

entities. Thus products produced cannot be competitive both

within and beyond the borders of countries of origin in terms

of cost, quality and delivery timeliness. A number of South

African entities face this dilemma, including the case study

company considered in this research work. The focus is more

on monetary value of products to be manufactured neglecting

the capacity that can be reached using the available resources

and facilities.

2. ERP overview

2.1 ERP scope

According to the American Production and Inventory

Control Society (2001), ERP is defined as a method for the

2212-8271 2016 Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license

(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Peer-review under responsibility of the International Scientific Committee of the 13th Global Conference on Sustainable Manufacturing

doi:10.1016/j.procir.2016.01.108

226

Ignatio Madanhire and Charles Mbohwa / Procedia CIRP 40 (2016) 225 229

effective planning and controlling of all resources needed to

take, make, ship and account for customer orders in a

manufacturing, distribution or service organization [4]. Such an

integration of functions, can be achieved through a software

package solution offered by vendors to support the seamless

integration of all information flowing through the company,

such as financial, accounting, human resources, supply chain

as well as customer information [5].

Traditionally, manufacturing entities treat each transaction

separately, as they are built around strong boundaries of

specific functions that a specific application is meant to cater

for. ERP stops treating transactions as stand-alone activities

and consider them as part of the interlinked processes that make

up the business. It is premised on the principle that the whole

is greater than the sum of its parts [5].

2.2 Basic ERP modules

The advancement in information technology (IT)

infrastructure is the backbone of ERP system implementation

in any manufacturing business operation. It is assumed the

companies implementing ERP solutions may have multiple

locations of operation and control. Hence on line data transfer

is done across locations where enabling technologies are used

such as Workgroup, Workflow, Groupware, Electronic Data

Interchange (EDI), Internet, Intranet and Data warehousing, to

facilitate transactions. This is to underline that ERP software is

made up of many software modules selected based on both

economical and technical feasibility for given manufacturing

units. The basic modules normally incorporated are [7]:

ERP production planning module this seeks to optimize the

utilization of manufacturing capacity, parts, components and

material resources using historical production data and sales

forecasting.

ERP purchasing module it streamlines procurement of

required raw materials, as it automates the process of

identifying potential suppliers, negotiating prices, placing

orders to suppliers, and related billing processes.

ERP inventory control module facilitates the process of

maintaining appropriate level of stock in the warehouse

through identifying inventory requirements, setting targets,

providing replenishment techniques and options, monitoring

item usage, reconciling inventory balances and reporting

inventory status.

ERP sales module its key functions are order placement,

order scheduling, shipping and invoicing. This is key as

revenues from sales are the live blood of the organizations.

ERP marketing module it supports lead generations, direct

mailing campaign and trends in customer tastes.

ERP financial module this the core module of ERP software

systems, as it gathers financial data from various departments

and generate reports such as balance sheet, general ledger, trial

balance as well as quarterly financial statements.

ERP human resources (HR) module it routinely maintains a

complete a complete employee data base to include contact

information, salary details, attendance, performance evaluation

and promotion of all employees. It is key in optimizing the

utilization of the expertise of all employees.

Thus ERP software system is all encompassing as it affords

one to manage all departments from production to distribution

and accounting in one integrated system. In this regard, the

process results in reducing operating costs, facilitating easy day

to day management and enabling overall strategic planning of

operations. With adequate training of employees on correct

ERP, it will in turn promote proper operation of business

processes and increase profits [6, 8].

It has to be noted that modules are integrated and provide

seamless data flow among the modules, increasing operational

transparency through standard interfaces. As the project is an

opportunity to reengineer processes in line with the ERP

adopted model, it is also the moment to rejuvenate the whole

business for competitiveness.

2.3 ERP and business process reengineering (BPR)

BPR is reconsideration and radical redesign of

organizational processes in order to achieve drastic

improvement of current performance in cost, service and speed

[9]. Now the organization should adopt the benefits of ERP

solutions right through the BPR exercise. Re-engineering

through ERP, has led to more drastic change for users as it

comes with several tried and tested best practices. A BPR

exercise has to precede ERP implementation, as ERP is there

to consolidate the process adjustment and rejuvenation with a

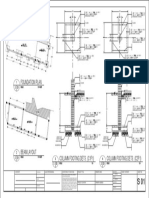

software package. Fig. 1 gives the ERP flow chart for various

top down levels involved which are: top management,

operations management, basic computer data and execution of

plans.

Fig. 1 Standard ERP flow chart

Business Planning comes up with objectives, followed by

Sales Planning which gives the demand and product lines to be

pursued. Production planning will ensure the availability of

resources to meet the sales forecasts.

227

Ignatio Madanhire and Charles Mbohwa / Procedia CIRP 40 (2016) 225 229

Master Scheduling will ensure the sequence of products on

the production line. While Material Planning gives measures or

specifics of materials into each of the product lines set to be

produced. Capacity planning looks at both human and plant

resources available to meet the set production targets.

reduce lead times. The work was based on existing information

and direct observation in the work study. The productivity over

a number of months was recorded for analysis. The clustered

data was collected from archived records from January 2012 to

June 2014 to develop an observed trend, the actual records were

taken for November 2013 to April 2014.

Basic Computer Data like bill of materials, item parameters,

inventory status and routing are critical for product costing.

Execution of plans are responsible for purchasing of

material for implementation of plans, also shop scheduling to

have an idea of product cycle time, as well as performance

measurement for accountability for any suffering points which

need urgent attention to be brought in line with the objectives.

2.4 ERP implementation

Implementing an ERP system will require significant

changes on staff and work practices [4, 10]. Hence for cost

effectiveness, it is recommended to use an external consultant

with specific training in ERP implementation. The consultants

are responsible for the initial stages, training of employees,

workflow study, customized interfaces, trouble shooting and

assistance with ERP issues. As so many changes take place that

affect almost everyone in the organization, it is important to

involve them in the project to make and use the ERP system as

a success.

4. Case study operations

The case study was done at a company manufacturing linen

and uniform for hospitality industry based in Cape Town,

South Africa. The major departments in the organization were:

Design section, Pattern making section, Cutting section,

production, and Technical Services section as given in Fig 2.

The organization was facing challenges of meeting the delivery

times, and traditional methods have been tried to solve these

operational challenges with particular focus on the

Manufacturing Department. ERP system was recommended to

address this persistent problem at the organization.

Measures to be closely monitored are capacity, utilization,

efficiency and load percentage [10]. The best operating level is

the percent of capacity utilization that minimizes average unit

cost.

Capacity = (No. of machines / workers) x (No. of shifts) x

(Utilization) x (Efficiency)

Where utilization is the percentage available time spent

working.

Utilization =

Actual hours charge

Scheduled available hours

And efficiency giving an indication of how well a machine or

worker performs compared to standard output level

Efficiency = Standard hours earned

Actual hours charged

3. Methodology

A steering committee was of senior managers was formed

including the General manager, Production manager,

Information System (IT) manager and the Purchasing manager

to formulate the project, integrate project resources and select

suitable ERP system. Experience representatives of different

user departments with expertise in particular fields were also

chosen to participate in the project and as resource person. The

grant objective was to improve operations quality and

efficiency, to standardize and simplify operations flow and

Fig. 2 Manufacturing process

5. Results and Discussion

The factory had two main product lines which were linen

and uniform section both for the hospitality industry as given

in the Table 1 below.

Table 1. Main product lines

LINEN

UNIFORMS

Table cloths & napkins

Chef jackets

Curtains

Chef pants

Cushions

Chef caps

228

Ignatio Madanhire and Charles Mbohwa / Procedia CIRP 40 (2016) 225 229

Kitchen cleaning clothes

Aprons

470

Cushion

The organization was using the conservative capacity lag

strategy for its capacity requirements planning (CRP). This led

to loss of customers due to failure to meet demand, as the

capacity was only increased after demand had increased. This

was causing delays during manufacturing process especially in

the uniform section.

As the operations are not fully automated, when demand

increased, new contract workers were hired. This meant

training had to be done every time putting a strain on the

production output as the just engaged casuals would not be

familiar with product requirements.

Although the computer machines were all connected to the

local network server, they were very few and a lot of paperwork

would move among the departments taking a lot of time to take

action. Quality control section which was under the Production

Department had no computer, and all their operations were

done manually.

The Linen section had the bulk of the full time workforce

numbering 25 working one shift of 8.5 hours per day. Records

showed that this section was constantly failing to deliver

products in line with deadlines given on the Master Production

Schedule due to human resources related challenges.

Table 2. Linen section production times

Scheduled

available

hours

Scheduled

hours

earned

Actual

hours

earned

Load

Nov13

Dec13

Jan14

Feb14

Mar14

Apr14

4 462.5

5 355

5 355

6 247.5

6 287.5

6

300.5

3 037.5

4 725

4 725

5 512.5

5 512.5

5

565.5

4 412.5

5 310.5

5

226.3

6 225.2

6 238.3

6

268.5

4 455.8

5 340.7

5

330.7

6 240.5

6 240.5

6

285.7

The efficiency and utilization were estimated to be 89.1%

and 99% respectively on overage over a period of six months

from November 2013 to April 2014 period. Table 2 shows the

data obtained from time sheets and weekly individual reports

for the Uniform Section. Table 3 gives load percentages above

100%, which means that the load schedules were beyond the

capacity of labor resources in this section. Thus delivery delays

would result for bulk of the orders, and unnecessary costs were

incurred in overtime or hiring excess contract workers due to

panic. This was caused by continuous scheduling beyond the

existing capacity of the plant.

The uniform section had a staff complement of 9 full time

workers who worked 8.5 hour per day, and were not adequate

to meet deadlines as well.

Table 5. Uniform section production times

Scheduled

available

hours

Scheduled

hours

earned

Actual

hours

earned

Load

Nov13

Dec13

Jan14

Feb14

Mar14

Apr14

1 963.5

2 363.5

2

258.5

2 306.5

2 606.5

2

606.5

1 400

1 658

1

569.2

1 696.8

1 696.8

1

950.5

1 564.5

2 009.5

2

065.5

2 098.2

2 264.5

2

363.5

1 645.5

2 020

2 005

2 039.2

2 071.8

2

185.2

Table 6 Uniform section capacity data

Nov13

Dec13

Jan14

Feb14

Mar14

Apr1

Efficiency

89.5

82.5

76.0

80.9

74.9

82.5

Utilization

79.7

85.0

91.5

91.0

86.9

90.7

Capacity

1 400.6

1 657.4

1 570.6

1698.0

1 696.5

1

950.4

Load %

117.5

121.9

127.7

120.1

122.1

112.0

Table 7. Uniform section: Quantity and duration data

Table 3. Linen section capacity data

Product Type

Product Qty

Chef jacket

Duration per

product hours

45.8

99.5

Chef pant

15

5

516.7

114.0

Chef cap

10

88.5

Apron

30

Nov13

Dec13

Jan14

Feb14

Mar14

Apr14

Efficiency

89.2

89.0

90.4

88.6

88.4

88.8

Utilization

98.9

99.2

97.6

99.6

99.2

Capacity

3 936.8

4 727.8

5 513.1

5 513.7

Load %

113.2

113.0

4

724.7

112.8

113.2

113.2

Table 4. Linen section: Quantity and duration data

Product Type

Product Qty

Duration per

product hours

Table cloth

461

Napkin

495

The efficiency and utilization is estimated to be 81.1% and

87.5% respectively considering the averages for the six months

in Table 6.Table 5 shows the data obtained from time sheets

and weekly individual reports for the Uniform Section. The

load percentages in Table 6 are above 100%, this revealed that

the resources could not handle the load assigned to it in the

Master Production Schedule (MPS). Again there is need to hire

more workforce for to build on the capacity.

Ignatio Madanhire and Charles Mbohwa / Procedia CIRP 40 (2016) 225 229

The Uniform section had low values of efficiency and

utilization compared to the same in the Linen section, this was

attributed to internal inherent poor activity coordination

resulting in delayed deliveries of uniforms.

entire enterprise to re-engineer core business processes by

taking advantage of software to automate information update

and incorporate best practices to facilitate rapid decisionmaking, cost-reduction, and greater managerial control for

improved organizational competitiveness.

References

6. Recommendations

In order to use ERP software, the computer hardware

structure had to be upgraded to Pentium 4 ( P4s) with large

capacities, which were compatible with ERP software. Also the

number had to be increased to appreciably reduce paper work,

and improve faster flow of information and quick decision

making processes. At the time of the study competitive

software could be sourced from Oracle, who had to initiate

expert training for the shop floor staff and supervisors.

Load percentages have shown that the work schedule was

beyond capacity of the Linen section, therefore capacity has to

be adjusted upwards. Thus a number of workers to be added

have to be calculated in order for the section to be sufficiently

capacitated for the existing load. A permanent solution would

be to hire 4 more permanent workers.

To address the problem at Uniform Section, capacity had also

to be adjusted by hiring 1 more casual worker to work for 6

days a month to match the load.

Other areas that ERP could improve is the elimination of all

resource wastages in form of material, energy, inventory,

defects or wasted capacity, through labor control and work in

progress control. The reducing of product cycle time could be

achieved through minimization of waiting and processing time.

Waiting time could be reduced by better coordinating the

flow of material( for example, intermediate products and

finished products) in the Uniform Section, while processing

time reduction is enabled by carefully optimizing the balance

between changeover times and inventory costs.

Reducing cycle times is important when implementing ERP

system. It is achieved by reducing setting up times and delays,

coordinating maintenance by Technical Services, with

production operation schedules, as well as optimizing space in

order to better utilize workers, equipment and workstations.

7. Conclusion

The project has come up with the implementation

framework for ERP, and it was shown how the implementation

was going to improve the operational efficiency of the

manufacturing system at this linen making company. The ERP

system improved the employee efficiency as data and

information could now be captured and updated at one point

with no duplication of effort which could waste resources.

Operational efficiency resulted from greatly improved

communication and corporation from all departments. Online

updates on inventory levels enabled informed decisions to meet

the products delivery dates. ERP requires consensus from the

[1] Holland C, Light B. A Critical Success Factor Model for ERP

Implementation, IEEE Software 1999. Vol .9, Issue3, p30-36.

[2] Norris G, Harley J, Dunleavy K, Balls J. E-Business and ERP, John

Wiley & Sons; 2000.

[3] Welti N. Successful SAP R/3 Implementation: Practical Management of

ERP Project, Addison Wesley Longman; 1999

[4] Chen C. Taiwan Enterprise Data Operation Requirement Analysis:

Manufacturing Version, 2003. MIC Research report.

[5] OLeary D. Enterprise Resource Planning Systems: Systems, Life; 2000.

[6] Ross J . The ERP Revolution: Surviving versus thriving. MIT White

Paper, Cambridge, MA; 1998.

[7] Zhang Z. A Framework for ERP Systems Implementation in China: An

Empirical Study. International of production Economics 2005. 98(1),

p56-80

[8] Umble E . Enterprise Resource planning: Implementation procedures and

Critical Success Factors. European Journal of Operational Research,

2003. 146, p 214 -257

[9] Summer M . Risk Factors in Enterprise-wide / ERP Projects. Journal of

information technology, 2000. (15), p 317 -327.

[10] Gefen D. A Multi-level Approach to Measuring the Benefits of an ERF

System in Manufacturing Firms. Information Systems management

(2005). 22(1), p 18-25

229

Das könnte Ihnen auch gefallen

- Datasheet of DS 2CE16C0T IT3F - 20161107 PDFDokument3 SeitenDatasheet of DS 2CE16C0T IT3F - 20161107 PDFtoroomionNoch keine Bewertungen

- DH XVR7208 16A 4KL X - Datasheet - 20180306 PDFDokument3 SeitenDH XVR7208 16A 4KL X - Datasheet - 20180306 PDFtoroomionNoch keine Bewertungen

- DH-PFM920I-6UN-C/U: 305m UTP CAT6 CableDokument3 SeitenDH-PFM920I-6UN-C/U: 305m UTP CAT6 CabletoroomionNoch keine Bewertungen

- 720P Wi-Fi Camera: Stay Close With What You CareDokument2 Seiten720P Wi-Fi Camera: Stay Close With What You CaretoroomionNoch keine Bewertungen

- DH-XVR1B16H: 16 Channel Penta-Brid 4M-N/1080P Cooper 1U Digital Video RecorderDokument3 SeitenDH-XVR1B16H: 16 Channel Penta-Brid 4M-N/1080P Cooper 1U Digital Video RecordertoroomionNoch keine Bewertungen

- Cronograma 2017 Grupo de Alabanza Iglesia Cristiana Cuadrangular PamplonaDokument1 SeiteCronograma 2017 Grupo de Alabanza Iglesia Cristiana Cuadrangular PamplonatoroomionNoch keine Bewertungen

- Biotransformation OF (22,62) - FARNESOL by The Plant Pathogenic Fungus GlomerellaDokument4 SeitenBiotransformation OF (22,62) - FARNESOL by The Plant Pathogenic Fungus GlomerellatoroomionNoch keine Bewertungen

- Cable RG59-95 Ref. CX25950301Dokument1 SeiteCable RG59-95 Ref. CX25950301toroomionNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Spare Parts Documentation: TD10004553 EN 00Dokument69 SeitenSpare Parts Documentation: TD10004553 EN 00Emon Sharma100% (1)

- Resonant Excitation of Coherent Cerenkov Radiation in Dielectric Lined WaveguidesDokument3 SeitenResonant Excitation of Coherent Cerenkov Radiation in Dielectric Lined WaveguidesParticle Beam Physics LabNoch keine Bewertungen

- Term Coalition Has Been Derived From The Latin Word 'Coalitio' Which Means To Grow Up TogetherDokument2 SeitenTerm Coalition Has Been Derived From The Latin Word 'Coalitio' Which Means To Grow Up TogetherShree MishraNoch keine Bewertungen

- Catalogue Maltep en PDFDokument88 SeitenCatalogue Maltep en PDFStansilous Tatenda NyagomoNoch keine Bewertungen

- Rehabilitation Major Repair of Permanent Bridges Bariis Br.Dokument2 SeitenRehabilitation Major Repair of Permanent Bridges Bariis Br.John Rheynor MayoNoch keine Bewertungen

- Brock CoursesDokument4 SeitenBrock Coursesapi-339025646Noch keine Bewertungen

- Bond - Chemical Bond (10th-11th Grade)Dokument42 SeitenBond - Chemical Bond (10th-11th Grade)jv peridoNoch keine Bewertungen

- Jewellery and ZakatDokument2 SeitenJewellery and ZakatTariq A MalikNoch keine Bewertungen

- Lease of Playground To A SchoolDokument2 SeitenLease of Playground To A SchoolSutapaNoch keine Bewertungen

- EpitheliumDokument48 SeitenEpitheliumdrpankaj28100% (1)

- Jurnal Arang AktifDokument7 SeitenJurnal Arang AktifSurya KrisNoch keine Bewertungen

- Essay On Stamp CollectionDokument5 SeitenEssay On Stamp Collectionezmt6r5c100% (2)

- Archive Purge Programs in Oracle EBS R12Dokument7 SeitenArchive Purge Programs in Oracle EBS R12Pritesh MoganeNoch keine Bewertungen

- Theory of ArchitectureDokument21 SeitenTheory of ArchitectureRana A MataryNoch keine Bewertungen

- AGENCY Summer Ed.Dokument109 SeitenAGENCY Summer Ed.AshAngeLNoch keine Bewertungen

- CDP Project InstructionsDokument6 SeitenCDP Project InstructionsNarendra ReddyNoch keine Bewertungen

- The Spartacus Workout 2Dokument13 SeitenThe Spartacus Workout 2PaulFM2100% (1)

- FinTech and Banking DisruptionDokument13 SeitenFinTech and Banking DisruptionMaru MasNoch keine Bewertungen

- Form A HypothesisDokument2 SeitenForm A Hypothesismrshong5bNoch keine Bewertungen

- The Basics of Effective Interpersonal Communication: by Sushila BahlDokument48 SeitenThe Basics of Effective Interpersonal Communication: by Sushila BahlDevesh KhannaNoch keine Bewertungen

- Grammar Summary Unit 8Dokument2 SeitenGrammar Summary Unit 8Luana Suarez AcostaNoch keine Bewertungen

- Syllabus Tourism Laws CKSCDokument6 SeitenSyllabus Tourism Laws CKSCDennis Go50% (2)

- Areopagitica - John MiltonDokument1 SeiteAreopagitica - John MiltonwehanNoch keine Bewertungen

- Dwnload Full Practicing Statistics Guided Investigations For The Second Course 1st Edition Kuiper Solutions Manual PDFDokument36 SeitenDwnload Full Practicing Statistics Guided Investigations For The Second Course 1st Edition Kuiper Solutions Manual PDFdavidkrhmdavis100% (11)

- Question QP MCQ A BDokument60 SeitenQuestion QP MCQ A BPrashant JhaNoch keine Bewertungen

- Assignment On How To Increase Own Brand Mantras: Submition Date: January 29,2021Dokument5 SeitenAssignment On How To Increase Own Brand Mantras: Submition Date: January 29,2021Ferari DroboNoch keine Bewertungen

- Class 11 Biology Notes Chapter 2 Studyguide360Dokument10 SeitenClass 11 Biology Notes Chapter 2 Studyguide360ANoch keine Bewertungen

- RAW TM & HM Users Manual V 11Dokument8 SeitenRAW TM & HM Users Manual V 11arcangelus22Noch keine Bewertungen

- Foundation Plan: Scale 1:100 MTSDokument1 SeiteFoundation Plan: Scale 1:100 MTSJayson Ayon MendozaNoch keine Bewertungen

- Polymer ConcreteDokument15 SeitenPolymer ConcreteHew LockNoch keine Bewertungen