Beruflich Dokumente

Kultur Dokumente

A Short-Term Production Planning Model For Dimension Stone Quarries PDF

Hochgeladen von

werewaroOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Short-Term Production Planning Model For Dimension Stone Quarries PDF

Hochgeladen von

werewaroCopyright:

Verfügbare Formate

SME Annual Meeting

Feb. 19 - 22, 2012, Seattle, WA

Preprint 12-049

A SHORT-TERM PRODUCTION PLANNING MODEL FOR DIMENSION STONE QUARRIES

E. Bakhtavar, Urima Univ. of Tech., Urmia, Iran

K. Oraee, Univ. of Stirling, Stirling, UK

ABSTRACT

In this paper, problem of short-term production planning for

dimension stone quarries was mathematically modeled using a binary

integer programming. The model includes an objective function, which

was founded as the minimization of the costs due to the total cutting

planes of the blocks. This objective may cause to maximization of the

net present value (NPV) in dimension stone quarries. During the

mathematical modeling the essential constraints are dimension stone

quarry capacities and the market demand, block accessibility for the

equipment and the reserve constraints. As a base, an optimal size and

shape of extractable blocks should be first assigned according to the

available extraction technique and the market demand, in order to

create a geological block model. Then an economical block model is

provided by assignment of a value of one for ore blocks and zero for

waste. Maximum profitability and minimum amount of the ore wastage

can be gained using this plan and modeling.

In dimension stone industry, a certain amount of blocks, which

may extracted during a short-term period, are usually ordered by the

market. Furthermore, if a quarry includes a non-homogeneous

dimension stone reserve, it is necessary to establish a short-term

production plan in order to supply the homogeneous materials

according to the market demand.

There are a great number of parameters which control the blocks

production plan are [3]:

INTRODUCTION

Providing the amount of dimension stones that is needed for the

processing factories (market) can be optimally achieved by means of a

short-term production planning. Numerous studies to the problem of

short and long term production planning and scheduling in open pit

mining have been appeared by using the operation research methods

in the literatures. But, for such planning in dimension stone quarrying

industry, there is no considerable study.

Mode of occurrence of the deposit (in the forms of flat,

tabular, inclined, orientation, rough, etc.)

Geological and geotechnical characteristics

Quarry configuration such as its dimensions, number of

working faces and etc.

Extraction technique (mechanized or manual) and capacities

of the available equipment

Block size and shape according to the market demand

In this case, characteristics of the waste and ore blocks and

enough working space for the extraction, splitting and transportation

play a major role in the process.

FORMULATION OF THE SHORT-TERM PRODUCTION PLANNING

Problem definition

Production planning over a period of time is known as planning

horizon. During the short-term production planning typically annual

plans should be performed on a planning horizon as an operational

guide, in order to provide the production planning requirements.

The production operation and concepts of dimension stone

quarrying are partly different than other metal and non-metal open-pit

mining. Unlike to the open-pit mining operation which produces ore in

form of fragmented materials by bench blasting, in the dimension stone

quarrying only the blocks with marketable size and shapes are desired.

These blocks can be appropriately provided using the mechanized

techniques such as diamond wire cutting and armed-chained cutting

machines.

As it was found in the literatures, both binary and mixed integer

mathematical programming can be effectively used for optimal open-pit

production planning and scheduling subject to the required crucial

constraints.

A production planning should be shortly set for the blocks

extraction with the objective of maximizing net present value (NPV) or

profit considering the maximum efficiency, minimum wastage,

maximum recovery of the reserves.

Total NPV should be maximized in production planning

optimization. The most sensitive parameters controlling the NPV are:

A certain stone quality was found as the best decision variable for

planning dimension stones [1]. A method was also presented for

determination of amount of the marketable blocks before extraction

operation.

Product price

Discount rate

Time sequence of the schedule

Production cost

In planning a dimension stone quarry or any mining industry, cost

is clearly a controlling factor. As a case, in hard-rock stone quarrying

by means of a diamond wire cutting machine, the costs are mostly

influenced by erosion on the diamond [3]. On the other hand, in

dimension stone quarries, NPV is mostly depends on cost of the blocks

extraction using the available cutting machines. Therefore, the

extraction cost for a dimension stone quarry should be minimized to a

possible value. For this purpose, the minimum possible amount of the

blocks cutting planes must be performed. It means that the

minimization of the total area of the extractable blocks planes, which

must be cut, can be directly caused to the maximization of the NPV.

PRODUCTION PLANNING

There are typically three time ranges of production planning:

short-term, medium-term and long-term. Although short-term

production planning usually ranges from one month to one year, it can

also define as daily and weekly sub-periods. A medium-term

production planning may commonly range 1-5 years. This period can

divide into 1-6 month sub-periods which are needed for a detailed

scheduling. Long-term planning often varies between 20 and 30 years.

It can also divide into 1-5 years sub-periods.

Totally, a long-term plan can make an operating and mining

strategy including some objectives as below [2]:

Minimization of risk to investors

Maximization of mine life.

In case a mathematical model minimizes the lateral cutting

planes, the optimal production planning is given. Hence, the most

Maximization of output (profit or NPV) for investors

Copyright 2012 by SME

SME Annual Meeting

Feb. 19 - 22, 2012, Seattle, WA

appropriate size and shape must be considered for the extractable

blocks according to the market demand. Number of cutting planes per

unit volume of dimension stones can be minimized if the optimal size

and shape is selected for the blocks. Upside and downside cutting

planes of the blocks are not considered. Because they do not have any

influence on optimization of short-term production planning [3].

xit, j : A binary decision variable, which is equal to 1 if the block i is to

be extracted in period t and equal to 0 otherwise;

Cit, j : Cost due to the lateral planes cutting for block i,j in period t;

Eil, j : Total area of the lateral cutting planes (m2) for block i,j;

Oi , j : Tonnage of ore block i,j;

Production planning in dimension stone quarrying can be defined

on an economical block model as the same of open-pit mining. In this

case, an optimal sequence of blocks extraction should be obtained

with the objective of maximizing the NPV. There are some economical

and technical constraints that should be considered in this process.

Wi, j : Tonnage of waste block i,j;

Pmax : Maximum amount of the ore to be sent for the processing

(maximum market demand) in period t;

Pmin : Minimum amount of the ore to be sent for the processing

(minimum acceptable market demand) in period t;

Qmax : Maximum amount of the ore to be extracted in period t; and

Accessibility of block for the quarry equipment is one of the

constraints during short-term production planning. It means that all

extractable blocks must be accessible to the equipment on a planning

horizon.

Qmin : Minimum amount of the ore to be extracted in period t;

In dimension stone quarrying contrary to open-pit mining, grade

blending constraints may not important and also play no major role in

the process.

Mathematical programming approach to production planning

objectives is to find the optimal sequence of extractable blocks. For the

target of this study an objective function is considered as minimization

of total area of the lateral cutting planes. This objective function may

finally cause to maximize NPV. The objective function is formulated as

given in Eq. 1.

The binary values of zero and one are assigned for the blocks

in dimension stones economical block model. The values one and

zero respectively indicate ore and waste blocks.

In this paper, the short-term production planning problem for

dimension stone quarries is mathematically modeled for a part of the

quarry according to the market demand. Maximum NPV and minimum

amount of ore wastage can be obtained using this model.

T N M L

Min Z = Cit, j Eil, j xit, j

t =1 i =1 j =1l =1

During this model the following notes as the required assumptions

and constraints are considered:

Constraints

A) Accessibility constraints. The blocks extraction operation

in dimension stone quarries is usually started from a side of the ore

reserve. In addition, it is assumed for setting up a cutting machine (like

diamond wire cutting) for extraction of a new block, at-least eight

contiguous blocks around the new block as Fig.1 should be extracted

previously. Therefore, each extractable block has some neighbor

blocks in a horizon that is considered for a short-term planning (Fig.1).

For this purpose, only if at-least one of the four cases (as shown in

Fig.1) have been accessed and their associated blocks extracted,

block i,j can be selected for extraction through the cutting machines

(according to Eq. 6). As it shown in Fig.1, block i,j can be accessed

and then cut from four directions. As it mentioned above, block i,j is

accessible if the blocks located in at-least one of the quadruplet areas

are extracted prior to block i,j. Hence, the accessibility constraints are

as Eqs. 2 to 6.

The amount of market demand for a dimension stone can be

provided from one level or one production horizon.

Upside and downside cutting planes of extractable-blocks are

ignored.

Maximum tonnage of extractable-blocks can be about 25 tonnes

in accord with the transportation regulation in Iran.

The extractable-blocks height and bench height are similar.

On-mine cutting planes should be minimized.

Transportation cost for the extractable-blocks to processing plant

(market) is not considered.

As the base of this study the following three steps must be

respectively taken into account:

(1)

Geological model creation.

The most suitable size of extractable-blocks is assigned

according to the market demand.

Economical block model creation including zero and one as the

block values.

Short-term production planning formulation

Geological block model with the certain blocks size according to

the exploration drilling data should be first created. Dimensions of the

blocks are assigned considering the market order and the maximum

weight of transportable blocks. Then economical block model is made

including zero and one values. The blocks with acceptable rock quality

for the market are assigned as ore (one) and the bad quality and fully

jointed (without the potential for being a block) rocks are named waste

(zero).

For the problem mathematical modeling a binary integer

programming is developed using the following symbols and their

meanings.

t: Index for planning period, t = 1, 2,, T;

T: Maximum number of periods in each planning horizon;

i,j: Indices for block number identification;

N,M: Total number of blocks to be planned in X and Y directions,

respectively;

l: Block lateral cutting planes identification;

L: Maximum lateral planes area of blocks to be cut;

Figure 1. Accessibility blocks around the block i,j and the free faces

directions.

Copyright 2012 by SME

SME Annual Meeting

Feb. 19 - 22, 2012, Seattle, WA

was founded as the minimization of the costs due to the total cutting

planes of the blocks which may finally cause to maximization of the net

present value (NPV) in dimension stone quarries for a short-term.

Some essential constraints associated with the short-term planning of

dimension stone production were mathematically modeled. They are

capacities and the market demand, block accessibility for the

equipment and the reserve constraints. This short-term plan ensures

that each block in a planning horizon has a free face for accessibility

by extraction, loading and transportation equipment. Using this plan

the maximum profitability and minimum amount of the ore wastage can

be also obtained.

8 xit, j ( xih, j +1 + xih, j + 2 + xih1, j + xih1, j +1

h =1

(2)

+ xih1, j + 2 + xih2, j + xih2, j +1 + xih2, j + 2 ) R y1t

t

8 xit, j ( xih, j +1 + xih, j + 2 + xih+1, j + xih+1, j +1

+

h =1

h

xi +1, j + 2 + xih+ 2, j

xih+ 2, j +1

xih+ 2, j + 2 )

(3)

y 2t

8 xit, j ( xih, j 1 + xih, j 2 + xih1, j + xih1, j 1

+

h =1

xih1, j 2 + xih2, j

xih2, j 1

xih2, j 2 )

REFERENCES

(4)

y3t

1.

Mutlutrk M. (2007), Determining the amount of marketable

blocks of dimesional stone before actual extraction, Journal of

Mining Science, 43 (1), pp. 67-72.

2.

Steffen O.K.H. (1997), Planning of open pit mines on a risk

basis, The Journal of The South African Institute of Mining and

Metallurgy, pp. 47-56.

3.

Abdollahisharif J. Bakhtavar E. (2009), "An intelligent algorithm of

minimum cutting plane to find the optimal size of extractableblocks in dimension stone quarries", Arch. Min. Sci., Vol. 54, No

4, pp. 641-656.

8 xit, j ( xih, j 1 + xih, j 2 + xih+1, j + xih+1, j 1

+

h =1

h

xi +1, j 2 + xih+ 2, j

xih+ 2, j 1

xih+ 2, j 2 )

(5)

y 4t

y1t + y 2t + y3t + y 4t 3

(6)

In Eq. 2 to 6, R is a big value and y is a binary variable.

B) Reserve constraints. Each block can be only extracted

once. The reserve constraints are formulated as below equation, which

indicates that all blocks in the model can be extracted only once.

T

xit, j 1

(7)

t =1

C) Processing capacity (market demand) constraints. As

the upper bound, the total amount of the ore to be extracted in period t

(tonnage) cannot be more than the market demand or processing

capacity (Pmax) in any period, t.

N M

(Oi, j xit, j ) Pmax

i =1 j =1

(8)

As the lower bound, the total amount of the ore to be extracted in

period t (tonnage) cannot be less than a certain amount (Pmin) in any

period, t.

N M

(Oi, j xit, j ) Pmin

i =1 j =1

(9)

D) Dimension stone quarrying capacity. As the upper

bound, the total amount of dimension stones including ore and waste

rocks to be extracted cannot be more than the total available

equipment capacity (Qmax) for each period, t.

N M

(Oi, j + Wi, j ) xit, j Qmax

i =1 j =1

(10)

The lower bound can be written as the following:

N M

(Oi, j + Wi , j ) xit, j Qmin

i =1 j =1

(11)

CONCLUSION

In this study a binary integer programming model has been

developed for the short-term production planning in dimension stone

quarries. For the purpose, the most appropriate dimensions and shape

of the extractable blocks should be first assigned for generation of the

geological block model according to the market demand, the maximum

transportable tonnage of the blocks and the cutting machines. After

that an economical block model is made using the values zero and

one for waste and ore blocks, respectively. The objective function

Copyright 2012 by SME

Das könnte Ihnen auch gefallen

- DagdelenDokument4 SeitenDagdelenWashington BobadillaNoch keine Bewertungen

- An Application of Branch and Cut To Open Pit Mine SchedulingDokument27 SeitenAn Application of Branch and Cut To Open Pit Mine SchedulingALBERTUSNoch keine Bewertungen

- Strategic OpenPit Mine PlanningDokument4 SeitenStrategic OpenPit Mine PlanningLehlabile MorenaNoch keine Bewertungen

- Pit Planing and DesignDokument6 SeitenPit Planing and DesignKeiko Uriol ReyesNoch keine Bewertungen

- Mine Planning & Design and ItsComponentsDokument5 SeitenMine Planning & Design and ItsComponentsAryan AnandNoch keine Bewertungen

- SHillDokument24 SeitenSHillsrivasthu100% (1)

- Open Pit OptimizationDokument6 SeitenOpen Pit Optimizationdeim0Noch keine Bewertungen

- An EDP-Model of Open Pit Short Term Production Scheduling Optimization For Stratiform OrebodiesDokument10 SeitenAn EDP-Model of Open Pit Short Term Production Scheduling Optimization For Stratiform OrebodiesrannscribdNoch keine Bewertungen

- Maximizing The Net Present Value by ApplDokument12 SeitenMaximizing The Net Present Value by Applbatman_Noch keine Bewertungen

- Open Cast Mine PlanningDokument21 SeitenOpen Cast Mine PlanningMadhu GovindanNoch keine Bewertungen

- SERRUCHODokument7 SeitenSERRUCHOYtamar Chavez SacaicoNoch keine Bewertungen

- Determining The Best Feasible Mining Sequence and Phase DesignDokument36 SeitenDetermining The Best Feasible Mining Sequence and Phase DesignNurlanOruziev100% (1)

- r1812651h MPD Ass 1Dokument5 Seitenr1812651h MPD Ass 1Panashe kapesiNoch keine Bewertungen

- Pit Planning and DesignDokument6 SeitenPit Planning and DesignMarshal MclaneNoch keine Bewertungen

- Simultaneous Destination and Schedule Optimization With Minemax Scheduling Technology at NewmontDokument44 SeitenSimultaneous Destination and Schedule Optimization With Minemax Scheduling Technology at Newmontraymond.jyl6807Noch keine Bewertungen

- Production SchedulingDokument35 SeitenProduction SchedulingRohit Kumar100% (1)

- Pit OptimisationDokument6 SeitenPit OptimisationJuan Pablo Henríquez ValenciaNoch keine Bewertungen

- Javad2008 PDFDokument10 SeitenJavad2008 PDFBat SbrNoch keine Bewertungen

- Javad2008 PDFDokument10 SeitenJavad2008 PDFBat SbrNoch keine Bewertungen

- Cut-Off Grade Optimization For Maximizing The Output Rate: A. Khodayari and A. JafarnejadDokument6 SeitenCut-Off Grade Optimization For Maximizing The Output Rate: A. Khodayari and A. JafarnejadluisparedesNoch keine Bewertungen

- Hard Rock TBM Performance PredictionDokument5 SeitenHard Rock TBM Performance PredictionantoniusnoroNoch keine Bewertungen

- A New Mine Planning Tool For Sub Level Caving Mines: White PaperDokument18 SeitenA New Mine Planning Tool For Sub Level Caving Mines: White PaperacadNoch keine Bewertungen

- AEbrahimi UltimatePitSizeSelection 2019 1 PDFDokument10 SeitenAEbrahimi UltimatePitSizeSelection 2019 1 PDFSimson MuliaNoch keine Bewertungen

- Development of A Mathematical Programming Model To Support The Planning of Short-Term MiningDokument15 SeitenDevelopment of A Mathematical Programming Model To Support The Planning of Short-Term MiningJhol Dueñas GutierrezNoch keine Bewertungen

- Universidad Nacional de Ingenieria EvaluDokument10 SeitenUniversidad Nacional de Ingenieria EvaluRony German Huacca NavarroNoch keine Bewertungen

- Optimization of Drilling Well Design A ReviewDokument9 SeitenOptimization of Drilling Well Design A ReviewMiguelNoch keine Bewertungen

- Surface Mining: Block Sizes For Outlining The Ore BodyDokument3 SeitenSurface Mining: Block Sizes For Outlining The Ore BodyChristian ChoqueNoch keine Bewertungen

- R187720V Hmie515 Assignment 1Dokument20 SeitenR187720V Hmie515 Assignment 1Panashe kapesiNoch keine Bewertungen

- Surface Mine Development (Hartman)Dokument7 SeitenSurface Mine Development (Hartman)maringanlamhot100% (1)

- Optimal Open Pit Short Term Planning Under Uncertainty and Blending ConstraintsDokument14 SeitenOptimal Open Pit Short Term Planning Under Uncertainty and Blending ConstraintsSudamBeheraNoch keine Bewertungen

- 2005 - The New Fundamental Tree AlgorithmDokument14 Seiten2005 - The New Fundamental Tree AlgorithmBurcu KaraözNoch keine Bewertungen

- Cutt Off SynopsisDokument13 SeitenCutt Off SynopsisDhruv ChatterjeeNoch keine Bewertungen

- MPD Assgnment 1 Malvern SamangaDokument6 SeitenMPD Assgnment 1 Malvern SamangaPanashe kapesiNoch keine Bewertungen

- Optimizacion UgDokument55 SeitenOptimizacion UgMilan LLanque Conde100% (2)

- Miranda. F - IncorporatingDokument9 SeitenMiranda. F - IncorporatingCristian PobleteNoch keine Bewertungen

- Optimizing Ore-Waste Dig-Limits As Part of Operational Mine Planning Through Genetic AlgorithmsDokument13 SeitenOptimizing Ore-Waste Dig-Limits As Part of Operational Mine Planning Through Genetic AlgorithmsErland PrasetyaNoch keine Bewertungen

- 03 Block DimensionsDokument9 Seiten03 Block DimensionsRenatoTerrybleTorbiscoAlvarezNoch keine Bewertungen

- Optimum Drill and Blast An Ever Changing TargetDokument13 SeitenOptimum Drill and Blast An Ever Changing TargetRony German Huacca NavarroNoch keine Bewertungen

- Combined Approach For Surface Mine Short Term Planning OptimizationDokument8 SeitenCombined Approach For Surface Mine Short Term Planning OptimizationrannscribdNoch keine Bewertungen

- Determination of A Mining Cutoff Grade Strategy Based On An Iterative Factor PDFDokument5 SeitenDetermination of A Mining Cutoff Grade Strategy Based On An Iterative Factor PDFRenzo MurilloNoch keine Bewertungen

- Comet TheoryDokument5 SeitenComet TheoryCatalina Andrea Badilla QuiñonesNoch keine Bewertungen

- Waste Dump OptimisationDokument8 SeitenWaste Dump OptimisationDody100% (1)

- Well Planning and DesignDokument7 SeitenWell Planning and DesignCyril PintoNoch keine Bewertungen

- Modeling and Optimization of Multi Gravity Separator To Produce Celestite ConcentrateDokument7 SeitenModeling and Optimization of Multi Gravity Separator To Produce Celestite ConcentrateManishankar PandaNoch keine Bewertungen

- Max OpenDokument16 SeitenMax OpenSelamet ErçelebiNoch keine Bewertungen

- A Practical, Long-Term Production Scheduling Model in Open Pit Mines Using Integer Linear ProgrammingDokument6 SeitenA Practical, Long-Term Production Scheduling Model in Open Pit Mines Using Integer Linear Programmingjeha kunramadiNoch keine Bewertungen

- Generic Approach To Developing An Algorithm For Mining-Related ProblemsDokument15 SeitenGeneric Approach To Developing An Algorithm For Mining-Related ProblemsCarles David Cristian AlvarezNoch keine Bewertungen

- Sublevel StopingDokument10 SeitenSublevel StopingAnthuanetDiazNoch keine Bewertungen

- Comparisonofcut-OffgrademodelsinmineplanningforimprovedvaluecreationbasedonNPV SOMP GithiriaDokument17 SeitenComparisonofcut-OffgrademodelsinmineplanningforimprovedvaluecreationbasedonNPV SOMP GithiriaJuniorMendoza97Noch keine Bewertungen

- Selection and Design of Blasting Techniques For SelectiveDokument8 SeitenSelection and Design of Blasting Techniques For SelectiveMostafaOmidNoch keine Bewertungen

- Journal of Sustainable Mining: Mohammad Reza AhmadiDokument8 SeitenJournal of Sustainable Mining: Mohammad Reza AhmadiDavid HalomoanNoch keine Bewertungen

- Underground Mine Planning: Stope Layout Optimisation Under Grade Uncertainty Using Genetic AlgorithmsDokument19 SeitenUnderground Mine Planning: Stope Layout Optimisation Under Grade Uncertainty Using Genetic AlgorithmsCecilia Obregón RiveraNoch keine Bewertungen

- Stripping Ratio ConsiderationsDokument18 SeitenStripping Ratio ConsiderationsFranz Diaz100% (2)

- Open Pit Mining: Mine Planning & Design: Focus On Surface Mining Technology: Lecture 2Dokument34 SeitenOpen Pit Mining: Mine Planning & Design: Focus On Surface Mining Technology: Lecture 2TinozivasheNoch keine Bewertungen

- Production Engineering: Jig and Tool DesignVon EverandProduction Engineering: Jig and Tool DesignBewertung: 4 von 5 Sternen4/5 (9)

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceVon EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNoch keine Bewertungen

- Philpot MoM 2nd Ch07-11 ISMDokument625 SeitenPhilpot MoM 2nd Ch07-11 ISMwerewaro100% (4)

- Mech 260-Final ExamDokument3 SeitenMech 260-Final ExamwerewaroNoch keine Bewertungen

- Sol Guide Final ExamDokument7 SeitenSol Guide Final ExamwerewaroNoch keine Bewertungen

- Sections To Study For Final Exam Dec 2011xDokument1 SeiteSections To Study For Final Exam Dec 2011xwerewaroNoch keine Bewertungen

- Sample Mech 260 Final (Dec 2010)Dokument3 SeitenSample Mech 260 Final (Dec 2010)werewaroNoch keine Bewertungen

- MarbleDokument42 SeitenMarblebiosunil20067790Noch keine Bewertungen

- Behre Dolbear China and Far East SOQDokument8 SeitenBehre Dolbear China and Far East SOQwerewaroNoch keine Bewertungen

- Regional Development StrategyDokument215 SeitenRegional Development StrategywerewaroNoch keine Bewertungen

- Bazian EIA Body 05dec2005Dokument73 SeitenBazian EIA Body 05dec2005werewaroNoch keine Bewertungen

- Compendium On Best Practices PDFDokument107 SeitenCompendium On Best Practices PDFwerewaroNoch keine Bewertungen

- Shingaly PDFDokument27 SeitenShingaly PDFwerewaroNoch keine Bewertungen

- ASTER Processing For Mineral ExplorationDokument8 SeitenASTER Processing For Mineral ExplorationwerewaroNoch keine Bewertungen

- Marble Quarry ProjectDokument23 SeitenMarble Quarry ProjectTessfaye Wolde GebretsadikNoch keine Bewertungen

- Presentation 23 - Worms As Bioindicators of HG Pollution - Jennifer HintonDokument35 SeitenPresentation 23 - Worms As Bioindicators of HG Pollution - Jennifer HintonwerewaroNoch keine Bewertungen

- Minerals - Space DevelopmentDokument50 SeitenMinerals - Space DevelopmentwerewaroNoch keine Bewertungen

- StonesDokument9 SeitenStonesSaud PathiranaNoch keine Bewertungen

- PHD Proposal (Shwan Omar Ismael)Dokument11 SeitenPHD Proposal (Shwan Omar Ismael)werewaroNoch keine Bewertungen

- CIVL215 Pipeline Design ProjectDokument2 SeitenCIVL215 Pipeline Design Projectwerewaro0% (1)

- Kurdistan Investment Guide 2011 PDFDokument128 SeitenKurdistan Investment Guide 2011 PDFwerewaroNoch keine Bewertungen

- Myb3 2010 IzDokument9 SeitenMyb3 2010 IzwerewaroNoch keine Bewertungen

- Full ReportDokument2 SeitenFull ReportwerewaroNoch keine Bewertungen

- Dimension Stone AfghanistanDokument26 SeitenDimension Stone AfghanistanwerewaroNoch keine Bewertungen

- Dimension Stone - Exploration, Evaluation NigeraiDokument8 SeitenDimension Stone - Exploration, Evaluation NigeraiwerewaroNoch keine Bewertungen

- Dimension Stone Quarrying KenyaDokument15 SeitenDimension Stone Quarrying Kenyawerewaro100% (2)

- Dimension Stone Feasibility Study MichiganDokument188 SeitenDimension Stone Feasibility Study MichiganwerewaroNoch keine Bewertungen

- Dimension Stone - The Latest Trends in ExplorationDokument36 SeitenDimension Stone - The Latest Trends in ExplorationwerewaroNoch keine Bewertungen

- Decorative and Dimensional Stone - Development Potential in KosovoDokument36 SeitenDecorative and Dimensional Stone - Development Potential in KosovowerewaroNoch keine Bewertungen

- Dictionary of Quarrying Terms ADokument8 SeitenDictionary of Quarrying Terms AfisicolocoNoch keine Bewertungen

- Dimension Stone - A Guide To Development and ProspectingDokument94 SeitenDimension Stone - A Guide To Development and ProspectingwerewaroNoch keine Bewertungen

- Akkoyun and AnkaraDokument11 SeitenAkkoyun and AnkaraZoheb BagwanNoch keine Bewertungen

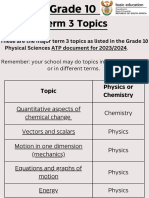

- Grade 10 Term 3 TopicsDokument10 SeitenGrade 10 Term 3 TopicsOwamiirh RsaNoch keine Bewertungen

- DG Notes BerkeleyDokument44 SeitenDG Notes BerkeleymaplebrandishNoch keine Bewertungen

- Neural Networks and Deep LearningDokument36 SeitenNeural Networks and Deep LearningAmir ForsNoch keine Bewertungen

- CP LAB1 Problem SolvingDokument11 SeitenCP LAB1 Problem SolvingFaizanAminNoch keine Bewertungen

- Step 1) Calculate The Pressure Derivative Functions of The Well-Test Data (Tabulated in Table 4.11)Dokument13 SeitenStep 1) Calculate The Pressure Derivative Functions of The Well-Test Data (Tabulated in Table 4.11)jonathan_leal09Noch keine Bewertungen

- A Detailed Lesson Plan in MathematicsDokument5 SeitenA Detailed Lesson Plan in MathematicsBe Len DaNoch keine Bewertungen

- 2 Bit Full AdderDokument21 Seiten2 Bit Full AdderSilvestre VásquezNoch keine Bewertungen

- Image Processing-Ch4 - Part 1Dokument63 SeitenImage Processing-Ch4 - Part 1saifNoch keine Bewertungen

- AlgebraDokument2 SeitenAlgebraNumber1tutorNoch keine Bewertungen

- Nanoantenna Directivity and EnhancementDokument4 SeitenNanoantenna Directivity and EnhancementRitesh kumar NayakNoch keine Bewertungen

- MathDokument5 SeitenMathvickimabelli100% (1)

- Fuzzy Neutrosophic SubgroupsDokument12 SeitenFuzzy Neutrosophic SubgroupsMia AmaliaNoch keine Bewertungen

- Tips For Using Truss Elements in ANSYSDokument10 SeitenTips For Using Truss Elements in ANSYSThota Sri K HarithaNoch keine Bewertungen

- Mean-Variance Analysis and Efficient FrontierDokument69 SeitenMean-Variance Analysis and Efficient FrontierNIKHIL DARYAVSING BHAMARENoch keine Bewertungen

- Pseudo 1Dokument1 SeitePseudo 1Chamari JayawanthiNoch keine Bewertungen

- Manual For Instructors: TO Linear Algebra Fifth EditionDokument7 SeitenManual For Instructors: TO Linear Algebra Fifth EditioncemreNoch keine Bewertungen

- Gitam PDFDokument4 SeitenGitam PDFSridhar AtlaNoch keine Bewertungen

- P1-Set TheoryDokument41 SeitenP1-Set TheoryDipanwita DebnathNoch keine Bewertungen

- Advanced Marine Structures Prof. Dr. Srinivasan Chandrasekaran Department of Ocean Engineering Indian Institute of Technology, MadrasDokument20 SeitenAdvanced Marine Structures Prof. Dr. Srinivasan Chandrasekaran Department of Ocean Engineering Indian Institute of Technology, MadrasmahakNoch keine Bewertungen

- Ellipse orDokument23 SeitenEllipse orTEJA SINGHNoch keine Bewertungen

- Lecture 3 Bilinear TFDokument32 SeitenLecture 3 Bilinear TFNathan KingoriNoch keine Bewertungen

- 09 Energy&Aeronautics&AuronauticsDokument211 Seiten09 Energy&Aeronautics&AuronauticsDorisman Feriandi SimorangkirNoch keine Bewertungen

- Handout-1 Foundations of SetsDokument3 SeitenHandout-1 Foundations of Setsapi-253679034Noch keine Bewertungen

- Verilog HDLDokument74 SeitenVerilog HDLgautamsvksNoch keine Bewertungen

- Petrophysics in Horizontal WellsDokument13 SeitenPetrophysics in Horizontal WellsusuarioNoch keine Bewertungen

- 8 Math Eng PP 2023 24 1Dokument7 Seiten8 Math Eng PP 2023 24 1aamirneyazi12Noch keine Bewertungen

- Memorandum of in Crafting The School Improvement Plan: Rodelio T. Laxamana Edna M. DabuDokument3 SeitenMemorandum of in Crafting The School Improvement Plan: Rodelio T. Laxamana Edna M. DabuMarife MagsinoNoch keine Bewertungen

- Hydro Mechanical Systems in Simulink in SL Part 2 PDFDokument20 SeitenHydro Mechanical Systems in Simulink in SL Part 2 PDFAbdulhmeed MutalatNoch keine Bewertungen

- Sessional-I Time TableDokument6 SeitenSessional-I Time TableRobin GautamNoch keine Bewertungen

- Attenuation and DispersionDokument92 SeitenAttenuation and Dispersionscribd01Noch keine Bewertungen