Beruflich Dokumente

Kultur Dokumente

Dimension Stone - The Latest Trends in Exploration

Hochgeladen von

werewaroCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dimension Stone - The Latest Trends in Exploration

Hochgeladen von

werewaroCopyright:

Verfügbare Formate

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

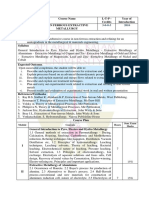

DIMENSION STONE: THE LATEST TRENDS IN EXPLORATION AND

PRODUCTION TECHNOLOGY

I. Ashmole1, M. Motloung2

1

Greenstone Marble and Granite (Pty) Ltd

2

Finstone (SA) (Pty) Ltd

ABSTRACT

The dimension stone industry is not widely known or appreciated within the mainstream mining

industry. This is in spite of the fact that the industry has grown at an average of over 7% per annum

since 1980, and is estimated to now have a global turnover in excess of US$ 60 Billion per annum.

Production technologies, particularly in the developed world where labour costs are high, have

developed rapidly over the past two decades. Aligned with this, there has been a significant trend in

adoption of a more professional mining approach in the exploration for and operation of dimension

stone quarries. In fact, in the experience of the authors, mining a dimension stone deposit

successfully if often more challenging from a mining engineering point of view than many

conventional surface mines.

This paper gives an overview of the industry and then proceeds to discuss best practice in

exploration for dimension stone and to outline the latest technologies applied in mining of

dimension stone. These technologies are varied and the specific combination of technologies

applied in any given quarry is determined by both the physical properties of the material as well as

the influence of geology which significantly impacts on the recovery of saleable material and hence

the economics of the quarry.

1

INTRODUCTION

Dimension stone is a collective term for various natural stones used for structural or decorative

purposes in construction and monumental applications[1]. The defining feature of dimension stone

is that unlike other mineral commodities which have value mainly as a result of their physical

properties, the physical properties of a rock are merely the minimum qualification in determining

whether it is fit for use in dimension stone applications. The ultimate success in marketing a natural

stone as a dimension stone lies firstly in its appearance, and secondly in the possibility of producing

rectangular blocks of suitable dimensions [2] (hence the term dimension stone - some authors prefer

the term ornamental stone [3], emphasising the decorative aspect of its use) to allow for

successful production of the final product in the required sizes. Indeed, the USBM defines

dimension stone as naturally occurring rock material cut, shaped or selected for use in blocks,

slabs, sheets or other construction units of specialised shapes and sizes[4]. A dimension stone

block thus has value as a result of its dimensions and appearance, underlain by a set of minimum

physical properties (among these are various strength parameters, workability, ability to take a

polish, and resistance to physical and chemical weathering).

The major application of dimension stone is within the construction sector, which accounts for over

80% of consumption, with the funerary monumental industry accounting for 15%, and various

special applications for around 3% (see Figure 1). Consumption patterns are thus cyclical in line

with the world economy, but production of dimension stone has nevertheless exhibited annualised

________________________________________________________________________________________________

Page 35

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

growth of 5% over the last 75 years. The growth in use of dimension stone products has accelerated

in recent years, with annualised growth of 7.5% since 1986 (see Figure 2). This has been attributed

to more frequent discoveries of new stone deposits, a more conscious stone culture (particularly in

countries without a long tradition of stone use), technical advances in extraction and beneficiation

techniques, and the fact that new enterprises in the field require quite limited investments[5], as

well as a new stone age where the use of natural stone is once again enjoying a renaissance[6],

[7]. In spite of this growth however, dimension stone quarrying still only accounts for under 0.5%

of worldwide quarrying tonnages [8], with sand, gravel, aggregate and limestone for cement

accounting for most of the remaining volume. In terms of value however, the industry is an

important one, with the total value chain estimated at over US$ 60 billion worldwide.

A common sub-classification scheme separates dimension stone into calcareous materials (marbles,

travertines, limestones etc), siliceous materials (granites, quartzites and sandstones) and slate. Note

that dimension stone sold as granite includes all feldspathic crystalline rocks of mainly

interlocking texture and with individual grains [9] that are visible to the naked eye and includes

fine, medium and coarse-grained, igneous rocks and some metamorphic rocks [10].

Memorial art

18%

Other uses

2%

Structural works

7%

Special works

18%

Figure 1

Internal wall Steps

3%

cladding

9%

Floors and paving

35%

External wall

cladding

8%

Main uses of dimension stone

Marble is defined commercially as any crystalline rock composed predominantly of calcite,

dolomite, or serpentine that is capable of taking a polish [9]. Calcareous materials account for

approximately 57%, siliceous materials for around 38% (of which granites account for probably

over 95%), and slates for around 5% of total world production of around 93 million tons in 2007

[8]. A major feature of the growth in the industry has been the growth in siliceous material relative

to calcareous materials and slates, with the former category having increased its share of world

stone production from less than 10% in 1926 to over 40% in the 2004, with a 199 fold increase in

absolute tonnage produced[8]. Over the same period, production of calcareous stone has increased

45 fold and slates only10 fold. The major producers of raw natural stone are China, India, Italy,

Iran, Turkey, Brasil, Egypt, Portugal, the USA, Greece, France and South Africa, while the major

consumers of finished products are China, the USA, India, Italy, Spain, , South Korea, Germany,

France, Japan, Taiwan, Brasil and the UK [8]. It can be seen from this that the concentration of

production has historically tended to be in the countries where the most stone is consumed, and

where there has been a long history of use of natural stone in construction, particularly in the

Mediterranean and Eastern countries. In terms of trade in raw

________________________________________________________________________________________________

Page 36

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

100

90

80

Tons (Millions)

70

60

50

40

30

20

10

0

1926

1936

1946

1956

Calcareous

Figure 2

1966

Siliceous

1976

Slate

1986

Total

1996

2006

Year

Growth in world stone production

stone, calcareous materials are generally processed in large volumes in their countries of origin

(mainly the Mediterranean countries, China and Korea), while siliceous materials tend to be mainly

produced in countries which are relative newcomers to the stone industry, and hence have not

historically had large beneficiation capacity. The major exporters of raw stone are thus India,

Turkey, Spain, Brasil, China, Egypt, and South Africa. Italy has long been the dominating force in

the natural stone industry, not only in terms of consumption of finished products and production of

raw material, and also the beneficiation of imported raw materials and export of finished products.

However, its dominance has been overcome by dramatic increases in all facets of the Chinese

market, while Indian production and importation of raw stone for processing and re-export is also

increasing rapidly.

The stone industry has historically been extremely fragmented in terms of the size and numbers of

companies involved, with most dimension stone operations being small under-capitalised owneroperated businesses [11]. This has been the case particularly in the production of raw material,

where a modern quarry can be established with an investment of between US$ 1 and 5 million,

depending on the scale of operation. In countries such as India, China and Brasil, where labour is

cheap, and SHE legislation virtually non existent in terms of enforcement, the investment required

can be as little as 10% of these figures. In comparison, a modern beneficiation facility of medium

size producing slabs for the construction market requires and investment of at least US$ 15 million,

which is around 4 to 5 times the investment required in a quarry that will produce the volume of

material consumed by the factory. The global nature of the dimension stone business, combined

with the lack of concentration necessitates a complex system of trading through intermediaries

(block traders) in order for a quarrys product to reach the factories. This is because factories need

to offer a wider choice of product range to their customers, and consequently often need to source

material from many locations. As blocks are generally inspected by the factory prior to purchase, it

________________________________________________________________________________________________

Page 37

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

is difficult for direct trade to take place economically between any but the largest quarrying

companies and factories. The block trader thus fulfils an important role in that he will travel around

the world selecting large quantities of blocks from quarries which are then shipped to stock yards

close to the major processing districts, where they are available for inspection by the small factory

customer. This obviously requires a large amount of working capital in order to fund the purchase

and transportation costs (at todays freight rates, the transport costs may be substantially higher than

the ex-quarry purchase price), as well as capital invested in the land and handing facilities at the

stock yards. The larger investment required, and thus larger companies involved has resulted in the

beneficiation and block trading companies having greater control of pricing and material selection

than the raw material producers. In addition, the quarry is several steps removed from the end user

and has little or no control over the promotion and marketing of its product, and often little

knowledge of changing fashion trends in the industry. However, market knowledge and the ability

to reach out is considerably more important in the dimension stone business than in both the metals

and industrial minerals sectors [12].

There has however been substantial consolidation of the industry at the raw material production

level over the past ten years, to the extent that the biggest producers worldwide now rival the larger

beneficiators and block traders in terms of the volume of stone produced/processed, if not in terms

of the number of companies. However, in turnover terms, no single company has yet reached even

one percent of the world market, with the twenty biggest companies in the industry probably having

a combined market share of around 10%. Growing realisation of the importance of market

knowledge and ability to reach out to customers further down the value chain has also resulted in a

trend for these larger raw material producers to move into the distribution and beneficiation arena.

Similarly, several of the large beneficiators and block distributors have integrated backwards into

raw material production in order to ensure reliable and sustainable supplies of key products.

What is surprising given the large value of the industry (several times larger than platinum

production for instance), is the minimal attention it has attracted from capital markets, the

mainstream mining industry and academia. Only a handful of dimension stone companies have ever

been listed on stock exchanges around the world, and while South Africa probably had the greatest

number (as many as 6 listed companies in the late 1980s), not a single listed company remains

today, and the authors are only aware of one publicly traded dimension stone company worldwide

currently. In terms of interest from large mining companies, only South African mining houses have

ever taken a stake in dimension

stone companies. During the 1980s, Anglo American bought a 30% stake in Deutsche

Steinindustrie AG, a German company which was probably somewhat ahead of its time (see

discussion above regarding industry trends) in that it had production interests on five continents as

well as a block trading company and beneficiation interests. This stake was later converted to a 30%

stake in Finstone s.a.r.l., today the most vertically integrated and probably the largest company in

the industry. Anglo however sold this stake to Finstones remaining shareholder in 2002 after

bowing to pressure from financial analysts to dispose of so-called non-core assets. Gencor bought a

controlling stake in Keeley Granite (later renamed Kelgran) during the early 1990s, although given

their subsequent exit after a fairly short period, this was probably largely aimed at stripping out the

PGM minerals rights held in Kelgrans quarries in the western lobe of the Bushveld complex.

While the importance of the industry has been recognised by the Society of Mining Professors [13],

academic interest has in the past come largely from the Italian universities, although over the past

10-15 years there has been an increasing volume of research from China, Eastern Europe, Turkey,

Portugal, Spain and India in the fields of dimension stone exploration, non-explosive cutting and

splitting, assessment of the quality and exploitability of stone deposits, ore reserve estimation, rock

mechanics in dimension stone mining and environmental impacts and reclamation.

________________________________________________________________________________________________

Page 38

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

2

Surface Mining 2008

EXPLORATION FOR DIMENSION STONE

Historically prospecting and exploration for dimension stone was the domain of non-professional

prospectors, who because of lack of knowledge of the market and industrial requirements of the

processing industry, coupled with the absence of professional exploration skills seldom conducted

formal investigations or evaluations prior to opening quarries [14], [15]. It has however become

good practice, especially in the more developed stone producing countries, to perform a thorough

geological investigation prior to making a decision to open a quarry, as the deposit is the one factor

that cannot be changed in a dimension stone project, while the initial investment in geological study

is small compared to other mining endeavours [16]. However, like other basic construction

materials which are extensively available, common in nature and appear at low depths, dimension

stone is not the object of huge exploration investment, nor does it permit the investment in complex

exploration techniques utilised in discovering metallic ores or hydrocarbon deposit, given the fact

that dimension stone deposits generally represent a high- volume, low-value commodity, and as a

consequence, adequate exploration methodologies have not been researched in spite of the high

level of technological development that has been achieved for exploitation operations [3].

How should we therefore go about conducting exploration for dimension stone deposits? In order to

arrive at this answer, we need to consider the relevant properties of required of successful a

dimension stone. According to Carvahlo et al [3], and as discussed above, the aesthetics of a stone

is the intrinsic factor on which depends its use as construction material with decorative functions.

While it may be strongly subjective, aesthetics can be used for the technical evaluation of a

dimension stone because it is the result of the conjoined perception of a set of criteria, namely the

colour, the texture, and the presence or absence of discontinuities [3]. Similarly, Luodes et al

identified three major criteria for use in evaluating a dimension stone [17], namely the appearance,

the soundness of the deposit and the market demand for that type of stone. In terms of appearance,

it is important that the colour should be as uniform as possible across the entire deposit. If a stone is

classified as a one-coloured type, stripes, inclusions, or veins of a differing colour are not accepted

in that stone by the market, while if the stone is classified as a multicoloured type, an appropriate

variation of the colours is required, even to the extent of the inclusion of defects mentioned above

[17], However, the colour and pattern of the stone must be homogeneous across the deposit that the

market can identify different blocks as being one and the same product. The soundness of a deposit

is defined by the use of the stone and by the demands of the processing industry [17], so that for

example blocks for construction application which are sawn by gangsaws are typically required to

have dimensions of 240-330cm x 120-190cm x 70-180cm, requiring that the deposit should have a

minimum spacing of fracturing of at least 2 to 3m. It thus the homogeneity of a dimension stone

deposit in terms of colour, texture and discontinuities that is particularly relevant during geological

surveys as it is the base for establishing the limits of a dimension stone deposit [3], and Carvalho et

al have proposed the following decision criteria on exploration for dimension stone:

Dimensioning

Homogeneity

Thickness of productive units ( Colour

sedimentary beds, metamorphic facies Texture

etc)

Discontinuities

Volume of the deposit

Spatial Disposition

Fracturing

Preferential directions

Frequency

Density

Intensity

Type and morphology

Table 1 : Decision criteria on the exploration of dimension stone [3]

________________________________________________________________________________________________

Page 39

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

According to Carvahlo et al, these criteria can be evaluated by the basic geological tools of

geological mapping and fracturing survey and they state that thematic geological mapping, with

strong support from the techniques of structural geology and diamond core drilling, is fundamental

for the research and evaluation of data that are intrinsic to the dimensioning and homogeneity

qualification of the deposits [3]. Geophysical methodologies can also be complement to the in situ

fracturing surveys, and can give valuable information with regard to the frequency and intensity of

fracturing in particular. While Carvahlo et al have focused exclusively on the above mentioned

tools in proving viable marble quarrying areas within the Portuguese Estremoz Anticline, we

believe them to be insufficient in general for taking a dimension stone quarry to full production

levels with a high degree of confidence. Taboada et al have distinguished between the quality and

the exploitability of a granite [18]. They define the exploitability of a granite as being determined

by structural characteristics such as orientation, family, extension, persistence, and continuity and

discontinuity densitiesirrespective of whether the fractures or joints are of primary or secondary

origin, while the quality depends on various factors such as grain size, colour, the presence of

black-knot ow structures, and weathering. Similarly, Venkat Reddy has identified the following

defects which affect the quality and exploitability of a dimension stone deposit [15]:

Colour variations

Textural characteristics and textural variation

Structural and macro-discontinuities

Micro-discontinuities

Intrusives

Inclusions

Accessory minerals

Contact zones

Alterations

While mapping and geophysical methods may help to define structural and macro discontinuities

such as fractures and joints, as well as contact zones, intrusives, and larger inclusions, core drilling

is required to give a full picture of colour variation and textural variations as well as microdiscontinuities and weathering. The disadvantage of core drilling however is that that a dimension

stone prospect cannot be drilled as densely as an ore body because the drill holes can spoil

otherwise suitable stone [17], while economic spacing of core drill holes will be vary large when

compared to the size of blocks required to be produced, while many defects are small enough to be

missed by drilling, but closely spaced enough to affect block quality. Luoden et al have proposed

an exploration sequence consisting of the desktop study, field mapping, detailed mapping, geo-radar

survey, core drilling, reserve assessment, test quarrying, test processing, and quarry planning [17].

We are in substantial agreement with this sequence, but would split the test quarrying into a bulk

sampling (including test processing) and a test quarrying phase. We would thus recommend the

following approach to the phases of a dimension stone exploration, where completion of each phase

prior to test quarrying does not guarantee a successful quarry, but provides sufficient information to

make an informed decision as to whether or not to proceed to the next stage taking the risks of a

negative outcome into account:

1.

2.

3.

4.

5.

6.

Desktop Study

Field evaluation

Detailed mapping

Drilling

Geophysical methods

Bulk Sampling

________________________________________________________________________________________________

Page 40

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

7. Test Quarrying

Each of these phases is discussed in more detail below.

2.1

Desktop Study

The first phase of any dimension stone exploration should comprise a desktop study. Target

generation should be accomplished by thorough investigation of available geological maps and

reports, with focus placed on desired rock types. For example, when looking for black granite,

gabbros, norites, diorites and dolerites would be suitable target lithologies, while if a multicoloured

patterned material is sought, regional metamorphic provinces should be examined for potential

outcrops of suitable stone. Marble is found in belts of regionally metamorphosed sedimentary rocks

or adjacent to a specific suite of intrusions, which have thermally metamorphosed carbonate beds

[19].

Common remote-sensing tools including satellite imagery and aerial photographs as they are good

aids in the initial surveying stages. The Indian Geological Survey carries out the first phase of

regional evaluations and resource inventories by identifying potential belts of dimension stone

using satellite imagery, aerial photographs, and geological maps [9]. A further tool that can be used

during target generation is GIS (Geographical Information Systems) which can facilitate desktop

studies by generating topographical and geological maps of identified targets. The Google Earth

mapping service is a recent remote-sensing tool with tremendous capacities as it grants the user a

simulated three-dimensional view with zoom capabilities and the ability of an interactive

management of the orientation view. Although not being geographically precise, it can be a very

effective tool for the selection of exploration-target areas of dimension stones as a function of the

fracturing degree of the rocks [3].

A desktop study should ideally also contain an indication of the economic factors that will affect the

project, or exploitability of the prospect. It is also important to bear in mind at this stage the likely

physical properties of the target rock, as it is necessary that these conform to the minimum

requirements for dimension stone. As pointed out above, a requirement for a good dimension stone

deposit is the market demand for a stone type [17]. Even if the appearance and soundness are at an

acceptable level, the stone has no value without demand from the market, which is again dependent

upon the ever-changing fashion. The geologist conducting exploration should thus have a good idea

of the stones that are currently in demand and be abreast of trends in the market. Aspects such as

infrastructure and basic services should be researched at this point in the exploration phase. For

example, an arid environment (e.g. Namibia or Northern Cape Province) will have a water scarcity.

An investigation as to what the availability of water is in the area most proximal to the project or an

investigation of what costs will be involved to transport water to the site should be undertaken. The

availability of electricity infrastructure should also be investigated, especially in South Africa where

there is an electricity scarcity. Another factor to take into account during this phase is the likely

transport costs for blocks of the stone to port or to processing factory, and compare this with the

likely range of prices for stone of the colour being sought.

After selecting targets, it is ideal to research the legal requirements and strive for compliance. In

South African legislation, there is somewhat of a dilemma for the dimension stone prospector in

terms of the legal process. While an initial field evaluation could be done under the auspices of a

reconnaissance permission, there are two problems with this. Firstly, a reconnaissance permission

does not entitle the holder to remove any samples, even if these are small hand samples which are

necessary to verify the colour and appearance of the polished stone, and secondly, a reconnaissance

________________________________________________________________________________________________

Page 41

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

permission does not convey any exclusive right (unlike the Exclusive Reconnaissance Licence in

Namibia) to apply for or be granted a prospecting right or mining right. It would seem that the

safest option at this stage would be to apply for a prospecting right for any prospects identified

which may be of value, even though they could be discarded after the initial field evaluation.

2.2

Field Evaluation

During this phase, the general soundness and appearance of the stone are defined [17].The first step

in field evaluation is to identify the colour of the stone. Often, the weathered outside surface of a

rock is in no way indicative of the colour inside, and it is thus necessary to use a hammer to expose

a fresh surface of the stone. If the colour is not acceptable, then the prospect could be discarded at

this stage, while a truly exceptional colour may be pursued to further stages even if the stones

formation is not ideal. It should be noted that even the colour of a freshly exposed surface may

differ from that shown by polishing, and so if the stone appears of acceptable colour and the

formation is in good physical shape, it will be necessary to remove several small samples to cut and

polish for further evaluation.

The second step is to study the formation of the rock outcrop in order to ascertain the possibility of

producing blocks of a commercial size. In some circumstances this is fairly easy, as there are solid

outcrops on which the joint and vein spacing can be readily evaluated. Where there are no solid

outcrops, the size of boulders on the surface can give some indication of the possibility of

producing blocks. Where there are only very small boulders present, it is unlikely that it will be

possible to produce blocks of marketable size, as in general the jointing and veining in the host rock

controls weathering that produces boulders. Small boulders are usually indicative of closely spaced

joints and veins in the underlying solid rock. The size of the outcrop and its consistency should also

be evaluated at this stage.

Should the colour appear acceptable, and the formation appears healthy, the next step should be to

remove several samples of the stone for cutting and polishing. Small boulders which can be carried

by hand can be removed, or else samples of approximately 30cm cubic can be extracted from the

solid rock or large boulders by means of a petrol powered rock drill and plugs and feathers or

expansive mortar. By removing these at several points around the formation, an idea of the

consistency of the colour can also be gained. These samples can be compared against existing

products on the market, and used to obtain feedback from customers as to the demand and expected

price for the material. These samples will also give some idea of whether or not the stone can be

polished to an acceptable finish, as well as giving an indication of the hardness of the stone from a

sawing and finishing point of view.

2.3

Detailed Mapping

Should initial field evaluation indicate a potentially economically viable resource, detailed

geological mapping of the deposit should be conducted. Mapping traverses should be planned, and

if necessary cleaned by mechanical means, compressed air or pressurized water jets [17] .After

cleaning and washing, the traverses should be measured (a tachymeter or GPS can be used for this

purpose).and mapped in detail on a scale of between 1:100 and 1:250 according to the size of the

deposit. During detailed mapping, special attention was paid to the composition, colour, and

structure of the stone, as well as the fracturing [17]. Important portions of the traverses should also

be photographed. A geological map should be constructed as a record of field results and also to

give a basis for further evaluations of the physical extent and morphology of the prospecting area.

________________________________________________________________________________________________

Page 42

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

Geological maps of this sort could also give a basis for calculation of reserves[18] or even

indications of regional discontinuities.

During the detailed mapping phase, several samples of the stone for cutting and polishing should be

collected, preferably along the traverses. Small boulders which can be carried by hand can be

removed (it is important to determine the effect of weathering on these and whether they are

reflective of fresh rock), or else samples of approximately 30cm cubic can be extracted from the

solid rock or large boulders by means of a petrol powered rock drill and plugs and feathers or

expansive mortar. By removing these at several points around the formation, an idea of the

consistency of the colour and mineral composition can also be gained. These samples can be

compared against existing products on the market, and used to obtain feedback from customers as

to the demand and expected price for the material. These samples will also give some idea of

whether or not the stone can be polished to an acceptable finish, as well as giving an indication of

the hardness of the stone from a sawing and finishing point of view.

It should be noted that in the South African mining legislation a prospecting right and

Environmental Management Plan (EMP) are required for the removal of these small samples even

though the environmental impact is negligible.

2.4

Geophysical Methods

While the previous steps give an indication of the deposit from a surface point of view, a thorough

three-dimensional assessment is a prerequisite prior to taking the risk of bulk sampling and test

quarrying, which entail significantly higher expense and are far more environmentally disruptive

than the previous stages of exploration for dimension stone. Indeed, Luodes et al concluded that for

a successful evaluation study, the discontinuous and varied nature of geological features in three

dimensions must be clearly understood [17]. Geophysical methodologies are important in the more

detailed research stages as a complement to the in situ fracturing surveys [3], [20] and are

significantly cheaper than core drilling. In particular, the very low frequency electromagnetic/radio

frequency electromagnetic (VLF-EM/RF-EM) and the ground-penetrating radar (GPR) techniques

are useful for dimension stone [3]. Geophysical resistivity surveys can reliably locate travertine

deposits, because travertine has a higher apparent resistivity than the bedrock, which is usually

weathered [9].

The VLF-EM/RF-EM method is based on the propagation of low- to very low-frequency radio

waves that generate a secondary electromagnetic field dependent on the lithology. The detection of

this secondary field allows the acquisition of data about the propagation environment and its

heterogeneities: clay-filled fractures, karst, paleo-channels, lateral facies variations, etc. [3]. This

method has a low investigation depth but can be quickly carried out with a very low cost, allowing

the acquisition of data related to major structures and the delimitation of suitable area targets for

more advanced ornamental-stone exploration stages [3].

In general, the advantage with of an GPR survey is that it gives a penetration depth of 10-25m,

gives a large cross section of the subsurface fracturing and can determine zones of significant

weakness, dykes, contacts etc. [20]. There are however limitations, as small and closed cracks do

not show up well in the radar profiles [17]. The geo-radar survey is however a more feasible method

in homogeneous rock types than in heterogeneous types. In the latter case, the proper interpretation

of the results is more difficult as different internal structures of the stone are often seen in the radar

profiles [17]. If the material is strongly deformed and folded, these structures can be falsely

________________________________________________________________________________________________

Page 43

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

interpreted as fractures, as was the case in a GPR survey conducted on the highly deformed Parys

granite by the CSIR on behalf of one of the authors in the mid 1990s.

Nevertheless, in spite of the limitations, the use of geophysical methods can be used to evaluate

whether or not to proceed to drilling, which is significantly more expensive, particularly in

homogenous (single coloured) rock types.

2.5

Drilling

If the outcome of field evaluation and geophysical investigations (if conducted) is positive, the next

step should be to drill the formation in order to demarcate the ore deposit as well as to provide

information on the vertical extent of the formation and possible defects with depth; which has

implications on the recovery. Generally diamond core drilling is preferable, as the core can be

evaluated not only for colour consistency, but also for defects such as joints, veins and banding

which may influence the recovery of marketable blocks. Percussion drilling is cheaper than

diamond core drilling, but has the limitation that chips of stone are produced which are only

indicative of colour consistency. Core drilling may be economically achieved by lightweight air

powered core drills such as the Metre-Eater, which are capable of drilling at least 100m with a

TBW sized core barrel which produces 45mm core, and at least 30m at NQ size (65mm core). Core

should be split and polished in order to log the colour as well as joints, veins and very fine veinlets

which may affect the acceptability of the stone in the market.

Vertical holes may be drilled in order to test the consistency of the colour and texture of the stone at

depth, as well as to identify possible mining cut-offs and horizontal or sub-horizontal joints which

may affect recovery, or assist with mining access. Horizontal or inclined holes should be planned at

right angles to the major joint sets in order to evaluate the spacing of these in order to get an idea of

recovery, and if there are two strongly defined joint sets, consideration should also be given to

several horizontal or inclined holes at right angles to the former holes. Depending on the size of

formation and the nature of the joint sets, initial hole spacings of the order of 50m could be

considered, with possible in fill drilling at a later stage. In practice, it is not economic to drill at a

spacing that will identify every single joint, and this would in any case destroy the reserves by

creating a hole through every block that could be recovered. Also, with strongly deformed multicoloured stones, and porphyritic granites, drilling may not be able to give a satisfactory indication

of the textural consistency of the stone. Drilling can however provide information that will lead to a

no go decision on the prospect.

In South Africa a prospecting right and EMP are required for drilling activities. If drilling is

properly planned, the major environmental impact is the access roads which need to be constructed

to gain access to the site for the air compressor and water truck. If the distance to actual drilling site

is not extreme, environmental damage may be limited by constructing pipelines for the supply of air

and water to the drill rig, thus minimising disturbance of the site, as the rig itself can be carried by

hand to the drilling site.

2.6

Bulk Sampling

Should the results of drilling prove positive, the next phase is to conduct bulk sampling to remove

several blocks in order to test market acceptance. The number of blocks required will depend on the

marketing strategy and whether or not the prospector has access to a factory which can cut slabs of

the material. In general, most non-vertically integrated companies will need to remove around

twenty blocks for distribution into the market, while a vertically integrated company may get away

________________________________________________________________________________________________

Page 44

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

with as few as two blocks, as it is able to distribute slabs into the world market in order to evaluate

response to the material.

Many operators confuse the stage of bulk sampling with the stage of test quarrying. It should be

emphasised that the aim of bulk sampling is to get sufficient representative sample blocks of the

stone in order to test the market reaction to the material, and that it is not necessary to open a full

blown quarry for this purpose. Bulk samples extracted under the scenario described above in South

Africa should fall within the definition provided in Section 20(1) of the MPRDA, and it should not

be necessary to get permission in terms of Section 20(2) of the Act to remove and dispose of

minerals. However in view of the authors experience of inconsistent application of the law by the

Department of Minerals and Energy, it would however be wise to consult apply for the Section

20(2) permission simultaneously with the application for a prospecting right. This application

should clearly state the amount of material for which permission for removal and disposal id

sought.

It should also be noted that in the case of a new deposit of an established material, it is possible to

skip the bulk sampling stage and proceed directly to test quarrying.

2.7

Test Quarrying

In the case of a successful market feedback to bulk samples, or in the case of an established

material, the final phase of prospecting is test quarrying. The aim of test quarrying is to fully

evaluate the recovery of saleable blocks within the formation in order to determine whether full

scale mining is economically viable, as well as to evaluate the implications of extraction methods

on the economics of quarrying. Test quarrying is required, as other methods described above can

only give an indication of the range of possible recovery, and the actual recovery possible can only

be established by actual mining of the formation and recording the resultant production and costs. It

also allows for the adjustment of extraction methods in order to determine the most feasible method

to be employed. While recent advances in dimension stone quarry evaluation [3], [18] have shown

that there is potential for geostatistical methods to provide reasonable assessments of potential

exploitability of a quarry, the authors would be somewhat hesitant to use this as a substitute for test

quarrying before proceeding the development of a full scale quarry, which has significant cost

implications, as well as being substantially more disruptive to the environment.

Test quarrying should however be conducted on as small a scale as possible in order to minimise

the environmental impacts in the event of a final decision not to proceed with further quarry

development. In terms of requirements under South African mining legislation, test quarrying could

be carried out under the auspices of a prospecting right, provided that the permission in terms of

Section 20(2) of the MPRDA referred to above is acquired. However, in the authors experience,

delays in the processing of mining right applications could result in the quarry having to be closed

for up to a year after the volume for which Section 20(2) permission has been obtained and before a

mining right is issued. Given the ever changing nature of the market for dimension stone, and the

requirement form the market for a consistent supply, this could have disastrous implications for the

prospect in terms of missing the market opportunities. In the authors view, it would be

recommended that an application for a mining permit (currently limited to 1.5 Ha and 2 years

duration, but expanded to 5 Ha in the draft Minerals and Petroleum Development Amendment Bill)

be made immediately it appears that there is a reasonable chance of a successful quarry. Such

applications are significantly cheaper than mining right applications since they do not require a

Social and Labour Plan, have much less restrictive environmental requirements and timeframes, and

they are processed significantly more quickly than mining right applications, and would allow for

________________________________________________________________________________________________

Page 45

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

test quarrying and the transition to full scale production to occur while a mining right is awaited,

without the risk of market disruption.

DIMENSION STONE MINING

In mining dimension stone it is necessary to split or cut the stone into successively smaller pieces

until the final desired block size is achieved, and saleable blocks are produced. The mining methods

utilised in the extraction of dimension stone range from relatively simple and low technology

methods to some quite technologically advanced methods. In general, marble is extracted using

relatively advanced non-explosive cutting technologies, and is even quarried in underground

situations, while granite tends to utilise more low-tech drilling and splitting technologies, although

this is changing. Mining of slates and quartzites generally utilises the simplest technologies. The

impact of historical climatic conditions on mining methods is also evident, as in the northern

hemisphere, loose boulders were removed by glaciation during the last ice age, and so stone is

extracted from relatively solid formations, while in the southern hemisphere warm wet conditions

favourable for weathering have in many cases left large reserves in the form of loose boulders.

Slates and quartzites for paving and roofing purposes are quarried by splitting blocks or slabs from

the body of the stone using drilling, and splitting with plug and feathers, or in some cases sawing

these loose. These are then cleft along the bedding planes to produce thin sheets for paving or

roofing purposes. The technology is simple, and quarrying generally on a very small scale. Small

earthmoving equipment is used for moving and transporting the blocks or slabs. Final products

consist of roofing tiles, sawn tiles of regular shape, and approximately regular thickness, and

irregular sheets used for crazy paving.

For most rocks, the mining stage of dimension stone extraction conforms to one of two general

strategies [21]. In the first of these, large volumes of rocks (usually in the 1000s of m3 range) are

loosened by means of primary cuts, and then divided stepwise into smaller pieces until commercial

blocks are obtained, discarding waste material as the process is performed. This is the main method

employed in most granite and marble quarries. Under the second strategy, commercial blocks are

directly cut from the rock body. This strategy is often employed in the production of sandstone,

where blocks are often extracted from relatively thin layers or between bedding planes. In case

where natural slabs, kerbs, paving stones etc are produced is considered a special case, where

cautious blasting is employed and suitable pieces are selected from the muckpile [21]. This latter

case is often applied in the extraction of slates, quartzites and prophyoids and ignimbrites [22]

A summary of the different extraction methods for dimension stone and the technologies involved

is given in Table 2 below.

Extraction method

Cutting

Splitting

Method of separating Blocks separated by Blocks separated by

blocks/slabs

means of kerfs

fractures induced in

pre-determined planes

Technology

Sand wire (helicoidal Explosives:

wire)

Detonating cord

Diamond wire

NG based explosives

Cautious Blasting

Blasting with minimal

breakage suitable

pieces selected from

muckpile

Explosives

________________________________________________________________________________________________

Page 46

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Products

Chain saw

Disc cutter

Diamond belt cutter

Flame jet

Water jet

Commercial blocks

Surface Mining 2008

Blasting gunpowder

Plug & feather

Expansive mortar

Hydraulic wedges

Commercial blocks

Natural slabs

Kerbs

Paving stones

Cobbles

Building blocks

Tiles

Table 2 : Summary of dimension stone extraction methods (adapted from Mancini et al [22])

While marble has in the past (as far back as Roman times) been quarried by various splitting

techniques, the last century has seen the advent of sawing techniques to loosen the stone and form

blocks. Initially, sawing was achieved using helicoidal wire with sand or some similar abrasive

added to perform the cutting. The last 30 years or so have seen the development of diamond wire, to

the extent that sawing with diamond wire is the main method of both primary and secondary cutting

as well as block squaring in marble quarries today. Chain cutters with tungsten carbide picks are

used extensively to perform blind cuts, especially in underground situations, as well as for primary

cutting in soft marbles and limestones, although recently diamond belt cutters have been introduced

to perform the same function. The latter can be quite technically advanced, with automatic

programming of cutting being a possibility. In some of the marbles with higher quartz content,

diamond wire life is not as favourable as in the softer stones, and so drilling and splitting methods

are still sometimes used, although generally non-explosive splitting methods are used. Depending

on the quarry geometry, handling of blocks is either by means of gantry cranes or front-end loaders.

Marble is generally extracted in fairly large blocks, and so fairly large earthmoving equipment

(Caterpillar 988 or Komatsu WA600) is generally the order of the day, particularly in first world

producing countries. However, as is the case with granite, in poorer countries smaller machines (the

Caterpillar 966 is the standard machine used in Brasil) or even timber gantries are used to lift and

move blocks.

3.1

Splitting Techniques

The splitting techniques are generally the oldest of techniques used in dimension stone extraction.

The earliest techniques involved chipping a V-shaped groove in the stone using hand tools, and then

either filling this groove with wooden wedges which expanded when wet, or in colder climates

filling this groove with water which froze to ice overnight in order to split the stone. Today, all of

the splitting techniques involve drilling of a series of small diameter co-planar holes in the stone in

order to introduce a splitting agent. In many cases, holes are notched using a special tungsten

carbide drilling bit in order to enhance the direction of split (see Figure 3)

________________________________________________________________________________________________

Page 47

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Figure 3

Surface Mining 2008

Use of directional notches to assist splitting

In the case where the stone has one or more grain or cleavage directions along which it splits

preferentially, the use of splitting technologies on these directions is often both effective and

economic. While it is possible, especially with the use of high VOD explosives to split in two or

more directions simultaneously, splitting techniques usually rely on the stone being loose and free

from the solid formation, either in the form of boulders, as a result of loose bedding planes between

layers of sandstone or slate, or having been loosened from the solid formation by cutting

techniques.

3.1.1 Plugs and Feathers

The use of plugs and feathers involves the drilling of a line of co-planar holes in the stone and

introducing into these two shaped steel feathers (half round steel strips) with a steel plug or wedge

in between them. These are orientated along the direction of the intended split, and the wedges are

driven with a hammer causing a lateral force in the hole, which causes splitting of the stone (see

Figure 4). The use of directional notches as described above may assist in splitting in the desired

direction, especially in a stone where there is not a distinct cleavage direction. In stones where there

is a distinct grain direction, the line may be cut using plugs and feathers at up to 10 from this

direction. Spacing of holes depends on the presence of a grain direction, and the strength of the

stone. In harder stones with no grain, the required holes spacing may be as little as 10cm, while in a

stone with a strongly developed freeway, hole spacing on this plane may be as much as 25cm.

Plug

Feather

Figure 4

Feather

The use of plugs and feather to split stone

________________________________________________________________________________________________

Page 48

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

In general, where there is no grain, or where cutting off the grain direction it is advisable to drill all

holes to the full length (approximately 90% of the height split), while on a strongly developed

freeway, it is only necessary to drill every 5th or so hole to the full depth, while intervening holes

may be drilled just deep enough to accommodate the plugs and feathers (see Figure 5). When using

plugs and feathers, a better split is obtained when all of the plugs are tensioned slowly and evenly,

rather than hitting too hard and too fast.

Figure 5

Drilling for plug and feather in stone with a strongly defined cleavage direction

3.1.2 Mechanical Splitting

With mechanical splitting, the same principles are applied as with plugs and feathers. The

equipment consists of a hydraulic cylinder which forces a steel plug between two feathers, causing

the lateral force which splits the stone. Although higher forces can be generated, allowing for much

bigger splits, caution must be exercised in terms of the speed at which the force is applied, as too

quick an application may result in a split which runs off the desired direction (see Figure 6). Often,

as many as 30 hydraulic splitters may be positioned of a jib carried by a tractor or other mobile

equipment to allow for rapid positioning of the splitters and splitting of large cuts (see Figure 7).

Intended line of split

Figure 6

Poor splitting from too quick application of splitting force

________________________________________________________________________________________________

Page 49

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Figure 7

Surface Mining 2008

Hydraulic splitters carried on jib to mechanise large splits

3.1.3 Expansive Mortar

Expansive mortars (limestone based compounds which set and swell after mixing with water) have

been around for some time. Their drawbacks in the past have been that they have been expensive,

and have taken several days to work. However, over the past 12 years, they have become

extensively used in the dimension stone industry, especially in the splitting of granites, as the

pricing has become more competitive, and splitting times have been reduced to as little as a few

hours Times of as little as a few minutes can be achieved, but in practice, the heated generated by

the reaction causes the water to boil, with the resulting steam pressure either ejecting the material

from the hole, or causing a split due to the gas pressure similar to the effect of gunpowder, often

negating the benefits of using expansive mortar. This can also have significant safety effects, as the

ejected material is both very hot and caustic, causing both thermal and chemical burns, while

fragments or slabs of rock mat be forcibly ejected unexpectedly, injuring workers.

Expansive mortars work to split rock in much the same basis as blasting gunpowder. The swelling

effect of the mortar generates a pressure which is applied evenly around the circumference and over

the length of the hole. When several holes within a plane are loaded simultaneously, the resolution

of the forces involved yields a resultant force at right angles to the line through the holes. When this

force exceeds the tensile strength of the material, splitting occurs. For Fract-Ag, the first

commercial expansive mortar to be widely applied in dimension stone, tests have determined that

the pressure generated on the sides of the drillhole is of the order of 80Mpa after 24 hours at 20oC

(at higher temperatures, the time is less, and it is likely that over longer times far higher pressures

may be achieved). In theory then, hole spacing can be determined by the following formula:

s = (p.h.d) / (t.h)

Where s = hole spacing

p = pressure exerted (Mpa)

h = depth of hole (m)

t= tensile strength (m)

h = depth to be cut (m)

For Rustenburg material which has tensile strength values of about 6.5MPa on freeway, 8MPa on

secondway and 9MPa on toughway, theoretical considerations result in hole spacings of the order

of 25cm on the latter two directions. At this spacing, splitting occurs long before maximum

pressures are generated, and in practice, even with spacings as large as 40cm, or at 25cm with only

every second hole filled, splitting occurs even though in theory it should not be possible. This is

probably due to the fact that splitting is not instantaneous as the formula above assumes, but occurs

gradually over time. Because the pressure is built up slowly and evenly over a long period of time,

________________________________________________________________________________________________

Page 50

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

splitting starts long before the theoretical splitting force is reached, due to tensile strength being

exceeded in the immediate vicinity of the hole, aided by the directional notching. As this split

slowly extends over time, the area remaining to be split becomes ever smaller, resulting in a

reduction of the splitting force required. At the same time, more and more pressure is being

generated, increasing the rate of splitting, and consequently the split occurs long before the

theoretical force is reached. The Fract-Ag however continues swelling after the split is complete,

displacing the loosened material by as much as 13mm.

The major advantage of expansive mortar over plug and feather or mechanical splitting is that the

force is applied evenly over the entire length of the hole, rather than just at the top of the hole. This

results in more even splitting, avoiding the problems shown above. In addition, it is also possible to

split a thinner piece of stone off when trimming a block (see Figure 8). Expansive mortar also has

advantages over explosives in that there is generally no shock effect on the stone surrounding the

hole, and when the reaction is not too fast (as described above), there is no gas pressure which

escapes into and extends existing fractures, and so better recovery of saleable material is often

achieved in quarries which have many existing open fractures.

An important factor to consider in the use of expansive mortar is the diameter of the drill hole. In

practice, no additional pressure is generated on the wall of the drill hole in larger holes, and while

the resulting force increases proportionally to the diameter, expansive mortar consumption increases

with the square of diameter. In practice in the Rustenburg quarries, no difference is observed

between 32mm and 34mm diameter holes, while consumption of expansive mortar increase by 13%

in the latter case.

3.1.4 Explosive Splitting

Extraction of granite has in the past relied heavily on the use of explosive splitting techniques. The

earliest of these relied on the use of blasting gunpowder (hereinafter referred to as BGP) to

achieve a soft split blast. In more recent times, the use of decoupled high velocity explosives has

become prevalent, especially in Scandinavia and parts of the USA.

Position of cut using

diamond wire

Position of cut using

expansive mortar

Position of cut using

plugs and feathers

Figure 8

Position of cut with alternative trimming methods

Blasting Gunpowder

Blasting gunpowder is a deflagrating, rather than a detonating explosive. It thus works by means of

the pressure generated by confined the product gases of deflagration, and has virtually no shock

energy. In practice, this is achieved by means of igniting the BGP in a suitably tamped drillhole. In

________________________________________________________________________________________________

Page 51

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

the early days, the lack of any technology for simultaneous ignition of the holes meant that this was

often achieved with a single hole drilled as to take advantage of the natural cleavage direction or

grain of the stone. Where it was not possible for a variety of reasons to utilise the natural cleavage

direction of the stone, or where this was absent, use was made of line drilling and splitting with

plugs and feathers (see above). Extraction of granite with this method required a high degree of

skill from the quarryman, which verged on an art form. With the advent of electric initiation, it

became possible to drill a series of co-planar holes which were charged with BGP and initiated

simultaneously to achieve a precise split, which made it possible to accurately split stone without

strong cleavage directions. The resultant force generated by the combined holes result in splitting of

the rock along this line due to its tensile strength being exceeded. This effect can be enhanced

through the use of directional notching of the drill holes (see above), to force the direction of the

split (a technique pioneered in dimension stone in Rustenburg material, but well known in explosive

theory). In Rustenburg material, BGP works exceptionally well due to the three co-perpendicular

strongly defined grain directions, all of which have substantially lower tensile strength than a

random direction. These are such that on freeway for instance, a perfect cut can be made over many

square metres using only a single drillhole.

Coplanar Holes drilled

Holes Charged and blasted with

gunpowder

Figure 9

Boulder splits along

cleavage plane

Splitting of boulder with BGP

A drawback of splitting with BGP, is that the stone must be loose and free to move in order to

achieve a good split. This is generally the case with loose boulders (see Figure 9) above, and while

BGP performs highly satisfactorily in the hands of a skilled quarryman in boulder formation, the

same cannot always be said for solid formations.

The use of BGP to successfully split (straight and without damaging the rock) dimension stone is a

highly specialised task relying heavily on the experience and judgement of the quarryman - while

powder factors can be calculated in theory, the slow nature of the cutting (compared to high VOD

explosives) has implications not taken into account by theoretical calculations (see discussion on

________________________________________________________________________________________________

Page 52

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

expansive mortars). The calculation is further complicated by the influence of the degree of

confinement (tamping) on the pressure generated. In practice, it is not desirable to tightly confine

the BGP in a point charge, as although it will cut, the extremely high pressures generated at the

point where the charge is placed can cause cracking of the rock around the hole, which is further

extended by the escaping gases. Many techniques have been developed, which are well known to

quarrymen and are beyond the scope of this discussion, to ensure that every split made is perfect.

However, such are the number of variables to be taken into account, that even the most experienced

quarrymen produce some poor splits, which inevitably impact on recovery. In the solid formations,

this becomes even worse, as there are many geological features such as unloading joints and veins

which are partially open but not completely loose (in boulders, these are by definition weathered

and loose). These features, the exact position of which is not always known in the drillhole (if this

is known, they can be compensated for by deck loading) allow for the escape of deflagration gases

from the drillhole in undesired directions, often causing significant blasting damage to the material,

and reducing recoveries.

In solid stone formations attempts to split using BGP are generally not successful, as the blast tends

to run towards the nearest free face, often with the development of horsetail cracks and back

damage which result in significant losses of material (see Figure 10) hereunder. While it is possible

to counteract this to a certain extent by drilling and blasting in two or more directions

simultaneously, this is often not successful with BGP, due to the slow burning speed and

anisotropic nature of the stone. BGP is thus mainly used in loose boulder formations in the

southern hemisphere.

Figure 10

Coplanar Holes drilled

Holes Charged and blasted with

gunpowder

Stone breaks irregularly with horsetail

cracking and backbreak

Blasting in solid formation

________________________________________________________________________________________________

Page 53

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

Decoupled High VOD Explosives

In the northern hemisphere, a range of blasting techniques have been developed using high VOD

explosives to split the stone. In the Scandinavian countries, decoupled nitroglycerine based charges

in small diameter tubes (11mm or 17mm) are used in holes of 30-40mm in diameter. While use of

natural joints in the rock is often made in order to facilitate splitting, techniques for two, three and

even four way simultaneous splitting have been developed. In the USA and other European

countries, detonating cord is normally used for split blasting, often with the holes filled with water

to assist transmission of the shock wave. In the USA, a special gel filled with microscopic air

bubbles has been developed to aid transmission of the shock wave, while cushioning the effects.

Different stones however have differing sensitivities to different types of blasting and a method that

is used in one material successfully may not be suitable in another, or even later in the life of the

same deposit, as blasting may cause the release of inherent stresses within the stone in deeper parts

of the formation. The advantage of using high VOD explosives, compared to BGP, is that as the

splitting does not rely on the gas pressure generated, the associated problems related to solid

formations discussed above fall away. In addition, high VOD explosives are more suited to splitting

in more than one direction simultaneously, and are therefore indispensable in key cuts where two

perpendicular directions must be split at the same time.

In theory high VOD detonating explosives work by means of their shock energy to produce a

splitting effect in the rock. This is achieved by drilling a series of co-planar holes, which are then

charged and detonated simultaneously. The resulting compression shock waves are superimposed

along the line between the drillholes, increasing the compressive forces generated along this line.

The compressive forces induce tensile forces in the rock at right angles to their direction of action,

and thus a split is caused along the line between the holes as a result of the tensile strength of the

rock being exceeded. The secret behind successful splitting with high VOD explosives lies in

arriving at the optimum balance of hole spacing and powder factors which result in tensile strength

of the rock being exceeded only where there is superimposition of the shockwaves, i.e. on the line

between the holes. Splitting with high VOD explosives is not an easy business - too high a powder

factor, and cracking will occur in many random directions in addition to the intended split line; too

low a powder factor, and the split will not occur perfectly, with much of the detonation gas energy

then dissipated into the surrounding rock in the form of cracking [23].

Another problem in attempting to split with high VOD explosives is that their shock energy is such

that they pulverise the rock immediately surrounding the borehole (compressive failure zone),

followed by a zone of radial cracking (tensile failure zone) where the compression wave is still

strong enough (intensity reduces with distance travelled) to induce tensile forces exceeding the

tensile strength of the rock. These cracks are then extended further by the gas pressures generated.

These effects are partially overcome by means of using decoupling (using a charge of much smaller

diameter than the drillhole, allowing for an air or water gap to absorb the worst of the shock energy)

and by not tamping the holes. In the dimension stone industry, specialised low energy explosives

have been developed to provide additional compensation for these effects.

Powder factors for splitting in dimension stone are traditionally prescribed by the manufacturers in

terms of a weight of explosives per cubic metre of rock to be loosened [24][25][26]. Conceptually,

this makes no sense in terms of the theory described above, and it can lead to large benches being

overcharged or small benches being undercharged, especially if the ratio of the three dimensions

varies dramatically from that used to determine the ideal powder factor. Much work was conducted

in the Rustenburg quarries of Finstone by one of the authors in the mid 1990s, using both Finnish

nitroglycerine based explosives especially developed for dimension stone blasting (F, K, G and KK

pipecharges), as well as Energex Barrel, an product of AEL Ltd for smooth blasting in tunnelling

________________________________________________________________________________________________

Page 54

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Surface Mining 2008

and shaft sinking. After consulting with Espley-Jones [27], it was decided to base the determination

of powder factors on a weight per square metre basis, which seems more conceptually correct. This

has the advantage of optimising the powder factor to the splitting mechanism independent of bench

geometry. It does however have the drawback of not taking into account the (desirable) movement

of the loosened bench which is effected by the gas energy of the explosion. Based on the results of

extensive testing, powder factors of 100-120g/m2 on the freeway direction and 130-160g/m2 in the

secondway and toughway directions have yielded the best results in terms of minimising blasting

induced fractures as well as achieving successful two-way splitting using both F11 and F17

pipecharges and Energex Barrel. Satisfactory results were not obtained with the K, KK and G

formulations of pipecharges at 17mm diameter, and these at 11mm diameter did not split the stone

at all. Previous testing conducted in the Rustenburg quarries in the early 1990s with Dynatrim (a

now discontinued AEL product based on the K pipe performance parameters) yielded optimum

reported results for two-way splitting at around 180g/m2, although no study of blast induced

fracturing was done.

One weakness however of a powder factor based solely on the square metres split is that it makes

no provision for displacement of the rock mass that is split. A three term powder factor formula

which attempts to make some compensation for the above deficiencies has been developed [21]

based on empiric observation in Italian granite quarries. The formula is as follows:

C = a + b.S/V + c.s

where C = overall powder factor (g/m3)

S = split surface area (m2)

V = volume (m3)

s = displacement (m)

a = minimum effective powder factor (10.52 g/m3)

b = specific surface consumption of explosive (26.47 g/m2)

c = displacement efficiency coefficient (28.74 g/m4)

The first and last terms of this formula account for the displacement effect, while the middle term

accounts for the splitting effect. This formula was developed in three way blasting in granites with

tensile strengths of around 15MPa. It was also developed using detonating cord (PETN explosive).

Typical reported powder factors for the Italian quarries observed range between 60 and 100g/m2

when converted to a powder factor based on surface area. While slightly lower than the results

obtained in the Rustenburg quarries, this is likely to be a result of the fact that holes were stemmed

with water, which increases shock wave transmission, but also increases the likelihood of cracks

forming around the holes.

In general, the sources quoted above prescribe a fixed powder factor independent of the type of

explosive. This seems strange, as there is a very wide range of properties of these various

explosives, and it seems logical that a powder factor which has been found to work well with one

type of explosive will not necessarily work well with an explosive of vastly differing parameters. In

practice therefore when testing was performed in Rustenburg, powder factors were adjusted

between explosives relative to their heat of explosion (the only parameter which is a reliable

indicator of relative strength which was available for all explosives), while still trying to balance the

volume of detonation gases side of the equation (In practice, it may be that relative weight strength

may be a better correcting factor if it is available for all explosives). The results obtained in testing

of various explosives listed in Table 3 below have however justified this approach.

________________________________________________________________________________________________

Page 55

The Southern African Institute of Mining and Metallurgy

I Ashmole, M Motloung

Explosive

Det Cord 40g/m

PETN

Det Cord 20g/m

PETN

Det Cord 10g/m

PETN

Det Cord 8g/m

PETN

F-17 Pipecharge

K-17 Pipecharge

KK-17 Pipecharge

G-17 Pipecharge

F-11 Pipecharge

K-11 Pipecharge

KK-11 Pipecharge

G-11 Pipecharge

Energex Barrel

Dynatrim

Surface Mining 2008

VOD Vol Det Heat of Density Diamet Charg Vol Det

Heat of

(m/s) Gas

Expl (kg/dm

er

e (g/m) Gas (l/m Expl (kJ/M

3

(l/kg) (MJ/kg)

)

(mm)

charge)

charge)

6500

780

5.9

n/a

n/a

40

31

236

6500

780

5.9

n/a

n/a

20

16

118

6500

780

5.9

n/a

n/a

10

59

6500

780

5.9

n/a

n/a

47

2500

1900

1700

1800

2500

1900

1700

1800

3200

1700

335

160

130

409

335

160

130

409

906

800

2.8

1.5

1.2

2.0

2.8

1.5

1.2

2.0

2.37

1.38

0.95

0.95

0.9

0.9

0.95

0.95

0.9

0.9

0.95

0.9

17

17

17

17

11

11

11

11

18

18

216

216

204

204

90

90

86

86

242

229

72

35

27

84

30

14

11

35

219

183

604

323

245

409

253

135

103

171

573

316