Beruflich Dokumente

Kultur Dokumente

OSHA Hazard Communication Checklist

Hochgeladen von

Nuky Dwifirly Pratiwi ArhathaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

OSHA Hazard Communication Checklist

Hochgeladen von

Nuky Dwifirly Pratiwi ArhathaCopyright:

Verfügbare Formate

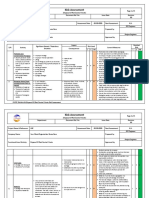

OSHA CHECKLIST FOR HAZARD COMMUNICATION STANDARD

OSHA SECTION

YES NO

ACTION TAKEN

A. HAZARD COMMUNICATION PROGRAM:

1.The program is in writing.

1910.1200(e)(1)

Our Written Program Provides The Following:

2.Describes how hazards will be evaluated and described (employers may rely on the chemical

1910.1200(d)(6)

manufacturer or importer).

3.Tests all hazardous materials in the workplace (employers may rely on the chemical manufacturer

1910.1200(d)(1)

or importers).

4.Describes our labeling system.

1910.1200(f)

5.Provides a list of hazardous chemicals referenced on MSDS for all hazardous materials used in the 1910.1200(e)(1)

workplace (see Section B).

6.Describes our employee education and training program.

1910.1200(h)

7.Describes hazards of non-routine tasks.

1910.1200(e)(1)(ii)

8.Describes how hazards of non-labeled pipes will be handled.

1910.1200(e)(1)(ii)

9.Includes procedures for informing of on-site contractors of the hazardous substances in the

1910.1200(e)(1)(iii)

workplace to which their employees amy be exposed.

10.Is available to employees, their designated representatives, assistant secretary of labor for OSHA,

1910.1200(e)(3)

and the director of NIOSH.

B. LIST OF HAZARDOUS MATERIALS IN THE WORKPLACE:

Our List contains all hazardous chemicals, including, but not limited to:

1.Raw materials.

1910.1200(e)(1)(i)

2.Both isolated and nonisolated intermediates.

1910.1200(e)(1)(i)

3.Final products.

1910.1200(e)(1)(i)

4.Cleaning and maintenance chemicals.

1910.1200(e)(1)(i)

5.Laboratory chemicals for which MSDS information has been received.

1910.1200(b)(ii),(iii)

6.Waste products not regulated under RCRA, but which are hazardous under this standard.

1910.1200(e)(1)(i)

7.Impurities and by products.

1910.1200(e)(1)(i)

8.Waste treatment and products.

1910.1200(e)(1)(i)

C. HAZARDOUS MATERIALS LABELING SYSTEM:

1.All products containing hazardous materials leaving the workplace are labeled (applicable to

1910.1200(f)(1)

chemical manufacturers, distributors and importers only).

2.Stationary containers are labeled.

1910.1200(f)(4)

3.Temporary containers used between workshifts or by different workers are labeled.

1910.1200(f)(6)

4.A method has been established to insure that our labels are correct and up-to-date.

1910.1200(f)(4)(ii)

D. CONTENTS OF HAZARDOUS MATERIAL LABEL:

Our Labels contain:

1.A chemical name that coincides with name on MSDS.

1910.1200(f)(1)(i)

2.The identity of hazards with words (in English), pictures or symbols.

1910.1200(f)(1)(ii)

3.Hazards of immediate and direct consequences of mishandling are included.

1910.1200(f)(1)(ii)

4.Information that does not conflict with DOT regulations.

1910.1200(f)(2)

49 CFR 172.101

5.Other OSHA standards if material is already regulated.

1910.1200(f)(3)

6.The name and address of a responsible party (or parties).

1910.1200(f)(1)(iii)

E. MATERIAL SAFETY DATA SHEETS:

1.A MSDS is available for every hazardous chemical which an employer uses.

1910.1200(g)(1)

2.Our MSDS are readily available to exposed employees in the work area throughout each work shift. 1910.1200(g)(8)

F. IN-HOUSE LABELING SYSTEM:

1.Containers are labeled with the identity of hazardous chemicals and hazard warnings (unless

hazard warning materials are used).

(continued on back)

OSHA SECTION

1910.1200(f)(4)(i)

YES

NO

ACTION TAKEN

2.Hazard warning materials for hazardous chemicals in stationary process containers are readily

1910.1200(f)(5)

accessible to the employee in the workplace.

3.The labels on incoming container have not been removed or defaced unless immediately replaced

1910.1200(f)(7)

with our own labels.

4.The hazards in pipelines are identified, although they do not have to be labeled under this standard. 1910.1200(e)(1)(ii)

5.Our labels are legible and in English.

1910.1200(f)(8)

G. PROCEDURES HAVE BEEN ESTABLISHED FOR:

1.Updating our MSDS (or for receiving updated copies from our supplier).

1910.1200(g)(5)

2.Taking appropriate action if a shipment is received without a MSDS.

1910.1200(g)(1)

3.Getting new and updated MSDS to employees handling materials.

1910.1200(g)(8)

4.Advising employees of any changes in MSDS.

1910.1200(h)

5.Documentation of efforts to obtain MSDS from supplier (recommended practice but not required by

-----

this standard).

H. HAZARDS OF NON-ROUTINE TASKS:

Procedures have been established assessing the hazards of non-routine tasks:

1.All non-routine tasks involving the use or exposure to hazardous materials are identified.

1910.1200(e)(1)(ii)

2.The hazards involved in the performance of non-routine tasks are described in writing.

1910.1200(e)(1)(ii)

3.A MSDS is prepared or obtained for the hazardous materials involved in these non-routine tasks.

1910.1200(e)(1)(ii)

4.A labeling system or written operating procedure has been established to identify the hazardous

1910.1200(e)(1)(ii)

substances and hazards involved in non-routine tasks.

5.Special training has been established for the performance of non-routine tasks, including written

1910.1200(e)(1)(ii)

operating procedures.

I. EMPLOYEE EDUCATION & TRAINING:

Procedures have been established to inform employees of:

1.Covers all manufacturing, quality control, plant service, and R&D employees who may be exposed

1910.1200(b)(1)

to hazardous materials.

2.Requirements of the Hazard Communication Standard.

1910.1200(h)(1)(i)

3.Operations where hazardous materials are present.

1910.1200(h)(1)(ii)

4.Location and availability of the written hazard communication program including the hazardous

1910.1200(h)(1)(iii)

chemical list and MSDS.

J. PROCEDURES FOR TRAINING EMPLOYEES INCLUDE:

1.Information about physical and health hazards of chemicals in work area.

1910.1200(h)(2)(ii)

2.Detecting the presence of hazardous materials - monitoring procedures, odors, visibility, etc.

1910.1200(h)(2)(i)

3.Proper use and selection of personal protective equipment.

1910.1200(h)(2)(iii)

4.Emergency procedures in the event of accidental exposure to hazardous materials, including

1910.1200(h)(2)(iii)

emergency phone numbers and locations of eye washes and safety showers.

5.How to determine hazards by reading a label.

1910.1200(h)(2)(iv)

6.The location of MSDS and procedures for reviewing and/or obtaining copies.

1910.1200(h)(1)(iii)

7.How to obtain the correct MSDS for the hazardous substance used by the employee, such as use of 1910.1200(h)(2)(iv)

the trade name as a key identifier.

8.How the MSDS is updated of the procedure for obtaining updated copies from the chemical

1910.1200(h)(2)(iv)

manufacturer, importer or distributor.

9.The significance to the employee of each section of information on the MSDS, how to read it and

1910.1200(h)(2)(iv)

what it means.

10.The measures employees can take to protect themselves from chemical exposure. (Examples

1910.1200(h)(2)(iii)

include eye washes, face shields, respirators, etc.).

11.Training which is done prior to the handling of the hazardous chemical, including employees who

1910.1200(h)

may only temporarily do this work.

12.Updated training is considered when the employee has transferred jobs or departments.

1910.1200(h)

13.Updated training is considered when significant changes in chemicals or operations have occurred. 1910.1200(h)

Das könnte Ihnen auch gefallen

- Hazard Communication Program 1Dokument4 SeitenHazard Communication Program 1myo lwinNoch keine Bewertungen

- MW-OPS-SP-3.6.13F1 Work Authorization Permit FormDokument3 SeitenMW-OPS-SP-3.6.13F1 Work Authorization Permit FormGabriel Tan100% (1)

- Checklist On PpeDokument3 SeitenChecklist On PpeNikka LopezNoch keine Bewertungen

- Assessment Checklist EnvironmentalDokument3 SeitenAssessment Checklist EnvironmentalSanket Patil100% (1)

- Contractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedDokument3 SeitenContractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedJayvee Baradas ValdezNoch keine Bewertungen

- 3.3.7 Hazdarous Waste LogDokument2 Seiten3.3.7 Hazdarous Waste LogSubzone ThreeNoch keine Bewertungen

- Man Basket Cert 7101Dokument1 SeiteMan Basket Cert 7101Mac-Ross CordovaNoch keine Bewertungen

- Demobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaDokument10 SeitenDemobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaNasrullahNoch keine Bewertungen

- Part Submission WarrantDokument4 SeitenPart Submission WarrantSam AnuNoch keine Bewertungen

- Daily HSSE Report TemplateDokument2 SeitenDaily HSSE Report TemplateBadr JLASSI100% (1)

- Monthly ESH Report & StatisticsDokument5 SeitenMonthly ESH Report & StatisticsEngr.Syed AmjadNoch keine Bewertungen

- CSHP Checklist 2011Dokument2 SeitenCSHP Checklist 2011JenniferValle0% (1)

- Mom For Table To Drill MeetingDokument2 SeitenMom For Table To Drill MeetingChaudhary Wasim MurtazaNoch keine Bewertungen

- HSE PRO 02 F01b Contractor Pre-Qual Questionnaire - 2016-08Dokument4 SeitenHSE PRO 02 F01b Contractor Pre-Qual Questionnaire - 2016-08DKY EDPAPNoch keine Bewertungen

- Confined Space Rescue Plan: Description of The WorkDokument2 SeitenConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- 3.3.4 Monthly Suction Septic Tank LogDokument2 Seiten3.3.4 Monthly Suction Septic Tank LogSubzone ThreeNoch keine Bewertungen

- Checklist 011 - Visitor InductionDokument1 SeiteChecklist 011 - Visitor InductionHolly Smith0% (1)

- Natural Gas Pipeline Safety Walk ReportDokument2 SeitenNatural Gas Pipeline Safety Walk ReportNibhaNoch keine Bewertungen

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDokument1 SeiteHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (2)

- Daily Safety Report TemplateDokument1 SeiteDaily Safety Report TemplateMarkNoch keine Bewertungen

- Powder Actuated ToolsDokument1 SeitePowder Actuated ToolsJayvee Baradas ValdezNoch keine Bewertungen

- Quarterly Safety ChecklistDokument2 SeitenQuarterly Safety ChecklistAJ CompilationNoch keine Bewertungen

- Health and Safety Monthly Performance Summary Report: ReactiveDokument2 SeitenHealth and Safety Monthly Performance Summary Report: ReactivegkNoch keine Bewertungen

- HSE 05-015a Ladder Inspection RegisterDokument1 SeiteHSE 05-015a Ladder Inspection RegisterQuentin KlynsmithNoch keine Bewertungen

- Cps 0460 Incident Notification ReportDokument2 SeitenCps 0460 Incident Notification ReporttabaquiNoch keine Bewertungen

- Hot Work PermitDokument1 SeiteHot Work PermitvarunstuffNoch keine Bewertungen

- Hse Passport PDFDokument2 SeitenHse Passport PDFTheresiaVickaaNoch keine Bewertungen

- Form: - Xxviii (See Rule 250 (C) ) : Certificate of Medical ExaminationDokument2 SeitenForm: - Xxviii (See Rule 250 (C) ) : Certificate of Medical ExaminationSaqueeb FodkarNoch keine Bewertungen

- Fall Protection Planner Appointment FormDokument1 SeiteFall Protection Planner Appointment FormHamish WilliamsNoch keine Bewertungen

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDokument9 SeitenAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNoch keine Bewertungen

- Form E - Entity Quarterly Performance Report - V3.0 EnglishDokument3 SeitenForm E - Entity Quarterly Performance Report - V3.0 Englishsamuel100% (2)

- Safety Panelty Matrix For Contractor: SR - No Type of Safety Violation 1 Warning 2 Warning 3 WarningDokument2 SeitenSafety Panelty Matrix For Contractor: SR - No Type of Safety Violation 1 Warning 2 Warning 3 WarningAejaz MujawarNoch keine Bewertungen

- Night Work PermitDokument2 SeitenNight Work Permitasem sawalmeh100% (1)

- GL-01-EHS-032 Guidelines On Work Environment MeasurementDokument8 SeitenGL-01-EHS-032 Guidelines On Work Environment MeasurementClarabelle Mae Dela RosaNoch keine Bewertungen

- Emergency Response and Contingency PlanDokument21 SeitenEmergency Response and Contingency PlanKarimo KilaniNoch keine Bewertungen

- SCRAP REGISTER - (Mention Scrap Name) : Logo Date Scrab Note Ref. From Qty Received UOM Total StockDokument2 SeitenSCRAP REGISTER - (Mention Scrap Name) : Logo Date Scrab Note Ref. From Qty Received UOM Total StockRaajha Munibathiran100% (1)

- Monthly OHSE ReportDokument4 SeitenMonthly OHSE ReportMutee MustafaNoch keine Bewertungen

- First Aid Box Monthly ChecklistDokument1 SeiteFirst Aid Box Monthly Checklistpurushottam JhariyaNoch keine Bewertungen

- Msds 0864 Aquafill Wallfiller Fine en 1Dokument10 SeitenMsds 0864 Aquafill Wallfiller Fine en 1baseet gazaliNoch keine Bewertungen

- Sungpoong Safety Warning NoticeDokument8 SeitenSungpoong Safety Warning NoticeMyungki OhNoch keine Bewertungen

- Spill Response Procedures OCLDokument14 SeitenSpill Response Procedures OCLThusithaNoch keine Bewertungen

- Short Employee Service AssessmentDokument2 SeitenShort Employee Service Assessmentdennisjuntak100% (1)

- Hazardous Substances RegisterDokument1 SeiteHazardous Substances RegisterArmandoNoch keine Bewertungen

- NCR FormatDokument2 SeitenNCR FormatStephen Lim Kean JinNoch keine Bewertungen

- OSHA Environmental Controls Subpart D - Medical, Sanitation, Noise, RadiationDokument2 SeitenOSHA Environmental Controls Subpart D - Medical, Sanitation, Noise, RadiationJohn Vem BansagNoch keine Bewertungen

- SAFCO scaffolding inspection checklistDokument3 SeitenSAFCO scaffolding inspection checklistApm FoumilNoch keine Bewertungen

- Ohs-Pr-09-03-F07 (A) Job Safe ProcedureDokument1 SeiteOhs-Pr-09-03-F07 (A) Job Safe ProcedureShafie ZubierNoch keine Bewertungen

- Appendix 17 OSH Incident Notification, Investigation and Reporting ProcessDokument1 SeiteAppendix 17 OSH Incident Notification, Investigation and Reporting ProcessXtreme-Designs100% (1)

- Weekly Report ExampleDokument3 SeitenWeekly Report Examplewawan setiawanNoch keine Bewertungen

- Tower Crane Work Permit ChecklistDokument1 SeiteTower Crane Work Permit Checklistfaisal nadeemNoch keine Bewertungen

- Safety Moment There Is No Shortcut To Safety 448cuoDokument6 SeitenSafety Moment There Is No Shortcut To Safety 448cuoInnocent BhaikwaNoch keine Bewertungen

- Workplace Inspection ChecklistDokument119 SeitenWorkplace Inspection ChecklistFarid SedekyNoch keine Bewertungen

- Disposal of Pest Control Waste Risk AssessmentDokument5 SeitenDisposal of Pest Control Waste Risk AssessmentLawrence adeleke Omisakin100% (1)

- SBOI Chklist PDFDokument1 SeiteSBOI Chklist PDFRajanNoch keine Bewertungen

- App D - OSHA Haz Com WEBDokument19 SeitenApp D - OSHA Haz Com WEBBambang Pamarta PNoch keine Bewertungen

- OSHA Construction ChecklistDokument24 SeitenOSHA Construction ChecklistjosiasNoch keine Bewertungen

- 1910.1200 - Hazard Communication. _ Occupational Safety and Health AdministrationDokument22 Seiten1910.1200 - Hazard Communication. _ Occupational Safety and Health Administrationmahomoud negmNoch keine Bewertungen

- IGC2 20marks M15Dokument3 SeitenIGC2 20marks M15Amit Mehta100% (1)

- Construction Check ListDokument27 SeitenConstruction Check ListUzank Mellitus100% (1)

- A Guide to Sanitation Safety Planning in the Philippines: Step-By-Step Risk Management for Safe Reuse and Disposal of Wastewater, Greywater, and ExcretaVon EverandA Guide to Sanitation Safety Planning in the Philippines: Step-By-Step Risk Management for Safe Reuse and Disposal of Wastewater, Greywater, and ExcretaNoch keine Bewertungen

- Kolb's Experiential Learning As A Critical Frame For Re Ective PracticeDokument15 SeitenKolb's Experiential Learning As A Critical Frame For Re Ective PracticeNuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- The Effect of Using The Learning Cycle Method in Teaching Science On The Educational Achievement of The Sixth GradersDokument10 SeitenThe Effect of Using The Learning Cycle Method in Teaching Science On The Educational Achievement of The Sixth GradersWitri H'yatiNoch keine Bewertungen

- Effect of Five-Step Learning Cycle Model On Students' Understanding of Concepts Related To ElasticityDokument9 SeitenEffect of Five-Step Learning Cycle Model On Students' Understanding of Concepts Related To ElasticityNuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- Tests of NormalitycDokument1 SeiteTests of NormalitycNuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- Msds KitosanDokument5 SeitenMsds KitosanNuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- OSHA Hazard Communication ChecklistDokument2 SeitenOSHA Hazard Communication ChecklistNuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- HTADokument25 SeitenHTANuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- Msds Sulphuric Acid PDFDokument7 SeitenMsds Sulphuric Acid PDFVeiliLookNoch keine Bewertungen

- Leftover Household Products That Contain CorrosiveDokument8 SeitenLeftover Household Products That Contain CorrosiveNuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- Msds Sulphuric Acid PDFDokument7 SeitenMsds Sulphuric Acid PDFVeiliLookNoch keine Bewertungen

- Katalog PT GlobalDokument8 SeitenKatalog PT GlobalNuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- Bab 1 Pengantar Karakterisasi MaterialDokument19 SeitenBab 1 Pengantar Karakterisasi MaterialNuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- Jurnal Natur Indonesia 13 (2) 118-122Dokument1 SeiteJurnal Natur Indonesia 13 (2) 118-122Nuky Dwifirly Pratiwi ArhathaNoch keine Bewertungen

- CH 13 The Future of Training and DevelopDokument38 SeitenCH 13 The Future of Training and DevelopShelkke TriptiiNoch keine Bewertungen

- 360 DegreeDokument14 Seiten360 DegreeJeevan Anthony100% (4)

- Pre-test Lesson 3 on occupational health and safety risksDokument16 SeitenPre-test Lesson 3 on occupational health and safety risksChristel Khazter Tan AriñolaNoch keine Bewertungen

- 04 23 12editionDokument32 Seiten04 23 12editionSan Mateo Daily JournalNoch keine Bewertungen

- OCI Director Remuneration Policy ExplainedDokument7 SeitenOCI Director Remuneration Policy ExplainedxymaanNoch keine Bewertungen

- Assignment Comper ProblemDokument2 SeitenAssignment Comper ProblemAmir ParwarishNoch keine Bewertungen

- United Parcel Service SummaryDokument6 SeitenUnited Parcel Service SummaryAnanda KurniawanNoch keine Bewertungen

- Project Report: Ratio AnalysisDokument72 SeitenProject Report: Ratio AnalysisShivjeet SinghNoch keine Bewertungen

- Online CEng App FormDokument16 SeitenOnline CEng App FormRantharu AttanayakeNoch keine Bewertungen

- FULL MANUSCRIPT 1 - 2 - 3 and 4Dokument37 SeitenFULL MANUSCRIPT 1 - 2 - 3 and 4Debbie BalandanNoch keine Bewertungen

- Booklet Inglés Convers - IV Ok (28julio 2014)Dokument36 SeitenBooklet Inglés Convers - IV Ok (28julio 2014)calamandro saezNoch keine Bewertungen

- Santuyo, Et Al. v. Remerco 260-261Dokument2 SeitenSantuyo, Et Al. v. Remerco 260-261Thea Dela Cruz CapunponNoch keine Bewertungen

- Industrial Law Case StudyDokument16 SeitenIndustrial Law Case StudyYazhini ManoharanNoch keine Bewertungen

- Employee Resistance To Change - Case StudyDokument5 SeitenEmployee Resistance To Change - Case StudyShirley Mwende MuhatoNoch keine Bewertungen

- CSHP Template ComprehensiveDokument15 SeitenCSHP Template Comprehensivejames john0% (2)

- Cost Study Notes on Cost Accounting FundamentalsDokument27 SeitenCost Study Notes on Cost Accounting FundamentalsLkjiklNoch keine Bewertungen

- Inter Intra Industry Wage Difference 2022Dokument41 SeitenInter Intra Industry Wage Difference 2022Vasanth KumarNoch keine Bewertungen

- Coral FLNG Offshore Staff CoordinatorDokument2 SeitenCoral FLNG Offshore Staff CoordinatorPídeler GracianoNoch keine Bewertungen

- Log Sheet: Mec532 Mechanical Engineering Design IiDokument1 SeiteLog Sheet: Mec532 Mechanical Engineering Design IiAhmad Syazni Bin MoktarNoch keine Bewertungen

- Maternity Benefit ProjectDokument16 SeitenMaternity Benefit ProjectS1626100% (1)

- Overview - Garments Industry in BangladeshDokument24 SeitenOverview - Garments Industry in Bangladeshzubair07077371100% (1)

- Job Analysis of Event ManagerDokument4 SeitenJob Analysis of Event ManagerTayyaba Ishtiaq100% (1)

- Interactive Class ExerciseDokument4 SeitenInteractive Class ExercisePage NumberNoch keine Bewertungen

- Joan H. Braitsch v. Emc Corporation, and Thomas Aaron Michael Grilli Frank Keaney, 96 F.3d 1438, 4th Cir. (1996)Dokument3 SeitenJoan H. Braitsch v. Emc Corporation, and Thomas Aaron Michael Grilli Frank Keaney, 96 F.3d 1438, 4th Cir. (1996)Scribd Government DocsNoch keine Bewertungen

- Aggregate Planning.Dokument9 SeitenAggregate Planning.Juan R. VillacortaNoch keine Bewertungen

- MGT103 C5Dokument3 SeitenMGT103 C5Bacquial, Phil Gio E. (Phil Gio)Noch keine Bewertungen

- Collective Occupations Among FDokument9 SeitenCollective Occupations Among Ffrondozo_cherry8668Noch keine Bewertungen

- Creating a Prevention Culture in Occupational SafetyDokument2 SeitenCreating a Prevention Culture in Occupational SafetyAndrea Afanador ArteagaNoch keine Bewertungen

- IPE Revision Test Bank 1-3Dokument11 SeitenIPE Revision Test Bank 1-3Nouran BakerNoch keine Bewertungen

- Bir 1902Dokument1 SeiteBir 1902Marc Howard Detera PanganibanNoch keine Bewertungen