Beruflich Dokumente

Kultur Dokumente

Us 2844129

Hochgeladen von

monem2014Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Us 2844129

Hochgeladen von

monem2014Copyright:

Verfügbare Formate

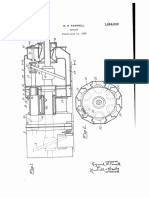

July 22, 1958

E. J. BECK, JR., ETAL

2,844,129

TEMPERATURE CONTROL FOR INTERNAL COMBUSTION EN =INE

Filed Oct. 2, 1956

Haj.

COOLANT LEVEL

EARL J BECK JR.

7 KEm/Em M 75v EPA 06/1

INVEN TORS

30

0621

W I ?TZ

BY

Arm/ms YS

United States Patent 0

1

2,844,129

TEMPERATURE CONTROL FOR INTERNAL

COMBUSTION ENGINE

Earl J. Beck, Jr., and Kenneth N. Tinklepaugh,

Oxnard, Calif.

Application October 2, 1956, Serial No. 613,587

3 Claims. (Cl. 123-41.21)

(Granted under Title 35, U. S. Code (1952), see. 266)

2,844,129

Patented July 22, 1958

2

lower tank. has an inclined bottom, as shown, which leads

to the bifurcated upper end of condensate line 28 which

connects with a heat exchanger 30in the crankcase of

the engine below the level of oil therein. The heat ex

changer is in turn connected by a condensate return tube

32 to the water jacket 16.

Forwardly of the condenser 17 is a small fan 34 to

circulate air past the tubes 24. The fan may be driven

from the crankshaft 14 by means of a pulley 36 and a

belt 38 which engages a second pulley 40 on the fan shaft.

If the engine is started while cold, the coolant in the

water jacket will become heated and will eventually

boil, the resulting steam ?owing into the condenser 17 to

The invention described herein may be manufactured 15 be cooled and condensed, the condensate ?owing down

wardly through line 28 to heat exchanger 30, where it

and used by or for the Government of the United States

gives up heat to the oil in the crankcase, and then through

of America for governmental purposes without the pay

tube 32 back to the water jacket. Circulation in this

ment of any royalties thereon or therefor.

manner is maintained because the coolant in water jacket

This invention relates to a system for controlling the

temperature of the engine block and of the lubricating 20 16 is warmer than that in the condensate line 28. Along

with the steam (or other vapor) passing through tube

oil in an internal combustion engine which may be sub

18 a certain amount of liquid coolant will be carried over

jected to extremes of external temperature.

into tank 22, and this process will continue until the

In operations in Arctic regions, the usual radiator of

- liquid level in line 28 is higher than that in the water

a liquid-cooled engine is larger than needed, and main

tains the engine temperature too low for e?icient opera 25 jacket, which further aids the circulation.

When the engine is fully warmed up, the condensate

tion. Also, the usual water pump is not needed, since

in heat exchanger 30 may act to absorb heat from the

a thermal-gravity system will circulate the coolant suf

oil in the oil pan if the temperature of said oil becomes

?ciently rapidly to maintain the engine at proper tempera

unduly high.

ture.

There is also a need to transfer heat to the oil in

It will be seen that the condenser 17 may be made

the crankcase while the engine is being warmed up, and 30

much smaller than the usual radiator, that no water pump

there is sometimes need to cool said oil when vthe engine

is required, and that the capacity of fan 34 may be

has been fully warmed up.

materially less than that of the usual fan.

The present invention vaims to provide a system which

Obviously many modi?cations and variations of the

will accomplish the functions above indicated, and do

present invention are possible in the light of the above

so in an economical and ei?cient manner.

35

teachings. It is therefore to be understood that within

An object of the invention is to provide a temperature

the scope of the appended claims the invention may be

control system of the type indicated which will operate

practiced otherwise than as speci?cally described.

e?iciently at extremely low circumambient temperatures.

What is claimed is:

A further object of the invention is to provide a simpli

1.

In

a

liquid

cooled

internal

combustion

engine

having

?ed cooling system for an internal combustion engine.

40 a liquid coolant jacket and a crankcase for containing oil,

Further objects and many of the attendant advantages

a boiling-condensing cooling system comprising a con

of this invention will be readily appreciated as the same

denser disposed above the upper level of the liquid coolant

becomes better understood by reference to the following

in the jacket and connected to the latter to receive there

description wherein

Fig. 1 is a view in perspective of an internal combus 45 from vapors at the boiling point of the liquid coolant, a

heat exchanger disposed below the condenser and in the

tion engine provided with a heat exchanging and trans

crankcase, conduit means for conducting condensate sub

ferring system which embodies the invention, and

stantially at the boiling point directly from the condenser

Fig. 2 is a diagrammatic representation of the appa

to the heat exchanger without substantial loss of heat, and

ratus shown in Fig. 1.

conduit means for returning the condensate from the heat

The engine shown in the drawing comprises the usual 50 exchanger to the coolant jacket, the construction and ar

engine block 10, crankcase 12, and crankshaft 14. De

rangement being such that circulation of the condensate

tails of the engine mechanism are omitted because they

is effected by its difference in density in the system.

may vary widely. The engine is provided with a water

2. Apparatus in accordance with claim 1 including an

jacket 16 of any usual type.

engine driven fan for passing ambient air in heat exchange

Mounted above the engine, and replacing the usual 55 relation to the condenser for extracting heat of vaporiza

radiator, is a separator and condenser 17 connected to

tion from the coolant to thereby condense the vapor de~

livered to the condenser.

the water jacket 16 by a tube 18 and comprising an upper

3. In a cooling system for a liquid cooled internal com

tank 20 and a lower tank 22 connected by heat-exchage

bustion engine of the type normally provided with a liquid

tubes 24. The level of coolant in the water jacket is

60 coolant radiator having su?cien't cooling capacity for

maintained at about the level of the tube 18 as shown.

maintaining the engine at optimum operating temperature

The upper tank is provided with an air vent 26 of the

when the engine is operated in ambient air above a cer

type used in steam radiators, and a ?ller cap 27 which may

tain temperature but of excessive cooling capacity when

incorporate a pressure release mechanism (not shown) of

engine is operated in ambient air below said certain

the type commonly used in automobile radiators. The 65 said

temperature, whereby under the last named operation the:

2,844,129

3

engine operates below said optimum temperature, said

engine alsohaving a- crankcase for containing oilv for lubri~

cating the engine, which oil would remain below optimum

temperature with the engine operating with said coolant

radiator, the improvements comprising; a condenser in

heat exchange relationship with ambient air adapted to

condense coolant vapors formed in said engine adapted to

be employed with said engine in lieu of said radiator and

having lesser cooling capacity than said radiator but of

cooling capacity sufficient to maintain said engine at

said optimum temperature when the engine is operated

below said certain temperature, a heat exchanger disposed

within-said crankcase in heat exchange relation to said

v4

oil, and means for conducting condensate from said con

denser to said heat exchanger without substantial loss of

heat whereby the temperature of said oil may be raised

as rapidly as practicable during the period the engine

temperature is increasing'toward its optimum temperature

of operation, and means for returning said condensate

from the heat exchanger to said engine.

10

References Cited in the ?le of this patent

FOREIGN PATENTS

508,150

Great Britain _______ _--_ June 27, 1939

Das könnte Ihnen auch gefallen

- W, B. Kidder. : Tree Climbing MotorDokument4 SeitenW, B. Kidder. : Tree Climbing Motormonem2014Noch keine Bewertungen

- Cumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2Dokument3 SeitenCumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2monem2014Noch keine Bewertungen

- SSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899Dokument7 SeitenSSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899monem2014100% (1)

- No. 748,348. PATENTED DEC. 29, 1903. Rotary'Fluid Engine.: J. F. GooleyDokument4 SeitenNo. 748,348. PATENTED DEC. 29, 1903. Rotary'Fluid Engine.: J. F. Gooleymonem2014Noch keine Bewertungen

- No. 648,153. - Patented Apr. 24, I900. J. P. Serve. : Means For Lubrigating Engine Fylinbers, 61.0Dokument3 SeitenNo. 648,153. - Patented Apr. 24, I900. J. P. Serve. : Means For Lubrigating Engine Fylinbers, 61.0monem2014Noch keine Bewertungen

- March23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion EnginésDokument3 SeitenMarch23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion Enginésmonem2014Noch keine Bewertungen

- Dec. 15, 1942. - R. Lang:1 Al Diesel Engine With Charging PancaDokument3 SeitenDec. 15, 1942. - R. Lang:1 Al Diesel Engine With Charging Pancamonem2014Noch keine Bewertungen

- Nov. 12, 1935. W. D. Appel 2,020,597: Filed Aug. 13, 1934Dokument3 SeitenNov. 12, 1935. W. D. Appel 2,020,597: Filed Aug. 13, 1934monem2014Noch keine Bewertungen

- Sept. 24, 1929. W. Siders: Filed Nov. 5. 1925Dokument3 SeitenSept. 24, 1929. W. Siders: Filed Nov. 5. 1925monem2014Noch keine Bewertungen

- May 15, l945-W. Kilchenmann: Reversible Supercharged Two-Stroke Internal-Combustion Engine IDokument3 SeitenMay 15, l945-W. Kilchenmann: Reversible Supercharged Two-Stroke Internal-Combustion Engine Imonem2014Noch keine Bewertungen

- Oct. 24, 1944, C. K. Newcombe 7 2,360,969: Supercharger For Internal-Combustion EnginesDokument3 SeitenOct. 24, 1944, C. K. Newcombe 7 2,360,969: Supercharger For Internal-Combustion Enginesmonem2014Noch keine Bewertungen

- March 25,1930. ' . V - (5 - APPLE 1,752,224: Filed Dec. 7, 1928Dokument4 SeitenMarch 25,1930. ' . V - (5 - APPLE 1,752,224: Filed Dec. 7, 1928monem2014Noch keine Bewertungen

- Us 2397941Dokument3 SeitenUs 2397941monem2014Noch keine Bewertungen

- Wwkzii: Jan. 10, 1933. R. H. FarwellDokument3 SeitenWwkzii: Jan. 10, 1933. R. H. Farwellmonem2014100% (1)

- 46, Tazecfeafe Fue) : Filed Oct. 5, 195.1IDokument42 Seiten46, Tazecfeafe Fue) : Filed Oct. 5, 195.1Imonem2014Noch keine Bewertungen

- June 13, 1961 ' F. Wankel Etal 2,988,065: Rotary Internal Conbustion Engine Filed Nov. 17, 1958 2l Sheets-Sheet 1Dokument33 SeitenJune 13, 1961 ' F. Wankel Etal 2,988,065: Rotary Internal Conbustion Engine Filed Nov. 17, 1958 2l Sheets-Sheet 1monem2014Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Efflux Time: TOGUN Iyanuoluwa JohnDokument24 SeitenEfflux Time: TOGUN Iyanuoluwa JohnJohnNoch keine Bewertungen

- List Some Standards ISODokument2 SeitenList Some Standards ISOAnonymous n4bJbeLAqNoch keine Bewertungen

- Dredging Giotto 2016Dokument40 SeitenDredging Giotto 2016Simon FuenmayorNoch keine Bewertungen

- Bernoulli Venturi NozzleDokument4 SeitenBernoulli Venturi NozzleFrank PingolNoch keine Bewertungen

- Boiler Tube Protection Systems A VALERO Energy Case StudyDokument73 SeitenBoiler Tube Protection Systems A VALERO Energy Case StudyTejas AhalparaNoch keine Bewertungen

- FlammabilityDokument10 SeitenFlammabilityHamza MasalawalaNoch keine Bewertungen

- Experiment 4 StoichiometryDokument17 SeitenExperiment 4 StoichiometrySiti Khadijah Binti Abu SaamahNoch keine Bewertungen

- Ibo Catalogue 2018Dokument88 SeitenIbo Catalogue 2018bobi gorgievskiNoch keine Bewertungen

- MYCOM Semi-Hermetic Screw CompressorDokument2 SeitenMYCOM Semi-Hermetic Screw CompressorEric GonçalvesNoch keine Bewertungen

- A Fixed-Bed Reactor Modeling Study On The Methanation of CO: Chemical Engineering Research and DesignDokument11 SeitenA Fixed-Bed Reactor Modeling Study On The Methanation of CO: Chemical Engineering Research and DesignJames LivingstonNoch keine Bewertungen

- Effects of NACA 65-BladeDokument6 SeitenEffects of NACA 65-BladeRonaldo LeiteNoch keine Bewertungen

- 07A - Chapter 7 - Sec 7.1-7.3, App F - BlackDokument14 Seiten07A - Chapter 7 - Sec 7.1-7.3, App F - BlackStevina LangrimariNoch keine Bewertungen

- Chiller Plant Manager - IO Summary-200219 PDFDokument1 SeiteChiller Plant Manager - IO Summary-200219 PDFShruti NandNoch keine Bewertungen

- Kinetics Part 2Dokument3 SeitenKinetics Part 2Aditya MenonNoch keine Bewertungen

- Thickness and Weld Branch Calc To ASME B31 3Dokument4 SeitenThickness and Weld Branch Calc To ASME B31 3alvinchuan100% (1)

- Go With The Flow: in Selecting The Right FluidDokument3 SeitenGo With The Flow: in Selecting The Right FluidMetwally NaserNoch keine Bewertungen

- Oxy Coal Combustion by Munawar HussainDokument24 SeitenOxy Coal Combustion by Munawar HussainMunawar HussainNoch keine Bewertungen

- FMC Max Recommended Flow Rates For Swivels & PupsDokument1 SeiteFMC Max Recommended Flow Rates For Swivels & Pupspaulegi5Noch keine Bewertungen

- Heat T ch1Dokument30 SeitenHeat T ch1Fira tubeNoch keine Bewertungen

- Heat Exchangers Design Experiment and Stimulation (2017)Dokument271 SeitenHeat Exchangers Design Experiment and Stimulation (2017)ATUL SHARMA100% (1)

- Heat Exchanger Tube RuptureDokument3 SeitenHeat Exchanger Tube RuptureKarthik Sakthivel100% (1)

- Experiment - Fre and Forced Vortex UitmDokument22 SeitenExperiment - Fre and Forced Vortex UitmAdil Rahman100% (1)

- PEB2063 - Production Engineering IDokument39 SeitenPEB2063 - Production Engineering IadlinaNoch keine Bewertungen

- FL Sonocheck Abd06 Biotech en SonotecDokument2 SeitenFL Sonocheck Abd06 Biotech en SonotecLarissa PereiraNoch keine Bewertungen

- En Manual City 1.24-2.24 FFDokument44 SeitenEn Manual City 1.24-2.24 FFduma262005Noch keine Bewertungen

- Spiral Heat ExchangersDokument8 SeitenSpiral Heat ExchangersHolayilNoch keine Bewertungen

- Din 24255 Curves - 13Dokument1 SeiteDin 24255 Curves - 13Muhammed Mudafi ElhaqNoch keine Bewertungen

- HLR 7955A: Hydraulic Interface ValveDokument2 SeitenHLR 7955A: Hydraulic Interface ValveMalique AdamNoch keine Bewertungen

- Nuflo Orifice PlatesDokument8 SeitenNuflo Orifice PlatesnwabukingzNoch keine Bewertungen

- SAIC-K-4020 Rev 08 - Chilled Water Piping Lay-OutDokument4 SeitenSAIC-K-4020 Rev 08 - Chilled Water Piping Lay-Outranausman1987Noch keine Bewertungen