Beruflich Dokumente

Kultur Dokumente

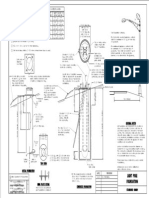

Roadway Elevation of Rail: at Intermediate at Abutments

Hochgeladen von

Pablo Guillermo Coca GarabitoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Roadway Elevation of Rail: at Intermediate at Abutments

Hochgeladen von

Pablo Guillermo Coca GarabitoCopyright:

Verfügbare Formate

Face of Abutment Backwall

End of Rail for Payment

Exp Joint or Splice

Joint as required

10" Min ~ 1'-6" Max

6

3

4"

2'-8

1

4"

C

L Intermediate Wall Joint 3

10'-0" Max Post Spa

10"

10'-0" Usual and Max Post Spacing

Min

7

10" Min

End of HSS if

Exp Joint or

turn-downs are omitted

12" Max

60

Splice Joint

(use Rail Caps)

C

L Splice Joint

Min

11

10" Min

10"

10" Min

12" Max

Min

12" Max

Concentric

Bars R

1

4"

Bars V at 12"(Max)

Bars U at 12"(Max)

10

3

4"

3 Spa

at 6

Bars V at 12"

If forming material is not left

(Max)

in place, plug bottom 6" with

Conc or slab joint sealing

5"

compound. 4

1

2"

AT INTERMEDIATE

AT SLAB EXP JTS

AT ABUTMENTS

AT SPLICE JOINTS

WALL JOINTS

ROADWAY ELEVATION OF RAIL

CONSTRUCTION NOTES:

Panel lengths of railing must be attached to a minimum of three posts except on abutment wingwalls.

1'-0" Min

Face of rail, posts and parapet must be vertical transversely unless otherwise approved. Rail posts

A

1"

3

4"

Nominal

6"

4"

2"

must be perpendicular to top of adjacent concrete parapet grade. Use Type VIII epoxy mortar under

Face of Rail

post base plates if gaps larger than

8"

8"

11

13

1'-0" Min

3

4"

10"

6"

6"

10

12

Post (PL

5

8

x 5 x 2'-3

drawings must be submitted to the Engineer for approval.

Round or chamfer exposed edges of HSS rail and HSS rail posts to approximately

Sleeve Members

1

2")

1

2"

1

4"

Anchor bolts must be

5"

1"

2"

1"

Base PL

1

2

x 5 x 0'-6

AT SPLICE OR EXP JTS

SECTION A-A

Deformed Welded Wire Reinforcement (WWR) (ASTM A1064) of equal size and spacing may be

substituted for Bars U, and V unless noted otherwise.

Uncoated ~ #4 = 1'-5"

Epoxy coated ~ #4 = 2'-1"

1

1'

-0"

one hex nut and

#4 Bars R

Provide bar laps, where required, as follows:

PIPE SPLICE DETAIL

Dia x 10"

A307 Bolts with

1'

-1"

Epoxy coat all reinforcing if slab bars are epoxy coated.

Provide Grade 60 reinforcing steel.

1

2"

at 12"(Max)

washer each

1

Provide Class "C" concrete. Provide Class "C" (HPC) if required elsewhere.

#4 Bars U

5

8"

1

2"

Min of 2 posts required on wingwall.

GENERAL NOTES:

Designed according to AASHTO LRFD Specifications.

Portion of railing with turn-downs to be used or omitted as

Do not use this railing on bridges with expansion joints providing more than 5" movement.

indicated on Bridge Layout.

Rail anchorage details shown on this standard may require modification for select structure

(Typ)

3

types. See appropriate details elsewhere in plans for these modifications.

Provide at all interior bents without slab expansion joints.

PL

5"

Location independent of HSS rail splices.

Const Jt

Dia ASTM A307 Grade A bolts (or A36 threaded rods with one tack welded

0.557" minimum diameter with rolled threads. Nuts must conform to A563 requirements.

(Typ)

1

2"

5

8"

hex nut each) with one hex nut and one hardened steel washer at each bolt. Threaded rods may be

Dia Pin (Driving

Fit) or welded lug

(Typ)

1

2"

1

2"

1

4"

2"

1

2"

Proj

3 Spa at 6

3'

-6"

Galvanize all steel components unless otherwise shown.

fit HSS (Typ).

Provide ASTM-A500 Grade B, A1085 or A53 Grade B for all HSS. Provide ASTM-A36 for post and

Cut post to

1

2"

by grinding.

plates.

3

16"

5

16

1

16"

MATERIAL NOTES:

10

Typ

exist.

Submit shop drawings for approval when tubes are required to be fabricated to a radius. Shop

Nominal

Face of Rail

3

4"

1" R

1

16"

For curved railing applications, fabricate the HSS rail to the radius when the radius is 600' or less.

11

2 ~

Top of Slab

or Sdwlk

For all rails, submit erection drawings showing section lengths, splice locations, rail post

3

16

spacing and anchor bolt setting for approval.

Average weight of railing: 102 plf ~ Conc (with no Overlay)

Material used in forming joint may be left in place if it is

23 plf ~ Steel

compressible and light in color such as the following

#4 Bars V

SECTIONS THRU RAIL

Outside

4

Face of

1

16"

7

8"

parapet

3

4"

"

7 16

1

2"

1

2"

3

4"

10" Min ~ 1'-6" Max if turn-downs are omitted.

Top longitudinal slab bar may be adjusted laterally

4

1

2"

One shop splice per panel is permitted (with minimum

PEDESTRIAN RAIL

or single vee groove. Grind smooth.

10

11

12

Bridge

Division

Standard

1

2"

HSS 2.375 x 0.154

HSS 3.500 x 0.216

10"

TYPE PR2

HSS 1.900 x 0.145

FILE:

13

Roadway

Face of

BASE PLATE DETAIL

Max

85 percent penetration). The weld may be square groove

10"

1

4"

1

2"

4"

5

16

1

2

3

4"

3" plus or minus to tie rail reinforcing.

9

PL

Min ~

1

2"

1

8"

RAIL CAP DETAIL

1

4"

1'

-11

Same as Slab opening

1

2"

5

8"

Reinforcing bar dimensions shown are out-to-out of bar.

Dia

Drain Hole

1'

-4

1

8"

1"

1

2"

1

3

4"

5"

Dia Holes

3

8"

sheet, etc.

CIP RETAINING WALL

ON BRIDGE SLAB

13

C

L 16"

Cover dimensions are clear dimensions, unless noted otherwise.

materials: polystyrene, molded cork granules, sponge rubber

ON ABUT WING OR

at 12"(Max)

FILE:

The use of this standard is governed by the "

Texas Engineering Practice Act"

. No warranty of any

open

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

HSS ends

1

2"

DATE:

DISCLAIM ER:

Curves 2

parapet

HSS 2.875 x 0.203

C TxDOT

5

8"Dia

rlstd029.dgn

July 2014

DN:

TxDOT

CONT

SECT

CK: TxDOT

JOB

DW:

JTR

CK: TxDOT

HIGHWAY

REVISIONS

OPTIONAL U BOLT

BARS V (#4)

BARS U (#4)

DIST

COUNTY

SHEET NO.

Das könnte Ihnen auch gefallen

- 5S Diagnostic ChecklistDokument6 Seiten5S Diagnostic Checklistvikkasverma.in50% (2)

- D502Dokument5 SeitenD502Gustavo Adolfo Quintero RuizNoch keine Bewertungen

- Kant Twist Clamp AssemblyDokument6 SeitenKant Twist Clamp Assemblysuzycreamcheeze60% (5)

- Lecture 1& 2 - Cost Planning and ControlDokument13 SeitenLecture 1& 2 - Cost Planning and ControlRans-Nana Kwame-Boateng0% (1)

- Thumb Rules For Structural DesignDokument3 SeitenThumb Rules For Structural DesignRajesh Mary75% (4)

- Light Pole FoundationDokument1 SeiteLight Pole FoundationMalik Imran Shakir100% (2)

- Icbo Es Report-Er2078pDokument65 SeitenIcbo Es Report-Er2078peltorro-tNoch keine Bewertungen

- Nato Accs Loc1Dokument2 SeitenNato Accs Loc1Uv GeloviNoch keine Bewertungen

- How To Build A SupercomputerDokument8 SeitenHow To Build A SupercomputerAravind IlangoNoch keine Bewertungen

- Hand RailDokument5 SeitenHand RailpandiangvNoch keine Bewertungen

- Traffic Rail T80HT (00000002)Dokument3 SeitenTraffic Rail T80HT (00000002)BobNobbitsNoch keine Bewertungen

- Framing Guidelines PDFDokument9 SeitenFraming Guidelines PDFJase72HR100% (3)

- 02 - Design of Steel Tension MembersDokument15 Seiten02 - Design of Steel Tension MembersMagdy BakryNoch keine Bewertungen

- Br100s AllDokument15 SeitenBr100s AllgabemzamanNoch keine Bewertungen

- Chapter 4 09Dokument22 SeitenChapter 4 09zhangjlNoch keine Bewertungen

- Concrete Blocking For Convex Vertical Bends Concrete Thrust Blocking (Horizontal)Dokument10 SeitenConcrete Blocking For Convex Vertical Bends Concrete Thrust Blocking (Horizontal)chithirai10Noch keine Bewertungen

- Square and Round Concrete PilesDokument14 SeitenSquare and Round Concrete PilesngumbanNoch keine Bewertungen

- Connections and Tension Member DesignDokument9 SeitenConnections and Tension Member DesignVigneshwari MahamuniNoch keine Bewertungen

- Probset PrelimDokument45 SeitenProbset PrelimAndrea MagtutoNoch keine Bewertungen

- Connection Design - Its Role in Steel DetailingDokument9 SeitenConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.Noch keine Bewertungen

- Moment Slab For Road BarriersDokument6 SeitenMoment Slab For Road BarriersaminjolesNoch keine Bewertungen

- OMC Roller Catalog PDFDokument77 SeitenOMC Roller Catalog PDFMarco ViniciusNoch keine Bewertungen

- Reinforcing Steel ReferenceDokument19 SeitenReinforcing Steel ReferenceMary Emalaine SerranoNoch keine Bewertungen

- Design of Structural MembersDokument153 SeitenDesign of Structural Membersquiron20100% (1)

- Shaft Design and Detailing Recommendations - Pile DetailingDokument3 SeitenShaft Design and Detailing Recommendations - Pile DetailingNoli PaladNoch keine Bewertungen

- Contraction Joint Transverse Construction Joint: Top ViewDokument2 SeitenContraction Joint Transverse Construction Joint: Top ViewMuhammad Ali BhuttoNoch keine Bewertungen

- 03 - Design of Tension ConnectionsDokument23 Seiten03 - Design of Tension ConnectionsAlvin LeongNoch keine Bewertungen

- Oregon Standard Drawings: Baseline Report Date Calc. Book NoDokument1 SeiteOregon Standard Drawings: Baseline Report Date Calc. Book NoDave ThompsonNoch keine Bewertungen

- 02 - Design of Steel Tension MembersDokument15 Seiten02 - Design of Steel Tension MembersMayur PatelNoch keine Bewertungen

- PART VI, Chapter 8, DetailingDokument25 SeitenPART VI, Chapter 8, DetailingLutfor RahmanNoch keine Bewertungen

- TECHNICAL SPECIFICATIONS CONSTRUCTION RodelDokument12 SeitenTECHNICAL SPECIFICATIONS CONSTRUCTION Rodelmary joy PanamaNoch keine Bewertungen

- Typical Deck EdgeDokument1 SeiteTypical Deck EdgeShane AndersonNoch keine Bewertungen

- Column Base Plates Prof Thomas MurrayDokument83 SeitenColumn Base Plates Prof Thomas Murrayandre2008chipo100% (2)

- Concrete Sheet Pile Drawingdrawing06040Dokument4 SeitenConcrete Sheet Pile Drawingdrawing06040ASKOKONoch keine Bewertungen

- Connections Manual ErrataDokument31 SeitenConnections Manual ErratalucianduNoch keine Bewertungen

- Steel Repair SleevesDokument7 SeitenSteel Repair SleevesErickNoch keine Bewertungen

- Metal Framing ChannelDokument30 SeitenMetal Framing ChanneltylerlhsmithNoch keine Bewertungen

- Foundation Plan & DetailsDokument21 SeitenFoundation Plan & DetailsIzri AndayaNoch keine Bewertungen

- Helical PilesDokument51 SeitenHelical Pilesmateus45680% (5)

- Sheet Pile Design Criteria and NotesDokument4 SeitenSheet Pile Design Criteria and NotesJoko Sudirmanns SNoch keine Bewertungen

- Wall SystemsDokument26 SeitenWall SystemsmurdicksNoch keine Bewertungen

- Automatic Air Relief Vault Installation: 5'-0" DIAMETER 6'-0" Diameter For 42" or 48" MainsDokument2 SeitenAutomatic Air Relief Vault Installation: 5'-0" DIAMETER 6'-0" Diameter For 42" or 48" MainsDzevad HuseinovicNoch keine Bewertungen

- A2 1 16junDokument2 SeitenA2 1 16junamitrai86Noch keine Bewertungen

- Reports NotesDokument1 SeiteReports Notesnaline_psNoch keine Bewertungen

- Structural Analysis and Design Lectures PDFDokument354 SeitenStructural Analysis and Design Lectures PDFgongmaozheNoch keine Bewertungen

- Design of Steel Tension ConnectionsDokument23 SeitenDesign of Steel Tension ConnectionsKyle Doyle100% (1)

- dms1 DeadmanDokument1 Seitedms1 DeadmanEviL_TunGNoch keine Bewertungen

- Document 3Dokument32 SeitenDocument 3NUR FATINAH BINTI ZOLKIFLI 5ENoch keine Bewertungen

- 14 Box CulvertDokument18 Seiten14 Box Culvertras_deepNoch keine Bewertungen

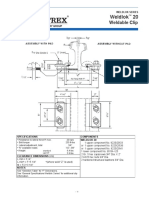

- Weldlok 20Dokument2 SeitenWeldlok 20Nicolas DelpNoch keine Bewertungen

- Engine Stand PlansDokument23 SeitenEngine Stand PlansJoey WilletNoch keine Bewertungen

- 6.design of Connections in Steel Building ConstructionDokument50 Seiten6.design of Connections in Steel Building ConstructionNovember RainNoch keine Bewertungen

- MechanicsDokument2 SeitenMechanicsNicole De Leon Miday0% (1)

- 15mm Strand Properties - VSLDokument1 Seite15mm Strand Properties - VSLenggmohanNoch keine Bewertungen

- EFX Approval DrawingDokument5 SeitenEFX Approval Drawingvenka07Noch keine Bewertungen

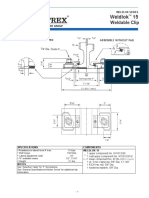

- Weldlok 15Dokument2 SeitenWeldlok 15cyper100% (1)

- Flanged Orifice Plate PDFDokument2 SeitenFlanged Orifice Plate PDFAlaa RamadanNoch keine Bewertungen

- TG13 03 Non-Standard Boarded PlatformsDokument4 SeitenTG13 03 Non-Standard Boarded PlatformsDaniel SarmientoNoch keine Bewertungen

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideVon EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNoch keine Bewertungen

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityVon EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNoch keine Bewertungen

- An Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverVon EverandAn Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverNoch keine Bewertungen

- Old 0103Dokument59 SeitenOld 0103Pablo Guillermo Coca GarabitoNoch keine Bewertungen

- Spiral Stair Installation Guide: Salter - Continuous Sleeve - Aluminum Handrail - GalvanizedDokument14 SeitenSpiral Stair Installation Guide: Salter - Continuous Sleeve - Aluminum Handrail - GalvanizedPablo Guillermo Coca GarabitoNoch keine Bewertungen

- Country Paper:: Dominican RepublicDokument101 SeitenCountry Paper:: Dominican RepublicPablo Guillermo Coca GarabitoNoch keine Bewertungen

- FormDokument2 SeitenFormPablo Guillermo Coca GarabitoNoch keine Bewertungen

- Final Report: Brazil - Case StudyDokument25 SeitenFinal Report: Brazil - Case StudyPablo Guillermo Coca GarabitoNoch keine Bewertungen

- Midterm ExamDokument1 SeiteMidterm ExamPablo Guillermo Coca GarabitoNoch keine Bewertungen

- B DP Erp Sap Hana GuideDokument84 SeitenB DP Erp Sap Hana GuideEsteban RestrepoNoch keine Bewertungen

- Readme FP SuiteDokument2 SeitenReadme FP SuiteFedericoHCNoch keine Bewertungen

- Edward Dim End Berg - From Berlin To Bunker Hill - Urban Space, Late Modernity, and Film Noir in Fritz Lang's and Joseph Losey's M - Wide Angle 19 - 4Dokument20 SeitenEdward Dim End Berg - From Berlin To Bunker Hill - Urban Space, Late Modernity, and Film Noir in Fritz Lang's and Joseph Losey's M - Wide Angle 19 - 4AnarchivistaNoch keine Bewertungen

- About Floatel An Eco-Friendly Hotel, KolkataDokument3 SeitenAbout Floatel An Eco-Friendly Hotel, KolkataSumit Thaker100% (1)

- DVR 4 Canales CNB HDF1212DVDokument1 SeiteDVR 4 Canales CNB HDF1212DVTecnoSmartNoch keine Bewertungen

- XCP or "Universal Measurement and Calibration Protocol" Is A Network ProtocolDokument2 SeitenXCP or "Universal Measurement and Calibration Protocol" Is A Network ProtocolAlejandra RodríguezNoch keine Bewertungen

- M-915a-Hum-Sal-3051 25.07.22Dokument1 SeiteM-915a-Hum-Sal-3051 25.07.22chow weng yewNoch keine Bewertungen

- Kameleo Datasheet PDFDokument3 SeitenKameleo Datasheet PDFskodgeNoch keine Bewertungen

- Skyrim Modding Guide - Something For Nobody PDFDokument8 SeitenSkyrim Modding Guide - Something For Nobody PDFlaidlajNoch keine Bewertungen

- Ice PlantDokument25 SeitenIce PlantAbenliciousNoch keine Bewertungen

- Hack GU Vol2 Sidequests + Ryu Books Code BreakerDokument2 SeitenHack GU Vol2 Sidequests + Ryu Books Code BreakertokinokaidanNoch keine Bewertungen

- Decora Interior Matt EmulsionDokument2 SeitenDecora Interior Matt EmulsionMuthuKumarNoch keine Bewertungen

- Kitchen 2015Dokument16 SeitenKitchen 2015Sushrut SalunkeNoch keine Bewertungen

- Group Policy Collection 1Dokument147 SeitenGroup Policy Collection 1Senthilkumar BalaramanNoch keine Bewertungen

- Fallout 3 Side QuestsDokument26 SeitenFallout 3 Side QuestsRachit GuptaNoch keine Bewertungen

- Beginners Guide To Successful Cardsharing PDFDokument8 SeitenBeginners Guide To Successful Cardsharing PDFhabibi_naNoch keine Bewertungen

- Office/Warehouse/ Rest Area LayoutDokument1 SeiteOffice/Warehouse/ Rest Area LayoutBNCHNoch keine Bewertungen

- This Drawing To Be Used For Rebar Placement OnlyDokument8 SeitenThis Drawing To Be Used For Rebar Placement Onlyangel crus crusNoch keine Bewertungen

- Subnetting Secrets Book 1Dokument0 SeitenSubnetting Secrets Book 1Gulshan NematovaNoch keine Bewertungen

- Dbms Mini ProjectDokument18 SeitenDbms Mini Projectsharmamms0% (3)

- MAchine and Unite States ImplementationDokument112 SeitenMAchine and Unite States ImplementationOscar Abundes GallegosNoch keine Bewertungen

- Backend XCPDokument12 SeitenBackend XCPcarver_uaNoch keine Bewertungen

- First Pages of ThesisDokument11 SeitenFirst Pages of ThesisRutu Patel50% (2)

- Spectra GL412Dokument4 SeitenSpectra GL412bbutros_317684077Noch keine Bewertungen