Beruflich Dokumente

Kultur Dokumente

Quality Standard - M & E (Plumbing & Sanitary)

Hochgeladen von

MuhammadIqbalMughalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Quality Standard - M & E (Plumbing & Sanitary)

Hochgeladen von

MuhammadIqbalMughalCopyright:

Verfügbare Formate

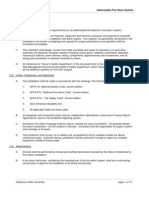

Quality Standard For : Mechanical and Electrical (M & E) Works (Plumbing and Sanitary)

OSB/WIR/F-02

Project :

Issue:2 Rev:0

Location of Structure : Ground Floor / 1st Floor / 2nd Floor / 3rd Floor / Roof

Effective Date: 1 Feb 2010

Block Number ;

Pass Inspection - To be initialled and Dated

Lot(s) Number :

Fail Inspection - To be rectified and to pass Inspection Upon Corrective Action

Drawing Ref :

ITEM

1

ELEMENT

Exposed Pipes

STANDARDS

TOLERANCE

ASSESSMENT TOOL

REMARKS

INSPECTION

(Hightlight major defects)

1. Installation

(a) Pipes properly support, bend without distostin kink

Visual

and damage

(b) Joints are watertight

Visual

(c) Pipe ends properly capped

Visual

(d) No cold water pipes below sewerage pipes

Visual

2. Alignment

(a) Horizantally, verticaly and povallel aligned to

Spirit Level and

building surface

Measuring Tape

(b) Inclined pipes laid to proper gradients

Visual

(c) Plumb 3mm per 1m height

Plumb Test and

Measuring Tape

3. Clearance

(a) Do not cause obstruction and pause safety hazard

Visual

at public area

Attended by

Inspected by

Verified by

Contractor

Technical Assistant /Project Engineer

QAQC Representative

Name :

Name :

Name :

Date :

Date :

Date :

Quality Standard For : Mechanical and Electrical (M & E) Works (Plumbing and Sanitary)

OSB/WIR/F-02

Project :

Issue:2 Rev:0

Location of Structure : Ground Floor / 1st Floor / 2nd Floor / 3rd Floor / Roof

Effective Date: 1 Feb 2010

Block Number ;

Pass Inspection - To be initialled and Dated

Lot(s) Number :

Fail Inspection - To be rectified and to pass Inspection Upon Corrective Action

Drawing Ref :

ITEM

ELEMENT

STANDARDS

TOLERANCE

(b) Sufficient clearance between installed pipes/ceiling

ASSESSMENT TOOL

REMARKS

INSPECTION

(Hightlight major defects)

Visual

and pipes/wall for accessibility

(c) Service pipe duct accessible

Visual

4. No visible damage

Water Tank

(a) Painting with good opacity and no dripping

Visual

(b) No visible damage

Visual

1. Installation

(a) All openings properly covered

Visual

(b) Joints and pipe connections are watertight

Visual

(c) Not located below swerage pipe

Visual

(d) Corrosion resistant external cat laddos provided for

Visual

cold water tank

(e) Overflow pipe to be discharged at proper location

Attended by

Visual

Inspected by

Verified by

Contractor

Technical Assistant /Project Engineer

QAQC Representative

Name :

Name :

Name :

Date :

Date :

Date :

Quality Standard For : Mechanical and Electrical (M & E) Works (Plumbing and Sanitary)

OSB/WIR/F-02

Project :

Issue:2 Rev:0

Location of Structure : Ground Floor / 1st Floor / 2nd Floor / 3rd Floor / Roof

Effective Date: 1 Feb 2010

Block Number ;

Pass Inspection - To be initialled and Dated

Lot(s) Number :

Fail Inspection - To be rectified and to pass Inspection Upon Corrective Action

Drawing Ref :

ITEM

ELEMENT

STANDARDS

(f) Well supported on plinth or beares

TOLERANCE

ASSESSMENT TOOL

Visual

2. Netting

(a) Netting properly fitted for overflow/warning/vent pipe

Visual

3. Clearances

(a) Accessible for maintenance minimum clearance

Visual

of 600m all rounded the water tank

4. No visible damage

Pump and Motor

(a) No visible damage

Visual

(b) Clean and free from debris

Visual

1. Installation

(a) No noticeable vibration and noise from pump motor

Visual

(b) Test certificate for alignment of pump and motor

Visual

from manufactory

INSPECTION

REMARKS

(Hightlight major defects)

Attended by

Inspected by

Verified by

Contractor

Technical Assistant /Project Engineer

QAQC Representative

Name :

Name :

Name :

Date :

Date :

Date :

Quality Standard For : Mechanical and Electrical (M & E) Works (Plumbing and Sanitary)

OSB/WIR/F-02

Project :

Issue:2 Rev:0

Location of Structure : Ground Floor / 1st Floor / 2nd Floor / 3rd Floor / Roof

Effective Date: 1 Feb 2010

Block Number ;

Pass Inspection - To be initialled and Dated

Lot(s) Number :

Fail Inspection - To be rectified and to pass Inspection Upon Corrective Action

Drawing Ref :

ITEM

ELEMENT

STANDARDS

TOLERANCE

ASSESSMENT TOOL

2. Electrical termination

(a) No bad/loose electrical/termination

3. No visible damage

Visual

INSPECTION

REMARKS

(Hightlight major defects)

Attended by

Inspected by

Verified by

Contractor

Technical Assistant /Project Engineer

QAQC Representative

Name :

Name :

Name :

Date :

Date :

Date :

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- 5 - Body Filler - Polyester Putty - 2019 EditionDokument2 Seiten5 - Body Filler - Polyester Putty - 2019 Editiondamax rec100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- DEP 30.10.02.13 Non-Metallic Materials - Selection and ApplicationDokument53 SeitenDEP 30.10.02.13 Non-Metallic Materials - Selection and ApplicationSergey Kichenko100% (1)

- 4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1Dokument7 Seiten4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1ABHISHEKNoch keine Bewertungen

- Minimum Load For Empty Minimum Load For OperatingDokument6 SeitenMinimum Load For Empty Minimum Load For OperatingjitendraNoch keine Bewertungen

- Astm A403Dokument7 SeitenAstm A403loretoNoch keine Bewertungen

- Atkins Construction ManagementDokument7 SeitenAtkins Construction ManagementMuhammadIqbalMughalNoch keine Bewertungen

- The City in The Islamic World Handbook of Oriental Studies Vol 1 2 PDFDokument1.521 SeitenThe City in The Islamic World Handbook of Oriental Studies Vol 1 2 PDFMuhammadIqbalMughal100% (1)

- Working Draft For CommentsDokument120 SeitenWorking Draft For CommentsMuhammadIqbalMughalNoch keine Bewertungen

- Portable Generator Wattage Chart PDFDokument1 SeitePortable Generator Wattage Chart PDFMuhammadIqbalMughal100% (1)

- Orientation Session: Board of Directors The Urban UnitDokument2 SeitenOrientation Session: Board of Directors The Urban UnitMuhammadIqbalMughalNoch keine Bewertungen

- Mosque General Design RegulationsDokument42 SeitenMosque General Design RegulationsMuhammadIqbalMughalNoch keine Bewertungen

- Emaar Dha Islamabad LimitedDokument4 SeitenEmaar Dha Islamabad LimitedMuhammadIqbalMughalNoch keine Bewertungen

- Ud2014 Submission 144Dokument9 SeitenUd2014 Submission 144MuhammadIqbalMughalNoch keine Bewertungen

- Consultant Firm Verification:: License No 1675Dokument2 SeitenConsultant Firm Verification:: License No 1675MuhammadIqbalMughalNoch keine Bewertungen

- Primaverap6v8 2session1 121213030622 Phpapp01Dokument7 SeitenPrimaverap6v8 2session1 121213030622 Phpapp01MuhammadIqbalMughalNoch keine Bewertungen

- Applied Mechanics and Graphic Statics Questions AnswersDokument15 SeitenApplied Mechanics and Graphic Statics Questions AnswersMuhammadIqbalMughalNoch keine Bewertungen

- Complete KYTC Standard Specifications - 2004Dokument618 SeitenComplete KYTC Standard Specifications - 2004MuhammadIqbalMughalNoch keine Bewertungen

- Dieless Wire Drawing-An Experimental and Numerical Analysis: P. Tiernan, M.T. HilleryDokument6 SeitenDieless Wire Drawing-An Experimental and Numerical Analysis: P. Tiernan, M.T. HillerycostytzuNoch keine Bewertungen

- NRL2 50 186yDokument3 SeitenNRL2 50 186yOnofreNoch keine Bewertungen

- Rittal Industrial Enclosure Solutions - Issue 7 5 3464 PDFDokument76 SeitenRittal Industrial Enclosure Solutions - Issue 7 5 3464 PDFyongNoch keine Bewertungen

- Cebex Cable GroutDokument4 SeitenCebex Cable GroutMohamed SalamaNoch keine Bewertungen

- IWM - Construction Material Recycling GuidebookDokument40 SeitenIWM - Construction Material Recycling GuidebookAllan HakNoch keine Bewertungen

- MultiTherm Heat Transfer Fluid BrochureDokument4 SeitenMultiTherm Heat Transfer Fluid BrochureSteranskoNoch keine Bewertungen

- Crude Storage Tanks Rev.CDokument9 SeitenCrude Storage Tanks Rev.CdhahiNoch keine Bewertungen

- Mechanical Anchoring TruBoltDokument3 SeitenMechanical Anchoring TruBoltwokeoooNoch keine Bewertungen

- Aerius VB1115 Parts Manual Rev BDokument13 SeitenAerius VB1115 Parts Manual Rev BNicola BattaglinoNoch keine Bewertungen

- HVAC Training ReportDokument47 SeitenHVAC Training ReportM samirNoch keine Bewertungen

- Oguni DomeDokument5 SeitenOguni DomeShubham PatidarNoch keine Bewertungen

- Staad Pro British ExampleDokument104 SeitenStaad Pro British ExampleCt NaSihahNoch keine Bewertungen

- TFP335 06 2016Dokument2 SeitenTFP335 06 2016Gustavo Adolfo Quintero RuizNoch keine Bewertungen

- Materials Science and Engineering by Callister Chapter 1 ReviewerDokument3 SeitenMaterials Science and Engineering by Callister Chapter 1 ReviewerTy ztickNoch keine Bewertungen

- List of Proposed Experiments For Simulation Lab Updated-30th SepDokument4 SeitenList of Proposed Experiments For Simulation Lab Updated-30th SepSachi DhanandamNoch keine Bewertungen

- SPEC Pulsatron E PLUS SeriesDokument2 SeitenSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethNoch keine Bewertungen

- Valvula Asiento Inclinado Serie E290 AscoDokument3 SeitenValvula Asiento Inclinado Serie E290 AscoBase SistemasNoch keine Bewertungen

- AstmDokument2.848 SeitenAstmNomar garciaparra67% (6)

- Updated 2/13/2020. Source: BLS: WWW - Bls.Gov/Cpi For Cpi, WWW - Bls.Gov/Ppi For Ppis WWW - Bls.Gov/Ect For EcisDokument12 SeitenUpdated 2/13/2020. Source: BLS: WWW - Bls.Gov/Cpi For Cpi, WWW - Bls.Gov/Ppi For Ppis WWW - Bls.Gov/Ect For EcisCrazyBookWormNoch keine Bewertungen

- Psychrometric Chart & Psychrometry in Air Conditioner SizingDokument8 SeitenPsychrometric Chart & Psychrometry in Air Conditioner SizingshoaibNoch keine Bewertungen

- Olear Ehv GroupDokument16 SeitenOlear Ehv GroupSRINIVAS KOMMINENINoch keine Bewertungen

- Glossary of Terms For Hollow Metal Doors and Frames: SDI Technical Data Series Industry Alert 14Dokument28 SeitenGlossary of Terms For Hollow Metal Doors and Frames: SDI Technical Data Series Industry Alert 14Г. БаянмөнхNoch keine Bewertungen

- FusesDokument8 SeitenFusesmohanNoch keine Bewertungen

- FDASDokument15 SeitenFDASPie Bernas100% (1)