Beruflich Dokumente

Kultur Dokumente

Solar Refrigeration Model

Hochgeladen von

bestmadeeasyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Solar Refrigeration Model

Hochgeladen von

bestmadeeasyCopyright:

Verfügbare Formate

solar power

KAPIL K. SAMAR, S. KOTHARI, S. JINDAL

DEPARTMENT OF RENEWABLE ENERGY ENGINEERING, MAHARANA PRATAP

UNIVERSITY OF AGRICULTURE AND TECHNOLOGY

Solar Refrigeration Model

A large number of people in developing countries still live in Rural and Remote area like India

where the grid electricity is yet unavailable or not envisaged by the people. Vaccine preservation

has become an important issue and the basic needs in rural areas. Solar power refrigeration

is the one of promising option to resolve such burning problem. This paper describes the

thermodynamic and economic results of developed solar photovoltaic panels operated 20liter

refrigerator system.

n the current situation the energy demand is increasing with increasing in

the population and improvement in the

living standard. Energy is the crucial input

to the social, economical, industrial and

technological development of any country. A rational use of energy brings both

economic and environmental benefits, by

reducing consumption of fossil fuels, electricity and pollutant emissions. The International Institute of Refrigeration in Paris

(IIF/IIR) has estimated that approximately

15% of all the electricity produced in the

whole world is employed for refrigeration

and air-conditioning processes (1). In a

tropical country, like India, refrigeration is

most widely used and generally the most

energy consuming process (2). In general,

refrigeration is defined as any process of

heat removal from a place for preserving

foods and medicines by enhancing their

shelf life (3). Immunization prevents illness,

disability and death from vaccine preventable diseases including diphtheria, measles, pertussis, pneumonia, polio, rotavirus

diarrhoea, rubella and tetanus. Immunization currently averts an estimated 2 to 3

million deaths every year but an estimated

Kapil Kumar Samar: Kapil K. Samar is working

as Research Engineer cum Programme Manager,

Biogas Development and Training Centre (BDTC),

CTAE, Udaipur. Samar has authored 3 books and 10

research paper publication.

Dr. Surendra Kothari: Dr. Surendra Kothari is

working as Professor at Department of Renewable

Energy Engineering, MPUAT, Udaipur. Dr. Kothari has

authored more than 5 books and 50 research paper

publications.

Scrap water dispenser.

22 million people from remote area of developing country worldwide are still missing out their routine vaccination programs

due to the lack in availability of the safe

vaccine (4). According to WHO guidelines,

vaccine should be kept in the temperature

range of 0-8 oC.

For the storage of life saving drugs or

vaccines in the innumerable area of the

developing country where the power supply is still irregular renewable has to be

a central part of energy solution. Out of

the various renewable sources of energy,

solar energy proves to the best candidate

for cooling because of the coincidence of

the maximum cooling load with the period

of greatest solar radiation input (5). Cooling from solar energy has great potential

for lower running costs, greater reliability

and a longer working life than other conventional cooling systems where as it may

also contribute in the reduction of global

warming.

Hwang and Redermacher (6) (2011), Kim

and Ferreira (7) (2008) broadly classified different technologies that are available to use

solar energy for refrigeration. The review

covers solar electric cooling, solar thermal

Front and back view of the refrigerator.

energtica

india

JUL15

solar power

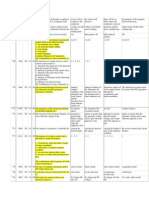

TABLE 1: TECHNICAL SPECIFICATION OF SOLAR REFRIGERATOR

S.N.

Parameters

Storage capacity

Specification

20 litres

Door

Front opening

Type of refrigeration

Vapour compression refrigeration system

pressor (Make: Godrej), a compressor used

in the common domestic refrigerators.

Technical specifications of the solar refrigerator and balance of system (BOS) for the

power supply are given in Table 1 and Table 2.

Compressor

4

Make

Godrej 90

Power consumption

90W

Refrigerant

R134a

Operating voltage

230V AC

Maximum and Minimum internal temperature

-4oC to 4oC

Thermostat

3 setting

Cut in temperature

9 oC

Cut out temperature

2 oC

Insulation

PUF, 2.5 cm thick

Dimension

371920 cm

Weight

21.2 kg

System Performance

Coefficient of performance: The coefficient of performance is an index of performance of a thermodynamic cycle or a

refrigeration system. COP is used instead

of thermal efficiency. For the vapour compression refrigeration cycle, COP is defined

as the amount of cooling produced per

unit work supplied on the refrigerant. For

a reversible or Carnot refrigeration cycle it

is expressed as (14):

TABLE 2: TECHNICAL SPECIFICATION OF THE COMPONENTS FOR THE POWER SUPPLY

S.N.

Parameters

Number of panels

Specification

3

Make

REIL, Jaipur

Max. power output

125Wp

Size of the array (LB)

1.673 meter

Battery bank

Make

5

Rocket ES7-12

No. of battery

Rated voltage

12V DC

Rating

7Ah

Type of the battery

Sealed lead acid

Inverter cum charge controller

Make

Radetron UPS

Rated capacity

1KVA

Input voltage

36V

cooling and solar combined power cooling. A comparison between these different

technologies is also described with individual COP value. M.M. Salah (8) (2006) briefly

discussed on application of solar power for

producing refrigeration effect. Possible solar power refrigeration system as discussed

are- absorption cycle, adsorption cycle, desiccant cycle, ejector cycle, solar mechanical

and solar PV operated refrigeration system.

Cooling system based on solar thermal technologies are having less thermodynamic efficiency as compare to vapour compression

refrigeration system (9) because it is very

difficult to keep the solar thermal system

operating at steady condition throughout

the day. Solar thermal based cooling systems are commercially available but mostly

having capacity of more than 20TR (10)

because solar collector cant scale down in

size. Further the small capacity of cooling

system, solar photovoltaic vapour compression refrigeration system is deemed to be

most viable route.

energetica

india

JUL15

Te = Evaporator temperature ()

To = Ambient/room temperature (

But all the real processes are irreversible

process. The actual COP of the refrigeration system was calculated with the help

of pressure enthalpy curve produced by

Hansen and Artu (Rathore et al). The COP

can be evaluated by using the formula-

Therefore an attempt has been made to

design and development of solar vapour

compression refrigeration system at the

Department of Renewable Energy Engineering, Udaipur. The principle objective

of this paper is to describe the result of

thermodynamic test conducted on the developed solar vapour compression refrigeration system.

System Description

The solar photovoltaic based refrigeration

system was designed, developed and evaluated by Department of Renewable Energy

Engineering, Udaipur (27 42 N, 75 33E)

under no load and full load conditions. A

PV panel consisting of three modules (125

Watt peak each) connected in series was

used to obtain the desired voltage and current, respectively. Three 12 V, 7 Ah sealed

lead acid battery was used to supply the

power at starting time and ensure for the

smooth operation. The refrigerator operates on an alternative current based com-

Fig.A Pressure enthalpy diagram of operating system

Photovoltaic efficiency: The efficiency of

the solar panels, defined as the ratio of the

electrical power produced to the incident

radiation.

solar power

Left, fig. 1 Cool down and warm characteristics of the refrigerator at no load condition. Right, fig. 2 Variation of solar photovoltaic exergy efficiency with time and solar

intensity during no load condition.

where

hpv = efficiency of photovoltaic system

Pmax: Maximum power from photovoltaic system (W)

S = Solar irradiance (W/m2)

Apv = Area of the photovoltaic system (m2)

Exergy analysis: Exergy is defined as the

maximum amount of work that can be

done by a system. Unlike energy, exergy is

not subject to a conservation law; exergy

is consumed or destroyed, due to the irreversibilitys present in every real process.

Photovoltaic Exergy: The energy of a PV

module depends on two major components--electrical and thermal. While electricity is generated by the PV effect, the PV

cells are also heated due to the thermal

energy present in the solar radiation. The

electricity (electrical energy), generated

by a photovoltaic system, is also termed

electrical exergy as it is the available

energy that can completely be utilized in

useful purpose. Since the thermal energy

available on the photovoltaic surface was

not utilized for a useful purpose it is considered to be a heat loss to the ambient.

Therefore, due to heat loss, it becomes exergy destruction. The exergy output of the

photovoltaic system can be calculated as:

where TSUN = temperature of the Sun taken as 5760 K

where Vm, Im hc , A ,Tcell and To are the maximum voltage and

current of the photovoltaic system, convective heat transfer coefficient from the photovoltaic cell to ambient, area

of the photovoltaic surface, cell temperature and ambient

temperature (dead state temperature), respectively.

Exergy input of the photovoltaic system,

which is the exergy of solar energy, can be

calculated approximately as below

3D view of the proposed refrigerator

Exergy efficiency of the photovoltaic system is defined as the ratio of total output

exergy (recovered) to total input exergy

(supplied). It can be expressed as

Conclusions

Energetic and Exergetic techniques helps

to evaluate the performance of the SPV

refrigerator with a view to get better information about useful work and lost

work and design some remedial techniques in future to overcome on these

losses. The installed system of solar photovoltaic refrigerator system is capable for

cooling the vaccine for 7 hour in a day.

The pull down test indicates that 375Wp

photovoltaic capacity and 21Ah battery

bank is the least possible configuration

Pictures of refrigerator. Left: Installed photovoltaic system used for the experiment. Right: Battery bank and UPS system.

energetica

india

JUL15

solar power

Left, fig. 3 Variation of energy consumption and COP with time during no load condition. Right: fig. 4 Cool down and warm characteristics of the refrigerator at full load

condition.

Fig. 5 Energy and Exergy efficiency with time and cell

temperature during full load condition.

No load and full load test pictures. Left: No load test picture. Right: Full load test picture

required for this converted system. The

average COP during no load and full load

tests were found high as 3.37. Second

law efficiency of the refrigerator system

remains close to 55% at no load full load

conditions. The photovoltaic conversion

efficiency and exergy efficiency found

nearer to 10% and 8.5% respectively in

both no load and full load condition. This

indicates that the product load condition

does not affect the PV system. The reason for low of overall efficiencies is due

to both the energy conversion efficiency

and exergy efficiency of the PV system is

low so that it can be said that exergy are

destroyed highly in PV. The payback pe-

riod of the proposed system was found

6 months.

It is suggested that the design procedure

may be improved by a variable speed compressor to cope with the variation of the

refrigeration load due to different modes

of operation. The performance curves are

shown in Fig. 1 to 5

Reference

1. Abdulateef, J.M., Sopian, K., Alghoul, M.A. and Sulaiman, M.Y. (2009). Review on

solar-driven ejector refrigeration technologies. Renewable and Sustainable Energy

Reviews. Vol. 13, issue 6-7, pages 1338-1349.

2. Modi, A., Chaudhuri, A., Vijay, B. and Mathur, A. (2010). Performance analysis

of a solar photovoltaic operated domestic refrigerator. Applied Energy 86 (2009)

25832591.

3. Rathor, N.S. and Panwar, N.L. (2010). Performance Evaluation of Solar Photovoltaic Refrigerating System. IE(I) Journal- ID. Volume 90. Page No. 15-16

4. Immunization coverage, World Health Organization (WHO), Fact sheet No. 378,

Date 14 October 2013

5. Syed A.M. S., Maged A.I. E., Muhammad U. S., (2012). Alternative designs for

a 24-h operating solar-powered absorption refrigeration technology. International

Journal of Refrigeration Vol. 35 (2012) Page No. 1967 to 1977.

6. Hwang,Y., Radermacher, R., Alili, A.A. and Kubo, I. (2011). Review of Solar Cooling Technologies. HVAC&R Research, 14:3, 507-528.

7. Kim, D.S. and Infante, C.A.F. (2007). Solar refrigeration options-a state-of-the-art

review Elsevier. International Journal of refrigeration. 31. 13-15.

8. Salah, M.M. (2006). Solar Refrigeration and Power Generation- an Overview. International Conference on Energy and Environment.

9. Solar-powered refrigeration system by National Aeronautics and Space Administration (NASA). Pintable Brochure (2009).Website- http://www.fuentek.com/technologies/Solar-Refrigerator/Solar-Powered-Refrigeration-TOP-2009.pdf. (Access

Date- 04/04/2012)

10. Technical bulletin CSIR News on Development of solar adsorption refrigeration

system at CMERI, Durgapur. Vol 61. No. 1&. 2011.

11. Khurmi, R.S. and Gupta, J.K. A text book of refrigeration and air conditioning.

Fifth edition. 2011. Eurasiya Publishing House (P) Ltd. New Delhi.

12. Bolaji, B.O., Akintunde, M.A. and Falade, T.O. (2011) Comparative Analysis of

Performance of Three Ozone-Friends HFC Refrigerants in a Vapour Compression

Refrigerator. Journal of Sustainable Energy & Environment, 2, 61-64.

energetica

india

JUL15

13. Dalkilic, A.S. and Wongwises, S. (2010) A performance comparison of vapourcompression refrigeration system using various alternative refrigerants. International Communications in Heat and Mass Transfer. 3, 13401349.

14. Thomachan A. Kattakayam and Srinivasan, K. (1999). Thermal performance characterization of a photovoltaic driven domestic refrigerator. International Journal of

Refrigeration 23 (2000) 190-196.

15. Axaopoulos, P.J. and Theodoridis, M.P. (2009). Design and experimental performance of a PV Ice-maker without battery. Solar Energy, 83:1360-1369.

16. Mehmet A.A. Experimental study of a multi-purpose PV-refrigerator system. International Journal of Physical Sciences Vol. 6(4), pp. 746-757, 18 February, 2011

17. Hepbasli, A. (2006). A key review on exergetic analysis and assessment of renewable energy resources for a sustainable future. Renewable and Sustainable Energy

Reviews. 12 (2008)593-661.

18. Yumruta, R., Mehmet, K. and Mehmet, K. (2002). Exergy analysis of vapor compression refrigeration systems. Exergy an International Journal. Volume 2. Issue

4. Pages 266-272.

19. Ekren and Yilanci. Experimental Performance Evaluation of a PV-Powered Refrigeration System. http://www.eejournal.ktu.lt/index.php/elt/article/view/684/897.

Assess on 10 October 2012.

20. Reddy, S. V. Kaushik, S.C. and Panwar N.L. Exergetic Analysis of a vapour compression refrigeration system with R134a, R143a, R152a, R404A, R407C, R410A,

R502 and R507A. Clean Technologies and Environmental Policy. DOI 10.1007/

s10098-011-0374-0

21. Chetan Singh Solanki. Solar Photovoltaic, Fundamentals, Technology and Applications Second edition. PHI Learning Pvt. Ltd. New-Delhi.

22. Desidari, U., Proietti, S. and Sdringola, P. (2009) Solar-powered cooling system:

Technical and economic on industrial refrigeration and air-conditioning applications. Applied Energy 86 (2009) Pg. No. 1376-1386

Das könnte Ihnen auch gefallen

- 2 67 1633416444 15ijmperdoct202115Dokument10 Seiten2 67 1633416444 15ijmperdoct202115TJPRC PublicationsNoch keine Bewertungen

- Analysis of Energy, Exergy, Environmental, and Economics (4E) On Photovoltaic-Thermal Collector SystemDokument15 SeitenAnalysis of Energy, Exergy, Environmental, and Economics (4E) On Photovoltaic-Thermal Collector SystemafshooabadaniNoch keine Bewertungen

- Solar RefrigeratorDokument5 SeitenSolar RefrigeratorJournalNX - a Multidisciplinary Peer Reviewed JournalNoch keine Bewertungen

- Design of A Solar Organic Rankine Cycle Prototype For 1 KW Power OutputDokument11 SeitenDesign of A Solar Organic Rankine Cycle Prototype For 1 KW Power Outputshilpi duttaNoch keine Bewertungen

- Performance Evaluation of Solar Photovoltaic / Thermal (PV/T) SystemDokument6 SeitenPerformance Evaluation of Solar Photovoltaic / Thermal (PV/T) SystemTana AzeezNoch keine Bewertungen

- Mr. SatishGhorpade IJTEsolarefficiencyimprovementDokument12 SeitenMr. SatishGhorpade IJTEsolarefficiencyimprovementBoyM BeaterNoch keine Bewertungen

- A New Design of PV Storage Solar CollectorDokument6 SeitenA New Design of PV Storage Solar CollectorSPE Baghdad sectionNoch keine Bewertungen

- Passive Cooling On The Performance of Photovoltaic Solar Panels Operating in Extremely Hot WeatherDokument14 SeitenPassive Cooling On The Performance of Photovoltaic Solar Panels Operating in Extremely Hot WeatherAnonymous pKuPK3zUNoch keine Bewertungen

- Small Hybrid Solar Power System: M. Kane, D. Larrain, D. Favrat, Y. AllaniDokument17 SeitenSmall Hybrid Solar Power System: M. Kane, D. Larrain, D. Favrat, Y. AllaniAbhi BNoch keine Bewertungen

- Turnitin Hasil Perbaikan Sementara Terhadap Jurnal IjepedsDokument16 SeitenTurnitin Hasil Perbaikan Sementara Terhadap Jurnal IjepedsAsri, S.T., MT Asri, S.T., MTNoch keine Bewertungen

- A Comparative Study of Solar Cooling Technologies: Beethoven Narváez-RomoDokument7 SeitenA Comparative Study of Solar Cooling Technologies: Beethoven Narváez-RomokunjNoch keine Bewertungen

- Integrated Solar Power Plants (ISCC)Dokument13 SeitenIntegrated Solar Power Plants (ISCC)carzanteNoch keine Bewertungen

- Int. J. Low Carbon Tech. 2011 Palmero Marrero 309 17Dokument9 SeitenInt. J. Low Carbon Tech. 2011 Palmero Marrero 309 17andy131078Noch keine Bewertungen

- Performance Evaluation of Photovoltaic System Designed For DC RefrigeratorDokument6 SeitenPerformance Evaluation of Photovoltaic System Designed For DC RefrigeratorndoyeNoch keine Bewertungen

- E3sconf Asee2017 00205Dokument11 SeitenE3sconf Asee2017 00205sabhanNoch keine Bewertungen

- Final Project ReportDokument15 SeitenFinal Project ReportHarishNoch keine Bewertungen

- Energies: Energy Performance of An Encapsulated Phase Change Material PVDokument16 SeitenEnergies: Energy Performance of An Encapsulated Phase Change Material PVRasha KaNoch keine Bewertungen

- Design and Simulation of A Low Concentrating Photovoltaic/thermal SystemDokument13 SeitenDesign and Simulation of A Low Concentrating Photovoltaic/thermal SystemRanjit Singh Sarban SinghNoch keine Bewertungen

- Experimental Investigation On Solar Photovoltaic Driven Cool Thermal Storage System For The Development of Sustainable Micro Grid in Building SectorsDokument11 SeitenExperimental Investigation On Solar Photovoltaic Driven Cool Thermal Storage System For The Development of Sustainable Micro Grid in Building SectorsRa muNoch keine Bewertungen

- Exergetic Performance Assessment of An IDokument12 SeitenExergetic Performance Assessment of An IJuan JerezNoch keine Bewertungen

- Temperature On PV Module Performance and Its Latest Mitigation Techniques: A ReviewDokument8 SeitenTemperature On PV Module Performance and Its Latest Mitigation Techniques: A ReviewVelumani sNoch keine Bewertungen

- Experimental Investigation of Thermoelectric Refrigeration System Running On Solar Energy and Development of Mathematical ModelDokument7 SeitenExperimental Investigation of Thermoelectric Refrigeration System Running On Solar Energy and Development of Mathematical Modelankita awasthiNoch keine Bewertungen

- An Electrical Analog of A Flat-Plate Solar Water Heating SystemDokument4 SeitenAn Electrical Analog of A Flat-Plate Solar Water Heating SystemChih-yuan WengNoch keine Bewertungen

- Experimental and Numerical Investigation of Photo-Voltaic Module Performance Via Continuous and Intermittent Water Cooling TechniquesDokument12 SeitenExperimental and Numerical Investigation of Photo-Voltaic Module Performance Via Continuous and Intermittent Water Cooling TechniquesIAEME PublicationNoch keine Bewertungen

- Journal Pre-Proofs: Applied Thermal EngineeringDokument48 SeitenJournal Pre-Proofs: Applied Thermal EngineeringDaniyal Poureyvaz BorazjaniNoch keine Bewertungen

- Experiment Study of Water Based Photovoltaic-Thermal (PV/T) CollectorDokument8 SeitenExperiment Study of Water Based Photovoltaic-Thermal (PV/T) CollectorYulia FithryNoch keine Bewertungen

- Energy: Yusuf Bicer, Ibrahim DincerDokument10 SeitenEnergy: Yusuf Bicer, Ibrahim DincerMuhammad OsamaNoch keine Bewertungen

- Modelling and Analysis of Thermo Electric Cooler Module Using AnsysDokument10 SeitenModelling and Analysis of Thermo Electric Cooler Module Using AnsysTJPRC PublicationsNoch keine Bewertungen

- Research Paper On Solar Power Air ConditioningDokument8 SeitenResearch Paper On Solar Power Air Conditioningipkpzjbkf100% (1)

- Numerical-Simulation and Experimental-Validation of The Largest Egyptian Solar Process-Heat SystemDokument18 SeitenNumerical-Simulation and Experimental-Validation of The Largest Egyptian Solar Process-Heat Systemgazali belhajNoch keine Bewertungen

- Experimental Investigation of PV PanelDokument8 SeitenExperimental Investigation of PV PanelGanapathi RNoch keine Bewertungen

- The Technology Resource For PV Professionals: Seventeenth EditionDokument8 SeitenThe Technology Resource For PV Professionals: Seventeenth EditionBalajiNoch keine Bewertungen

- Taqwa 2020 J. Phys. Conf. Ser. 1500 012013Dokument11 SeitenTaqwa 2020 J. Phys. Conf. Ser. 1500 012013Mauricio Neut SantosNoch keine Bewertungen

- Experimental Study On The Thermal Performance of SDokument6 SeitenExperimental Study On The Thermal Performance of SSagarNoch keine Bewertungen

- Performance Analysis of Vapour Compression and Vapour Absorption Refrigeration Units Working On Photovoltaic Power SupplyDokument10 SeitenPerformance Analysis of Vapour Compression and Vapour Absorption Refrigeration Units Working On Photovoltaic Power SupplygamailkabaaaapNoch keine Bewertungen

- Solar Receivers for Thermal Power Generation: Fundamentals and Advanced ConceptsVon EverandSolar Receivers for Thermal Power Generation: Fundamentals and Advanced ConceptsNoch keine Bewertungen

- Jten 2021 7 4.5062Dokument15 SeitenJten 2021 7 4.5062putrastevanofyNoch keine Bewertungen

- Manuscript Khaled Et Al Cooling PVDokument15 SeitenManuscript Khaled Et Al Cooling PVthakkar.futureNoch keine Bewertungen

- Batch 2Dokument12 SeitenBatch 2venkatesaperumal eNoch keine Bewertungen

- Performance Analysis of Innovative Top Cooling Thermal Photovoltaic (TPV) Modules Under TropicsDokument5 SeitenPerformance Analysis of Innovative Top Cooling Thermal Photovoltaic (TPV) Modules Under Tropicsdung nguyenNoch keine Bewertungen

- Solar Powered Automatic Cabin Cooling SystemDokument18 SeitenSolar Powered Automatic Cabin Cooling SystemGRD JournalsNoch keine Bewertungen

- Evaluation of Single-Pass Photovoltaic-Thermal Air Collector With Rectangle Tunnel AbsorberDokument6 SeitenEvaluation of Single-Pass Photovoltaic-Thermal Air Collector With Rectangle Tunnel Absorbersilent1000Noch keine Bewertungen

- Ijisetr S 1 2020Dokument5 SeitenIjisetr S 1 2020Adeleke AyobamiNoch keine Bewertungen

- Zhijun Peng, Mohammad R Herfatmanesh, Yiming Liu: Cooled Solar PV Panels For Output Energy Efficiency OptimisationDokument18 SeitenZhijun Peng, Mohammad R Herfatmanesh, Yiming Liu: Cooled Solar PV Panels For Output Energy Efficiency OptimisationArtie MandiNoch keine Bewertungen

- Zulakmal 2019 IOP Conf. Ser. Earth Environ. Sci. 268 012120Dokument11 SeitenZulakmal 2019 IOP Conf. Ser. Earth Environ. Sci. 268 012120Mainul HossainNoch keine Bewertungen

- Peltier Enabled Dual Purpose Thermo-Electric Solar Refrigerator - A SurveyDokument5 SeitenPeltier Enabled Dual Purpose Thermo-Electric Solar Refrigerator - A Surveyprajwal gowdaNoch keine Bewertungen

- Steady-State Analysis of Four Effects EvaporationDokument6 SeitenSteady-State Analysis of Four Effects Evaporationrando methinguscribdNoch keine Bewertungen

- 1 s2.0 S0038092X20305491 MainDokument9 Seiten1 s2.0 S0038092X20305491 MainAhmed HazemNoch keine Bewertungen

- 689-Article Text-1873-1-10-20221005Dokument9 Seiten689-Article Text-1873-1-10-20221005Nur Fadhil SaputraNoch keine Bewertungen

- Solar Stirling EngineDokument23 SeitenSolar Stirling EngineDnalzir MontanteNoch keine Bewertungen

- Battery Charging Application With Thermoelectric Generators As Energy HarvestersDokument12 SeitenBattery Charging Application With Thermoelectric Generators As Energy HarvestersIEREKPRESSNoch keine Bewertungen

- Energy and Exergy Analysis of An Organic Rankine CycleDokument10 SeitenEnergy and Exergy Analysis of An Organic Rankine Cyclekamy_8524Noch keine Bewertungen

- A Novel Hybrid Solar Ejector Cooling System With Thermoelectric GeneratorsDokument17 SeitenA Novel Hybrid Solar Ejector Cooling System With Thermoelectric Generatorsmbt2004Noch keine Bewertungen

- 4 Double Effect Solar Absorption Thermal Energy StorageDokument17 Seiten4 Double Effect Solar Absorption Thermal Energy StoragehawxflyNoch keine Bewertungen

- ANovel Hybrid Solar System Using NanofluidDokument6 SeitenANovel Hybrid Solar System Using NanofluidMihaela IleniNoch keine Bewertungen

- Ocean ThermalDokument10 SeitenOcean ThermalTienRienNoch keine Bewertungen

- Research Article New Design of Solar Photovoltaic and Thermal Hybrid System For Performance Improvement of Solar PhotovoltaicDokument6 SeitenResearch Article New Design of Solar Photovoltaic and Thermal Hybrid System For Performance Improvement of Solar PhotovoltaicafshooabadaniNoch keine Bewertungen

- Ijaret: ©iaemeDokument15 SeitenIjaret: ©iaemeIAEME PublicationNoch keine Bewertungen

- Simulation Based Intelligent Water CoolingDokument10 SeitenSimulation Based Intelligent Water CoolingnivamNoch keine Bewertungen

- Modeling and Design of Hybrid Power Plants: Ahmed KH A. E. AlkhezimDokument5 SeitenModeling and Design of Hybrid Power Plants: Ahmed KH A. E. AlkhezimIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNoch keine Bewertungen

- 15 Nov 1993 Male SC No: Communication Address GATE Exam DetailsDokument1 Seite15 Nov 1993 Male SC No: Communication Address GATE Exam DetailsbestmadeeasyNoch keine Bewertungen

- Fluid MachineDokument53 SeitenFluid MachineVineet K. MishraNoch keine Bewertungen

- New 3Dokument9 SeitenNew 3bestmadeeasyNoch keine Bewertungen

- 1 1 Welding Q A For StudentsDokument10 Seiten1 1 Welding Q A For StudentsRavinder Antil100% (4)

- Design and Performance Analysis of A Solarthermal Assisted Vapour Absorption Airconditioning SystemDokument7 SeitenDesign and Performance Analysis of A Solarthermal Assisted Vapour Absorption Airconditioning SystembestmadeeasyNoch keine Bewertungen

- 2.2 Force, Power in Metal Cutting Q&A For Student DD PDFDokument7 Seiten2.2 Force, Power in Metal Cutting Q&A For Student DD PDFbestmadeeasyNoch keine Bewertungen

- News PapDokument1 SeiteNews PapbestmadeeasyNoch keine Bewertungen

- Syllabus GATE 2016Dokument14 SeitenSyllabus GATE 2016bestmadeeasyNoch keine Bewertungen

- 15 Nov 1993 Male SC No: Communication Address GATE Exam DetailsDokument1 Seite15 Nov 1993 Male SC No: Communication Address GATE Exam DetailsbestmadeeasyNoch keine Bewertungen

- Mahindra Gears Transmiision Training ReportDokument32 SeitenMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- Engmech-Script 2012 PDFDokument80 SeitenEngmech-Script 2012 PDFbestmadeeasyNoch keine Bewertungen

- Procedure For Payment of Application Fee: 1. Tick The Check Box and Click ButtonDokument4 SeitenProcedure For Payment of Application Fee: 1. Tick The Check Box and Click ButtonbestmadeeasyNoch keine Bewertungen

- List of Defective Applications As On 14.10.2015Dokument296 SeitenList of Defective Applications As On 14.10.2015bestmadeeasyNoch keine Bewertungen

- Uptu SyllabusDokument74 SeitenUptu SyllabusKhalid AnwarNoch keine Bewertungen

- Gemi 201516 1Dokument13 SeitenGemi 201516 1bestmadeeasyNoch keine Bewertungen

- Sand CastingDokument31 SeitenSand CastingRodrigo Cruces100% (1)

- Amarujala 06jan2013Dokument1 SeiteAmarujala 06jan2013bestmadeeasyNoch keine Bewertungen

- GateDokument1 SeiteGatebestmadeeasyNoch keine Bewertungen

- Smirk in The FacadeDokument4 SeitenSmirk in The FacadebestmadeeasyNoch keine Bewertungen

- Up CPMT Paper 1 2009Dokument16 SeitenUp CPMT Paper 1 2009bestmadeeasyNoch keine Bewertungen

- (Annexure I) AdvertisementDokument4 Seiten(Annexure I) Advertisementaravindhana1a1Noch keine Bewertungen

- Advertisment Instrumentation Engineer On ContractDokument2 SeitenAdvertisment Instrumentation Engineer On ContractbestmadeeasyNoch keine Bewertungen

- Important Topics For GATE by SK MondalDokument4 SeitenImportant Topics For GATE by SK MondalBenevant Mathew100% (13)

- Uptu Exam DatesDokument97 SeitenUptu Exam DatesKnucasior BichNoch keine Bewertungen

- HCL Exe Rec 2015Dokument6 SeitenHCL Exe Rec 2015bestmadeeasyNoch keine Bewertungen

- 2df064e2-Merged Document 2Dokument7 Seiten2df064e2-Merged Document 2bestmadeeasyNoch keine Bewertungen

- Advt 310315Dokument5 SeitenAdvt 310315bestmadeeasyNoch keine Bewertungen

- Vajiram-Developmental Policies IssuesDokument58 SeitenVajiram-Developmental Policies IssuesJallaluddinAkbarNoch keine Bewertungen

- Ethanol Blending ProgrammeDokument2 SeitenEthanol Blending ProgrammebestmadeeasyNoch keine Bewertungen

- AD353-132 r1Dokument9 SeitenAD353-132 r1Hrishikesh RokadeNoch keine Bewertungen

- Seminar Presentation On Micro Power GeneratorDokument25 SeitenSeminar Presentation On Micro Power GeneratorDev Kumar100% (5)

- 021Dokument1 Seite021sollyy1971Noch keine Bewertungen

- Training Session 1 Gas Turbine Basics: by Jim Noordermeer, P.Eng. Gryphon International Engineering Services IncDokument24 SeitenTraining Session 1 Gas Turbine Basics: by Jim Noordermeer, P.Eng. Gryphon International Engineering Services IncM Azri Zulkipli100% (1)

- IIAR Ammonia Refrigeration Piping HandbookDokument5 SeitenIIAR Ammonia Refrigeration Piping HandbookALFONSO THAWENoch keine Bewertungen

- Nuclear Power: Dr. M. SubramanianDokument33 SeitenNuclear Power: Dr. M. SubramanianNkugwa Mark WilliamNoch keine Bewertungen

- Hydraulic Filter CFMEDokument2 SeitenHydraulic Filter CFMEAhmadFadzliNoch keine Bewertungen

- 10.0 Pump Design & Pump System Design Preface: Bechtel ConfidentialDokument54 Seiten10.0 Pump Design & Pump System Design Preface: Bechtel ConfidentialCristhianNoch keine Bewertungen

- TSPL-OPN-SOP-Aux BoilerDokument9 SeitenTSPL-OPN-SOP-Aux Boilersourav mahapatraNoch keine Bewertungen

- Status of Innovative Small and Medium Sized Reactor Designs 2005Dokument712 SeitenStatus of Innovative Small and Medium Sized Reactor Designs 2005Myo ThihaNoch keine Bewertungen

- Module 3.1 HD Single-Stage Compressor TMS CARDIFF - en 2014 - Rev02 PDFDokument51 SeitenModule 3.1 HD Single-Stage Compressor TMS CARDIFF - en 2014 - Rev02 PDFiuliiulian50% (2)

- 2c ECOTHERM Shower Water ChillerDokument8 Seiten2c ECOTHERM Shower Water ChillerVocansonNoch keine Bewertungen

- Lab B Che 247Dokument9 SeitenLab B Che 247Muhd FirdausNoch keine Bewertungen

- Low Energy Consumption Ammonia Production 2011 Paper PDFDokument14 SeitenLow Energy Consumption Ammonia Production 2011 Paper PDFKailash NarainNoch keine Bewertungen

- Online Certification Program: Installation & Working of Solar Power PlantsDokument5 SeitenOnline Certification Program: Installation & Working of Solar Power PlantsSarath Chandra VNoch keine Bewertungen

- Dwg. No.10 - 42 20 DN002 - ERDokument4 SeitenDwg. No.10 - 42 20 DN002 - ERSean Chen GyarinoNoch keine Bewertungen

- Technical Information Letter: TIL1365-2 Ge Energy Services Product Service 21 OCTOBER 2002Dokument3 SeitenTechnical Information Letter: TIL1365-2 Ge Energy Services Product Service 21 OCTOBER 2002Chidiebere Samuel OkogwuNoch keine Bewertungen

- Daikin Altherma 3 H EPGA-D 11-14-16 KW: Product Catalogue 2020Dokument40 SeitenDaikin Altherma 3 H EPGA-D 11-14-16 KW: Product Catalogue 2020wiwiNoch keine Bewertungen

- NEM326 HW 1 PDFDokument2 SeitenNEM326 HW 1 PDFyaprak dönerNoch keine Bewertungen

- 9 Cooling SystemDokument11 Seiten9 Cooling SystemMehar Tariq GoheerNoch keine Bewertungen

- Pang Malakasang Pipe RefresherDokument478 SeitenPang Malakasang Pipe Refresheraljay balingitNoch keine Bewertungen

- Turgo Spear Nozzle DesignDokument15 SeitenTurgo Spear Nozzle DesignCliff smythNoch keine Bewertungen

- BCP Technical & Operating DataDokument24 SeitenBCP Technical & Operating DataKrishnan SanthanarajNoch keine Bewertungen

- Appendix - D Hydroulic Calculation For New Booster Pumps Unit 4-5-6 Rev A1Dokument2 SeitenAppendix - D Hydroulic Calculation For New Booster Pumps Unit 4-5-6 Rev A1Elias EliasNoch keine Bewertungen

- Engine Reviewer Oic 2015Dokument64 SeitenEngine Reviewer Oic 2015Freddie Ven P Cortan100% (5)

- Hosereel SystemDokument5 SeitenHosereel Systemrmaffireschool100% (3)

- DRRR - Infographic By: Langala and RobiatoDokument1 SeiteDRRR - Infographic By: Langala and RobiatoPan panorNoch keine Bewertungen

- TurbomDokument2 SeitenTurbomjuchaca36Noch keine Bewertungen

- Solar Based Air Compressor Pump For Car, Bike Tire Inflate: AbstractDokument2 SeitenSolar Based Air Compressor Pump For Car, Bike Tire Inflate: AbstractArpan BariaNoch keine Bewertungen

- Design Features Puffer Interrupters: Contact PartingDokument1 SeiteDesign Features Puffer Interrupters: Contact PartingDoan Anh TuanNoch keine Bewertungen