Beruflich Dokumente

Kultur Dokumente

TAP Quik Cast B-1gal 23028

Hochgeladen von

arieza.perdhana82330 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten1 SeiteAP Quik Cast B-1gal 23028

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAP Quik Cast B-1gal 23028

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten1 SeiteTAP Quik Cast B-1gal 23028

Hochgeladen von

arieza.perdhana8233AP Quik Cast B-1gal 23028

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

PHYSICAL PROPERTIES OF CURED RESIN

TAP Plastics

Quik-Cast Side B

Color: White

Peak Exotherm: 170F

Shrinkage: .01inin

A water thin liquid that picks up minute

detaildown to a fingerprint.

Quik-Cast can be machined when cured. It can

be turned, drilled, ground, and sanded.

Quik-Cast can be filled with microspheres,

bronze powder, pigment, etc. to create a wide

variety of weights, surface finishes, and

patterns.

KEEP OUT OF REACH OF CHILDREN.

FIRST AID:

SKIN Remove contaminated clothing. Wash

exposed area thoroughly with warm soapy

water. Contaminated clothing should be properly

laundered before reusing. Not considered to

have any adverse effects.

EYE Flush with clean, lukewarm water at low

pressure for at least 15 minutes, occasionally

lifting eyelids. Not considered to have any

adverse effects.

INGESTION Induce vomiting. Never give

anything to drink to an unconscious person or

induce vomiting in an unconscious person. Not

considered to have adverse effects.

INHALATION Remove victim from area of

exposure to safe area. Not considered to have

any adverse effects.

Rev. 6/14/11

WARRANTY

TAP Products are manufactured to quality specifications

but should be tested to determine their suitability for your

application. Because we have no control over working

conditions or methods, our liability does not exceed the

value or replacement of this product. TAP Resin products

are guaranteed for six months from date of purchase or

nine months from code date on container.

Shore Hardness: D60-70

Pot Life: 3 to 4 minutes

SEE INSTRUCTIONS FOR QUIK-CAST ON PART A.

TIPS FOR USING QUIK-CAST: Read CAUTIONS (on side

label) and Instructions before starting project. Measure by

volume, not weight. Tolerates a 5% to 10% variation. Wear

eye protection and gloves when mixing. Performs best at

75-80F and performs faster at higher temperature (shorter

working time). A lower temperature of the resin, mold, or

room may slow or adversely affect the casting. The A

component is temperature critical and may separate under

low temperatures. Warm to 70F or above for best results.

When using TAP Color Pigment, disperse into a small

quantity of Side B. Add this mixture to balance of Side B

and mix again. Next pour Side A and Side B into container

and mix thoroughly. See Instructions on Side A to continue.

CASTING RESIN

Opaque Fast Curing

One-to-One Mix Ratio

SIDE B

Net 1 Gallon 128 fl oz

Use with 1 Gallon Quik-Cast Side A

Quality Products Since 1952

TAP Plastics Inc. San Leandro, CA 94577

the fantastic plastic place www.tapplastics.com

When using filler, add equal amounts to Parts A and B in

separate containers before combining sides. Porous,

absorbent-type fillers are not suitable because liquids

absorbed in the filler do not combine with other liquids.

Fillers containing moisture will cause bubbles in final

product.

De-mold time is 10-15 minutes depending on volume,

temperature, etc. Cool on paper, wood or an insulated

surface. A large molded part cooled on metal or glass may

warp. Part can be trimmed with a knife when it first comes

out of the mold. It fully cures in 36 hours. Moisture can

affect Quik-Cast. It may cause the liquids to separate and a

slight foaming (rising) reaction to occur. After pouring,

reseal containers to prevent moisture contamination and

shorter shelf life.

Pol-Ease 2300 or Rocket Release are recommended

releases for Quik Cast. Use a barrier coat when painting

and to prolong life of mold. Use mold release when casting

with TAP Urethane RTV System or TAP Premium Liquid

Latex Rubber. Paint parts to be used outdoors. Finished

parts exposed to sunlight will yellow. Remove mold release

before painting.

See Tips for Using Quik-Cast on Part B.

For more information, read TAP Product Bulletins 7A, 7B and 7C.

Date Code: 23028

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- H870X Is005Dokument1 SeiteH870X Is005arieza.perdhana8233Noch keine Bewertungen

- Pattern Boys Short-Sleeve Shirt PDFDokument2 SeitenPattern Boys Short-Sleeve Shirt PDFarieza.perdhana8233Noch keine Bewertungen

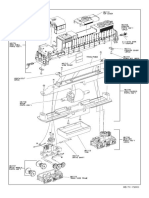

- Ho Birney Street Car Exploded Drawing h802xDokument1 SeiteHo Birney Street Car Exploded Drawing h802xarieza.perdhana8233Noch keine Bewertungen

- Ho Birney Street Car Exploded Drawing h802xDokument1 SeiteHo Birney Street Car Exploded Drawing h802xarieza.perdhana8233Noch keine Bewertungen

- Ho Birney Street Car Exploded Drawing h802xDokument1 SeiteHo Birney Street Car Exploded Drawing h802xarieza.perdhana8233Noch keine Bewertungen

- H870X Is005 PDFDokument1 SeiteH870X Is005 PDFarieza.perdhana8233Noch keine Bewertungen

- Gp-38 Dummy Diesel Locomotive InstructionsDokument4 SeitenGp-38 Dummy Diesel Locomotive Instructionsarieza.perdhana8233Noch keine Bewertungen

- www.ebook777.com.txtDokument1 Seitewww.ebook777.com.txtarieza.perdhana8233Noch keine Bewertungen

- Active Rfid in School Attendance System - Buy Active Rfid, School Attendance System Rfid, Attendance System Product On Alibaba PDFDokument6 SeitenActive Rfid in School Attendance System - Buy Active Rfid, School Attendance System Rfid, Attendance System Product On Alibaba PDFarieza.perdhana8233Noch keine Bewertungen

- H617X Is001Dokument1 SeiteH617X Is001arieza.perdhana8233Noch keine Bewertungen

- Tarif Impor - Respatindo PDFDokument2 SeitenTarif Impor - Respatindo PDFarieza.perdhana8233Noch keine Bewertungen

- Etching PCBs With Press'n'PeelDokument20 SeitenEtching PCBs With Press'n'Peelarieza.perdhana8233Noch keine Bewertungen

- Map of Waterbom Bali ParkDokument1 SeiteMap of Waterbom Bali ParkDiane MoutranNoch keine Bewertungen

- Aluminum Powder PDFDokument5 SeitenAluminum Powder PDFarieza.perdhana8233Noch keine Bewertungen

- Us 6417315Dokument6 SeitenUs 6417315arieza.perdhana8233Noch keine Bewertungen

- PQ Formulary PDFDokument16 SeitenPQ Formulary PDFjcriveroNoch keine Bewertungen

- BW 4.8 Installation NotesDokument18 SeitenBW 4.8 Installation NotesQamar SiddiqueNoch keine Bewertungen

- Journal Journal of Fire Sciences 2000 456Dokument28 SeitenJournal Journal of Fire Sciences 2000 456arieza.perdhana8233Noch keine Bewertungen

- Brochure Generalite S GBDokument22 SeitenBrochure Generalite S GBarieza.perdhana8233Noch keine Bewertungen

- DIY Hydrogen GeneratorDokument33 SeitenDIY Hydrogen Generatorarieza.perdhana8233Noch keine Bewertungen

- DIY Making Beeswax Polish For FurnitureDokument10 SeitenDIY Making Beeswax Polish For Furniturearieza.perdhana8233Noch keine Bewertungen

- How To Make PH IndicatorDokument13 SeitenHow To Make PH Indicatorarieza.perdhana8233Noch keine Bewertungen

- DIY Bio PlasticsDokument16 SeitenDIY Bio Plasticsarieza.perdhana8233Noch keine Bewertungen

- DIY Heavy Duty RackDokument20 SeitenDIY Heavy Duty Rackarieza.perdhana8233Noch keine Bewertungen

- Disc SanderDokument21 SeitenDisc Sanderarieza.perdhana8233Noch keine Bewertungen

- DIY Arduino Controlled Egg-BotDokument25 SeitenDIY Arduino Controlled Egg-Botarieza.perdhana8233100% (1)

- Build A Multi-Voltage Portable Power Supply You Can Take AnywhereDokument14 SeitenBuild A Multi-Voltage Portable Power Supply You Can Take Anywherearieza.perdhana8233Noch keine Bewertungen

- Cool A Drink in 2 MinutesDokument15 SeitenCool A Drink in 2 Minutesarieza.perdhana8233Noch keine Bewertungen

- Control A Computer With Your Mind!Dokument26 SeitenControl A Computer With Your Mind!arieza.perdhana8233Noch keine Bewertungen

- Copy A Key in MinutesDokument11 SeitenCopy A Key in Minutesarieza.perdhana8233Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Sample BQ TNB Double ChamberDokument14 SeitenSample BQ TNB Double ChamberrokiahhassanNoch keine Bewertungen

- Gic AdvancesDokument3 SeitenGic Advancesrahul sharmaNoch keine Bewertungen

- Freund Product BroschDokument24 SeitenFreund Product Broscheternal_harpyNoch keine Bewertungen

- TCN-01 B1206Dokument23 SeitenTCN-01 B1206Riya AgarwalNoch keine Bewertungen

- TTT DiagramDokument31 SeitenTTT DiagramEducated SmugglerNoch keine Bewertungen

- Extrusion & DrawingDokument40 SeitenExtrusion & DrawingDida KhalingNoch keine Bewertungen

- Sectional Panel TankDokument4 SeitenSectional Panel TankfazyroshanNoch keine Bewertungen

- BitumenDokument7 SeitenBitumenArjun KumarNoch keine Bewertungen

- Section 6 - CARPENTRY AND JOINERY PDFDokument4 SeitenSection 6 - CARPENTRY AND JOINERY PDFادزسر بانديكو هادولهNoch keine Bewertungen

- Art Lab For KidsDokument146 SeitenArt Lab For Kidscopepina96% (25)

- Specification For Brick MasonryDokument6 SeitenSpecification For Brick Masonrysri10888Noch keine Bewertungen

- Ceramics TestingDokument2 SeitenCeramics TestingDhedhe PrasetyaNoch keine Bewertungen

- M80 Mix Design ReportDokument22 SeitenM80 Mix Design ReportAnonymous YHcvra8Xw6100% (2)

- Poly SurfDokument13 SeitenPoly SurfRajNoch keine Bewertungen

- The Iron-Iron Carbide Equilibrium DiagramDokument15 SeitenThe Iron-Iron Carbide Equilibrium DiagramjhangeerNoch keine Bewertungen

- Aggregates in ConcreteDokument16 SeitenAggregates in Concretevinaykrishna123Noch keine Bewertungen

- 2 Ton Epoxy TDSDokument2 Seiten2 Ton Epoxy TDSFrichsGabinoCondoriMonzonNoch keine Bewertungen

- Shaker Nightstand PlanDokument18 SeitenShaker Nightstand PlanJess HendriksmaNoch keine Bewertungen

- HdpeDokument33 SeitenHdpeThiruThirunavukkarasuNoch keine Bewertungen

- Machining LabDokument6 SeitenMachining LabArunachalam NarayananNoch keine Bewertungen

- Sintering Plant at A GlanceDokument72 SeitenSintering Plant at A Glanceskt9560Noch keine Bewertungen

- Epoxyresinpresentedby Biswajitmaity 140923062212 Phpapp02Dokument55 SeitenEpoxyresinpresentedby Biswajitmaity 140923062212 Phpapp02Oai NgôNoch keine Bewertungen

- Polymer DispersionsDokument25 SeitenPolymer Dispersionsmitimas2003Noch keine Bewertungen

- Technical ProgrammeDokument60 SeitenTechnical ProgrammeAmy FitzgeraldNoch keine Bewertungen

- CAPISEALDokument2 SeitenCAPISEALrudrabirNoch keine Bewertungen

- Technical Specifications With SaddlesDokument6 SeitenTechnical Specifications With Saddlesmihaidanpan791Noch keine Bewertungen

- Portland Bolt Strength Requirements by Grade ChartDokument3 SeitenPortland Bolt Strength Requirements by Grade Chartanta520Noch keine Bewertungen

- Is 01Dokument4 SeitenIs 01Hany HanfyNoch keine Bewertungen

- British Nova Product Guide For Nova Wood Gloss: Water-Based Wood Cork Seals Polyurethane / Acrylic SealersDokument2 SeitenBritish Nova Product Guide For Nova Wood Gloss: Water-Based Wood Cork Seals Polyurethane / Acrylic SealersFloorkitNoch keine Bewertungen