Beruflich Dokumente

Kultur Dokumente

LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)

Hochgeladen von

Garcia C L AlbertoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)

Hochgeladen von

Garcia C L AlbertoCopyright:

Verfügbare Formate

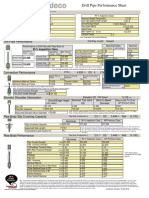

Landing String Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Warning: Connection thread shear strength is too weak; the connection must be streamlined or a waiver must be signed. Advisory: Elevator Capacity is

weaker than nominal pipe in tension. Note: Connection torsional strength is less than 80% pipe body torsional strength.

Drill Pipe Configuration

Pipe Body OD

(in)

Pipe Body Wall Thickness

(in)

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

(in)

(in)

(in)

(in)

Box Tong

Landing String Rating

Drill Pipe Performance

(lbs)

80 % Inspection Class

5.875

0.750

S-135

Range2

XT57

7.250

3.500

10

15

Nominal Weight Designation

Drill Pipe Approximate Length

SmoothEdge Height

Tool Joint SMYS

Upset Type

Max Upset OD (DTE)

Friction Factor

Drill Pipe Length

Minimum MUT

67,900

0

52,700

Max Tension

(lbs)

1,266,000

1,176,200

Note: Oil field barrel equals 42 US gallons.

Range2

Drill Pipe Adjusted Weight

(lbs/ft)

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

(gal/ft)

(Bbls/ft)

(gal/ft)

(Bbls/ft)

(in)

(without

Coating)

Nominal

(with Coating)

48.53

0.74

0.0177

0.73

0.0174

3.375

(least accurate)

46.83

0.72

0.017

0.76

0.018

0.72

0.0172

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

XT57

Connection Performance

7.250

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

Maximum Make-up Torque

Minimum Make-up Torque

81,500

67,900

(lbs)

Tensile Limited

1,700,100

OD X

(in)

3.500

Tension at Connection

Yield

(lbs)

Tool Joint Torsional Strength

Tool Joint Tensile Strength

(ft-lbs)

ID

(in)

120,000

1,463,500

1,748,300

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

Premium Class

(in)

Minimum Tool Joint OD for

Counterbore

Note: To maximize connection operational tensile, a MUT (T4) = 69,800 (ft-lbs) should be applied.

(in)

7.337

6.846

6.566

135,800

(lbs) 1,748,300

Elevator Shoulder Information

SmoothEdge OD

Box OD

Elevator Capacity

Assumed Elevator Bore

(in)

120,000

IEU

6.000

Best Estimates

1,266,000

1,168,500

0

50,700

(psi)

Based on:

80 % Inspection Class Pipe Body,

tool joint operational tensile, elevator OD, no applied drilling torque.

80 % Inspection Class

69,800

3/32 Raised

1.0

Performance of Drill Pipe with Pipe Body at

Recommended

MUT (T4)

(in)

Note: Tong spcae may include hardfacing.

851,000

Applied Make-up Operational Torque

Torque

(ft-lbs)

(ft-lbs)

41.05

31.8

(ft)

(in)

(lbs)

3/32 Raised

7.438

1,539,200

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

7.250

1,301,100

6.846

808,600

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

(lbs)

(in)

Pipe Body Performance

1,073,300

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

Cross Sectional Area of Pipe Body

(in^2)

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in^2)

(in^2)

(in^3)

(in^3)

5.875 (in) OD

80 % Inspection Class

851,000

Pipe Body Configuration

(lbs)

0.750 (in) Wall

S-135 )

API Premium Class

851,000

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

6.125

Slip Crushing Capacity

Assumed Slip Length

Transverse Load Factor (K)

6.721

662,000

7.438

1,630,200

179,000

0.76

143,200

30,160

30,068

5.875

0.750

4.375

12.075

27.109

15.033

13.786

27.571

5.875 (in) OD

80 % Inspection Class

1,266,000

137,100

0.99

109,700

27,574

25,931

5.575

0.600

4.375

9.378

24.411

15.033

10.560

21.119

0.750 (in) Wall

S-135 )

API Premium Class

1,266,000

137,100

0.99

109,700

27,574

25,931

5.575

0.600

4.375

9.378

24.411

15.033

10.560

21.119

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is

intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions

(remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings,

acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID.

Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 02-03-2014

Operational Limits of Drill Pipe

Connection

Pipe Body

XT57

80 % Inspection Class

Tool Joint OD

(in)

7.250

Tool Joint ID

Pipe Body OD

(in)

5.875

Wall Thickness (in) 0.750

(in)

Combined Loading for Drill Pipe at

(ft-lbs)

0

3,400

6,900

10,300

13,700

17,200

20,600

24,000

27,500

30,900

34,300

37,800

41,200

44,600

48,100

51,500

54,900

58,400

61,800

65,200

(lbs)

S-135

Minimum Make-up Torque = 67,900

(ft-lbs)

Connection Max

Pipe Body

Max Tension Tension

(lbs)

1,266,000

1,265,600

1,264,400

1,262,400

1,259,600

1,256,000

1,251,600

1,246,400

1,240,300

1,233,400

1,225,700

1,216,900

1,207,500

1,197,100

1,185,500

1,173,300

1,160,000

1,145,400

1,130,000

1,113,500

Pipe Body Grade

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 81,500

Operational Assembly

Torque

Max Tension

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

3.500

Operational Assembly

Torque

Max Tension

(ft-lbs)

(lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

1,266,000 1,463,500

1,266,000

1,266,000

1,700,100

1,265,600 1,463,500

2,700

1,265,700

1,265,700

1,700,100

1,700,100

1,264,400 1,463,500

5,300

1,265,000

1,265,000

1,262,400 1,463,500

8,000

1,263,800

1,263,800

1,700,100

1,259,600 1,463,500

10,700

1,262,100

1,262,100

1,700,100

1,256,000 1,463,500

13,300

1,260,000

1,260,000

1,700,100

1,251,600 1,463,500

16,000

1,257,300

1,257,300

1,700,100

1,246,400 1,463,500

18,700

1,254,200

1,254,200

1,700,100

1,240,300 1,463,500

21,400

1,250,500

1,250,500

1,700,100

1,700,100

1,233,400 1,463,500

24,000

1,246,400

1,246,400

1,225,700 1,463,500

26,700

1,241,700

1,241,700

1,700,100

1,216,900 1,463,500

29,400

1,236,500

1,236,500

1,700,100

1,207,500 1,463,500

32,000

1,231,000

1,231,000

1,700,100

1,197,100 1,463,500

34,700

1,224,800

1,224,800

1,700,100

1,185,500 1,463,500

37,400

1,218,000

1,218,000

1,700,100

1,700,100

1,173,300 1,463,500

40,000

1,210,900

1,210,900

1,160,000 1,463,500

42,700

1,203,000

1,203,000

1,700,100

1,145,400 1,463,500

45,400

1,194,500

1,194,500

1,700,100

1,130,000 1,463,500

48,000

1,185,800

1,185,800

1,700,100

1,113,500 1,463,500

50,700

1,176,200

1,176,200

1,700,100

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

67,900

69,400

70,900

72,400

73,900

75,500

77,000

78,500

80,000

81,500

Connection Max

Tension

(lbs)

1,700,100

1,737,600

1,722,100

1,685,500

1,648,900

1,609,900

1,573,300

1,536,700

1,500,100

1,463,500

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

Connection Wear Table

Connection

XT57

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

7.25

7.188

7.126

7.063

7.001

6.939

6.877

6.815

6.753

6.69

6.628

6.566

Worn OD

(in)

7.250

Tool Joint ID

(in)

3.500

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

135,800

131,700

127,600

123,500

119,500

115,500

111,600

107,800

104,000

100,200

96,500

92,800

81,500

79,000

76,500

74,100

71,700

69,300

67,000

64,700

62,400

60,100

57,900

55,700

(ft-lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

Min MUT

(lbs)

1,463,500

1,514,900

1,565,600

1,577,500

1,545,500

1,509,300

1,463,500

1,346,200

1,233,700

1,124,900

1,023,600

926,800

Connection Max

Tension

(lbs)

(ft-lbs)

67,900

1,700,100

65,800

1,657,700

63,800

1,617,500

61,700

1,539,800

59,700

1,427,900

57,800

1,322,500

55,800

1,218,900

53,900

1,121,500

52,000

1,028,100

50,100

937,700

48,200

852,100

46,400

772,000

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

80 % Inspection Class

Pipe Body Torque

Pipe Body OD

12,500

24,900

(in)

5.875

37,400

49,900

Wall Thickness (in) 0.750

62,300

74,800

87,200

Pipe Body Grade

S-135

99,700

112,200

124,600

137,000

868,900

727,400

528,000

45,900

(ft-lbs)

Pipe Body Max

1,266,000 1,260,700 1,244,900 1,218,000 1,179,100 1,127,700 1,060,900 976,900

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

Das könnte Ihnen auch gefallen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance Sheetjinyuan74Noch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance Sheetjinyuan74Noch keine Bewertungen

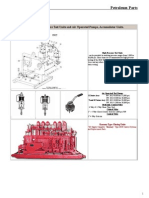

- 14P-220 Mud Pump Brochure PDFDokument2 Seiten14P-220 Mud Pump Brochure PDFjoseluisvalera100% (1)

- Rubicon D455 Safety JointsDokument12 SeitenRubicon D455 Safety JointsEmad JamshidiNoch keine Bewertungen

- IDS 350PE Top DriveDokument2 SeitenIDS 350PE Top Drivealan camposNoch keine Bewertungen

- Design of Raft FoundationDokument4 SeitenDesign of Raft FoundationDayo Idowu100% (2)

- Building Utilities SwitchesDokument59 SeitenBuilding Utilities SwitchesMeryll Mae Bicol100% (1)

- Aether of SpaceDokument184 SeitenAether of SpaceMartin A. SalaNoch keine Bewertungen

- Drill CollarDokument1 SeiteDrill CollarGuillermo Rangel AvalosNoch keine Bewertungen

- HWDPDokument15 SeitenHWDPjinyuan74Noch keine Bewertungen

- Well Pressure Profile BetaDokument3 SeitenWell Pressure Profile BetaDevito PradiptaNoch keine Bewertungen

- Min - TJL API RP 7G-2 - For MSDokument1 SeiteMin - TJL API RP 7G-2 - For MSQuality controllerNoch keine Bewertungen

- Composite CatalogDokument128 SeitenComposite Catalogmkwetco75% (4)

- 5-12 HSVS MOD-B Radial DoorDokument62 Seiten5-12 HSVS MOD-B Radial Doornardo_ing100% (5)

- Manual F 1300 1600Dokument71 SeitenManual F 1300 1600Camilo Sanchez VanegasNoch keine Bewertungen

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Dokument18 SeitenOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNoch keine Bewertungen

- GJ-204-016 Mud Pump 2 & 3 UpgradeDokument6 SeitenGJ-204-016 Mud Pump 2 & 3 UpgradeKuna Stanbekov100% (1)

- Slips Maintenance, Inspection, & Wear Data PDFDokument3 SeitenSlips Maintenance, Inspection, & Wear Data PDFcorsini999100% (1)

- Itco Spear Bull Noze Make Up PDFDokument1 SeiteItco Spear Bull Noze Make Up PDFmbhadelNoch keine Bewertungen

- 1 A Varco Company: Part Number TW524Dokument18 Seiten1 A Varco Company: Part Number TW524Luis Eduardo Albarracin RugelesNoch keine Bewertungen

- 16-25k Hydraulic Power Tong WatherfordDokument6 Seiten16-25k Hydraulic Power Tong WatherfordJose Mauricio SandovalNoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- 5-12 HSVS Mod-B 416+ 062212Dokument73 Seiten5-12 HSVS Mod-B 416+ 062212Alan MaidaNoch keine Bewertungen

- Griffith Drilling JarDokument1 SeiteGriffith Drilling JarFakhrurrozi ArbianNoch keine Bewertungen

- DRAFT - Requirements For Pressure TestingDokument3 SeitenDRAFT - Requirements For Pressure TestingAdhie WaelacxhNoch keine Bewertungen

- Drawworks and Rig Sizing PDFDokument8 SeitenDrawworks and Rig Sizing PDFAmine Mimo100% (1)

- Manual: CDQ (S) Sucker Rod ElevatorsDokument5 SeitenManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaNoch keine Bewertungen

- 20-1718 Rig Tongs AOTDokument10 Seiten20-1718 Rig Tongs AOTRahul M.R100% (1)

- Formation Testing: Supercharge, Pressure Testing, and Contamination ModelsVon EverandFormation Testing: Supercharge, Pressure Testing, and Contamination ModelsNoch keine Bewertungen

- HH SwivelDokument3 SeitenHH SwivelHoracio LafuenteNoch keine Bewertungen

- Cougar DLLG Solutions FaqDokument5 SeitenCougar DLLG Solutions FaqLenis CeronNoch keine Bewertungen

- CHE 503 Agitation LiquidsDokument33 SeitenCHE 503 Agitation LiquidsNurtasha Atikah100% (1)

- Varco TDS-4S & TDS-4H Top Drive Pocket GuideDokument21 SeitenVarco TDS-4S & TDS-4H Top Drive Pocket GuideMuhammad SaiedNoch keine Bewertungen

- TPWSD Catalog 2010Dokument36 SeitenTPWSD Catalog 2010miguel mendozaNoch keine Bewertungen

- Hammer UnionsDokument5 SeitenHammer UnionsiljicsNoch keine Bewertungen

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDokument3 SeitenDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDokument3 Seiten5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNoch keine Bewertungen

- Araña BJ 350 Ton 13 3-8Dokument60 SeitenAraña BJ 350 Ton 13 3-8ceciliachableNoch keine Bewertungen

- Manual Manual Power TongDokument13 SeitenManual Manual Power TongJAVIER EDUARDO MANTILLA BUITRAGONoch keine Bewertungen

- API 16C Choke and KillDokument26 SeitenAPI 16C Choke and Killtry&tryNoch keine Bewertungen

- Specification:: Hammer UnionsDokument5 SeitenSpecification:: Hammer Unionscmpuck100% (1)

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoNoch keine Bewertungen

- 2016.06.20 GNZYQ Poor Boy Degasser ManualDokument14 Seiten2016.06.20 GNZYQ Poor Boy Degasser ManualGeorge100% (1)

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNoch keine Bewertungen

- 2-36, TMC Jar, OpDokument15 Seiten2-36, TMC Jar, OpAli HosseiniNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Circulating SwagesDokument1 SeiteCirculating Swageskaveh-bahiraeeNoch keine Bewertungen

- Float Valve Recess DimensionsDokument1 SeiteFloat Valve Recess DimensionsQuality controllerNoch keine Bewertungen

- Shock Sub Tool: Impact and Vibration Reduction ToolDokument4 SeitenShock Sub Tool: Impact and Vibration Reduction ToolLeonardo Barrios0% (1)

- Full-Circle Casing Scraper: Instruction Manual 6255Dokument6 SeitenFull-Circle Casing Scraper: Instruction Manual 6255Jubin JacobNoch keine Bewertungen

- ZJ70/4500DB RIG 钻机: Parts ListDokument3 SeitenZJ70/4500DB RIG 钻机: Parts Listwaleed100% (1)

- Koomey Air Operated Pumps and Pressure Test UnitsDokument1 SeiteKoomey Air Operated Pumps and Pressure Test UnitsCricri CriNoch keine Bewertungen

- Mud Gas Separator InfoDokument2 SeitenMud Gas Separator InfoHIPAPNoch keine Bewertungen

- BOP BoltsDokument5 SeitenBOP BoltsHadirah DunglahNoch keine Bewertungen

- Chuck CatalogueDokument44 SeitenChuck CatalogueSharad SharmaNoch keine Bewertungen

- 575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFDokument8 Seiten575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFJhonathan MirandaNoch keine Bewertungen

- Casing Cup TesterDokument3 SeitenCasing Cup TesterWei ShangNoch keine Bewertungen

- Maintanence Manual Triplex Pump WS-1300/1600: White Star Pump CoDokument45 SeitenMaintanence Manual Triplex Pump WS-1300/1600: White Star Pump Cojosebernal_mzaNoch keine Bewertungen

- Cement Plug SidetrackDokument2 SeitenCement Plug SidetrackAnilNoch keine Bewertungen

- HE Hydra Jar Manual 6-80Dokument31 SeitenHE Hydra Jar Manual 6-80Yuri KostNoch keine Bewertungen

- B2 Anchor Catcher Technical DatasheetDokument3 SeitenB2 Anchor Catcher Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- LPR-N Tester Valve Funcionamiento 1Dokument33 SeitenLPR-N Tester Valve Funcionamiento 1Александр КинтероNoch keine Bewertungen

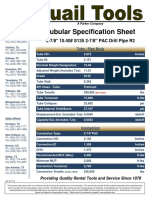

- Tubular Specification Sheet: 2-7/8" 10.40# S135 2-7/8" PAC Drill Pipe R2Dokument1 SeiteTubular Specification Sheet: 2-7/8" 10.40# S135 2-7/8" PAC Drill Pipe R2Mamani Vargas Wiljho100% (1)

- Ram BOP Manual BookDokument28 SeitenRam BOP Manual BookIgor Ungur100% (2)

- Tenaris Running Manual 01Dokument20 SeitenTenaris Running Manual 01advantage025Noch keine Bewertungen

- 5 7/8" 23.4 PPF S135 Pipe SpecsDokument2 Seiten5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNoch keine Bewertungen

- 5 7/8" 23.4 PPF S135 Pipe SpecsDokument2 Seiten5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument1 SeitePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- DPPS PDFDokument2 SeitenDPPS PDFStowartNoch keine Bewertungen

- DPPSDokument2 SeitenDPPSGarcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokument3 SeitenDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNoch keine Bewertungen

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokument3 SeitenDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNoch keine Bewertungen

- WS36-01 DPPSDokument2 SeitenWS36-01 DPPSGarcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokument3 SeitenDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNoch keine Bewertungen

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokument3 SeitenDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNoch keine Bewertungen

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDokument3 Seiten3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokument3 SeitenDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNoch keine Bewertungen

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDokument3 Seiten3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDokument3 Seiten3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokument3 SeitenDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNoch keine Bewertungen

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokument3 SeitenDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNoch keine Bewertungen

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokument3 SeitenDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNoch keine Bewertungen

- FET Basics 1Dokument63 SeitenFET Basics 1Juno Hera Magallanes HuyanNoch keine Bewertungen

- T3 (Ch5+6) KeyDokument6 SeitenT3 (Ch5+6) KeyIlyasNoch keine Bewertungen

- Reynolds Transport TheoremDokument3 SeitenReynolds Transport TheoremanimeshkumarvermaNoch keine Bewertungen

- Mathematical ModellingDokument13 SeitenMathematical ModellingCrazy about JunglesNoch keine Bewertungen

- Critical-State Soil Mechanics For Dummies: Paul W. Mayne, PHD, P.EDokument22 SeitenCritical-State Soil Mechanics For Dummies: Paul W. Mayne, PHD, P.EdaviNoch keine Bewertungen

- PS7 SolutionsDokument5 SeitenPS7 SolutionsYenhao Philip ChenNoch keine Bewertungen

- Maths SyllabusDokument3 SeitenMaths SyllabusSabari BalaNoch keine Bewertungen

- Hjhy 6dcvb GGDokument10 SeitenHjhy 6dcvb GGAngel FajmNoch keine Bewertungen

- Chapter 5: Laws of Motion Class: XI Subject: Physics: Topic: Dynamics of Uniform Circular Motion, Banking of RoadDokument5 SeitenChapter 5: Laws of Motion Class: XI Subject: Physics: Topic: Dynamics of Uniform Circular Motion, Banking of RoadKirtan KumarNoch keine Bewertungen

- Decl Conf XPS30Dokument1 SeiteDecl Conf XPS30iriniNoch keine Bewertungen

- Mole Concept - DPP 01Dokument3 SeitenMole Concept - DPP 01locohe4969Noch keine Bewertungen

- Lecture06 FEG Basics & Heat Capacity1Dokument51 SeitenLecture06 FEG Basics & Heat Capacity1lalitbickNoch keine Bewertungen

- Module 2 - VariationsDokument25 SeitenModule 2 - VariationsCherry Ann M NaboNoch keine Bewertungen

- A Compendium of Spherical Astronomy, NewcombDokument470 SeitenA Compendium of Spherical Astronomy, Newcombandresmejia68100% (1)

- The Effects of Overload On The Fatigue LifeDokument12 SeitenThe Effects of Overload On The Fatigue Lifesaeed-21100% (1)

- Center of Gravity ReportDokument5 SeitenCenter of Gravity ReportTheOnesNoch keine Bewertungen

- Answer Table For The Multiple-Choice Questions: Quantum Mechanics NameDokument24 SeitenAnswer Table For The Multiple-Choice Questions: Quantum Mechanics Nameمؤيد العليNoch keine Bewertungen

- Electrostatics. ProblemsDokument3 SeitenElectrostatics. Problemsscs942609Noch keine Bewertungen

- Advanced Fluid Mechanics - Chapter 05 - Boundary Layer TheoryDokument33 SeitenAdvanced Fluid Mechanics - Chapter 05 - Boundary Layer Theorysunil481Noch keine Bewertungen

- Unit 4Dokument76 SeitenUnit 4Hemant TulsaniNoch keine Bewertungen

- Symmetry and Spectroscopy of Molecules ReddyDokument31 SeitenSymmetry and Spectroscopy of Molecules ReddyVijay Pradhan58% (12)

- Week1HW S15 SolutionsbDokument6 SeitenWeek1HW S15 SolutionsbDeym GómezNoch keine Bewertungen

- Aldehydes PresentationDokument40 SeitenAldehydes PresentationEric ArcillasNoch keine Bewertungen

- Esolutions Manual - Powered by CogneroDokument26 SeitenEsolutions Manual - Powered by CogneroZar ArhNoch keine Bewertungen