Beruflich Dokumente

Kultur Dokumente

Application of AC Motors and Drives in Steel Industries: A K Paul, I Banerjee, B K Santra and N Neogi

Hochgeladen von

Mohamed Elsaid El ShallOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Application of AC Motors and Drives in Steel Industries: A K Paul, I Banerjee, B K Santra and N Neogi

Hochgeladen von

Mohamed Elsaid El ShallCopyright:

Verfügbare Formate

Fifteenth National Power Systems Conference (NPSC), IIT Bombay, December 2008

Application of AC motors and drives in Steel

Industries

A K Paul, I Banerjee, B K Santra and N Neogi

Abstract - This paper deals with a few major application of AC

motors and drives with special controls in steel plants.

Application of AC drives for electrically operated overhead

crane have been discussed in details. Application of AC drives

has reduced the maintenance expenses and a large amount of

power is saved. AC power is also used for high frequency

welding and other special applications. Large numbers of high

power AC motors are used in steel industries which require

control of speed to suit the process requirement. In a steel

plant, power electronics plays an important role in process

improvement and dimensional control of rolled products.

Proper selection of drives not only saves electrical energy but

also produce quality products. Advancements in the field of

drives and control techniques are responsible for improvements

in the quality and yield of steel products.

II.

A. VVVF drive for crane application

Conventional AC operated EOT cranes uses slip ring

induction motor whose rotor windings are connected to

power resistance in 4 to 5 steps by power contactors.

Reversing is done by changing the phase sequence of the

stator supply through line contactors. Braking is achieved by

plugging operation. A crane control system has been

developed and implemented using variable voltage variable

frequency drive and a programmable controller. The main

advantage achieved are precise positioning of the object,

reduction in electrical energy consumption by regenerative

braking, increased motor life by applying low voltage at the

starting and thus reducing in rush current .

Index Terms: Cyclo converter for rolling stand motor, Electro

magnetic stirrer, Power Factor correction, VVVF Drive for

Crane.

I.

AC DRIVES FOR CRANE

A crane with following details has been taken for

experimentation with adjustable frequency drive.

Capacity : Main Hoist 30 T

Auxiliary Hoist: 5 T

Current Collector: Gravity collector, Festoon with double

collector arrangement.

Speed : Traveling

: 80 m/min

Traversing

: 40 m/min

Main hoist

: 8 m/min

Aux. hoist

: 20 m/min

INTRODUCTION

The integrated steel plants are having very large capacity

motors and power electronics devices, which are used during

processing of steel. The process of manufacturing steel

products from iron ore involves Raw material preparation,

Primary reduction, Refining, Casting, Hot and Cold rolling,

Surface coating etc. Energy such as gas and electric power is

required in each of these processes. The motors used in the

primary area (Coke oven, Blast furnace, Steel melting shop)

do not require speed regulation of high order; on the other

hand motors used in finishing mills require speed regulation

of high accuracy.

The motor details are shown in Table-1

The basic requirement of crane drives are (i) Bi directional

movement of the motors, (ii) Regenerative braking facilities,

(iii) Controlled acceleration to reduce the load swing, (iv)

Precise positioning of the load, (v) Torque at Zero speed and

(vi) Safety features.

In most of the steel plant applications, variable speed was

obtained through DC motors driven four quadrant

converters. During modernization, the DC motors and drives

are replaced by AC motors and drives.

A VVVF drive, operated in four quadrant operation and

consisting of one three phase forward converter, one three

phase reverse converter and one transistor based inverter

unit has been developed for crane application. The inverter

output is fed to the stator winding and the rotor windings are

shorted at the slip ring. The reference speed is set to the

speed regulator unit. The drive accepts 0 to + 10 V DC as set

point for forward movement and 0 to 10 V DC for reverse

movement. No pulse tacho / encoder are connected to the LT

/ CT motor for speed feedback. The speed feedback is taken

as (1-s).ns. The value of ns depends on the output frequency

of the inverter.

Large AC power is also used for induction heating in ladle

furnace during secondary refining of steel, high frequency

heating during welding process in a pipe plant. Control of

this power is very important for process control. These

controls are done by application of power electronics.

AC drives are used mostly in primary area (Raw material

handling, Sinter plant, Steel melting shop) in steel plant.

Variable speed AC drives are used in soaking pits and reheat

furnaces. AC motors of very high capacities (4 MW in Sinter

plant and 14.4 MW in the prime mover of MG set in Plate

Mill) are used in steel plants. A few applications are given in

this paper.

159

Fifteenth National Power Systems Conference (NPSC), IIT Bombay, December 2008

Each motor of the crane has to sustain 20 nos of start / stop

operation in an hour.

Table-1: Motor details

Motors

Nos Power

in kW

Long Travel

23.5

Speed

in

RPM

965

Cross Travel

5.5

965

415

Main hoist

30

730

415

Aux. hoist

10

736

415

B.

Stator

voltage

Type

415

Slip

Ring

Slip

Ring

Slip

Ring

Slip

Ring

ii) Precise positioning of the hook at very low speed

operation is possible. With rotor resistance control

operator has to reverse the motor a few times for

positioning

iii) During braking, the drive regenerates and power is fed

back to busbar through current collector

iv) All controls and safety interlocks are done in a

Programmable controller and thereby the panel size is

small.

v) Easy of maintenance as the faults are indicated on the

display board

vi) High starting torque.

Table-2: LT drive steady state behavior

Master

Speed

Reference Motor

Controller reference frequency Speed

Position

voltage

of drive

in

from PLC

RPM

Neutral

0.0

0.0

0

Left-1

-1.8

9.1

175

(RBY)

Left-2

-3.7

18.3

351

(RBY)

Left-3

-7.0

35.0

675

(RBY)

Left-4

-10.0

50.0

960

(RBY)

Right-1

1.8

9.1

174

(RYB)

Right-2

3.7

18.3

349

(RYB)

Right-3

7.0

35.0

675

(RYB)

Right-4

10.0

50.0

958

(RYB)

LT Drive capacity selected;

Motor: 23.5 kW X 2 Nos.

VVVF drive capacity: 120 kVA

Type: Four quadrant operation with regenerative facility

Converter unit: 3 Phase thyristor bridge

Inverter unit: 2 series connected power transistor with anti

parallel diode.

DC link capacitor: electrolytic type

Continuous output: 150 kVA

Rated current: 165 Amps

Overload capacity: 50% for 60 sec

LT Drive steady state behavior is shown in Table-2.

C.

LT Drive acceleration time

During initial trial period, the acceleration time was kept at

15 sec. After several trials it was reduced to 8 sec. It was

observed that further reduction of time swings the load

heavily and load starts oscillating.

D.

LT drive deceleration time

During initial trial period, the acceleration time was kept at

40 sec. After several trials it was reduced to 10 sec. It was

observed that further reduction of time swings the load

heavily and load starts oscillating.

E.

III.

0.0

25.6

24.6

23.4

23.0

25.4

24.3

23.1

22.4

AC DRIVE FOR ROLLING STAND

MOTOR

AC synchronous motors are used for driving the roughing

stand rolls in a rolling mill. Synchronous motors are used

when power requirement is very high and speed of rolling is

low. The R0/V0 stand motors of Hot Strip Mill of Rourkela

Steel Plant are synchronous motor. These motors are driven

by cyclo converter. The capacity of R0 stand motors are 3

MW x 2 Nos, 953 Volt, 1121 Amps, 70 RPM. The capacity

of V0 stand motors are 1 MW X 2 Nos at 953 volt. The

cyclo converter output frequency is 5-15 Hz. The following

technological benefits have been obtained from these drives;

i) Speed regulation is precise

ii) The control system is having high dynamic response

LT drive transient behavior

LT motor transient current

Position-0 to Position-1 Acceleration current 76 Amps

Position-1 to Position-2, Acceleration current 48 Amps

Position-2 to Position-3, Acceleration current 36 Amps

Position-3 to Position-4, Acceleration current 32 Amps

F.

Steady state

current of

both motors

Technological Benefits

The following are the technological benefit over

conventional rotor resistance control

i) Savings in electrical power as there is no loss in rotor

resistance

160

Fifteenth National Power Systems Conference (NPSC), IIT Bombay, December 2008

iii) The over load capacity of the drive is very high and

hence the number of tripping due to over load is very

less.

IV.

V.

SPECIAL APPLICATION

Other than drive system, there are several special

applications where power electronics is used in steel plants.

A few of them are described below:

AC DRIVE REQUIREMENT FOR LARGE

MACHINES

A.

A. Exhauster of Sinter Plant II of Durgapur Steel Plant

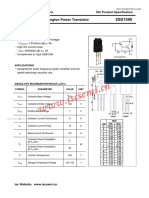

Electro magnetic stirrer

During casting of billets and blooms the liquid steel is stirred

to improve the quality of cast product. A stirrer acts like a

stator of an AC motor. It is fed by 3 phase or 2 phase power

supply and a rotating magnetic field is created. The rotating

magnetic field induces a torque in the liquid steel of the

billet or bloom passing through the mould. The liquid steel

acts like a rotor of an AC motor and rotates around the axis

of the cast products in a plane perpendicular to the casting

direction.

The Sinter Plant-II of DSP has two exhausters to suck air

through sinter machine. The suction pressure is around 1500

mm WC. The installed electrical load is 21 MW. The

average energy consumption at rated capacity is 13-14 MW,

out of which 8 MW is consumed in the exhausters. The

power line frequency varies from 49 to 53 Hz. When the

frequency is high (say 53 Hz), motor speed increases to 1060

RPM and the blade speed increases to 1442 RPM. With this

speed load on the exhauster motor increases and

consequently stator current increases. When the current

increases above safe limit, the motor trips. Such a trip causes

a delay of around 1 hour. Each synchronous motor is rated

for 4670 kVA, Stator 11kV, 244 A, Rotor 78 V, 295 A,

Cos = 0.9. During high frequency, the load on the

machine is reduced by closing the damper in the suction line.

Coil

These synchronous motors are excited in such a way that it

draws leading current so that the overall power factor of the

plant is nearer to unity.

Coil

A variable frequency drive to suit this motor capacity shall

help to control the suction by varying the supply frequency.

This shall stabilize the plant.

B. Compressors of Oxygen Plant of Durgapur Steel Plant

Fig. 1 - Principle of

rotative stirring

The capacity of oxygen plant is 700 t/day. The plant consists

of two numbers of air separation units each of capacity 350

t/day. There are two air compressors for 2 air separation

unit. Each air compressor is driven by synchronous motor of

rating 11 kV, 6 MW, 0.9 pf lead. There are three oxygen

compressors, driven by synchronous motor of rating 11 kV,

1700 kW, 0.9 pf lead. There are two nitrogen compressors

driven by induction motor of rating 11 kV, 1320 kW. At

higher frequency above 50 Hz, the plant becomes unstable.

The plant is made stable by changing vent and by this way

specific power consumption increases. There is no provision

for regulating the speed of the compressors at higher

frequency.

A rotating stirrer induces axial symmetrical forces creating a

torque over the whole section of the liquid pool, whatever

the size of the liquid pool is and even if the strand is not

centered inside the stirrer. It follows that all the forces

induces within the whole section of the liquid pool and

consequently the full power induced inside liquid pool

contributes to the stirring of the liquid steel. The frequency

of the supply varies from 3-10 Hz depending on the stirrer.

The principle of rotating stirrer is shown in Fig.1.

The scheme for generating the rotating magnetic field

consists of converting AC power to DC power and then DC

power to a variable frequency AC power. The main units are

(i) Converter transformer, (ii) Diode bridge for AC to DC

and (iii) Inverter bridge for DC to AC. A schematic diagram

of the power line is shown in Fig 2. A stirrer system installed

in continuous casting plant of DSP is having the following

specification.

Variable frequency drives to suit these motor capacities shall

help to control the process by varying the supply frequency.

161

Fifteenth National Power Systems Conference (NPSC), IIT Bombay, December 2008

Converter: Input 415 V + 10%, Output 350 V, 180 kVA, 400

A

plant of DSP, has been tuned to achieve minimum stator

current. The result shows a decrease in stator current and

elimination of unwanted tripping during high frequency. A

typical curve is shown in Fig 4.

Coil: 100 kVA at 400 A

350V

Driver

Driver

415V, 3-Ph

473 V

Driver

V

To stirrer coil

Fig. 2 - Power Scheme of electro magnetic stirrer

B. Variable voltage fixed frequency inverter for magnetic

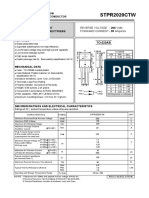

amplifier replacement

A system has been developed for a three-phase AC to single

phase AC inverter that produces a regulated AC voltage as

per the reference voltage. These inverters are having several

applications in steel rolling mill where the speeds of

successive stands are to be proportional in steady state and

in transient conditions. The system consists of a converter

transformer, three-phase diode rectifier, DC link capacitors,

control voltage generation scheme, a single-phase inverter

and an inverter transformer. The application of such an

inverter has been demonstrated in wire rod mill of Bhilai

Steel Plant. The similar inverter can be used for control

application in a continuous rolling mill. A single line

diagram of the rectifier inverter system is shown in Fig 3.

VI.

VII.

CONCLUSION

Very large capacity motors are used in steel industries. It

requires various types of special drives to meet the quality

requirement. Power Electronics and control system requires

implementation in steel industries to sustain the customers

quality requirement.

Acknowledgement

The authors are thankful to the Electro Technical Lab

department of Bhilai, Durgapur & Bokaro Steel Plant and

Electronics Engineering Department of Rourkela Steel Plant

for extending detailed information in preparing this paper.

The authors express their gratitude to the management of

SAIL for the support provided in preparation of this paper.

TECHNO ECONOMIC IMPACT

References

A. Tuning of excitation of large synchronous machine for

Power factor correction

[1] Frederick L Hoadley, AC drive for critical

applications, Iron and Steel Engineer, November 1994,

pp 30-35.

[2] Thomas F Lowery, David W Petro Application

Consideration for PWM Inverter Fed Low Voltage

Induction Motors, IEEE transaction s on Industry

applications, Vol 30, No 2, March / April 1994, pp 286293.

In a synchronous motor, delivering constant mechanical

power when energized from a source of constant voltage and

constant frequency, the stator current is a function of field

excitation. At unity power factor, current drawn in the HT

line is minimum. The excitation of 4 MW, 11 kV

synchronous motor, used as a suction device in the sinter

162

Fifteenth National Power Systems Conference (NPSC), IIT Bombay, December 2008

415 V, 3 , 50 Hz.

415 / 315 V

4.4 KVA, Y-

T1

HRC Fuse, 16 A

Diode 600 V 20 A

e=f (Vc)

Vc

Vf

HRC Fuse, 32 A

IGBT

MODULE

TEST

VOLTAGE

FIRING

MODULE

FREQENCY

SET

175 / 175 V

1.75 KVA

T2

175 V, 10 A,

50 Hz.

Fig. 3 - Single line diagram of the rectifier inverter system

Stator Current in Amps

[3] Prashant Gupta, Asoke Kumar Paul, S Bhattacharya, N

Neogi and D Mukherjee, Design of digital controller

for tension control of coiler drive in tandem cold rolling

mill, Published in Steel India, Vol 27, No 1, April

2004, page 10-14.

235

230

225

220

215

210

205

210

230

250

[4] A. K. Paul, S. Mazumdar, B. K. Santra and G. J.

Mahajan, Status of power Electronics in SAIL,

Presented in National Workshop on Power Electronics,

Industry academic interaction. Held at IISc, Bangalore,

23-24 July, 1998.

[5] A. K. Paul, S. C. Khan, G. J. Mahajan, S. Mishra, N.

Neogi, G. S. Sangar and S. Sinha. On-line control of

looping in a wire rod mill. Published in ASIA Steel,

1996.

[6] A. K. Paul, M. Gangadharan, S. Mazumdar, N. Neogi.

AC Operated EOT Crane Control with Variable

Voltage Variable Frequency Drive. Proceedings of

IEEE International Conference on Power Electronics,

Drives & Energy systems for Industrial growth. Held at

IIT, Delhi, 8-11 January, 1996.

270

Rotor current in Amps

The authors are with Research & Development Centre for Iron and

Steel, Steel Authority of India Limited, Ranchi 834002. E-mail:

akpaul@sail-rdcis.com

Fig.4 - Variation of Stator current with rotor

current

163

Das könnte Ihnen auch gefallen

- IGt To IGf CircuitDokument5 SeitenIGt To IGf Circuitdamm35100% (1)

- How To Use Digital MultimeterDokument23 SeitenHow To Use Digital Multimeternafees100% (2)

- AC Drives MSc2016Dokument21 SeitenAC Drives MSc2016Mohamed Elsaid El ShallNoch keine Bewertungen

- Industrial Drives and ControlDokument10 SeitenIndustrial Drives and ControlMohit SanandiyaNoch keine Bewertungen

- 17th Edition - Exam 100 QuestionsDokument18 Seiten17th Edition - Exam 100 Questionsloborhox100% (2)

- Power Electronics: Lecture Notes of Power Electronics CourseVon EverandPower Electronics: Lecture Notes of Power Electronics CourseNoch keine Bewertungen

- Part II - AC MotorsDokument30 SeitenPart II - AC MotorsYan Liang HaoNoch keine Bewertungen

- Variable Frequency DrivesDokument17 SeitenVariable Frequency DrivesVinay Tarsem Lal100% (1)

- Variable Frequency Drive or VFDDokument4 SeitenVariable Frequency Drive or VFDramsingh2613Noch keine Bewertungen

- PLC Training - SCADA - HMI - Video - Nebosh - Safety Training - Profibus - Ethernet - Engineering - Advanced Automation System Professional Training Pa PDFDokument86 SeitenPLC Training - SCADA - HMI - Video - Nebosh - Safety Training - Profibus - Ethernet - Engineering - Advanced Automation System Professional Training Pa PDFhippong niswantoroNoch keine Bewertungen

- DC Motor Speed ControlDokument54 SeitenDC Motor Speed ControlAbhishek Gupta100% (3)

- Chapter 4 DC MachineDokument101 SeitenChapter 4 DC Machinekelemyas ayalew100% (2)

- TM 104 Low Voltage European Fuses Am GG IEC 60269 en 01Dokument15 SeitenTM 104 Low Voltage European Fuses Am GG IEC 60269 en 01eyumaru13Noch keine Bewertungen

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlVon EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlBewertung: 5 von 5 Sternen5/5 (1)

- Energy-saving Principles and Technologies for Induction MotorsVon EverandEnergy-saving Principles and Technologies for Induction MotorsNoch keine Bewertungen

- Variable Speed Units For Pumped Storage Power Plants: Page 1 of 9Dokument9 SeitenVariable Speed Units For Pumped Storage Power Plants: Page 1 of 9raj sekharNoch keine Bewertungen

- Mechatronics Electronic Control Systems in Mechanical and Electrical Engineering 6th Edition Bolton Solutions ManualDokument9 SeitenMechatronics Electronic Control Systems in Mechanical and Electrical Engineering 6th Edition Bolton Solutions ManualRagavanNoch keine Bewertungen

- Three-Phase Squirrel-Cage Induction Motor Drive Analysis Using LabVIEWDokument26 SeitenThree-Phase Squirrel-Cage Induction Motor Drive Analysis Using LabVIEWCarlos Roberto Amaya Rodriguez100% (1)

- 04 10280165 SP 48-3000HE (Rectifier) Datasheet V1.0 171212Dokument2 Seiten04 10280165 SP 48-3000HE (Rectifier) Datasheet V1.0 171212Will F AlvesNoch keine Bewertungen

- Ata 24Dokument118 SeitenAta 24Sohaib Aslam ChaudharyNoch keine Bewertungen

- Design and Simulation of Speed Control of Three Phase Induction Motor Using Power Electronics ConverterDokument52 SeitenDesign and Simulation of Speed Control of Three Phase Induction Motor Using Power Electronics Converterzelalem wegayehu100% (1)

- Synchronous Motor Drives: Open Loop V/F Control of Synchronous MotorDokument11 SeitenSynchronous Motor Drives: Open Loop V/F Control of Synchronous MotorSaish Dalvi100% (1)

- Drive Selection of Rolling MillsDokument4 SeitenDrive Selection of Rolling MillsCihan OzturkNoch keine Bewertungen

- Induction Motors Fed by PWM MV7000 Converters Enhance Electric Propulsion PerformanceDokument9 SeitenInduction Motors Fed by PWM MV7000 Converters Enhance Electric Propulsion Performancemlkz_01Noch keine Bewertungen

- Study of a reluctance magnetic gearbox for energy storage system applicationVon EverandStudy of a reluctance magnetic gearbox for energy storage system applicationBewertung: 1 von 5 Sternen1/5 (1)

- Understanding Electric Arc Furnace OperationDokument6 SeitenUnderstanding Electric Arc Furnace Operationsalonki6162100% (1)

- Application of Ac Drives in Steel Industries in IndiaDokument5 SeitenApplication of Ac Drives in Steel Industries in IndiavishiwizardNoch keine Bewertungen

- 'Application of AC Motors and Drives in Steel Industries: January 2008Dokument6 Seiten'Application of AC Motors and Drives in Steel Industries: January 2008siddsunnyNoch keine Bewertungen

- (VT Ranganathan) Course Notes On Electric DrivesDokument119 Seiten(VT Ranganathan) Course Notes On Electric DrivesPowerranger2.0Noch keine Bewertungen

- Module 4 Drives and Mechanisms Elements of CNC Machine Tools: Electric MotorsDokument47 SeitenModule 4 Drives and Mechanisms Elements of CNC Machine Tools: Electric MotorsDhanish KumarNoch keine Bewertungen

- VVVF DrivesDokument16 SeitenVVVF DrivesIsradani MjNoch keine Bewertungen

- MINI PROJECT DC Main DrivesDokument35 SeitenMINI PROJECT DC Main DrivesSriram MogalapalliNoch keine Bewertungen

- Converters Automation of Rotary Kiln Using FrequencyDokument8 SeitenConverters Automation of Rotary Kiln Using FrequencyHat HackersNoch keine Bewertungen

- Drives in Mechatronics1Dokument14 SeitenDrives in Mechatronics1Durga PrasadNoch keine Bewertungen

- Irjet V4i1140 PDFDokument5 SeitenIrjet V4i1140 PDFMohamed AhmedNoch keine Bewertungen

- Effect of Mine Hoist Drives On The Electrical Power Supply SystemDokument6 SeitenEffect of Mine Hoist Drives On The Electrical Power Supply SystemGlenn Adalia BonitaNoch keine Bewertungen

- Lecture 6Dokument31 SeitenLecture 6amanuel abrehaNoch keine Bewertungen

- AlernatorDokument47 SeitenAlernatorMayank SrivastavaNoch keine Bewertungen

- Igbt DC DriverDokument5 SeitenIgbt DC Driverjimy_312Noch keine Bewertungen

- ElectricalDokument157 SeitenElectricalnaguNoch keine Bewertungen

- DK9222 0410 0014Dokument10 SeitenDK9222 0410 0014Balachander KalappanNoch keine Bewertungen

- Synchronous Motor Drive: Presented By: Electrical (6 Sem)Dokument19 SeitenSynchronous Motor Drive: Presented By: Electrical (6 Sem)Swarup MadduriNoch keine Bewertungen

- Module 5Dokument20 SeitenModule 5yakomi suraNoch keine Bewertungen

- Introduction To Special MachinesDokument11 SeitenIntroduction To Special MachinesSankaran Nampoothiri KrishnanNoch keine Bewertungen

- ActuatorDokument61 SeitenActuatorforeverdieselNoch keine Bewertungen

- ReportfinalDokument44 SeitenReportfinalYuvraj GogoiNoch keine Bewertungen

- Speed Control of DC MotorDokument31 SeitenSpeed Control of DC Motorabhinav. alpheus651997Noch keine Bewertungen

- Doubly-Fed Electric Machine - WikipediaDokument5 SeitenDoubly-Fed Electric Machine - WikipediavineeshNoch keine Bewertungen

- Ac Electrical Machines: Provided by Pn. Zuraidah BT Ali Mech. Eng. Dept. PUODokument21 SeitenAc Electrical Machines: Provided by Pn. Zuraidah BT Ali Mech. Eng. Dept. PUOMuhd AkmalNoch keine Bewertungen

- DC Motor Speed Control: Bayan University For Science & TechnologyDokument12 SeitenDC Motor Speed Control: Bayan University For Science & TechnologyAltayeb AbdulhameedNoch keine Bewertungen

- 15EEE401 - II Ass - Aug 2018Dokument2 Seiten15EEE401 - II Ass - Aug 2018sriharshitha vegesnaNoch keine Bewertungen

- Speed Control of 3 Phase Ac Induction Motor Using Micro 2407Dokument58 SeitenSpeed Control of 3 Phase Ac Induction Motor Using Micro 2407sundarspace100% (2)

- Lecture No 5Dokument27 SeitenLecture No 5Walid salamaNoch keine Bewertungen

- IDC Unit-4Dokument9 SeitenIDC Unit-4Gaurav SinghNoch keine Bewertungen

- Machine Tool DrivesDokument21 SeitenMachine Tool DrivesChaitanyaSrivastava100% (1)

- Wind Energy Training Ch#5Dokument34 SeitenWind Energy Training Ch#5Munseb AliNoch keine Bewertungen

- L T D I V F D: Atest Echnological Evelopments N Ariable Requency RivesDokument18 SeitenL T D I V F D: Atest Echnological Evelopments N Ariable Requency RivesBijay AgrawalNoch keine Bewertungen

- Types of Ac GeneratorDokument10 SeitenTypes of Ac GeneratorJherel BerinNoch keine Bewertungen

- 1.1 Introduction of Project: 1.1.1 MOTORSDokument37 Seiten1.1 Introduction of Project: 1.1.1 MOTORSSanjit PanchalNoch keine Bewertungen

- ست خطوات العاكس لقيادة المحرك التعريفي ثلاث مراحلDokument113 Seitenست خطوات العاكس لقيادة المحرك التعريفي ثلاث مراحلMOUHSSINE BEN HAMMOUNoch keine Bewertungen

- For Quadrant DC Motor ControlDokument43 SeitenFor Quadrant DC Motor ControlDarshanRupani100% (1)

- History of CLW: Chittaranjan Locomotive Works. CLW Is The Proud Recipient of The SafetyDokument10 SeitenHistory of CLW: Chittaranjan Locomotive Works. CLW Is The Proud Recipient of The SafetyRahul SinhaNoch keine Bewertungen

- Chapter-2 Principle-Operation-Applications of Different Stepper Motors and Significance of Permanent Magnet Hybrid Stepper MotorDokument14 SeitenChapter-2 Principle-Operation-Applications of Different Stepper Motors and Significance of Permanent Magnet Hybrid Stepper MotorPriya PerumalNoch keine Bewertungen

- LCIs and Syn Motors Applied To Roller Mills - Zayechek - 2000Dokument10 SeitenLCIs and Syn Motors Applied To Roller Mills - Zayechek - 2000Parameswararao BillaNoch keine Bewertungen

- AC and DC MotorDokument13 SeitenAC and DC MotorrikechNoch keine Bewertungen

- Topic: DC Motor Using Mechanical Application: New Era University College of Engineering and TechnologyDokument13 SeitenTopic: DC Motor Using Mechanical Application: New Era University College of Engineering and TechnologyMAr Lon Dela CruzNoch keine Bewertungen

- Unit VDokument32 SeitenUnit Vrahulmeenameenarahul26Noch keine Bewertungen

- 3827-E10-031 - Flow Element List - EDokument37 Seiten3827-E10-031 - Flow Element List - EMohamed Elsaid El ShallNoch keine Bewertungen

- 3827-E10-063 - Modulating Control Valve - EDokument6 Seiten3827-E10-063 - Modulating Control Valve - EMohamed Elsaid El ShallNoch keine Bewertungen

- 3827-E10-067 - High Performance Butterfly Valve - BDokument2 Seiten3827-E10-067 - High Performance Butterfly Valve - BMohamed Elsaid El ShallNoch keine Bewertungen

- 3827-E10-064 - Pressure Reducing Valve - CDokument2 Seiten3827-E10-064 - Pressure Reducing Valve - CMohamed Elsaid El ShallNoch keine Bewertungen

- 3827-E10-062 - Two Position Valve - DDokument4 Seiten3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNoch keine Bewertungen

- 3827-E10-066 - Knife Gate (On-Off) Control Valve - DDokument2 Seiten3827-E10-066 - Knife Gate (On-Off) Control Valve - DMohamed Elsaid El ShallNoch keine Bewertungen

- 3827-E10-066 - Knife Gate (On-Off) Control Valve - DDokument2 Seiten3827-E10-066 - Knife Gate (On-Off) Control Valve - DMohamed Elsaid El ShallNoch keine Bewertungen

- A54 2 Korzeniewski Improved Algorithms of Direct Torque Control MethodDokument11 SeitenA54 2 Korzeniewski Improved Algorithms of Direct Torque Control MethodMohamed Elsaid El ShallNoch keine Bewertungen

- How To Write Technical PapersDokument4 SeitenHow To Write Technical PapersManjunath Keshav D MNoch keine Bewertungen

- 50BFDokument8 Seiten50BFSven del PinoNoch keine Bewertungen

- Field Oriented ControlDokument25 SeitenField Oriented ControlrussellsabirNoch keine Bewertungen

- Slide MV SSTDokument36 SeitenSlide MV SSTMohamed Elsaid El ShallNoch keine Bewertungen

- 01CourseII CompleteDokument39 Seiten01CourseII CompleteMohamed Elsaid El ShallNoch keine Bewertungen

- Research DR - SamiDokument197 SeitenResearch DR - SamiMohamed Elsaid El ShallNoch keine Bewertungen

- Second Assignment: Abstract and Summary (Due: April 16: Problem No. 1Dokument3 SeitenSecond Assignment: Abstract and Summary (Due: April 16: Problem No. 1Mohamed Elsaid El ShallNoch keine Bewertungen

- 8 TitlesReferencesDokument9 Seiten8 TitlesReferencesMohamed Elsaid El ShallNoch keine Bewertungen

- Generators and Nonlinear LoadsDokument15 SeitenGenerators and Nonlinear LoadsAl-Kawthari As-SunniNoch keine Bewertungen

- First Assignment: Topic and Thesis Statements (Due: April 9: Problem No. 1Dokument1 SeiteFirst Assignment: Topic and Thesis Statements (Due: April 9: Problem No. 1Mohamed Elsaid El ShallNoch keine Bewertungen

- 11 SentenceErrorsDokument39 Seiten11 SentenceErrorsMohamed Elsaid El ShallNoch keine Bewertungen

- 00 Full Course Level III 2014Dokument63 Seiten00 Full Course Level III 2014Mohamed Elsaid El ShallNoch keine Bewertungen

- The Scientific Article: CUFE, M. Sc. MPM, 2014-2015Dokument5 SeitenThe Scientific Article: CUFE, M. Sc. MPM, 2014-2015Mohamed Elsaid El ShallNoch keine Bewertungen

- 06-Summaries Abstract1Dokument12 Seiten06-Summaries Abstract1Mohamed Elsaid El ShallNoch keine Bewertungen

- 05-Outlining OrganizingDokument14 Seiten05-Outlining OrganizingMohamed Elsaid El ShallNoch keine Bewertungen

- 9-The Scientific ArticleDokument44 Seiten9-The Scientific ArticleMohamed Elsaid El ShallNoch keine Bewertungen

- 7 Effective Sentences10 12Dokument92 Seiten7 Effective Sentences10 12Mohamed Elsaid El ShallNoch keine Bewertungen

- 05-Outlining OrganizingDokument14 Seiten05-Outlining OrganizingMohamed Elsaid El ShallNoch keine Bewertungen

- MOSFET Short Channel EffectsDokument11 SeitenMOSFET Short Channel EffectsPranali A JadhavNoch keine Bewertungen

- FSN240003 eDokument8 SeitenFSN240003 eAnıl KahyaNoch keine Bewertungen

- TTS Marine Cargo Cranes: Technical InformationDokument3 SeitenTTS Marine Cargo Cranes: Technical InformationDima KryzhanovskyiNoch keine Bewertungen

- HJ3600 ManualDokument4 SeitenHJ3600 Manualmauro zarateNoch keine Bewertungen

- Alstom Referral Guide W.E.F 01.01.2013Dokument1 SeiteAlstom Referral Guide W.E.F 01.01.2013Sagar ThakerNoch keine Bewertungen

- MicrophoneDokument11 SeitenMicrophoneChew Kah MengNoch keine Bewertungen

- AURETR009 Install Vehicle Lighting and Wiring SystemsDokument97 SeitenAURETR009 Install Vehicle Lighting and Wiring Systemsjaredmuge808Noch keine Bewertungen

- East Point College of Engineering & TechnologyDokument2 SeitenEast Point College of Engineering & TechnologyVasavi VaasuNoch keine Bewertungen

- Timebase CircuitsDokument2 SeitenTimebase Circuitsjeravi84Noch keine Bewertungen

- DatasheetDokument2 SeitenDatasheetDidier DoradoNoch keine Bewertungen

- Inovance Md290 VFD Quick Guide English 20-4-20Dokument103 SeitenInovance Md290 VFD Quick Guide English 20-4-20DEE - 5 BKUNoch keine Bewertungen

- Ground Bounce Part 1:: BrookspeakDokument3 SeitenGround Bounce Part 1:: BrookspeakKurien AnnaNoch keine Bewertungen

- Zener Controlled Transistor Voltage RegulatorDokument9 SeitenZener Controlled Transistor Voltage Regulatorkanye eastNoch keine Bewertungen

- Clamp Meters Working Principle Instrumentation ToolsDokument4 SeitenClamp Meters Working Principle Instrumentation ToolsTEUKUNoch keine Bewertungen

- ME20P03Dokument5 SeitenME20P03gaston30-3@Noch keine Bewertungen

- CRG15T60A83LDokument10 SeitenCRG15T60A83LVadim PopovichNoch keine Bewertungen

- Stancor Ultra-Linear Williamson Amplifier W A-8054 XFMRDokument6 SeitenStancor Ultra-Linear Williamson Amplifier W A-8054 XFMRVaslejeanNoch keine Bewertungen

- P-Channel Enhancement Mode Power Mosfet: Product SummaryDokument5 SeitenP-Channel Enhancement Mode Power Mosfet: Product Summaryserrano.flia.coNoch keine Bewertungen

- Category 6 250Mhz Gel Filled Outdoor Lan CableDokument2 SeitenCategory 6 250Mhz Gel Filled Outdoor Lan Cablesoulkidnyc4920Noch keine Bewertungen

- STPR2020CTW 3Dokument3 SeitenSTPR2020CTW 3RaghuNoch keine Bewertungen

- SARGENT Exit Trim 773 - 774 - 775 Series Installation InstructionsDokument4 SeitenSARGENT Exit Trim 773 - 774 - 775 Series Installation InstructionsXavier TamashiiNoch keine Bewertungen

- CH3 TransformerDokument57 SeitenCH3 TransformerDoktor CintaNoch keine Bewertungen

- A Full-Bridge Phase-Shifted Inverter For Induction HeatingDokument78 SeitenA Full-Bridge Phase-Shifted Inverter For Induction HeatingCCNoch keine Bewertungen