Beruflich Dokumente

Kultur Dokumente

ABRASION-RESISTANT STEEL PLATE DATA

Hochgeladen von

Baihaki StOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ABRASION-RESISTANT STEEL PLATE DATA

Hochgeladen von

Baihaki StCopyright:

Verfügbare Formate

ABRASION-RESISTANT PLATE

ProductDataSheet20120401

P a g e |1

AR235

Abrasion-Resistant Steel Plate

General Product Description

AR235 is an as-rolled, carbon-steel plate with a nominal hardness of 235 HBW, intended for

moderate wear applications. AR235 is available as temper-leveled, cut-to-length plate. AR235

is not intended for structural applications.

Applications

Typical applications for AR235 steel plate include cement mixer drums and fins, bulk material

handling chute liners, skirtboard liners, and screw conveyers.

Dimensions Available: The following AR235 plate sizes are available.

Product Type

Thickness, in [mm]

0.188 0.375

[4.8 9.5]

>0.375 0.500

[>9.5 12.7]

Cut-to-Length Plate

Width, in [mm]

72 96

[1,830 - 2,438]

72

[1,830]

Length, in [mm]

96 720

[2,438 18,288]

96 720

[2,438 18,288]

Mechanical Properties

AR235 has a nominal hardness of 235 HBW. Applications requiring specific mechanical

properties should be inquired.

HBW

Typical

235

Chemical Composition (ladle analysis, wt. % max.)

C

0.50

Mn

0.90

P

0.020

S

0.010

Si

0.35

15

CEV, Typical

0.65

10

CET, Typical

0.55

20

40

Testing

Brinell hardness, HBW, according to ASTM A370, on a milled or ground surface 0.020 to

0.118 (0.5 - 3.0 mm) below the plate surface.

Tolerances

Thickness, width, and length tolerances according to ASTM A6. ASTM A6 half-standard

flatness tolerance is available.

www.ssab.com

ABRASION-RESISTANT PLATE

ProductDataSheet20120401

P a g e |2

Fabrication and Other Recommendations

Cutting

AR235 steel plate can be gas cut satisfactorily. Preheating at 300oF is recommended for

thermal cutting. The hardened, heat-affected zones adjacent to the cut surfaces should be

removed before any subsequent forming or welding operations.

Weldability

AR235 is weldable by conventional electric arc welding processes, using low-hydrogen

consumables and appropriate welding practices. The following recommendations should be

considered.

Welding Process

Thickness

Shielded Metal Arc (SMAW)

Gas Metal Arc (GMAW)

Submerged Arc Weld (SAW)

Flux Cored Arc Welding (FCAW)

Up to

Up to

Up to

Up to

Preheat / Interpass

Temperature

300oF (150oC)

300oF (150oC)

300oF (150oC)

300oF (150oC)

Consumables

AWS-E11018

AWS ER110S-X

AWS F11X-EXXX

AWS E11XT-X

When matching consumables are not required, lower strength electrodes (ER70/ER80,

E7XT/E7XT, E7X/E8X or E7018/E8018) are recommended. Slow-cooling after welding and a

post-weld heat treatment at 1100F (595C) are suggested to minimize the potential for cold

cracking. The electrodes for shielded metal arc welding must be properly stored and dried; the

welding flux for submerged arc welding must be properly dried.

Formability

AR235 may be employed in moderate cold forming applications. Proper edge preparation (i.e.

removal of hardened heat-affected zones adjacent to the cut surfaces) is essential to minimize

the potential for cracking. Cold forming should be performed at a minimum temperature of 68F

(20C). The minimum recommended punch radius, R, and die width opening, W, as a function

of bending orientation are provided in the following table.

Thickness

in [mm]

0.1875 0.500

[4.8 12.7]

Bend axis perpendicular

to rolling direction

Min. Punch

Die width, W

Radius, R

4t

11t

Bend axis parallel

to rolling direction

Min. Punch

Die width, W

Radius, R

6t

15t

Sales Contacts

For sales information, please call 877-294-3858 (Southern USA & Mexico), 800-340-5566

(Western and Central USA), 800-383-9031 (North Central USA), and 888-576-8530 (Northeast

USA & Canada) or consult www.ssab.com.

www.ssab.com

Das könnte Ihnen auch gefallen

- 010 - AR200 Product Data Sheet 2012 04 01Dokument2 Seiten010 - AR200 Product Data Sheet 2012 04 01Baihaki StNoch keine Bewertungen

- ABRASION-RESISTANT STEEL PLATE DATA SHEETDokument2 SeitenABRASION-RESISTANT STEEL PLATE DATA SHEETFernanNoch keine Bewertungen

- Preheat Ions For A 514 Grade B MaterialDokument2 SeitenPreheat Ions For A 514 Grade B Materialjrod64Noch keine Bewertungen

- Recom. de Soldadura XARDokument4 SeitenRecom. de Soldadura XARelias667Noch keine Bewertungen

- Midalloy ER70S-2Dokument1 SeiteMidalloy ER70S-2nasirfahimNoch keine Bewertungen

- High-Strength Steel Plate Data SheetDokument2 SeitenHigh-Strength Steel Plate Data SheetRodolfoMarínNoch keine Bewertungen

- Arcelor Deep Draw MaterialDokument7 SeitenArcelor Deep Draw MaterialJayDadrassNoch keine Bewertungen

- Cast-iron welding guide covers standardsDokument10 SeitenCast-iron welding guide covers standardsclnNoch keine Bewertungen

- Alumec PDFDokument7 SeitenAlumec PDFetamil87Noch keine Bewertungen

- A514 Grade S Brochure 06-25-08Dokument2 SeitenA514 Grade S Brochure 06-25-08anjangandak2932Noch keine Bewertungen

- Standard Steel PlatesDokument39 SeitenStandard Steel PlatesCuong TranHung100% (1)

- 9ni Cryogenic Materials PDFDokument5 Seiten9ni Cryogenic Materials PDFyogie4061100% (1)

- AL201LNDokument6 SeitenAL201LNCastoriadisNoch keine Bewertungen

- Duplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dokument6 SeitenDuplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dell_RevanNoch keine Bewertungen

- STANDARD - ASTM A792 - Brief DescriptionDokument3 SeitenSTANDARD - ASTM A792 - Brief DescriptionSeyong ParkNoch keine Bewertungen

- Guide To Structural Steel Selection - G-SpecificationsDokument56 SeitenGuide To Structural Steel Selection - G-SpecificationsFelix RanillaNoch keine Bewertungen

- Manual de Alambres Solidos LincolnDokument32 SeitenManual de Alambres Solidos LincolnBartolome VasquezNoch keine Bewertungen

- Filler Wires PDFDokument7 SeitenFiller Wires PDFJayaram MVNoch keine Bewertungen

- Steel Clasification and WeldabilityDokument32 SeitenSteel Clasification and Weldabilitycentaury2013Noch keine Bewertungen

- Arc Welding ElectrodesDokument6 SeitenArc Welding ElectrodeswaleedyossefNoch keine Bewertungen

- Welding Cast Iron GuideDokument10 SeitenWelding Cast Iron GuideRoberto CordovaNoch keine Bewertungen

- Hot Rolled Structural Steel Plate Data SheetDokument2 SeitenHot Rolled Structural Steel Plate Data SheetHugo RodriguezNoch keine Bewertungen

- 6061 Aluminium Alloy - WikipediaDokument33 Seiten6061 Aluminium Alloy - WikipediaMangesh MishraNoch keine Bewertungen

- How To Weld 254 SMODokument12 SeitenHow To Weld 254 SMOsateesh chand100% (7)

- Algoma SteelDokument18 SeitenAlgoma Steelsahzaidi544Noch keine Bewertungen

- Welding Parameters of XABO 890 960Dokument11 SeitenWelding Parameters of XABO 890 960Tomáš BrtníkNoch keine Bewertungen

- Arcelormittal A514 and T-1Dokument6 SeitenArcelormittal A514 and T-1Ali Varmazyar0% (1)

- 380.1 PropiedadesDokument3 Seiten380.1 PropiedadesNini CortesNoch keine Bewertungen

- Atmospheric Corrosion Resisting SteelDokument10 SeitenAtmospheric Corrosion Resisting SteelCarlos PadillaNoch keine Bewertungen

- F enDokument6 SeitenF enBunPământNoch keine Bewertungen

- Aluminium Welding Pocket GuideDokument31 SeitenAluminium Welding Pocket GuideRavindra S. Jivani100% (1)

- Guia Practica Eleccion AporteDokument26 SeitenGuia Practica Eleccion AporteNegrito RosarinoNoch keine Bewertungen

- How To Weld "T-1" Constructional Alloy Steels: ForewordDokument12 SeitenHow To Weld "T-1" Constructional Alloy Steels: ForewordjoseritoNoch keine Bewertungen

- N, BNDokument1 SeiteN, BNmomenziNoch keine Bewertungen

- Tata Steel Cutting Edges GuideDokument2 SeitenTata Steel Cutting Edges GuideKen SmithNoch keine Bewertungen

- ASTM A514 Grade S: General Product DescriptionDokument2 SeitenASTM A514 Grade S: General Product DescriptionAGUSTINNoch keine Bewertungen

- KISWEL Mag Welding ConsumableDokument4 SeitenKISWEL Mag Welding Consumablekhwanta-btaNoch keine Bewertungen

- Al AlloyDokument20 SeitenAl AlloyFaizan AkbarNoch keine Bewertungen

- SAILMA Steel Grades & SheetsDokument2 SeitenSAILMA Steel Grades & SheetsElumalai SrinivasanNoch keine Bewertungen

- ASTM A153 Guide for Galvanized Hardware & FastenersDokument5 SeitenASTM A153 Guide for Galvanized Hardware & FastenersMekhmanNoch keine Bewertungen

- Ruukki Hot Rolled Steels Processing of Material WeldingDokument11 SeitenRuukki Hot Rolled Steels Processing of Material Weldingprince5621Noch keine Bewertungen

- How To Weld T-1 SteelDokument21 SeitenHow To Weld T-1 SteelMuthu Barathi ParamasivamNoch keine Bewertungen

- Application - Cast Iron RepairDokument16 SeitenApplication - Cast Iron RepairAnonymous L0ChmPGNoch keine Bewertungen

- Alloy Steel Round BarDokument10 SeitenAlloy Steel Round BarSingarao KattaNoch keine Bewertungen

- OneSteel TablesDokument34 SeitenOneSteel TablesScott DennettNoch keine Bewertungen

- PB Alumec EnglishDokument12 SeitenPB Alumec EnglishByron RodriguezNoch keine Bewertungen

- Technical DataDokument17 SeitenTechnical Datat_syamprasadNoch keine Bewertungen

- 65 45 12 Ductile IronDokument2 Seiten65 45 12 Ductile IronD_D_76100% (1)

- Alform-Plate High-Strength Rev3 EnglDokument12 SeitenAlform-Plate High-Strength Rev3 EnglTomáš BrtníkNoch keine Bewertungen

- Sae Ams 5515L-2013Dokument6 SeitenSae Ams 5515L-2013Mehdi MokhtariNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkVon EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNoch keine Bewertungen

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantVon EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Data Sheet for E 12/2 U0/V/U2H MT Green BeltDokument3 SeitenData Sheet for E 12/2 U0/V/U2H MT Green BeltBaihaki StNoch keine Bewertungen

- Data Sheet PVC Belt 900025 - enDokument3 SeitenData Sheet PVC Belt 900025 - enBaihaki StNoch keine Bewertungen

- 304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFDokument16 Seiten304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFAndressa EgerNoch keine Bewertungen

- 215 0 e S IDokument16 Seiten215 0 e S IBaihaki StNoch keine Bewertungen

- Ansi Cema 401Dokument24 SeitenAnsi Cema 401Baihaki StNoch keine Bewertungen

- Fuji Pressed Bearing B - p03 PDFDokument2 SeitenFuji Pressed Bearing B - p03 PDFBaihaki StNoch keine Bewertungen

- 301 eDokument16 Seiten301 eBaihaki StNoch keine Bewertungen

- Ansi Cema 401Dokument24 SeitenAnsi Cema 401Baihaki StNoch keine Bewertungen

- Vertex Catalog Reply 1Dokument1 SeiteVertex Catalog Reply 1Alejandro HurtadoNoch keine Bewertungen

- Data Sheet for Polyurethane Green Conveyor BeltDokument3 SeitenData Sheet for Polyurethane Green Conveyor BeltBaihaki StNoch keine Bewertungen

- Capacitance Multiplier Power Supply FilterDokument7 SeitenCapacitance Multiplier Power Supply FilterBaihaki StNoch keine Bewertungen

- Steel Comp A Ration TableDokument1 SeiteSteel Comp A Ration TablekazdoelahNoch keine Bewertungen

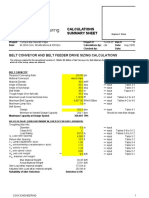

- Belt Conveyors With Shaft SizingDokument5 SeitenBelt Conveyors With Shaft SizingRakhi Mor100% (2)

- YANGLI JH21series Open Back PressDokument6 SeitenYANGLI JH21series Open Back PressBaihaki StNoch keine Bewertungen

- Yadon YC1Dokument1 SeiteYadon YC1Baihaki St100% (1)

- YANGLI JH21series Open Back Press PDFDokument6 SeitenYANGLI JH21series Open Back Press PDFBaihaki StNoch keine Bewertungen

- Volume6 Hydraulic Seals Fluid Conductor and Hydraulic OilDokument64 SeitenVolume6 Hydraulic Seals Fluid Conductor and Hydraulic Oillink2u_007Noch keine Bewertungen

- Rubber Plastic MananufDokument17 SeitenRubber Plastic MananufBaihaki StNoch keine Bewertungen

- Fuji Pressed Bearing B - p03Dokument2 SeitenFuji Pressed Bearing B - p03Baihaki StNoch keine Bewertungen

- Part CNC 1 Detail ModelDokument1 SeitePart CNC 1 Detail ModelBaihaki StNoch keine Bewertungen

- RT BanjarsariDokument1 SeiteRT BanjarsariBaihaki StNoch keine Bewertungen

- Volume-7. Essential Knowledge Required For Design and Manufacturing of Hydraulic PressesDokument62 SeitenVolume-7. Essential Knowledge Required For Design and Manufacturing of Hydraulic PressesQ.S. Khan100% (5)

- Volume 5 Design and Manufacturing of Hydraulic PressesDokument64 SeitenVolume 5 Design and Manufacturing of Hydraulic PressesBaihaki St100% (1)

- Induction MotorsDokument28 SeitenInduction MotorsMarvin MarcaidaNoch keine Bewertungen

- Apex Regulated PSU - Nabuco Layout PDFDokument4 SeitenApex Regulated PSU - Nabuco Layout PDFBaihaki StNoch keine Bewertungen

- Design of Hydraulic CylinderDokument23 SeitenDesign of Hydraulic Cylindermmkvrde81% (31)

- VF PDFDokument42 SeitenVF PDFBaihaki StNoch keine Bewertungen

- Volume-3. Study of Hydraulic Valves, Pumps, and AccumulatorsDokument79 SeitenVolume-3. Study of Hydraulic Valves, Pumps, and AccumulatorsQ.S. Khan100% (25)

- Volume6 Hydraulic Seals Fluid Conductor and Hydraulic OilDokument64 SeitenVolume6 Hydraulic Seals Fluid Conductor and Hydraulic Oillink2u_007Noch keine Bewertungen

- x3528 Enus 3528 PtprosellsDokument2 Seitenx3528 Enus 3528 PtprosellsBaihaki StNoch keine Bewertungen

- Elastomeric Sealing Compound Specification for BuildingsDokument33 SeitenElastomeric Sealing Compound Specification for BuildingsSivaram KottaliNoch keine Bewertungen

- LJF Installation Manual ACQA36-00270Dokument11 SeitenLJF Installation Manual ACQA36-00270Raymundo Rangel RdzNoch keine Bewertungen

- Thermon Sa - Heat Trace Technologies - Energy SavingsDokument9 SeitenThermon Sa - Heat Trace Technologies - Energy Savingsjose manuel alvarez rodriguezNoch keine Bewertungen

- Effect of Barite On Density of Drilling MudDokument3 SeitenEffect of Barite On Density of Drilling MudAtif MalikNoch keine Bewertungen

- Microstructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialDokument17 SeitenMicrostructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialEditor IJTSRDNoch keine Bewertungen

- Section A: Answer All Questions in This SectionDokument10 SeitenSection A: Answer All Questions in This SectionFazliawati MahayuddinNoch keine Bewertungen

- Determination of DensitiesDokument4 SeitenDetermination of DensitiesJulian CarantoNoch keine Bewertungen

- 1586 - CDH - 4e - Errata No. 1 - 3 July 2018Dokument4 Seiten1586 - CDH - 4e - Errata No. 1 - 3 July 2018Hamid Reza GholamianNoch keine Bewertungen

- Cmos Process FlowDokument25 SeitenCmos Process FlowSHAIK MUSTHAFANoch keine Bewertungen

- Earthquake Protection of Buildings by Seismic Isolation. Devices and ConceptsDokument9 SeitenEarthquake Protection of Buildings by Seismic Isolation. Devices and ConceptsMuhammed Mundhir PNoch keine Bewertungen

- Rigid Pavement: Postgraduate Studies Highways EngineeringDokument15 SeitenRigid Pavement: Postgraduate Studies Highways EngineeringHANAN HUSSNoch keine Bewertungen

- Lab Manual Foundation EngineeringDokument39 SeitenLab Manual Foundation Engineeringartiraha100% (1)

- Soil test kit instructions and reagent listDokument8 SeitenSoil test kit instructions and reagent listhromeroeNoch keine Bewertungen

- Evacuated Tube Collector SpecificationDokument5 SeitenEvacuated Tube Collector SpecificationJaswinder SinghNoch keine Bewertungen

- RCD Beam Analysis and DesignDokument33 SeitenRCD Beam Analysis and DesignJayChristian Quimson50% (12)

- British Standards CableDokument2 SeitenBritish Standards CableVarun Chandran100% (1)

- 2007 World Copper Fact BookDokument66 Seiten2007 World Copper Fact Bookaclarke100% (2)

- Chapter 6 MOSFET: Slide 6-1Dokument74 SeitenChapter 6 MOSFET: Slide 6-1Windarto Properti SoloNoch keine Bewertungen

- Ces S Manf 13 PDFDokument160 SeitenCes S Manf 13 PDFJohn SokolNoch keine Bewertungen

- Primary Clarifier Removes Organic SolidsDokument1 SeitePrimary Clarifier Removes Organic SolidsiastraNoch keine Bewertungen

- List of Welding ProcessesDokument5 SeitenList of Welding ProcessesFilipe CordeiroNoch keine Bewertungen

- Oxidation and Reduction SPM Form 5Dokument63 SeitenOxidation and Reduction SPM Form 5Azie Nurul Akhtar85% (13)

- 15E282 18lab1Dokument10 Seiten15E282 18lab1Yadhuvanth kumarNoch keine Bewertungen

- Bachmann Process For RDXDokument4 SeitenBachmann Process For RDXjoshuaericksonNoch keine Bewertungen

- Problems: CHEM1020Dokument45 SeitenProblems: CHEM1020Ahmed AliNoch keine Bewertungen

- Requirement For Crown Industrial ParkDokument1 SeiteRequirement For Crown Industrial ParkAbdul RafaeNoch keine Bewertungen

- APPC-Soil Properties PDFDokument5 SeitenAPPC-Soil Properties PDFroy1zhouNoch keine Bewertungen

- Paul Meijering: Focusing On Quality and Relationships Ensures SuccessDokument68 SeitenPaul Meijering: Focusing On Quality and Relationships Ensures SuccesssagarNoch keine Bewertungen

- Process Scheme Mechanical & Electrical Equipments & Guidlines For DesignDokument24 SeitenProcess Scheme Mechanical & Electrical Equipments & Guidlines For DesignPravin BoteNoch keine Bewertungen

- Topic 3 - Hydrogen - 2022Dokument45 SeitenTopic 3 - Hydrogen - 2022Hafizh PpNoch keine Bewertungen