Beruflich Dokumente

Kultur Dokumente

Sensor Signal (PWM) - Test: Troubleshooting

Hochgeladen von

ronaldOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sensor Signal (PWM) - Test: Troubleshooting

Hochgeladen von

ronaldCopyright:

Verfügbare Formate

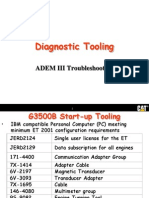

Media Search - RENR5006 - 3500B Engines for Caterpillar Built Power Modules with the ADEM 3 Electronic Contr...

Page 1 of 6

Shutdown SIS

Previous Screen

Product: NO EQUIPMENT SELECTED

Model: NO EQUIPMENT SELECTED

Configuration: NO EQUIPMENT SELECTED

Troubleshooting

3500B Engines for Caterpillar Built Power Modules with the ADEM 3 Electronic Control Module

Media Number -RENR5006-00

Publication Date -2008/02/01

Date Updated -2008/02/19

i02896522

Sensor Signal (PWM) - Test

SMCS - 1439-038

System Operation Description:

Use this procedure to troubleshoot the electrical system if a problem is suspected with the exhaust temperature sensors or if any one

of the diagnostic codes in Table 1 is active or easily repeated.

Table 1

Diagnostic Codes Table

Code and Description

827-8 Left Exhaust Temperature Sensor

abnormal frequency, pulse width, or

period

828-8 Right Exhaust Temperature Sensor

abnormal frequency, pulse width, or

period

Conditions which Generate this Code

The Electronic Control Module (ECM) detects a

sensor frequency that is greater than 1000 Hz or less

than 150 Hz.

The ECM detects a duty cycle that is greater than 90

percent or a duty cycle that is less than 10 percent.

System Response

The code is logged.

The ECM flags exhaust

temperature as invalid data.

The value of the parameter

is set to a default value.

System Operation

The PWM sensors provide a signal to the engine's ECM. The sensors receive a 8.0 0.4 VDC regulated voltage from the ECM.

The sensor's wires are routed from the ECM to the sensor connectors. The following list gives the terminal locations for the sensor

connector.

z

Terminal A digital sensor supply

Terminal B digital sensor return

Terminal C sensor signal

The ECM provides short circuit protection for the internal power supply. A short circuit to the battery will not damage the internal

power supply.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheade... 09/06/2008

Media Search - RENR5006 - 3500B Engines for Caterpillar Built Power Modules with the ADEM 3 Electronic Contr... Page 2 of 6

Illustration 1

Typical schematic

Illustration 2

P1 ECM connector

g01442587

g01213937

(P1-4) Digital sensor supply

(P1-5) Digital sensor return

(P1-11) Left exhaust temperature

(P1-12) Right exhaust temperature

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheade... 09/06/2008

Media Search - RENR5006 - 3500B Engines for Caterpillar Built Power Modules with the ADEM 3 Electronic Contr... Page 3 of 6

Illustration 3

P2 ECM connector

g01383859

(P2-54) Digital sensor return

(P2-56) Digital sensor supply

Illustration 4

g01094844

Sensor connector

(Pin A) Sensor supply

(Pin B) Sensor return

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheade... 09/06/2008

Media Search - RENR5006 - 3500B Engines for Caterpillar Built Power Modules with the ADEM 3 Electronic Contr... Page 4 of 6

(Pin C) Signal

Illustration 5

Location of ECM connectors

g01234146

Test Step 1. Check for "Active" or "Logged" Diagnostic Codes

A. Connect Caterpillar Electronic Technician (ET) to the service tool connector.

B. Turn the main disconnect switch to the ON position.

C. Monitor the diagnostic codes on Cat ET. Check and record any diagnostic codes.

Note: Wait at least 30 seconds in order for the diagnostic codes to become active.

D. Determine if a -8 diagnostic code is active for one of the exhaust temperature sensors.

Note: A diagnostic code that is logged several times is an indication of an intermittent problem. Most intermittent problems

are the result of a bad connection between a socket and a pin in a connector or a bad connection between a wire and a

terminal.

Expected Result:

No diagnostic code is active for the exhaust temperature sensors.

Results:

z

OK - No diagnostic codes are active.

Repair: If the problem is intermittent, refer to Troubleshooting, "Electrical Connectors - Inspect" for the correct procedures

for inspecting electrical connectors.

STOP

Not OK - A -8 diagnostic code is active or the diagnostic code is logged several times. Proceed to Test Step 2.

Test Step 2. Check the Digital Sensor Supply Voltage at the Sensor Connector

A. Turn the main disconnect switch to the OFF position.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheade... 09/06/2008

Media Search - RENR5006 - 3500B Engines for Caterpillar Built Power Modules with the ADEM 3 Electronic Contr... Page 5 of 6

B. Disconnect the suspect sensor(s) at the sensor connector.

C. Turn the main disconnect switch to the ON position.

D. Measure the voltage on the ECM side of the sensor connector between pin A and pin B for the suspect sensor(s).

Expected Result:

The digital sensor supply voltage is 8.0 0.4 VDC.

Results:

z

OK - The supply voltage is 8.0 0.4 VDC. Proceed to Test Step 4.

Not OK - The supply voltage is not 8.0 0.4 VDC. Proceed to Test Step 3.

Test Step 3. Check the Digital Sensor Supply Voltage at the ECM

A. Turn the main disconnect switch to the OFF position.

B. Remove the wire for the digital sensor supply from P1-4. Install a wire jumper into the socket for P1-4.

C. Remove the wire for the digital sensor supply from P2-56. Install a wire jumper into the socket for P2-56.

D. Turn the main disconnect switch to the ON position.

E. Measure the voltage between the wire jumper in terminal P1-4 and engine ground.

F. Measure the voltage between the wire jumper in terminal P2-56 and engine ground.

G. Turn the main disconnect switch to the OFF position.

H. Remove the wire jumper and reconnect all wires. Reconnect ECM connector J1/P1.

Expected Result:

The digital sensor supply voltage is 8.0 0.4 VDC.

Results:

z

OK - The supply voltage is 8.0 0.4 VDC. The supply voltage at the ECM is correct. There is a problem in the wiring

between the ECM and the sensor connector. Repair the connectors or wiring and/or replace the connectors or wiring.

Repair: Repair the connectors or wiring and/or replace the connectors or wiring.

STOP

Not OK - The supply voltage is not 8.0 0.4 VDC. The voltage at the ECM is not correct.

Repair: Replace the ECM. Refer to Troubleshooting, "ECM - Replace". Verify that the problem is resolved.

STOP

Test Step 4. Check the Digital Sensor's Signal Frequency and the Duty Cycle at the Sensor Connector

A. Turn the main disconnect switch to the OFF position.

B. Remove the suspect sensor's signal wire from pin C of the sensor connector.

C. Reconnect the suspect sensor connector.

D. Turn the main disconnect switch to the ON position.

E. Measure the frequency and the duty cycle between the sensor's signal wire and pin B of the suspect digital sensor at the

sensor connector.

F. Turn the main disconnect switch to the OFF position.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheade... 09/06/2008

Media Search - RENR5006 - 3500B Engines for Caterpillar Built Power Modules with the ADEM 3 Electronic Contr... Page 6 of 6

G. Replace the sensor's signal wire and reconnect the sensor.

Expected Result:

The duty cycle is between 10 to 90 percent. The frequency reading is approximately 500 Hz.

Results:

z

OK - The frequency and the duty cycle are correct. Proceed to Test Step 5.

Not OK - The frequency or the duty cycle is not correct.

Repair: Replace the sensor. Verify that no diagnostic codes are active for the suspect sensor before permanently installing

the sensor.

STOP

Test Step 5. Check the Digital Sensor's Duty Cycle at the ECM

A. Remove the suspect signal wire for the sensor from ECM connector P1. Refer to Illustration 1 for the terminal locations for

the ECM connector.

B. Turn the main disconnect switch to the ON position.

C. Measure the duty cycle between the sensor's signal wire and the sensor's return wire.

Note: Set the multimeter to "VDC". Press the "Hz" button twice so that the % symbol is displayed.

D. Turn the main disconnect switch to the OFF position. Reconnect all wires.

Expected Result:

The duty cycle is between 10 to 90 percent.

Results:

z

OK - The duty cycle is correct.

Repair: Replace the ECM. Refer to the diagnostic procedure Troubleshooting, "ECM - Replace".

STOP

Not OK - The duty cycle is not correct.

Repair: There is a problem in the wiring between the ECM and the connector for the sensor. Repair the connectors and/or

wiring between the ECM and the connector for the sensor.

STOP

Copyright 1993 - 2008 Caterpillar Inc.

All Rights Reserved.

Private Network For SIS Licensees.

Mon Jun 9 00:51:17 EST 2008

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheade... 09/06/2008

Das könnte Ihnen auch gefallen

- Injection Actuation CircuitDokument9 SeitenInjection Actuation Circuitsamsularief03Noch keine Bewertungen

- Cat Data Link Circuit - Test 01-02-2009Dokument7 SeitenCat Data Link Circuit - Test 01-02-2009harikrishnanpd3327Noch keine Bewertungen

- Speed Control (Switch) - Test (RENR5096)Dokument4 SeitenSpeed Control (Switch) - Test (RENR5096)Josip MiškovićNoch keine Bewertungen

- Diagrama Electrico D9N-CBJ000481Dokument2 SeitenDiagrama Electrico D9N-CBJ000481luisitolokitod100% (1)

- Injection Actuation Pressure Control Valve - Test: TroubleshootingDokument10 SeitenInjection Actuation Pressure Control Valve - Test: TroubleshootingsatyaNoch keine Bewertungen

- Kirloskar: Diesel Generating SetsDokument4 SeitenKirloskar: Diesel Generating SetsKevin LoayzaNoch keine Bewertungen

- Cat 307B Control JoystickDokument2 SeitenCat 307B Control JoystickAtaa AssaadNoch keine Bewertungen

- Cat Electronic Technician 2014A v1.0 Product Status ReportDokument6 SeitenCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNoch keine Bewertungen

- 3020-07 14m ArarDokument14 Seiten3020-07 14m ArarKhaled KamelNoch keine Bewertungen

- Dredging Pumps MaartDokument20 SeitenDredging Pumps MaartHotnCrispy CrispyNoch keine Bewertungen

- Re 95023Dokument8 SeitenRe 95023Rafael Torres SabalzaNoch keine Bewertungen

- Philips (Funai) PL10.4 40PFL5705Dokument59 SeitenPhilips (Funai) PL10.4 40PFL5705Israel B ChavezNoch keine Bewertungen

- Cat Electronic Technician 2014A v1.0 Product Status ReportDokument6 SeitenCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNoch keine Bewertungen

- Electrical Output Components: Operación de SistemasDokument11 SeitenElectrical Output Components: Operación de SistemasPatricio Esteban Gallegos Tiska100% (1)

- Ether Injection Control SolenoidDokument3 SeitenEther Injection Control SolenoidBlowby HighNoch keine Bewertungen

- Celect Codes: A Complete List of All Celect Fault Codes For The Cummins EcmDokument3 SeitenCelect Codes: A Complete List of All Celect Fault Codes For The Cummins EcmEduardo TorresNoch keine Bewertungen

- 966 F Loader444 PDFDokument14 Seiten966 F Loader444 PDFmarsh2002Noch keine Bewertungen

- Status Report Wickler M315D W5M05442 Low Engine Oil Pressure - PSRPT - 2021-07-19 - 10.08.10Dokument9 SeitenStatus Report Wickler M315D W5M05442 Low Engine Oil Pressure - PSRPT - 2021-07-19 - 10.08.10Jean DiscretNoch keine Bewertungen

- Diagnostic Codes: Shutdown SISDokument3 SeitenDiagnostic Codes: Shutdown SISNovakurniawanNoch keine Bewertungen

- Re95201 2007-11Dokument16 SeitenRe95201 2007-11renatNoch keine Bewertungen

- 311Dokument2 Seiten311Anonymous cS9UMvhBq100% (2)

- Murphy PDFDokument3 SeitenMurphy PDFeduardo100% (1)

- MID 164, PPID 390 Power Supply Fault in Control 1, in Relation To PotentiometerDokument1 SeiteMID 164, PPID 390 Power Supply Fault in Control 1, in Relation To Potentiometeruser1Noch keine Bewertungen

- Diagrama Hdraulico 928hz CXKDokument2 SeitenDiagrama Hdraulico 928hz CXKManuel BarronNoch keine Bewertungen

- Machine Profiles: D9R Track-Type TractorsDokument8 SeitenMachine Profiles: D9R Track-Type TractorsJavier Pagan TorresNoch keine Bewertungen

- Instructions For 35si HP 36si HP Replacing Delco Remy 21si, 22si, 23si, 33si, 34si, 35si and 36siDokument2 SeitenInstructions For 35si HP 36si HP Replacing Delco Remy 21si, 22si, 23si, 33si, 34si, 35si and 36sishinichieNoch keine Bewertungen

- CAT 336E Excavator Hydrolic SystemDokument5 SeitenCAT 336E Excavator Hydrolic SystemAbdul KhaliqNoch keine Bewertungen

- Engine Cranks But Will Not Start: Shutdown SIS Previous ScreenDokument8 SeitenEngine Cranks But Will Not Start: Shutdown SIS Previous ScreenAHMED2ALINoch keine Bewertungen

- Plano Electrico 1HLDokument2 SeitenPlano Electrico 1HLRamon Hidalgo100% (1)

- Cat Electronic Technician 2014A v1.0 Product Status ReportDokument10 SeitenCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNoch keine Bewertungen

- SYMC Eu IV DTC Description V1 070307Dokument28 SeitenSYMC Eu IV DTC Description V1 070307Sooziet RegmiNoch keine Bewertungen

- RENR1439Dokument2 SeitenRENR1439omarNoch keine Bewertungen

- Fill d6tDokument8 SeitenFill d6tClaudionorGomesFilhoNoch keine Bewertungen

- Fan Motor Speed (Hydraulic and Radiator Cooling) - Test and Adjust PDFDokument3 SeitenFan Motor Speed (Hydraulic and Radiator Cooling) - Test and Adjust PDFHarol Ariel Sanchez MezaNoch keine Bewertungen

- Codigo de Falla 0091 Fmi 08Dokument1 SeiteCodigo de Falla 0091 Fmi 08José100% (1)

- Sensor, Pressure CUMMINS QSC8.3, OEMNO - 3085140, Application - 3085140 Sensor, Pressure CUMMINS QSC8.3 PDFDokument3 SeitenSensor, Pressure CUMMINS QSC8.3, OEMNO - 3085140, Application - 3085140 Sensor, Pressure CUMMINS QSC8.3 PDFVictor Hugo Benitez PaezNoch keine Bewertungen

- m325d MH SlidesDokument27 Seitenm325d MH SlidesElmer Cueva Requelme100% (1)

- 6es5 095-8mc01 ManualDokument3 Seiten6es5 095-8mc01 Manualtopan100% (1)

- Extract of HEIL Old Manual Valve SectionsDokument10 SeitenExtract of HEIL Old Manual Valve SectionsL.kolekar100% (1)

- Part2 06 AuxDokument15 SeitenPart2 06 AuxNoel Olvera100% (1)

- Pilot Hydraulic SystemDokument24 SeitenPilot Hydraulic SystemRizqi Huda100% (1)

- Front Suspension (Cylinder) - Purge and Charge: Part Number - S/N - Dls1-Up Part Number - S/N - Eed1-UpDokument14 SeitenFront Suspension (Cylinder) - Purge and Charge: Part Number - S/N - Dls1-Up Part Number - S/N - Eed1-UpzhenyupanNoch keine Bewertungen

- 2.even ImplementosDokument9 Seiten2.even ImplementosCristiam AguilarNoch keine Bewertungen

- Cummins ISM Fault CodesDokument14 SeitenCummins ISM Fault CodesFlavio EdisonNoch keine Bewertungen

- Esab Edw 510D-3Dokument2 SeitenEsab Edw 510D-3Allia AliNoch keine Bewertungen

- Catepilar ParameterDokument3 SeitenCatepilar ParameterHAriantonoNoch keine Bewertungen

- Thursday, July 9, 2015: Main Electrical SystemDokument3 SeitenThursday, July 9, 2015: Main Electrical Systemjohn ayengahNoch keine Bewertungen

- HL7607ADokument6 SeitenHL7607AluismdmjNoch keine Bewertungen

- CAT Diagnostic ECO Tools 11pgDokument11 SeitenCAT Diagnostic ECO Tools 11pgRegulo TrujilloNoch keine Bewertungen

- Codigos de Falla 640GIIIDokument4 SeitenCodigos de Falla 640GIIIAlfredo Antonio Lopez MuñozNoch keine Bewertungen

- 320 C RAW ElectricDokument2 Seiten320 C RAW ElectricRudolph Prieto M100% (2)

- Tabella Codici Evento e DiagnosticaDokument4 SeitenTabella Codici Evento e DiagnosticajorgedavidgonzalezNoch keine Bewertungen

- Service Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Dokument5 SeitenService Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Milorad Zelenovic100% (1)

- Electronic Control ModuleDokument7 SeitenElectronic Control ModuleBroCactusNoch keine Bewertungen

- Electronic Control System ComponentsDokument4 SeitenElectronic Control System ComponentsThein Htoon lwinNoch keine Bewertungen

- Sensor Signal (PWM) - Test: TroubleshootingDokument9 SeitenSensor Signal (PWM) - Test: TroubleshootingOsvaldo UrbanoNoch keine Bewertungen

- Digital Sensor: SupplyDokument6 SeitenDigital Sensor: SupplyYUDI WAHYUDI 17249Noch keine Bewertungen

- Speed Control Test Cat C15Dokument8 SeitenSpeed Control Test Cat C15Mantenimiento La Punta100% (1)

- Engine Pressure Sensor Open or Short PDFDokument14 SeitenEngine Pressure Sensor Open or Short PDFNydRomG100% (2)

- Future Tense With "Going To" - What Is Sara Going To Do?Dokument5 SeitenFuture Tense With "Going To" - What Is Sara Going To Do?ronaldNoch keine Bewertungen

- Brall 2007Dokument6 SeitenBrall 2007ronaldNoch keine Bewertungen

- Plano de Transmision D6TDokument2 SeitenPlano de Transmision D6TronaldNoch keine Bewertungen

- Sensor Signal (Analog, Active) - Test: TroubleshootingDokument11 SeitenSensor Signal (Analog, Active) - Test: TroubleshootingronaldNoch keine Bewertungen

- CE0510 4.0v1 Sophos Central Protection OverviewDokument32 SeitenCE0510 4.0v1 Sophos Central Protection Overviewing.victorm.bastidassNoch keine Bewertungen

- SpaceLabs Qube 91390 Service ManualDokument160 SeitenSpaceLabs Qube 91390 Service ManualGandy Torres TorresNoch keine Bewertungen

- Etn21 Card ManualDokument290 SeitenEtn21 Card ManualMel AwrNoch keine Bewertungen

- BJT Cascade AmplifierDokument3 SeitenBJT Cascade Amplifiermemoivy_24Noch keine Bewertungen

- Question Paper Generator - SRSDokument3 SeitenQuestion Paper Generator - SRSKhurram Ali33% (9)

- DSP Lectures Full SetDokument126 SeitenDSP Lectures Full SetAsad JaviedNoch keine Bewertungen

- Leexyod Digital CatalogueDokument21 SeitenLeexyod Digital CatalogueLexyod DigitalNoch keine Bewertungen

- Module 7 - Assembly LanguageDokument19 SeitenModule 7 - Assembly LanguageKelly Anne Shane LectorNoch keine Bewertungen

- Aastra MX ONE Telephony System: Building BlocksDokument4 SeitenAastra MX ONE Telephony System: Building BlocksbstrellowNoch keine Bewertungen

- FlashFX Tera Getting Started GuideDokument1 SeiteFlashFX Tera Getting Started Guidebleep j blorpensteinNoch keine Bewertungen

- Raid PDFDokument24 SeitenRaid PDFamitNoch keine Bewertungen

- Dogecoin Core (DOGE, Ð) : What Is Dogecoin? - Such CoinDokument5 SeitenDogecoin Core (DOGE, Ð) : What Is Dogecoin? - Such CoinAvanish VermaNoch keine Bewertungen

- Ec6013 Advanced Microprocessors and Microcontrollers L T P CDokument2 SeitenEc6013 Advanced Microprocessors and Microcontrollers L T P Csharmila.mNoch keine Bewertungen

- Massive Mimo Handbook: 1st EditionDokument76 SeitenMassive Mimo Handbook: 1st EditionLokendra RathoreNoch keine Bewertungen

- An IC Operational Transconductance Amplifier (OTA) With Power CapabilityDokument11 SeitenAn IC Operational Transconductance Amplifier (OTA) With Power CapabilityhakimshujaNoch keine Bewertungen

- Laptop - Simple English Wikipedia, The Free EncyclopediaDokument2 SeitenLaptop - Simple English Wikipedia, The Free EncyclopediaglennNoch keine Bewertungen

- A Quick Tutorial On RS485 and MODBUSDokument6 SeitenA Quick Tutorial On RS485 and MODBUSAleksandar LucicNoch keine Bewertungen

- Mosfet CharacteristicsDokument12 SeitenMosfet CharacteristicsNavaneethaan NathamoorthyNoch keine Bewertungen

- FAQ For Windows PortDokument3 SeitenFAQ For Windows PortDerek Souza E SouzaNoch keine Bewertungen

- Fflpii - M - Pqijoni: Is Will Fonn An S) ) Resources Does &, ND Rh1S - Ri, EDokument25 SeitenFflpii - M - Pqijoni: Is Will Fonn An S) ) Resources Does &, ND Rh1S - Ri, ESuraj DasguptaNoch keine Bewertungen

- Chip Renesas UsbDokument43 SeitenChip Renesas UsbvoicuNoch keine Bewertungen

- Assignment 2Dokument3 SeitenAssignment 2Hanan AhmadNoch keine Bewertungen

- ViewPower User ManualDokument51 SeitenViewPower User ManualNha ArtNoch keine Bewertungen

- Design of A New 3 Bit Flash Analog To DiDokument11 SeitenDesign of A New 3 Bit Flash Analog To DisayemeeceNoch keine Bewertungen

- Data Crow Howto Create A ReportDokument21 SeitenData Crow Howto Create A ReportMichael madsenNoch keine Bewertungen

- Data Engineer - Roadmap and FREE Resources - Paper 2021Dokument7 SeitenData Engineer - Roadmap and FREE Resources - Paper 2021svdNoch keine Bewertungen

- Drop BoxDokument86 SeitenDrop Boxmmmmmmmm987654321987Noch keine Bewertungen

- Out of This World Manual DOSDokument5 SeitenOut of This World Manual DOSAnonymous FGY7goNoch keine Bewertungen

- Samsung LN46C610N1FXZA Fast Track Guide (SM)Dokument4 SeitenSamsung LN46C610N1FXZA Fast Track Guide (SM)Carlos OdilonNoch keine Bewertungen

- Datasheet of DS 7608NI K2 - 8P NVRD - V4.31.610 - 20220412Dokument4 SeitenDatasheet of DS 7608NI K2 - 8P NVRD - V4.31.610 - 20220412SamiraNoch keine Bewertungen