Beruflich Dokumente

Kultur Dokumente

Baldwin DAF Systems for Wastewater Treatment

Hochgeladen von

mcsfuvOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Baldwin DAF Systems for Wastewater Treatment

Hochgeladen von

mcsfuvCopyright:

Verfügbare Formate

BALDWIN INDUSTRIAL SYSTEMS

DISSOLVED AIR FLOTATION

WASTEWATER MANAGEMENT

Dissolved Air Flotation is a liquid/solid separation process in which microscopic air bubbles

(10-100) become attached to solid particles suspended in liquid, causing the solid particles to

float. In a DAF system air is dissolved into liquid under pressure. The dissolved air remains in

solution until the pressure is released to atmospheric pressure, causing the air to come out of

solution in the form of microscopic air bubbles. The bubbles are mixed intimately with the

wastewater and become attached to the solids in the waste stream causing the air solids

agglomerate to float to the liquid surface where a solids (float) blanket is formed. Surface

skimmers then remove the float blanket.

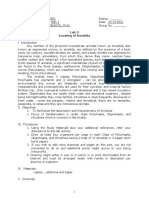

Typical Flowsheet of DAF Clarification

SCREEN

WASTE EQUALISATION

WASTE CONDITIONING

RAW WASTE

PRODUCT REUSE

WASTE DISPOSAL

FLOAT DEWATERING

FLOTATION CELL

WATER REUSE

MUNICIPAL WWTP

BIOLOGICAL TREATMENT

BENEFITS OF THE BALDWIN DAF

Air Dissolving System

The Dissolving System provides an air dissolving efficiency of approximately 80%.

The key to the consistently high dissolving efficiency is the proprietary, non-clogging spray

cone inside the unit, which ensures excellent air/liquid contact, thus a high mass transfer.

The efficiency of the air dissolving system permits lower recycle rates and hence allows

higher wastewater feed rates.

Air Release System

The Air Release System is designed to maximise (greater than 95%) the conversion of air into

bubbles appropriately sized for flotation (10 - 100).

Air/Solids/Polymer Mixing Chamber

The Swirl inducing mixing chamber provides intimate mixing for the air bubbles, solids and

polymer. This allows for optimum air/solids bond formation.

SWIRL INDUCING MIXING CHAMBER

WA

(08) 9412 6100

hydramet@hydramet.com.au

SA & NT

(08) 8374 7800

hydrasa@hydramet.com.au

VIC & TAS

(03) 9325 3900

hydravic@hydramet.com.au

NSW & ACT

(02) 4350 8200

hydransw@hydramet.com.au

www.hydramet.com.au

QLD

(07) 3802 9500

hydraqld@hydramet.com.au

DISSOLVED AIR FLOTATION

WASTEWATER MANAGEMENT

Quiescent Flotation Cell

The addition of vertical baffles, called Lamellas, allows laminar flow conditions to

be maintained at unusually high hydraulic loading. To ensure the float blanket remains

undisturbed, a free air venting system has also been included.

Baldwins standard range of DAF units are designed with capacities from 1m3/hr

to 100m3/hr.

For larger applications custom designs are available to suit site conditions.

Process Optimisation

Baldwins service, know-how and experience are unparalleled in the industry.

A bench scale test unit allows troubleshooting or optimising of existing units in

a quick and professional manner without interrupting the full-scale DAF process.

The same bench scale unit is utilised in our Feasibility Studies to assess the suitability

of DAF as a treatment method and to accurately size and determine various design

parameters including the hydraulic loading and air/solids ratio.

Pilot Unit Available

Although the bench scale unit almost eliminates the need to conduct site trials,

pilot scale units are available to prove performance and generate a float for

dewatering trials.

Performance Guarantee

Baldwins commitment to solving your waste water problem starts with a thorough

evaluation of your process, the components contributing to the generation of waste

water, and continues through equipment selection and design to the final

commissioning and operator training phases.

Selecting a Baldwin DAF unit is your way of ensuring your wastewater problems

are solved.

WA

(08) 9412 6100

hydramet@hydramet.com.au

SA & NT

(08) 8374 7800

hydrasa@hydramet.com.au

VIC & TAS

(03) 9325 3900

hydravic@hydramet.com.au

NSW & ACT

(02) 4350 8200

hydransw@hydramet.com.au

www.hydramet.com.au

QLD

(07) 3802 9500

hydraqld@hydramet.com.au

Das könnte Ihnen auch gefallen

- From Air Sparged Hydrocyclone To Gas Energy Mixing (GEM) Floration, Clean Water TechnologyDokument18 SeitenFrom Air Sparged Hydrocyclone To Gas Energy Mixing (GEM) Floration, Clean Water TechnologyCamille Nunes LeiteNoch keine Bewertungen

- DAF Oil RemovalDokument2 SeitenDAF Oil RemovalAVIJIT MITRANoch keine Bewertungen

- Brochure Producedwater Sorbwater For WEBDokument12 SeitenBrochure Producedwater Sorbwater For WEBManvendra SinghNoch keine Bewertungen

- Dissolved Air Flotation SystemDokument4 SeitenDissolved Air Flotation SystemHari Dwipayanto DwipayantoNoch keine Bewertungen

- Daf PDFDokument10 SeitenDaf PDFHRK65Noch keine Bewertungen

- Saturator Design and CalsDokument11 SeitenSaturator Design and Calschuanpham08Noch keine Bewertungen

- DAF Brochure Centerfold PDFDokument3 SeitenDAF Brochure Centerfold PDFJulio TovarNoch keine Bewertungen

- Comparison of Dissolved Air Flotation and Sedimentation PDFDokument5 SeitenComparison of Dissolved Air Flotation and Sedimentation PDFPrie TeaNoch keine Bewertungen

- Practica Lab Induced Gas FlotationDokument19 SeitenPractica Lab Induced Gas Flotationneurolepsia3790Noch keine Bewertungen

- Daf 2004Dokument7 SeitenDaf 2004leonardo285Noch keine Bewertungen

- Dissolved Air Flotation To Improve The Reuse of WaterDokument10 SeitenDissolved Air Flotation To Improve The Reuse of WaterCarlos GamarraNoch keine Bewertungen

- Ultra Pure WaterDokument6 SeitenUltra Pure Watergauravgarg115Noch keine Bewertungen

- Coagulation and Dissolved Air Floatation For Treatment of OilWater EmulsionDokument10 SeitenCoagulation and Dissolved Air Floatation For Treatment of OilWater EmulsionTI Journals Publishing100% (1)

- Oily Waste Water Cleanup by Gas FlotationDokument17 SeitenOily Waste Water Cleanup by Gas Flotationsivainduri100% (2)

- MF Uf NFDokument69 SeitenMF Uf NFNguyen Huu HieuNoch keine Bewertungen

- Dewatering sludge through filtration and drying bedsDokument46 SeitenDewatering sludge through filtration and drying bedsClaudia AvramNoch keine Bewertungen

- ClarifierDokument7 SeitenClarifiersuleman205Noch keine Bewertungen

- Tube Settler Application in 40 CharactersDokument10 SeitenTube Settler Application in 40 CharactersIlu SinghNoch keine Bewertungen

- Radial Flow Settler WhitepaperDokument15 SeitenRadial Flow Settler WhitepaperDavidSondervanNoch keine Bewertungen

- High Efficiency Reverse OsmosisDokument21 SeitenHigh Efficiency Reverse OsmosisPranav KumarNoch keine Bewertungen

- TA5 water treatment plant process flow diagramDokument14 SeitenTA5 water treatment plant process flow diagrammarishankar1990Noch keine Bewertungen

- RBBR System Description PDFDokument8 SeitenRBBR System Description PDFChokri HmeidiNoch keine Bewertungen

- Water Treatment PlantsDokument16 SeitenWater Treatment PlantsKaten MistryNoch keine Bewertungen

- Epcon - Tech (CFU)Dokument5 SeitenEpcon - Tech (CFU)achmadh_2010Noch keine Bewertungen

- Treatment of Industrial WastewaterDokument42 SeitenTreatment of Industrial WastewaterchanlalNoch keine Bewertungen

- Saltworks Zero Liquid Discharge InfographicDokument2 SeitenSaltworks Zero Liquid Discharge InfographicSameer HussainNoch keine Bewertungen

- 4 FlotationDokument27 Seiten4 FlotationAnonymous c8tyA5XlNoch keine Bewertungen

- Gas Flotation of Petroleum Produced Water: A Review On Status, Fundamental Aspects, and PerspectivesDokument15 SeitenGas Flotation of Petroleum Produced Water: A Review On Status, Fundamental Aspects, and PerspectivesfNoch keine Bewertungen

- Lab DI Water Systems Guide - Filtration, RO, Resin Filters ExplainedDokument6 SeitenLab DI Water Systems Guide - Filtration, RO, Resin Filters ExplainedHaidee Che RizminNoch keine Bewertungen

- Lamella Clarifier Leopold TexlerDokument4 SeitenLamella Clarifier Leopold TexlerAntony ThanosNoch keine Bewertungen

- 1st Presentation On Chemistry of Water TreatmentDokument7 Seiten1st Presentation On Chemistry of Water TreatmentAnonymous RsTfwYVcNoch keine Bewertungen

- Co2 Degasifier To Adjust The PHDokument2 SeitenCo2 Degasifier To Adjust The PHGhuna UcihaNoch keine Bewertungen

- Finnish Industrial Wastewater GuideDokument183 SeitenFinnish Industrial Wastewater Guidelifemillion2847Noch keine Bewertungen

- MM Aqua Technologies LTD.: TubedekDokument47 SeitenMM Aqua Technologies LTD.: TubedekSourabh Manuja100% (1)

- Internal Circulation Reactor Pushing The LimitsDokument9 SeitenInternal Circulation Reactor Pushing The LimitsAbhishek TripathiNoch keine Bewertungen

- Inclined Plate ClarifierDokument2 SeitenInclined Plate ClarifierKelvin SiewNoch keine Bewertungen

- Sand Filtration Units150Dokument3 SeitenSand Filtration Units150Smriti PrasadNoch keine Bewertungen

- Today'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"Dokument57 SeitenToday'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"saravan1891Noch keine Bewertungen

- Huber ProduseDokument78 SeitenHuber ProduseDan PetricNoch keine Bewertungen

- Stages Water Treatment ProcessDokument2 SeitenStages Water Treatment Processglo lipaodNoch keine Bewertungen

- 7 - Pre-Treatments To Reduce Fouling of Low Pressure Microfiltration (MF) Membranes PDFDokument10 Seiten7 - Pre-Treatments To Reduce Fouling of Low Pressure Microfiltration (MF) Membranes PDFRinaAprianiAapNoch keine Bewertungen

- Tefsa Belt Filter Presses BrochureDokument8 SeitenTefsa Belt Filter Presses BrochureMashudi FikriNoch keine Bewertungen

- Coagulacion FloculacionDokument538 SeitenCoagulacion FloculacionGUido JUarezNoch keine Bewertungen

- X-Flow AquaflexDokument6 SeitenX-Flow Aquaflexmykingboody2156Noch keine Bewertungen

- Comparing Common Wastewater Aeration SolutionsDokument2 SeitenComparing Common Wastewater Aeration SolutionsprannoyNoch keine Bewertungen

- Hitachi Compact MBRDokument11 SeitenHitachi Compact MBRYasin ArafathNoch keine Bewertungen

- Coalesce RDokument4 SeitenCoalesce Rrieza_fNoch keine Bewertungen

- DAF Theory 1Dokument3 SeitenDAF Theory 1rvkumar61Noch keine Bewertungen

- Filtration Process DescriptionDokument4 SeitenFiltration Process DescriptionJoy Das MahapatraNoch keine Bewertungen

- Ultrapure Water ReprintDokument2 SeitenUltrapure Water Reprintluispereira89Noch keine Bewertungen

- Water Maze Delta-3000a 1Dokument2 SeitenWater Maze Delta-3000a 1Marcelita AraujoNoch keine Bewertungen

- Dissolved Air Flotation HandoutDokument5 SeitenDissolved Air Flotation HandoutJen Astoveza0% (1)

- Ammonia to Nitrate: Nitrification ProcessDokument8 SeitenAmmonia to Nitrate: Nitrification ProcessLionel MenezesNoch keine Bewertungen

- Dissolved Air Flotation SystemsDokument2 SeitenDissolved Air Flotation Systemsleonardo285100% (1)

- Aquaponic Equipment - The Carifier. Nelson, Rebecca. Pade, JohnDokument2 SeitenAquaponic Equipment - The Carifier. Nelson, Rebecca. Pade, JohnSelbor951Noch keine Bewertungen

- Enpro Project ReportDokument51 SeitenEnpro Project ReportYadav VirendraNoch keine Bewertungen

- DowDokument8 SeitenDowrammu2001Noch keine Bewertungen

- Everything You Need to Know About Performance Curves for Oil SeparatorsDokument8 SeitenEverything You Need to Know About Performance Curves for Oil SeparatorsRanjit PaulNoch keine Bewertungen

- Water Treatment Plant Performance Evaluations and OperationsVon EverandWater Treatment Plant Performance Evaluations and OperationsNoch keine Bewertungen

- BQ SewerDokument37 SeitenBQ SewerLuna LatisyaNoch keine Bewertungen

- EIA - Purpose and AimsDokument3 SeitenEIA - Purpose and AimsmcsfuvNoch keine Bewertungen

- MST 006 Repair To Existing Road Patching and PotholesDokument14 SeitenMST 006 Repair To Existing Road Patching and PotholesmcsfuvNoch keine Bewertungen

- EIA Terms of ReferenceDokument2 SeitenEIA Terms of ReferencemcsfuvNoch keine Bewertungen

- CavitationDokument1 SeiteCavitationmcsfuvNoch keine Bewertungen

- RefsDokument2 SeitenRefsmcsfuvNoch keine Bewertungen

- D 791Dokument15 SeitenD 791mcsfuvNoch keine Bewertungen

- Practical Design of Water Distribution Systems PDFDokument29 SeitenPractical Design of Water Distribution Systems PDFmcsfuvNoch keine Bewertungen

- List of Figure StablesDokument2 SeitenList of Figure StablesmcsfuvNoch keine Bewertungen

- 04 WaterDokument42 Seiten04 WaterPuneet SharmaNoch keine Bewertungen

- Bases & Columns ScheduleDokument4 SeitenBases & Columns SchedulemcsfuvNoch keine Bewertungen

- #11 Road MaintenanceDokument44 Seiten#11 Road MaintenancemcsfuvNoch keine Bewertungen

- 14 Lobatse Abattoir - 2Dokument10 Seiten14 Lobatse Abattoir - 2mcsfuvNoch keine Bewertungen

- Civil and Water - BudgetingDokument7 SeitenCivil and Water - BudgetingmcsfuvNoch keine Bewertungen

- Zinara Statement 2015Dokument2 SeitenZinara Statement 2015mcsfuvNoch keine Bewertungen

- Design Manual for Ethiopia's Low-Volume Rural RoadsDokument45 SeitenDesign Manual for Ethiopia's Low-Volume Rural Roadsmcsfuv100% (2)

- Site InvestigationDokument11 SeitenSite InvestigationmcsfuvNoch keine Bewertungen

- Zim AssetDokument129 SeitenZim AssetNyamutatanga Makombe100% (5)

- Comparison With Active and Passive Earth PressuresDokument4 SeitenComparison With Active and Passive Earth PressuresmcsfuvNoch keine Bewertungen

- Chapter 5 Technical Manual 2012Dokument30 SeitenChapter 5 Technical Manual 2012mcsfuvNoch keine Bewertungen

- 2014-09-25 WASH Seminar GIS PresentationDokument28 Seiten2014-09-25 WASH Seminar GIS PresentationmcsfuvNoch keine Bewertungen

- 4 FlotationDokument27 Seiten4 FlotationgabmakerNoch keine Bewertungen

- Lecture 3Dokument10 SeitenLecture 3shujah1106853Noch keine Bewertungen

- Spiral StaircasesDokument16 SeitenSpiral Staircasesvrajan1988100% (1)

- Presentation On Basement Waterproofing-1Dokument70 SeitenPresentation On Basement Waterproofing-1shrikant78% (9)

- Fact 2014Dokument41 SeitenFact 2014mcsfuvNoch keine Bewertungen

- 2014 ConstitutionDokument13 Seiten2014 ConstitutionmcsfuvNoch keine Bewertungen

- EMA ActDokument67 SeitenEMA ActmcsfuvNoch keine Bewertungen

- Steps To Project ProposalDokument3 SeitenSteps To Project ProposalYahya HassniNoch keine Bewertungen

- Astm C27Dokument2 SeitenAstm C27nee2790Noch keine Bewertungen

- Adeptus Evangelion 2.5 - Operations ManualDokument262 SeitenAdeptus Evangelion 2.5 - Operations ManualGhostwheel50% (2)

- Animal Names in English and IndonesianDokument7 SeitenAnimal Names in English and IndonesianAndi KurniawanNoch keine Bewertungen

- ARES SC4 Service Manual (HP-300UA)Dokument20 SeitenARES SC4 Service Manual (HP-300UA)mike_net8903Noch keine Bewertungen

- Fairs in Punjab 2021-22Dokument9 SeitenFairs in Punjab 2021-22Suchintan SinghNoch keine Bewertungen

- 4 Ideal Models of Engine CyclesDokument23 Seiten4 Ideal Models of Engine CyclesSyedNoch keine Bewertungen

- 366 Community Service IdeasDokument5 Seiten366 Community Service IdeasAhmetYılmazVuralNoch keine Bewertungen

- Frobenius Method for Solving Differential EquationsDokument9 SeitenFrobenius Method for Solving Differential EquationsMario PetričevićNoch keine Bewertungen

- Lab Manual Cape Bio Unit 1 2023Dokument37 SeitenLab Manual Cape Bio Unit 1 2023drug123addict25Noch keine Bewertungen

- Orientation Report PDFDokument13 SeitenOrientation Report PDFRiaz RasoolNoch keine Bewertungen

- Knowing Annelida: Earthworms, Leeches and Marine WormsDokument4 SeitenKnowing Annelida: Earthworms, Leeches and Marine WormsCherry Mae AdlawonNoch keine Bewertungen

- Cosmic Freedom: David MolineauxDokument2 SeitenCosmic Freedom: David Molineauxsalomon46Noch keine Bewertungen

- Desiderata: by Max EhrmannDokument6 SeitenDesiderata: by Max EhrmannTanay AshwathNoch keine Bewertungen

- Electrical Machines Multiple Choice Questions - Mcqs - QuizDokument10 SeitenElectrical Machines Multiple Choice Questions - Mcqs - Quiztooba mukhtarNoch keine Bewertungen

- DGPS Sensor JLR-4331W Instruction ManualDokument42 SeitenDGPS Sensor JLR-4331W Instruction ManualantonioNoch keine Bewertungen

- Sensor Controlled Animatronic Hand: Graduation Project PresentationDokument24 SeitenSensor Controlled Animatronic Hand: Graduation Project PresentationAnonymous D2FmKSxuuNoch keine Bewertungen

- Nitocote WP DDokument4 SeitenNitocote WP DdaragNoch keine Bewertungen

- The Creators College of Science & Commerce: 1 TermDokument2 SeitenThe Creators College of Science & Commerce: 1 TermJhangir Awan33% (3)

- The Relevance of Vivekananda S Thought IDokument16 SeitenThe Relevance of Vivekananda S Thought IJaiyansh VatsNoch keine Bewertungen

- 37th APSDC Scientific PresentationsDokument7 Seiten37th APSDC Scientific PresentationsSatyendra KumarNoch keine Bewertungen

- Module 37 Nur 145Dokument38 SeitenModule 37 Nur 145Marga WreatheNoch keine Bewertungen

- 4608 Eed 01Dokument29 Seiten4608 Eed 01NickNoch keine Bewertungen

- Kundalini Meditation & The Vagus Nerve - Eleven Minute MedsDokument5 SeitenKundalini Meditation & The Vagus Nerve - Eleven Minute Medstimsmith1081574100% (5)

- News Writing April 2019Dokument39 SeitenNews Writing April 2019Primrose EmeryNoch keine Bewertungen

- Kingspan Spectrum™: Premium Organic Coating SystemDokument4 SeitenKingspan Spectrum™: Premium Organic Coating SystemNikolaNoch keine Bewertungen

- TP5 W9 S9 R0Dokument2 SeitenTP5 W9 S9 R0DickiEffendy0% (1)

- Chapter-8 Turbine and Governor TestingDokument10 SeitenChapter-8 Turbine and Governor Testingafru2000Noch keine Bewertungen

- Design of PID controllersDokument4 SeitenDesign of PID controllersFseha GetahunNoch keine Bewertungen

- District: Surkhet: PopulationDokument13 SeitenDistrict: Surkhet: PopulationkarunNoch keine Bewertungen

- Basler Electric 87T - Great InfoDokument3 SeitenBasler Electric 87T - Great InfoMrNoch keine Bewertungen