Beruflich Dokumente

Kultur Dokumente

UIUC Concrete Tie and Fastener - 20140722 - Final

Hochgeladen von

Hastya Tatas Herarki ItcOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

UIUC Concrete Tie and Fastener - 20140722 - Final

Hochgeladen von

Hastya Tatas Herarki ItcCopyright:

Verfügbare Formate

RR 14-23 | July 2014

UIUC Concrete Tie and Fastener Field Testing

at TTC

SUMMARY

BACKGROUND

In July 2012, the University of Illinois at UrbanaChampaign (UIUC) began an extensive

experimental program at the Transportation

Technology Center (TTC) in Pueblo, CO. The

field experimentation program was part of a

larger research program funded by the Federal

Railroad Administration (FRA) to improve the

design and performance of concrete crossties

and fastening systems. The UIUC program

recorded loads, strains, and displacements of

the track components under passenger consists

traveling at speeds of 2102 mph, freight

consists with car weights ranging from 263,000

to 315,000 pounds, and static responses from a

track loading vehicle (TLV). The results of the

experiment have yielded insight into the transfer

of forces between the train wheels and the

rail/fastener/crosstie system and provided a

means to validate a comprehensive finite

element model (FEM).

As part of a 3-year research program funded by

FRA, UIUC has begun work to improve the

design methodology and performance of

concrete crossties and elastic fastening systems

in the United States.

Program objectives

include the development of an FEM, as well as

laboratory and field experimentation to fill voids

in the current understanding of concrete crosstie

and fastening system behavior, which will allow

us to improve mechanistic design procedures

for these systems. Such an improvement will

lead to the decreased life cycle costs of track

components, as well as increased robustness

and improved safety of critical infrastructure

components.

OBJECTIVES

The

primary

objective

of

the

field

experimentation is to characterize the behavior

and quantify the demands placed on each

component of the crosstie and fastening system

under varying field conditions. Additionally,

these experiments will provide a means to

validate the FEM being developed by UIUC.

Finally, the program will provide the industry and

future researchers with insight into industryaccepted and novel instrumentation strategies.

METHODS

Figure 1. UIUC team at the test site in Pueblo, Colorado

The

test

program

involved

extensive

instrumentation of two 15-crosstie test sections

(tangent and curved track) to synchronously

measure force and displacement at various

interfaces.

RR 14-23 | July 2014

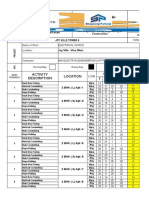

Of the 15 crossties, 4 rail seats were fully

instrumented with each methodology mentioned

in this report, and 10 additional rail seats were

instrumented with vertical rail web strains on

each side of the rail (see Figure 2).

Figure 3. Configuration of strain gages for attaining

vertical and lateral loads

Figure 2. Locations of fully (orange) and partially (blue)

instrumented rail seats

As shown in Figure 3, strain gages were

positioned in the crib on the rail neutral axis (for

vertical circuits) and rail base (for lateral circuits)

to measure wheel-rail loads.

For each

configuration, there were two planes of shear

strain being measured. (When the wheel is

between these planes, the load is proportional

to the difference between the two shears.)

Strain gages were also placed on the rail seat to

measure these forces.

Three strain gages were oriented vertically on

each side of the rail web over the tie, as shown

in Figure 3.

These strains measure the

compressive forces in the rail and the relative

load distribution of adjacent crossties. Strain

gages placed perpendicularly to the rail base

were used to measure rail base bending

stresses. Strains were also measured (1) on

the surface of the fastening clips to estimate

clamping forces and fastener demands and (2)

on the insulator post to estimate lateral loads on

the insulator.

RESEARCH RESULTS REPORT

Linear potentiometers were used to capture

displacements of the rail and crosstie, as shown

in Figure 4.

For rail displacements,

potentiometers were screwed into brackets on

aluminum fixtures which were epoxied to the

crosstie. Rail displacements included lateral

measurements of the web and base and vertical

displacements of the rail base on the gaugeside.

Vertical crosstie displacements were

measured using linear potentiometers clamped

to a 6-foot rod driven into the subgrade.

Figure 4. Detailed instrumentation

Of the 15 newly installed crossties, 3 were

internally and externally instrumented with strain

gages (see Figure 5).

During the

manufacturing process, embedment gages were

positioned below the rail seat surface in a 2x2

matrix to measure stress distributions and rail

seat forces.

2|Page

RR 14-23 | July 2014

Figure 5. Locations of crosstie strain gages

The Association of American Railroads (AAR)

TLV was used to calibrate the vertical and

lateral load circuits. This calibration consisted of

vertical loads up to 40 kips being applied

statically at various locations along the track

(crib centers and rail seats) with the TLV.

Additionally, lateral loads up to 20 kips were

applied. Further tests were conducted with the

TLV, including a dynamic test with a constant

10-kip lateral load.

Next, 10-car passenger and freight consists

were driven over the 2 test sections: from 2 to

102 mph on the tangent and 245 mph on the

curve. Additional tests using these two consists

included pneumatic braking and accelerating

from a stopped position over each test section.

RESULTS

From the vertical and lateral load circuits,

adjacent cribs had agreeable axle loads and the

range of input loads compared well with existing

wheel impact load detector data. Results of the

rail seat load circuits at low speeds agreed with

expected values (e.g., 50 percent of load

transfer for well-supported crossties).

RESEARCH RESULTS REPORT

Vertical rail strain data was used to identify the

effect of lateral load on the vertical load path.

The vertical rail strains, averaged from the field

and gauge side of the rail, are shown in

Figure 6 for seven crossties. A 40-kip static

vertical load was applied to the center crosstie

while increasing the lateral load from 0 to 20kips. The strain due to bending has been

removed through the process of averaging the

strains. Therefore, the distribution of the rail

strains are equivalent to the distribution of

vertical rail seat loads. Through the comparison

of the three loading cases shown in Figure 6,

which are 40-kip vertical load with 0-kip, 10-kip,

and 20-kip lateral load, one can see the vertical

rail strain (i.e. vertical load) distributions are very

similar. The difference that is evident can be

attributed to the change in wheel-rail contact

patch location that occurred as a result of the

increasing lateral load applied (e.g. the contact

patch location shifted at approximately a 12-kip

lateral load). Therefore, a lateral wheel load, in

and of itself, does not affect the longitudinal

distribution of the vertical load path.

50

Strain ()

After curing, surface strain gages were placed

parallel with the length of the crossties at each

rail seat and crosstie center in order to

determine bending moments at critical locations.

0

-50

V=40k L=0k

V=40k L=10k

V=40k L=20k

-100

-150

Crosstie #

Figure 6. Average vertical rail strains (field and gauge)

Beyond understanding the vertical load path,

these vertical rail strains were also used as part

of the comprehensive FEM development and

calibration process.

3|Page

RR 14-23 | July 2014

The displacement instrumentation strategy

showed varied success.

The vertical

displacements were measured with minipotentiometers, which proved to be problematic

and provided noisy data in the field

environment.

The lateral web and base displacements of the

rail showed mixed results. Slightly more than

half of the potentiometers had clean

displacement waveforms with distinct peaks,

whereas the others had excessive noise.

The measurements of clip strains were clean

and, together with the UIUC FEM, successfully

estimated expected clamping forces. Signals of

transverse rail base strains were also clear and

are being used as validation for the FEM. Most

strain gages on the insulator post failed during

installation, so different procedures for acquiring

these lateral loads are being explored.

The embedment gages showed promising

results. Vertical rail seat loads were obtained

from the strain data and most embedment

gages successfully output clean signals and are

fully qualified for further analysis. The surface

strain gages showed promise as well. Bending

moments at rail seats and tie center can be

obtained from the strain data.

In June 2013, UIUC published a YouTube video

about the field experimentation program. This

video is available at: the following URL:

http://www.youtube.com/watch?v=1GGS5lwy2p

A&feature=youtu.be

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the United

States Department of Transportation (U.S.

DOT) Federal Railroad Administration (FRA) for

funding this research effort under FRA BAA

In addition, we would like to

2010-1.

acknowledge the following FRA Tie and

Fastener BAA Industry Partners for their

assistance in the project: Amsted RPS/Amsted

Rail, Inc.; BNSF Railway; CXT Concrete Ties,

Inc., LB Foster Company; GIC Ingeniera y

Construccin; Hanson Professional Services,

Inc.; National Railway Passenger Corporation

(Amtrak); and Union Pacific Railroad.

CONTACT

Cameron Stuart

Federal Railroad Administration

Office of Research and Development

1200 New Jersey Avenue, SE

Washington, DC 20590

(202) 493-6384

cameron.stuart@dot.gov

FUTURE WORK

KEYWORDS

Following the July 2012 instrumentation

program, UIUC carried out an additional field

study in May 2013.

This second study

consisted of a similar instrumentation program,

Concrete crossties, elastic fastening systems,

field instrumentation, concrete sleepers, loading

conditions, displacements

RESEARCH RESULTS REPORT

4|Page

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 11b Design of Struttings (2015)Dokument98 Seiten11b Design of Struttings (2015)susan87100% (4)

- Weights of MaterialsDokument25 SeitenWeights of MaterialsAnonymous o5VxyCg73% (30)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Of The Lunatic ExpressDokument6 SeitenOf The Lunatic ExpressoliversmithwritingNoch keine Bewertungen

- Class 4 SST WorksheetDokument1 SeiteClass 4 SST WorksheetA DNoch keine Bewertungen

- CEC025 - Rail Track CodeDokument411 SeitenCEC025 - Rail Track Codealdert_pathNoch keine Bewertungen

- Student Handbook (07272018)Dokument29 SeitenStudent Handbook (07272018)Delaney Conales Ofrecio100% (1)

- Maintenance of ICF CoachesDokument204 SeitenMaintenance of ICF CoachesDebasis MajhiNoch keine Bewertungen

- Hostelworld PDF Guide BudapestDokument3 SeitenHostelworld PDF Guide BudapestDiscovery_22Noch keine Bewertungen

- 1487153979637-JE-II Question Bank PDFDokument43 Seiten1487153979637-JE-II Question Bank PDFSk zalaluddin100% (2)

- 0990 - Manual Servicio Monorail OverheadDokument31 Seiten0990 - Manual Servicio Monorail OverheadNorberto MartinezNoch keine Bewertungen

- Joint Feasibility ProformaDokument1 SeiteJoint Feasibility ProformaAayush AggarwalNoch keine Bewertungen

- Mumbai2005 25Dokument27 SeitenMumbai2005 25krunalpshahNoch keine Bewertungen

- Question Bank On LHB Design CoachesDokument30 SeitenQuestion Bank On LHB Design CoachesCRS Tirupati100% (1)

- Haryana AEE Civil Paper Public Health Solution of Test Held On 17.10.17Dokument41 SeitenHaryana AEE Civil Paper Public Health Solution of Test Held On 17.10.17ajaydevmalikNoch keine Bewertungen

- How Skyscrapers Can Save The CityDokument4 SeitenHow Skyscrapers Can Save The CitySeraMa JambuiNoch keine Bewertungen

- Electrical 5th Sem PDFDokument23 SeitenElectrical 5th Sem PDFAbhishek RanjanNoch keine Bewertungen

- HSEP 13 8 A1 Fall Prevention System Requirement Rev 5Dokument5 SeitenHSEP 13 8 A1 Fall Prevention System Requirement Rev 5mojgfdNoch keine Bewertungen

- OFO Installation Guidelines For ADSS Cables V6 PDFDokument27 SeitenOFO Installation Guidelines For ADSS Cables V6 PDFUdriste DanielNoch keine Bewertungen

- Cross-Section and SuperelevationDokument14 SeitenCross-Section and SuperelevationMarilu' CrNoch keine Bewertungen

- 24th Bza MasDokument1 Seite24th Bza MasGowri Sankara Rao UritiNoch keine Bewertungen

- Benny Pezzino (3) 1 1Dokument17 SeitenBenny Pezzino (3) 1 1benny pezzino100% (1)

- Project Report On Gas Plant at NTPC DadriDokument16 SeitenProject Report On Gas Plant at NTPC DadriSunil MåüřÿäNoch keine Bewertungen

- Trains 05 2024 Freemagazines TopDokument60 SeitenTrains 05 2024 Freemagazines Topkyc7c87qf7Noch keine Bewertungen

- 075 Oil Mist Application Manual PDFDokument34 Seiten075 Oil Mist Application Manual PDFAdolfo EirasNoch keine Bewertungen

- IEC List of International Electrotechnical Commission Standards - Wikipedia PDFDokument30 SeitenIEC List of International Electrotechnical Commission Standards - Wikipedia PDFShariman Azmi - GDENoch keine Bewertungen

- KL-SG High Speed Rail: Riding The HSR RevivalDokument44 SeitenKL-SG High Speed Rail: Riding The HSR Revival@yuan100% (1)

- Daily Progress Report: M/s Shapoorji Pallonji Real Estate M/s Shapoorji Pallonji Engineering & ConstructionDokument24 SeitenDaily Progress Report: M/s Shapoorji Pallonji Real Estate M/s Shapoorji Pallonji Engineering & ConstructionBenadict JoshuaNoch keine Bewertungen

- B2 Exam PracticeDokument7 SeitenB2 Exam PracticemonicanacaNoch keine Bewertungen

- Astm A700-05Dokument41 SeitenAstm A700-05İlter KilerciNoch keine Bewertungen

- TCKTDokument2 SeitenTCKTJagdip DhillonNoch keine Bewertungen