Beruflich Dokumente

Kultur Dokumente

LED Driver Inrush Currents - Technical Paper

Hochgeladen von

IppiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

LED Driver Inrush Currents - Technical Paper

Hochgeladen von

IppiCopyright:

Verfügbare Formate

LED Driver Inrush Currents - Technical paper

1 of 5

https://adlt.com.au/technology/%uFEFFled-driver-inrush-currents/

products

application

case studies

latest new s

lighting design se

A Light Em itting Diode (LED),also referred to as SSL (Solid State

Lighting),is an electronic device (chip)that produces light w hen an

electricalcurrent is passed through it.LED chips are inherently

low -voltage devices that need additionalelectronic com ponents to

convert the line-voltage 240V AC to the low DC voltage needed for

the LEDs.These electronics units also interpret controlsignals and

dim the LEDs accordingly.These devices are referred to as LED

drivers.

The lam p inrush current on sw itching LEDs has becom e an area of

concern in the lighting industry.Inrush currentof the LED drivers

refers to the input current of short duration that flow s into the LED

driver,during the initialstart-up,to charge the capacitors on the

input side.Typically,this is a short duration current,w hose

am plitude is m uch greater than the operating or steady-state

current.The inrush current is due to the EM C filter on the input

and bulk capacitor on the boost circuit this is inherent to the LED

technology.

The figure show s the nature of the inrush current and its peak,

IM AX.T50 is the tim e duration in w hich the inrush current pulse is

equalto 50% of IM AX.It show s an exam ple of inrush current (IM AX)

and T50 tim es for a typicalLED driver.

If there are a num ber of LED drivers in an LED Lum inaire,and if there are a num ber of such LED Lum in

inrush current and its duration m ay be additive.How ever,it is not an exact m athem aticalcalculation;i

paralleldoes not equalexact Ntim es the inrush current for one driver or N tim es the T50 tim e for on

im pedance of each driver and the line im pedance.

30/04/2016 09:16

LED Driver Inrush Currents - Technical paper

2 of 5

https://adlt.com.au/technology/%uFEFFled-driver-inrush-currents/

The line im pedance has a significant effect on the peak and duration of the inrush current.Transform e

runs,and other devices in the circuit path are a few things that could lead to high im pedance.

The inrush current and the duration of the LED driver differs from m anufacturer to m anufacturer and

duration is very sm all,sophisticated instrum ents w ith very high sam pling rates need to be used for exa

also depends on the exact m om ent of sw itching,during the alternating cycle.

For a typical150W ,0.7A LED driver,Philips M odel9137012116,used in various CREE lum inaires,the inrus

165 M icro Seconds.It is suggested that up to 7 -10 of these drivers be used /per 20A C curve M CB,h

individualcircuit im pedance.

For a typical220W ,1.05A LED driver,CREE M odelLE098X01 used in CREE High Output Edge lum inaires

Am p for 1000uS (1m S).It is suggested that up to 6 8 of these drivers be used /per 20A C curve M CB

individualcircuit im pedance.

A generalrecom m endation is to use C curve circuit breaker w ith the highest current rating that is allow

M CB used needs to have sufficient clearing tim e for the inrush current to clear,w ithout creating the n

w illgive protection from a short circuit and prevent overheating of w iring and connections.M CBs opera

an overload or short circuit condition.The tripping point relates to the m agnitude of electricalenergy be

depends significantly on both the inrush current peak value and its tim e duration.Accordingly,an M CB

peak of short duration,or a low er peak of longer duration.In either case,the objective is to ensure tha

excessive energy,yet does not trip and cause lighting blackouts,w hen it does not need to.

Please see below ,a typicalM CB tripping curve show ing the am ount of tim e required for a circuit breake

These curves differ from m anufacturer to m anufacturer and from type to type.Typically,the B type M C

3 to 5 In,C type has 5 to 10In and D type has 10-14 In.

30/04/2016 09:16

LED Driver Inrush Currents - Technical paper

3 of 5

https://adlt.com.au/technology/%uFEFFled-driver-inrush-currents/

Note:M any low -end relay system s in the lighting controls industry are designed for low inrush current

of high inrush LED technology.The high inrush on LEDs can cause these products to fail,by w elding t

be taken that the photocells and occupancy sensors are rated suitably to handle the LED inrush curr

solution.Advanced Lighting suggests using high quality photocellproducts able to handle the inrush c

A typicalexam ple of the inrush current event has been presented below for easier understanding.This

inrush current captured at the tim e of test and not as absolute proof of correct values.

30/04/2016 09:16

LED Driver Inrush Currents - Technical paper

4 of 5

https://adlt.com.au/technology/%uFEFFled-driver-inrush-currents/

30/04/2016 09:16

LED Driver Inrush Currents - Technical paper

5 of 5

https://adlt.com.au/technology/%uFEFFled-driver-inrush-currents/

Disclaim er:The inform ation provided in this docum ent has been provided in good faith by ADLTA.It is in

ADLTA w elcom es any com m ents or feedback on this subject.

Professionaladvice should be sought before relying on the inform ation provided.ADLTA does not w arra

disclaim s any legalresponsibility for any loss or dam age w hich m ay be suffered directly or indirectly,by

provided.

Privacy Policy

Claim s Policy

W arranty

Term s & Conditions

Contact Us

Copyright 2012 Advanced Lighting Technologies Australia inc.Allrights reserved.

30/04/2016 09:16

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Wind Shear: Course Notes Course NotesDokument1 SeiteWind Shear: Course Notes Course NotesIppiNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Reactive Power Compensation and Voltage ControlDokument14 SeitenReactive Power Compensation and Voltage ControlIppiNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- What Is An Excitation System - Reivax North AmericaDokument16 SeitenWhat Is An Excitation System - Reivax North AmericaIppiNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Transient Response AnalysisDokument55 SeitenTransient Response AnalysisIppiNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- SCR Thyristor Crowbar - Overvoltage Protection Circuit Electronics NotesDokument6 SeitenSCR Thyristor Crowbar - Overvoltage Protection Circuit Electronics NotesIppiNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Nickel-Cadmium Batteries: Basic Theory and Maintenance ProceduresDokument6 SeitenNickel-Cadmium Batteries: Basic Theory and Maintenance ProceduresIppiNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- GPG289 Getting Signed Up Energy Services in The Public Sector 2000 PDFDokument52 SeitenGPG289 Getting Signed Up Energy Services in The Public Sector 2000 PDFIppiNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- ECG73 Saving Energy in SchoolsDokument12 SeitenECG73 Saving Energy in SchoolsIppiNoch keine Bewertungen

- Building Energy Management SystemsDokument90 SeitenBuilding Energy Management SystemsIppi50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- GIL033 Passive Solar Design Looe Junior and Infant SchoolDokument6 SeitenGIL033 Passive Solar Design Looe Junior and Infant SchoolIppiNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- GPCS324 Staff Awareness BTDokument6 SeitenGPCS324 Staff Awareness BTIppiNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- GPG216 Energy Saving in The Filtration and Drying of Compressed AirDokument31 SeitenGPG216 Energy Saving in The Filtration and Drying of Compressed AirIppiNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- GPG192 Designing Energy Efficient Multi Residential BuildingsDokument34 SeitenGPG192 Designing Energy Efficient Multi Residential BuildingsIppiNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- GPG251 Maintaining The Momentum Sustaining Energy Management 1999 PDFDokument25 SeitenGPG251 Maintaining The Momentum Sustaining Energy Management 1999 PDFIppiNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- GPG245 Desktop Guide To Daylighting For Architects PDFDokument12 SeitenGPG245 Desktop Guide To Daylighting For Architects PDFIppiNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- GPG235 Managing People, Managing Energy PDFDokument49 SeitenGPG235 Managing People, Managing Energy PDFIppiNoch keine Bewertungen

- GPG287 the Design Team's Guide to Environmentally Smart Buildings – Energy Efficient Options for New and Refurbished OfficesDokument24 SeitenGPG287 the Design Team's Guide to Environmentally Smart Buildings – Energy Efficient Options for New and Refurbished OfficesIppiNoch keine Bewertungen

- GPG231 Introducing Information Systems For Energy ManagementDokument45 SeitenGPG231 Introducing Information Systems For Energy ManagementIppiNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- GPG102 Energy Efficiency in New Housing Site Practice For Tradesmen External Walls Injected Cavity Insulation (1995 Rep 1996) PDFDokument1 SeiteGPG102 Energy Efficiency in New Housing Site Practice For Tradesmen External Walls Injected Cavity Insulation (1995 Rep 1996) PDFIppiNoch keine Bewertungen

- GIL074 Domestic Condensing BoilersDokument4 SeitenGIL074 Domestic Condensing BoilersIppiNoch keine Bewertungen

- GPG167 Organisational Aspects of Energy Management A Self Assess Manual For ManagersDokument35 SeitenGPG167 Organisational Aspects of Energy Management A Self Assess Manual For ManagersIppiNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- GPG176 Small Scale Combined Heat and Power CHP For Buildings 1996Dokument6 SeitenGPG176 Small Scale Combined Heat and Power CHP For Buildings 1996IppiNoch keine Bewertungen

- GPG291 Designer's Guide To The Options For Ventilation and Cooling 2001Dokument40 SeitenGPG291 Designer's Guide To The Options For Ventilation and Cooling 2001IppiNoch keine Bewertungen

- ECG81 Benchmarking Tool For Industrial Buildings Heating and Internal Lighting PDFDokument32 SeitenECG81 Benchmarking Tool For Industrial Buildings Heating and Internal Lighting PDFIppiNoch keine Bewertungen

- DS - 20190906 - E2 - E2D Platform Introduction - V10 - ENDokument7 SeitenDS - 20190906 - E2 - E2D Platform Introduction - V10 - ENCristina CorfaNoch keine Bewertungen

- Catalog HB MCCBDokument116 SeitenCatalog HB MCCBiwan sanusiNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- 12.1. Electrical Safety ProgramDokument9 Seiten12.1. Electrical Safety ProgramMehmood Khan MarwatNoch keine Bewertungen

- Magnet OfferDokument5 SeitenMagnet Offernaren1202Noch keine Bewertungen

- How To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic SystemDokument2 SeitenHow To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic Systemgetsweet100% (1)

- Mitsubishi MSCA12YV ManualDokument32 SeitenMitsubishi MSCA12YV Manualsansegundo79Noch keine Bewertungen

- 3WA1350-5AF02-0AA0 Datasheet En123376727239589023Dokument8 Seiten3WA1350-5AF02-0AA0 Datasheet En123376727239589023Luis Eduardo Vargas NeriNoch keine Bewertungen

- En 60204 1 Enquiry Form For The Electrical Equipment of MachinesDokument4 SeitenEn 60204 1 Enquiry Form For The Electrical Equipment of MachinesalbatsNoch keine Bewertungen

- BMT1B 01 04 00 A1Dokument6 SeitenBMT1B 01 04 00 A1bemltc3rsdm 2022Noch keine Bewertungen

- 3X240 - AL - XLPE - STA - PVC - 12 - 20 (24) KV - DistributionDokument1 Seite3X240 - AL - XLPE - STA - PVC - 12 - 20 (24) KV - DistributionMohamed AliNoch keine Bewertungen

- Performance of PV PanelsDokument6 SeitenPerformance of PV PanelsAnish John PaulNoch keine Bewertungen

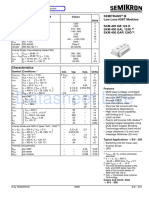

- Skm400gal124d Semikron Igbt ModuleDokument6 SeitenSkm400gal124d Semikron Igbt ModuleElectronics Learn and FunNoch keine Bewertungen

- Epcos Thyristor ModuleDokument6 SeitenEpcos Thyristor ModuleSanthosh OsNoch keine Bewertungen

- Power Electronics NotesDokument263 SeitenPower Electronics NotesKalakata Manoj Reddy100% (1)

- E2063 Teknologi Elektrik 2 UNIT6Dokument16 SeitenE2063 Teknologi Elektrik 2 UNIT6dbu2952Noch keine Bewertungen

- Rancang Bangun Simulator Trouble Shooting Sistem Kelistrikan Ac MobilDokument14 SeitenRancang Bangun Simulator Trouble Shooting Sistem Kelistrikan Ac MobilJm'kosongtujuh RudiNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Siemens Power Engineering Guide 7E 118Dokument1 SeiteSiemens Power Engineering Guide 7E 118mydearteacherNoch keine Bewertungen

- A 1179 - A 1257 - A 1395 Flex Current Clamps - ANGDokument15 SeitenA 1179 - A 1257 - A 1395 Flex Current Clamps - ANGruben condeNoch keine Bewertungen

- Lab-04 DC Electronics Part 2Dokument8 SeitenLab-04 DC Electronics Part 2pioneer boysNoch keine Bewertungen

- Coupler REG-K Mounting The Coupler: Areas 1 and 2 With Lines 1.1 and 2.1Dokument1 SeiteCoupler REG-K Mounting The Coupler: Areas 1 and 2 With Lines 1.1 and 2.1Carlos HerreraNoch keine Bewertungen

- AC/DC Voltage Power Supply: Testing The Minimum Trip Voltage of A BreakerDokument3 SeitenAC/DC Voltage Power Supply: Testing The Minimum Trip Voltage of A BreakerRicardo Cabrera OsinagaNoch keine Bewertungen

- Electromechanical Systems & ActuatorsDokument8 SeitenElectromechanical Systems & ActuatorsanandakumarNoch keine Bewertungen

- Fender Amp - Manual PDFDokument16 SeitenFender Amp - Manual PDFAnonymous EUf81NUpizNoch keine Bewertungen

- Sunpower - Solar Panel - 225WDokument2 SeitenSunpower - Solar Panel - 225Wankur yadavNoch keine Bewertungen

- TEM4 - PRODUCT DATA TraneDokument20 SeitenTEM4 - PRODUCT DATA Traney9fs8vf7d9Noch keine Bewertungen

- Buck BoostDokument11 SeitenBuck Boostkima lachgarNoch keine Bewertungen

- 3G3PV Series Advanced General-Purpose Inverter Users Manual - I537-E2-01 PDFDokument320 Seiten3G3PV Series Advanced General-Purpose Inverter Users Manual - I537-E2-01 PDFАлександрNoch keine Bewertungen

- Sugar Mill DrivesDokument8 SeitenSugar Mill Drivessayyadmannan67% (3)

- Cable Termination - ABB PDFDokument2 SeitenCable Termination - ABB PDFrasheed313Noch keine Bewertungen

- SSS 7 Edition MANUAL The Analysis and Designs of Linear Circuit PDFDokument987 SeitenSSS 7 Edition MANUAL The Analysis and Designs of Linear Circuit PDFEngr Azeem Awan100% (3)

- University of Chicago Press Fall 2009 CatalogueVon EverandUniversity of Chicago Press Fall 2009 CatalogueBewertung: 5 von 5 Sternen5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesVon EverandUniversity of Chicago Press Fall 2009 Distributed TitlesBewertung: 1 von 5 Sternen1/5 (1)